Transforming Industry Protocols with Hypochlorous Acid Applications

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCL Tech Evolution

The evolution of hypochlorous acid (HOCl) technology in industrial applications has been marked by significant advancements and paradigm shifts. Initially discovered in the early 19th century, HOCl's potential as a powerful oxidizing agent and disinfectant remained largely untapped for decades. The turning point came in the late 20th century when researchers began to explore its applications beyond traditional water treatment.

The 1980s saw the first major breakthrough in HOCl technology with the development of on-site generation systems. These systems allowed for the production of HOCl solutions at the point of use, eliminating the need for storage and transportation of hazardous chemicals. This innovation paved the way for broader industrial adoption, particularly in food processing and healthcare sectors.

In the 1990s, advancements in electrochemical cell design led to more efficient and cost-effective HOCl production methods. This period also witnessed the emergence of stabilized HOCl solutions, which extended shelf life and expanded potential applications. The improved stability allowed for the development of HOCl-based products for surface disinfection, wound care, and agricultural use.

The early 2000s marked a significant leap in HOCl technology with the introduction of nanotechnology-enhanced production processes. These innovations resulted in higher purity HOCl solutions with enhanced antimicrobial efficacy. Concurrently, the development of precise pH control mechanisms enabled the production of HOCl solutions with optimal stability and effectiveness.

The past decade has seen a surge in research focused on HOCl's potential in advanced oxidation processes for industrial wastewater treatment. Scientists have explored its synergistic effects with other oxidants and catalysts, leading to more efficient and environmentally friendly treatment protocols. Additionally, the integration of HOCl technology with IoT and smart monitoring systems has revolutionized its application in various industries, allowing for real-time adjustments and optimized performance.

Recent years have witnessed a growing interest in HOCl's role in sustainable manufacturing practices. Researchers are exploring its potential as a green alternative to traditional chemical processes in industries such as textiles, paper production, and metal finishing. The development of HOCl-based fog and mist systems has also opened new avenues for large-scale disinfection in public spaces and transportation hubs.

Looking ahead, the evolution of HOCl technology is poised to continue its upward trajectory. Emerging areas of research include the development of HOCl-infused materials for long-lasting antimicrobial surfaces, the exploration of HOCl's potential in air purification systems, and its application in advanced medical therapies. As industries increasingly prioritize sustainability and safety, HOCl technology is expected to play a pivotal role in transforming industrial protocols across various sectors.

The 1980s saw the first major breakthrough in HOCl technology with the development of on-site generation systems. These systems allowed for the production of HOCl solutions at the point of use, eliminating the need for storage and transportation of hazardous chemicals. This innovation paved the way for broader industrial adoption, particularly in food processing and healthcare sectors.

In the 1990s, advancements in electrochemical cell design led to more efficient and cost-effective HOCl production methods. This period also witnessed the emergence of stabilized HOCl solutions, which extended shelf life and expanded potential applications. The improved stability allowed for the development of HOCl-based products for surface disinfection, wound care, and agricultural use.

The early 2000s marked a significant leap in HOCl technology with the introduction of nanotechnology-enhanced production processes. These innovations resulted in higher purity HOCl solutions with enhanced antimicrobial efficacy. Concurrently, the development of precise pH control mechanisms enabled the production of HOCl solutions with optimal stability and effectiveness.

The past decade has seen a surge in research focused on HOCl's potential in advanced oxidation processes for industrial wastewater treatment. Scientists have explored its synergistic effects with other oxidants and catalysts, leading to more efficient and environmentally friendly treatment protocols. Additionally, the integration of HOCl technology with IoT and smart monitoring systems has revolutionized its application in various industries, allowing for real-time adjustments and optimized performance.

Recent years have witnessed a growing interest in HOCl's role in sustainable manufacturing practices. Researchers are exploring its potential as a green alternative to traditional chemical processes in industries such as textiles, paper production, and metal finishing. The development of HOCl-based fog and mist systems has also opened new avenues for large-scale disinfection in public spaces and transportation hubs.

Looking ahead, the evolution of HOCl technology is poised to continue its upward trajectory. Emerging areas of research include the development of HOCl-infused materials for long-lasting antimicrobial surfaces, the exploration of HOCl's potential in air purification systems, and its application in advanced medical therapies. As industries increasingly prioritize sustainability and safety, HOCl technology is expected to play a pivotal role in transforming industrial protocols across various sectors.

Market Demand Analysis

The market demand for hypochlorous acid (HOCl) applications is experiencing significant growth across various industries. This environmentally friendly and highly effective disinfectant is gaining traction due to its broad-spectrum antimicrobial properties and safety profile. The healthcare sector represents a major market for HOCl, with increasing adoption in wound care, sanitization, and medical device sterilization. Hospitals, clinics, and long-term care facilities are incorporating HOCl-based solutions into their infection control protocols, driving market expansion.

The food and beverage industry is another key driver of HOCl demand. As consumers become more health-conscious and regulatory bodies tighten food safety standards, manufacturers are turning to HOCl for its efficacy in sanitizing food processing equipment, surfaces, and produce. The ability of HOCl to eliminate pathogens without leaving harmful residues aligns with the industry's push towards cleaner label products and sustainable practices.

Water treatment applications represent a growing segment for HOCl technology. Municipal water systems and industrial wastewater treatment facilities are exploring HOCl as an alternative to traditional chlorine-based disinfection methods. The reduced formation of harmful disinfection by-products and improved safety for operators are driving factors in this sector.

The agriculture industry is increasingly adopting HOCl for crop protection and post-harvest treatment. Its use in hydroponics, greenhouse operations, and organic farming is expanding due to its ability to control plant pathogens without the environmental concerns associated with conventional pesticides. The rising demand for organic produce and sustainable farming practices is fueling this market segment.

In the personal care and cosmetics industry, HOCl is finding applications in skincare products, mouthwashes, and hygiene solutions. The non-irritating nature of HOCl and its effectiveness against a wide range of microorganisms make it an attractive ingredient for manufacturers looking to develop gentle yet powerful products.

The COVID-19 pandemic has further accelerated market demand for HOCl-based disinfectants across various sectors. Businesses, schools, and public spaces are seeking safe and effective sanitization solutions, leading to increased adoption of HOCl foggers and sprayers for large-scale disinfection.

As industries continue to prioritize safety, sustainability, and efficacy in their protocols, the market for HOCl applications is expected to expand. The versatility of HOCl across multiple sectors, coupled with ongoing research into new applications, suggests a positive growth trajectory for this technology in the coming years.

The food and beverage industry is another key driver of HOCl demand. As consumers become more health-conscious and regulatory bodies tighten food safety standards, manufacturers are turning to HOCl for its efficacy in sanitizing food processing equipment, surfaces, and produce. The ability of HOCl to eliminate pathogens without leaving harmful residues aligns with the industry's push towards cleaner label products and sustainable practices.

Water treatment applications represent a growing segment for HOCl technology. Municipal water systems and industrial wastewater treatment facilities are exploring HOCl as an alternative to traditional chlorine-based disinfection methods. The reduced formation of harmful disinfection by-products and improved safety for operators are driving factors in this sector.

The agriculture industry is increasingly adopting HOCl for crop protection and post-harvest treatment. Its use in hydroponics, greenhouse operations, and organic farming is expanding due to its ability to control plant pathogens without the environmental concerns associated with conventional pesticides. The rising demand for organic produce and sustainable farming practices is fueling this market segment.

In the personal care and cosmetics industry, HOCl is finding applications in skincare products, mouthwashes, and hygiene solutions. The non-irritating nature of HOCl and its effectiveness against a wide range of microorganisms make it an attractive ingredient for manufacturers looking to develop gentle yet powerful products.

The COVID-19 pandemic has further accelerated market demand for HOCl-based disinfectants across various sectors. Businesses, schools, and public spaces are seeking safe and effective sanitization solutions, leading to increased adoption of HOCl foggers and sprayers for large-scale disinfection.

As industries continue to prioritize safety, sustainability, and efficacy in their protocols, the market for HOCl applications is expected to expand. The versatility of HOCl across multiple sectors, coupled with ongoing research into new applications, suggests a positive growth trajectory for this technology in the coming years.

HOCL Challenges

Despite the numerous advantages of hypochlorous acid (HOCl) in various industrial applications, several challenges hinder its widespread adoption and implementation. One of the primary obstacles is the stability of HOCl solutions. The compound is inherently unstable and tends to degrade over time, especially when exposed to light, heat, or organic matter. This instability poses significant challenges in storage, transportation, and long-term effectiveness of HOCl-based products.

Another critical challenge is the precise control of HOCl concentration. The efficacy of HOCl is highly dependent on its concentration, with different applications requiring specific concentration levels. Maintaining the optimal concentration throughout the production, storage, and application processes is technically demanding and often requires sophisticated monitoring and control systems.

The production of HOCl at scale also presents challenges. While small-scale generation of HOCl through electrolysis of salt water is relatively straightforward, scaling up this process for industrial applications introduces complexities in terms of equipment design, energy efficiency, and quality control. Ensuring consistent production of high-quality HOCl at industrial scales remains a significant technical hurdle.

Compatibility with existing industrial equipment and processes is another area of concern. Many industries have established protocols and infrastructure designed for traditional disinfectants and cleaning agents. Integrating HOCl into these existing systems often requires modifications to equipment, procedures, and safety protocols, which can be costly and time-consuming.

The regulatory landscape surrounding HOCl usage in various industries also presents challenges. While HOCl is generally recognized as safe, its classification and approval for specific applications vary across different regions and regulatory bodies. Navigating these regulatory requirements and obtaining necessary approvals can be a complex and lengthy process, potentially slowing down the adoption of HOCl-based solutions.

Furthermore, there are challenges related to the perception and understanding of HOCl among industry professionals and end-users. Despite its effectiveness, there is often a lack of awareness or misconceptions about HOCl's properties, benefits, and proper usage. Overcoming these knowledge gaps and changing established practices requires significant educational and marketing efforts.

Lastly, the economic aspects of implementing HOCl solutions pose challenges. While HOCl can be cost-effective in the long run, the initial investment in production equipment, storage facilities, and training can be substantial. Convincing stakeholders to make this investment, especially in industries with tight profit margins, remains a significant hurdle in the widespread adoption of HOCl technologies.

Another critical challenge is the precise control of HOCl concentration. The efficacy of HOCl is highly dependent on its concentration, with different applications requiring specific concentration levels. Maintaining the optimal concentration throughout the production, storage, and application processes is technically demanding and often requires sophisticated monitoring and control systems.

The production of HOCl at scale also presents challenges. While small-scale generation of HOCl through electrolysis of salt water is relatively straightforward, scaling up this process for industrial applications introduces complexities in terms of equipment design, energy efficiency, and quality control. Ensuring consistent production of high-quality HOCl at industrial scales remains a significant technical hurdle.

Compatibility with existing industrial equipment and processes is another area of concern. Many industries have established protocols and infrastructure designed for traditional disinfectants and cleaning agents. Integrating HOCl into these existing systems often requires modifications to equipment, procedures, and safety protocols, which can be costly and time-consuming.

The regulatory landscape surrounding HOCl usage in various industries also presents challenges. While HOCl is generally recognized as safe, its classification and approval for specific applications vary across different regions and regulatory bodies. Navigating these regulatory requirements and obtaining necessary approvals can be a complex and lengthy process, potentially slowing down the adoption of HOCl-based solutions.

Furthermore, there are challenges related to the perception and understanding of HOCl among industry professionals and end-users. Despite its effectiveness, there is often a lack of awareness or misconceptions about HOCl's properties, benefits, and proper usage. Overcoming these knowledge gaps and changing established practices requires significant educational and marketing efforts.

Lastly, the economic aspects of implementing HOCl solutions pose challenges. While HOCl can be cost-effective in the long run, the initial investment in production equipment, storage facilities, and training can be substantial. Convincing stakeholders to make this investment, especially in industries with tight profit margins, remains a significant hurdle in the widespread adoption of HOCl technologies.

Current HOCL Solutions

01 Production methods of hypochlorous acid

Various methods are employed to produce hypochlorous acid, including electrolysis of salt solutions, chemical reactions involving chlorine and water, and controlled mixing of precursor chemicals. These production methods aim to create stable and effective hypochlorous acid solutions for different applications.- Production methods of hypochlorous acid: Various methods are employed to produce hypochlorous acid, including electrolysis of salt solutions, chemical reactions involving chlorine and water, and controlled mixing of precursor chemicals. These production methods aim to create stable and effective hypochlorous acid solutions for different applications.

- Antimicrobial applications of hypochlorous acid: Hypochlorous acid is widely used as an antimicrobial agent in various fields, including healthcare, food processing, and water treatment. Its effectiveness against a broad spectrum of pathogens, combined with its low toxicity to humans, makes it a valuable disinfectant and sanitizer.

- Stabilization techniques for hypochlorous acid solutions: Researchers have developed various stabilization techniques to extend the shelf life and maintain the efficacy of hypochlorous acid solutions. These methods may involve pH adjustment, addition of stabilizing agents, or specialized packaging to prevent degradation and ensure long-term stability.

- Medical and therapeutic uses of hypochlorous acid: Hypochlorous acid has found applications in medical and therapeutic fields, including wound care, eye care, and respiratory treatments. Its ability to effectively kill pathogens while being gentle on human tissues makes it suitable for various medical applications.

- Environmental and industrial applications of hypochlorous acid: Hypochlorous acid is utilized in environmental and industrial settings for purposes such as water treatment, air purification, and surface disinfection. Its eco-friendly nature and effectiveness in removing contaminants make it a preferred choice in various industrial processes.

02 Antimicrobial applications of hypochlorous acid

Hypochlorous acid is widely used as an antimicrobial agent in various fields, including healthcare, food processing, and water treatment. Its effectiveness against a broad spectrum of pathogens, combined with its low toxicity to humans, makes it a valuable disinfectant and sanitizer.Expand Specific Solutions03 Stabilization techniques for hypochlorous acid solutions

Researchers have developed various stabilization techniques to prolong the shelf life and maintain the efficacy of hypochlorous acid solutions. These methods may involve pH adjustment, addition of stabilizing agents, or specialized packaging to prevent degradation and ensure long-term stability.Expand Specific Solutions04 Medical and therapeutic uses of hypochlorous acid

Hypochlorous acid has found applications in various medical and therapeutic contexts, including wound care, eye care, and respiratory treatments. Its ability to promote healing, reduce inflammation, and combat infections without causing significant tissue damage has led to the development of numerous medical products and treatments.Expand Specific Solutions05 Environmental and industrial applications of hypochlorous acid

Hypochlorous acid is utilized in various environmental and industrial applications, such as water treatment, agriculture, and surface disinfection. Its eco-friendly nature and effectiveness in removing contaminants and pathogens make it a preferred choice in many industrial processes and environmental remediation efforts.Expand Specific Solutions

Key Industry Players

The market for hypochlorous acid applications is in a growth phase, with increasing adoption across various industries. The global market size is expanding, driven by rising demand for eco-friendly disinfectants and water treatment solutions. Technologically, the field is advancing rapidly, with companies like Fluid Energy Group and Aquaox leading innovation in production methods and application technologies. Established players such as Zep Inc. and Industrie De Nora SpA are leveraging their expertise to develop new hypochlorous acid-based products. Research institutions like Jilin University and Dalian Institute of Chemical Physics are contributing to technological advancements, while companies like Toyota Motor Corp. are exploring novel applications in automotive and industrial sectors. The competitive landscape is diverse, with a mix of specialized chemical manufacturers and larger conglomerates entering the market, indicating growing maturity and potential for further innovation.

Fluid Energy Group Ltd.

Technical Solution: Fluid Energy Group has developed a range of hypochlorous acid-based products under their Envirolyte® brand, specifically designed for industrial applications. Their technology focuses on producing stable, high-concentration HOCl solutions that can be effectively used in various industrial processes. The company's proprietary formulation allows for HOCl concentrations up to 500 ppm while maintaining a near-neutral pH, which is crucial for many industrial applications[4]. Fluid Energy Group has also developed specialized delivery systems and application methods to optimize the use of HOCl in industries such as oil and gas, water treatment, and agriculture[5]. Their research has shown that their HOCl solutions can achieve a 99.999% reduction in harmful microorganisms within 60 seconds of contact time[6].

Strengths: High-concentration HOCl solutions; specialized delivery systems for industrial use; proven efficacy in microbial control. Weaknesses: May require industry-specific adaptations; potential cost considerations for large-scale industrial applications.

Aquaox, Inc.

Technical Solution: Aquaox has developed a proprietary Electrochemical Activation (ECA) technology for producing hypochlorous acid (HOCl) on-site. Their system uses salt, water, and electricity to generate a stable and effective HOCl solution. The company's ECA devices can produce HOCl with a concentration of 500 ppm and a pH range of 6.5-7.5, which is ideal for various industrial applications[1]. Aquaox's technology allows for the production of HOCl without the need for hazardous chemicals, making it a safer and more environmentally friendly option for industries[2]. The company has also developed a patented stabilization process that extends the shelf life of their HOCl solutions, addressing one of the main challenges in HOCl application[3].

Strengths: On-site production eliminates transportation and storage issues; environmentally friendly process; extended shelf life of HOCl solutions. Weaknesses: Requires initial investment in ECA equipment; may have limitations in producing very high concentrations of HOCl for certain industrial applications.

HOCL Innovations

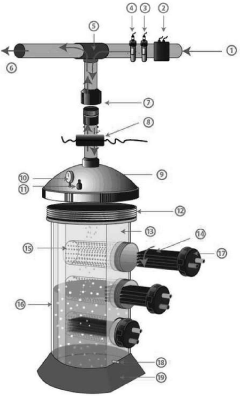

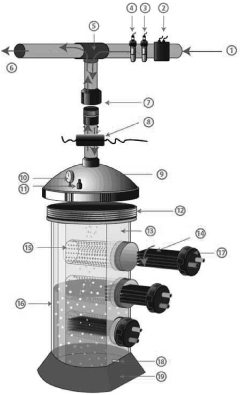

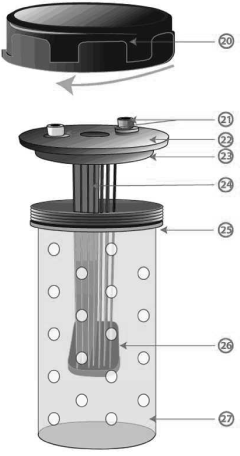

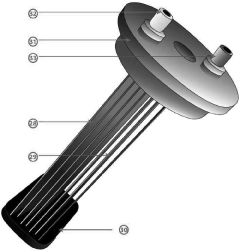

Device for manufacturing sodium hypochlorite or hypochlorous acid and water treatment system in general

PatentActiveAU2017225104A1

Innovation

- A device comprising a cylinder with perforated tubes for electrolysis chambers, allowing bipolar electrolytic cells to contact salt-saturated water without direct contact with solid salt, and a control unit for remote data processing and safety features, enabling efficient production and safe handling of sodium hypochlorite or hypochlorous acid directly in water pipelines.

Regulatory Framework

The regulatory framework surrounding hypochlorous acid (HOCl) applications in various industries is complex and multifaceted, reflecting the diverse uses and potential impacts of this versatile compound. In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating HOCl as an antimicrobial agent. The EPA has approved HOCl for use in food processing, water treatment, and as a disinfectant in healthcare settings under specific conditions and concentrations.

The Food and Drug Administration (FDA) also oversees the use of HOCl in food-related applications, ensuring its safety for consumers. The FDA has granted Generally Recognized as Safe (GRAS) status to HOCl when used as an antimicrobial agent in the production of meat and poultry products, as well as in the processing of fruits and vegetables.

In the healthcare sector, the Centers for Disease Control and Prevention (CDC) provides guidelines for the use of HOCl as a disinfectant, particularly in the context of infection control and prevention. These guidelines outline proper usage, concentration levels, and safety precautions for healthcare professionals and facilities.

Internationally, regulatory bodies such as the European Chemicals Agency (ECHA) and the World Health Organization (WHO) have established guidelines for the use of HOCl in various applications. The ECHA, for instance, has registered HOCl under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, providing a framework for its safe use within the European Union.

As the applications of HOCl continue to expand across industries, regulatory bodies are adapting their frameworks to address emerging uses and potential risks. This includes ongoing assessments of environmental impact, occupational safety, and long-term health effects associated with HOCl exposure.

The Occupational Safety and Health Administration (OSHA) in the United States has established workplace safety standards for handling and using HOCl, including requirements for personal protective equipment and proper ventilation in industrial settings.

As research into HOCl applications advances, regulatory agencies are likely to update their guidelines and regulations to reflect new findings and potential risks. This dynamic regulatory landscape requires industries to stay informed and adaptable, ensuring compliance with evolving standards while leveraging the benefits of HOCl technology.

The Food and Drug Administration (FDA) also oversees the use of HOCl in food-related applications, ensuring its safety for consumers. The FDA has granted Generally Recognized as Safe (GRAS) status to HOCl when used as an antimicrobial agent in the production of meat and poultry products, as well as in the processing of fruits and vegetables.

In the healthcare sector, the Centers for Disease Control and Prevention (CDC) provides guidelines for the use of HOCl as a disinfectant, particularly in the context of infection control and prevention. These guidelines outline proper usage, concentration levels, and safety precautions for healthcare professionals and facilities.

Internationally, regulatory bodies such as the European Chemicals Agency (ECHA) and the World Health Organization (WHO) have established guidelines for the use of HOCl in various applications. The ECHA, for instance, has registered HOCl under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, providing a framework for its safe use within the European Union.

As the applications of HOCl continue to expand across industries, regulatory bodies are adapting their frameworks to address emerging uses and potential risks. This includes ongoing assessments of environmental impact, occupational safety, and long-term health effects associated with HOCl exposure.

The Occupational Safety and Health Administration (OSHA) in the United States has established workplace safety standards for handling and using HOCl, including requirements for personal protective equipment and proper ventilation in industrial settings.

As research into HOCl applications advances, regulatory agencies are likely to update their guidelines and regulations to reflect new findings and potential risks. This dynamic regulatory landscape requires industries to stay informed and adaptable, ensuring compliance with evolving standards while leveraging the benefits of HOCl technology.

Environmental Impact

The application of hypochlorous acid (HOCl) in industrial protocols presents significant environmental benefits compared to traditional chemical treatments. HOCl is a naturally occurring compound produced by the human immune system, making it inherently biodegradable and environmentally friendly. When used in industrial settings, it breaks down into simple salt and water, leaving no harmful residues or by-products.

One of the primary environmental advantages of HOCl is its potential to reduce the use of harsh chemicals in various industries. In water treatment, for instance, HOCl can replace chlorine-based disinfectants, which are known to form harmful disinfection by-products (DBPs) when reacting with organic matter. By contrast, HOCl produces minimal DBPs, leading to cleaner water systems and reduced environmental impact.

In agriculture and food processing, HOCl offers a sustainable alternative to conventional pesticides and sanitizers. Its broad-spectrum antimicrobial properties allow for effective pathogen control without the risk of chemical residues on crops or food products. This not only ensures food safety but also minimizes the introduction of synthetic chemicals into the ecosystem.

The production of HOCl through electrolysis of salt water is an energy-efficient process that can be powered by renewable energy sources, further reducing its carbon footprint. Additionally, on-site generation capabilities eliminate the need for transportation and storage of hazardous chemicals, decreasing the risk of spills and associated environmental contamination.

HOCl's rapid action and short half-life mean it quickly neutralizes pathogens without persisting in the environment. This characteristic is particularly beneficial in aquaculture and marine applications, where it can be used for water treatment without harming aquatic ecosystems. The compound's low toxicity to non-target organisms further enhances its environmental profile.

In industrial cleaning and disinfection, HOCl can replace a range of chemical products, simplifying waste management processes and reducing the volume of hazardous materials requiring disposal. This transition not only lowers the environmental burden but also improves workplace safety by minimizing exposure to toxic substances.

As industries increasingly prioritize sustainability, the adoption of HOCl aligns with circular economy principles. Its production from readily available materials and its complete biodegradability support closed-loop systems, minimizing resource consumption and waste generation. This shift towards more environmentally responsible practices can contribute to improved corporate sustainability metrics and regulatory compliance.

One of the primary environmental advantages of HOCl is its potential to reduce the use of harsh chemicals in various industries. In water treatment, for instance, HOCl can replace chlorine-based disinfectants, which are known to form harmful disinfection by-products (DBPs) when reacting with organic matter. By contrast, HOCl produces minimal DBPs, leading to cleaner water systems and reduced environmental impact.

In agriculture and food processing, HOCl offers a sustainable alternative to conventional pesticides and sanitizers. Its broad-spectrum antimicrobial properties allow for effective pathogen control without the risk of chemical residues on crops or food products. This not only ensures food safety but also minimizes the introduction of synthetic chemicals into the ecosystem.

The production of HOCl through electrolysis of salt water is an energy-efficient process that can be powered by renewable energy sources, further reducing its carbon footprint. Additionally, on-site generation capabilities eliminate the need for transportation and storage of hazardous chemicals, decreasing the risk of spills and associated environmental contamination.

HOCl's rapid action and short half-life mean it quickly neutralizes pathogens without persisting in the environment. This characteristic is particularly beneficial in aquaculture and marine applications, where it can be used for water treatment without harming aquatic ecosystems. The compound's low toxicity to non-target organisms further enhances its environmental profile.

In industrial cleaning and disinfection, HOCl can replace a range of chemical products, simplifying waste management processes and reducing the volume of hazardous materials requiring disposal. This transition not only lowers the environmental burden but also improves workplace safety by minimizing exposure to toxic substances.

As industries increasingly prioritize sustainability, the adoption of HOCl aligns with circular economy principles. Its production from readily available materials and its complete biodegradability support closed-loop systems, minimizing resource consumption and waste generation. This shift towards more environmentally responsible practices can contribute to improved corporate sustainability metrics and regulatory compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!