Hypochlorous Acid as a Solution for Industrial Odor Control

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCl Odor Control Background and Objectives

Hypochlorous acid (HOCl) has emerged as a promising solution for industrial odor control, addressing a longstanding challenge in various sectors. The evolution of odor control technologies has been driven by the increasing awareness of environmental impacts and stricter regulations on air quality. HOCl, a naturally occurring compound in the human immune system, has gained attention for its potent antimicrobial and deodorizing properties.

The primary objective of researching HOCl for industrial odor control is to develop an effective, safe, and environmentally friendly alternative to traditional odor management methods. This aligns with the growing demand for sustainable practices across industries and the need to mitigate the negative effects of industrial odors on surrounding communities and ecosystems.

HOCl's potential in odor control stems from its unique chemical properties. As a weak acid, it can effectively neutralize a wide range of odor-causing compounds through oxidation processes. Unlike harsh chemicals often used in odor control, HOCl breaks down into harmless byproducts, making it an attractive option for environmentally conscious applications.

The development of HOCl-based odor control solutions has been influenced by advancements in production technologies, enabling the stable generation of HOCl at industrial scales. This has opened up new possibilities for its application in diverse settings, from wastewater treatment plants to food processing facilities and agricultural operations.

Recent technological trends in this field include the integration of HOCl generation systems with smart sensors and IoT devices, allowing for real-time monitoring and adjustment of odor control measures. This represents a shift towards more efficient and responsive odor management strategies, capable of adapting to varying environmental conditions and odor intensities.

The research into HOCl for odor control also aims to address several key challenges. These include optimizing the stability of HOCl solutions, enhancing its effectiveness across a broader spectrum of odor-causing compounds, and developing cost-effective production methods to make HOCl-based solutions competitive with existing odor control technologies.

As industries face increasing pressure to reduce their environmental footprint, the exploration of HOCl as an odor control solution reflects a broader trend towards adopting nature-inspired technologies. This research not only seeks to solve immediate odor control problems but also contributes to the development of more sustainable industrial practices overall.

The primary objective of researching HOCl for industrial odor control is to develop an effective, safe, and environmentally friendly alternative to traditional odor management methods. This aligns with the growing demand for sustainable practices across industries and the need to mitigate the negative effects of industrial odors on surrounding communities and ecosystems.

HOCl's potential in odor control stems from its unique chemical properties. As a weak acid, it can effectively neutralize a wide range of odor-causing compounds through oxidation processes. Unlike harsh chemicals often used in odor control, HOCl breaks down into harmless byproducts, making it an attractive option for environmentally conscious applications.

The development of HOCl-based odor control solutions has been influenced by advancements in production technologies, enabling the stable generation of HOCl at industrial scales. This has opened up new possibilities for its application in diverse settings, from wastewater treatment plants to food processing facilities and agricultural operations.

Recent technological trends in this field include the integration of HOCl generation systems with smart sensors and IoT devices, allowing for real-time monitoring and adjustment of odor control measures. This represents a shift towards more efficient and responsive odor management strategies, capable of adapting to varying environmental conditions and odor intensities.

The research into HOCl for odor control also aims to address several key challenges. These include optimizing the stability of HOCl solutions, enhancing its effectiveness across a broader spectrum of odor-causing compounds, and developing cost-effective production methods to make HOCl-based solutions competitive with existing odor control technologies.

As industries face increasing pressure to reduce their environmental footprint, the exploration of HOCl as an odor control solution reflects a broader trend towards adopting nature-inspired technologies. This research not only seeks to solve immediate odor control problems but also contributes to the development of more sustainable industrial practices overall.

Industrial Demand for Odor Control Solutions

The industrial demand for odor control solutions has been steadily increasing across various sectors, driven by stringent environmental regulations, growing public awareness of air quality, and the need for improved workplace conditions. Industries such as wastewater treatment, food processing, chemical manufacturing, and agricultural operations are particularly seeking effective and sustainable odor control methods.

In the wastewater treatment sector, the need for odor control is paramount due to the inherent nature of the processes involved. As urbanization continues and treatment facilities are often located near residential areas, the pressure to mitigate unpleasant odors has intensified. This has led to a surge in demand for advanced odor control technologies that can effectively neutralize sulfurous compounds and other malodorous substances.

The food processing industry faces similar challenges, with odors from cooking, fermentation, and waste management processes requiring robust control measures. As consumer expectations for food quality and safety rise, manufacturers are increasingly investing in odor control solutions to maintain a clean and hygienic production environment. This not only improves working conditions for employees but also helps in meeting regulatory standards and preserving product quality.

Chemical manufacturing plants have long been associated with strong odors, often leading to community complaints and regulatory scrutiny. The industry is now actively seeking innovative odor control solutions that can address a wide range of volatile organic compounds (VOCs) and other odorous emissions. This demand is further fueled by the implementation of stricter air quality regulations in many countries, compelling chemical manufacturers to adopt more effective odor management strategies.

In the agricultural sector, particularly in livestock farming and composting operations, odor control has become a critical issue. As farms expand and come closer to urban areas, the need to minimize odor emissions has become essential for maintaining good relationships with neighboring communities and complying with local regulations. This has led to increased interest in biological and chemical odor control methods that can be integrated into existing farm management practices.

The demand for odor control solutions is not limited to these industries alone. Sectors such as pharmaceuticals, petroleum refining, and solid waste management are also seeking advanced odor control technologies. This widespread need across diverse industries has created a significant market opportunity for innovative odor control solutions, driving research and development in this field.

As environmental consciousness grows and regulations become more stringent, industries are increasingly looking for odor control solutions that are not only effective but also environmentally friendly and cost-efficient. This has led to a shift towards sustainable technologies, such as biological treatments and advanced oxidation processes, which can address odor issues without creating secondary environmental problems.

In the wastewater treatment sector, the need for odor control is paramount due to the inherent nature of the processes involved. As urbanization continues and treatment facilities are often located near residential areas, the pressure to mitigate unpleasant odors has intensified. This has led to a surge in demand for advanced odor control technologies that can effectively neutralize sulfurous compounds and other malodorous substances.

The food processing industry faces similar challenges, with odors from cooking, fermentation, and waste management processes requiring robust control measures. As consumer expectations for food quality and safety rise, manufacturers are increasingly investing in odor control solutions to maintain a clean and hygienic production environment. This not only improves working conditions for employees but also helps in meeting regulatory standards and preserving product quality.

Chemical manufacturing plants have long been associated with strong odors, often leading to community complaints and regulatory scrutiny. The industry is now actively seeking innovative odor control solutions that can address a wide range of volatile organic compounds (VOCs) and other odorous emissions. This demand is further fueled by the implementation of stricter air quality regulations in many countries, compelling chemical manufacturers to adopt more effective odor management strategies.

In the agricultural sector, particularly in livestock farming and composting operations, odor control has become a critical issue. As farms expand and come closer to urban areas, the need to minimize odor emissions has become essential for maintaining good relationships with neighboring communities and complying with local regulations. This has led to increased interest in biological and chemical odor control methods that can be integrated into existing farm management practices.

The demand for odor control solutions is not limited to these industries alone. Sectors such as pharmaceuticals, petroleum refining, and solid waste management are also seeking advanced odor control technologies. This widespread need across diverse industries has created a significant market opportunity for innovative odor control solutions, driving research and development in this field.

As environmental consciousness grows and regulations become more stringent, industries are increasingly looking for odor control solutions that are not only effective but also environmentally friendly and cost-efficient. This has led to a shift towards sustainable technologies, such as biological treatments and advanced oxidation processes, which can address odor issues without creating secondary environmental problems.

HOCl Technology Status and Challenges

Hypochlorous acid (HOCl) has emerged as a promising solution for industrial odor control, with its technology status and challenges evolving rapidly in recent years. The current state of HOCl technology for odor control is characterized by a growing understanding of its efficacy and an increasing adoption across various industries.

One of the primary advantages of HOCl in odor control is its strong oxidizing properties, which allow it to effectively neutralize a wide range of odorous compounds. This has led to its application in diverse sectors, including wastewater treatment, food processing, and agricultural facilities. The technology has shown particular promise in addressing complex odor issues where traditional methods have fallen short.

Despite its potential, HOCl technology faces several challenges in its widespread implementation for industrial odor control. One significant hurdle is the stability of HOCl solutions. The compound is known to degrade over time, especially when exposed to light or heat, which can limit its shelf life and effectiveness in long-term applications. This has spurred research into stabilization techniques and improved storage methods to enhance the practicality of HOCl-based odor control systems.

Another challenge lies in the production of HOCl at industrial scales. While small-scale generation of HOCl through electrolysis of salt water is relatively straightforward, scaling up this process for large industrial applications presents technical and economic challenges. Researchers and manufacturers are working on developing more efficient and cost-effective production methods to make HOCl a viable option for widespread industrial use.

The regulatory landscape surrounding HOCl use in odor control is also evolving. As a relatively new application, there are ongoing efforts to establish clear guidelines and standards for its use in different industrial settings. This regulatory uncertainty can pose challenges for companies looking to adopt HOCl-based odor control solutions.

From a geographical perspective, the development and adoption of HOCl technology for odor control vary significantly across regions. North America and Europe have seen more rapid adoption and research in this area, driven by stricter environmental regulations and a greater focus on sustainable industrial practices. In contrast, adoption in some developing countries has been slower, often due to a combination of regulatory, economic, and technological factors.

Looking at the technical aspects, current research is focused on optimizing HOCl generation systems, improving delivery methods, and enhancing the compound's stability. There is also ongoing work to better understand the mechanisms by which HOCl interacts with different odorous compounds, aiming to improve its efficacy across a broader range of applications.

In conclusion, while HOCl shows great promise as a solution for industrial odor control, its technology status is still evolving. The challenges of stability, large-scale production, and regulatory compliance are driving ongoing research and development efforts. As these challenges are addressed, HOCl is likely to play an increasingly important role in industrial odor control strategies.

One of the primary advantages of HOCl in odor control is its strong oxidizing properties, which allow it to effectively neutralize a wide range of odorous compounds. This has led to its application in diverse sectors, including wastewater treatment, food processing, and agricultural facilities. The technology has shown particular promise in addressing complex odor issues where traditional methods have fallen short.

Despite its potential, HOCl technology faces several challenges in its widespread implementation for industrial odor control. One significant hurdle is the stability of HOCl solutions. The compound is known to degrade over time, especially when exposed to light or heat, which can limit its shelf life and effectiveness in long-term applications. This has spurred research into stabilization techniques and improved storage methods to enhance the practicality of HOCl-based odor control systems.

Another challenge lies in the production of HOCl at industrial scales. While small-scale generation of HOCl through electrolysis of salt water is relatively straightforward, scaling up this process for large industrial applications presents technical and economic challenges. Researchers and manufacturers are working on developing more efficient and cost-effective production methods to make HOCl a viable option for widespread industrial use.

The regulatory landscape surrounding HOCl use in odor control is also evolving. As a relatively new application, there are ongoing efforts to establish clear guidelines and standards for its use in different industrial settings. This regulatory uncertainty can pose challenges for companies looking to adopt HOCl-based odor control solutions.

From a geographical perspective, the development and adoption of HOCl technology for odor control vary significantly across regions. North America and Europe have seen more rapid adoption and research in this area, driven by stricter environmental regulations and a greater focus on sustainable industrial practices. In contrast, adoption in some developing countries has been slower, often due to a combination of regulatory, economic, and technological factors.

Looking at the technical aspects, current research is focused on optimizing HOCl generation systems, improving delivery methods, and enhancing the compound's stability. There is also ongoing work to better understand the mechanisms by which HOCl interacts with different odorous compounds, aiming to improve its efficacy across a broader range of applications.

In conclusion, while HOCl shows great promise as a solution for industrial odor control, its technology status is still evolving. The challenges of stability, large-scale production, and regulatory compliance are driving ongoing research and development efforts. As these challenges are addressed, HOCl is likely to play an increasingly important role in industrial odor control strategies.

Current HOCl Odor Control Solutions

01 Odor reduction methods for hypochlorous acid

Various methods are employed to reduce or eliminate the characteristic odor of hypochlorous acid. These may include chemical treatments, physical processes, or the use of additives that mask or neutralize the odor. Such techniques are crucial for improving the user experience and broadening the application range of hypochlorous acid-based products.- Odor reduction methods for hypochlorous acid: Various methods are employed to reduce or eliminate the characteristic odor of hypochlorous acid. These may include chemical treatments, physical processes, or the addition of masking agents. The goal is to maintain the efficacy of hypochlorous acid while improving its sensory properties for better user acceptance.

- Stabilization of hypochlorous acid solutions: Techniques for stabilizing hypochlorous acid solutions are developed to maintain their effectiveness and reduce odor over time. These may involve pH adjustment, addition of stabilizing agents, or special packaging methods. Stabilized solutions tend to have less pronounced odors and longer shelf lives.

- Formulation of hypochlorous acid with fragrances: Hypochlorous acid is formulated with compatible fragrances or essential oils to mask its characteristic odor. The challenge lies in selecting fragrances that do not react with or degrade the hypochlorous acid while effectively masking its smell. This approach aims to improve user experience without compromising antimicrobial efficacy.

- Production methods to minimize odor formation: Innovative production methods are developed to minimize the formation of odorous compounds during the generation of hypochlorous acid. These may include optimized electrolysis processes, purification techniques, or the use of high-purity precursors. The goal is to produce hypochlorous acid with inherently lower odor profiles.

- Encapsulation and controlled release of hypochlorous acid: Encapsulation technologies are applied to hypochlorous acid to control its release and minimize odor. This may involve microencapsulation, nanoencapsulation, or incorporation into matrices that slowly release the active compound. These methods aim to reduce the immediate perception of odor while maintaining the antimicrobial properties of hypochlorous acid.

02 Stabilization of hypochlorous acid solutions

Stabilization techniques are developed to maintain the efficacy of hypochlorous acid while minimizing odor formation over time. These may involve pH adjustment, addition of stabilizing agents, or packaging innovations that prevent degradation and subsequent odor development in hypochlorous acid solutions.Expand Specific Solutions03 Formulation of hypochlorous acid with odor-masking agents

Odor-masking agents are incorporated into hypochlorous acid formulations to counteract its characteristic smell. These agents may include natural or synthetic fragrances, essential oils, or other compounds that effectively mask the odor without compromising the acid's antimicrobial properties.Expand Specific Solutions04 Production methods to minimize hypochlorous acid odor

Innovative production methods are developed to generate hypochlorous acid with reduced odor from the outset. These may involve modifications to electrolysis processes, use of high-purity precursors, or novel synthesis routes that result in a final product with minimal odor while maintaining desired properties.Expand Specific Solutions05 Application-specific odor control for hypochlorous acid products

Tailored approaches are developed for controlling hypochlorous acid odor in specific applications such as medical devices, water treatment, or personal care products. These may involve combining odor control techniques with application-specific requirements to create effective, low-odor hypochlorous acid solutions for diverse uses.Expand Specific Solutions

Key Players in HOCl Odor Control Industry

The research on hypochlorous acid for industrial odor control is in a developing stage, with growing market potential due to increasing environmental regulations and public awareness of air quality. The global market for odor control solutions is expanding, driven by industrialization and urbanization. Technologically, hypochlorous acid applications are advancing, with companies like Colgate-Palmolive, Kao Corp., and Kurita Water Industries leading innovation. These firms, along with others like Aquaox and Industrie De Nora, are developing more efficient and eco-friendly hypochlorous acid-based solutions. The technology's maturity varies across sectors, with some applications well-established and others still in experimental phases, indicating a dynamic and competitive landscape with room for further advancements and market growth.

Aquaox, Inc.

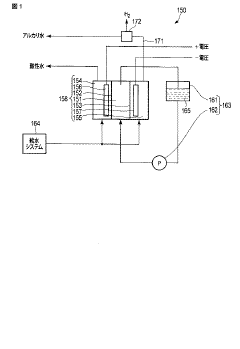

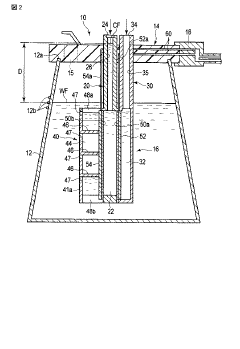

Technical Solution: Aquaox has developed an advanced electrolysis system for on-site generation of hypochlorous acid (HOCl) solutions. Their technology utilizes a proprietary electrochemical cell design that allows for precise control of HOCl concentration and pH[1]. The system produces a stable HOCl solution with a neutral pH range of 6.5-7.5, which is highly effective for odor control while being safe for human contact and environmentally friendly[2]. Aquaox's HOCl generators can produce solutions with concentrations ranging from 50-500 ppm, suitable for various industrial applications including food processing, wastewater treatment, and air purification systems[3].

Strengths: On-site generation eliminates transportation and storage issues; Precise control over HOCl concentration and pH; Environmentally friendly solution. Weaknesses: Requires initial investment in equipment; Ongoing maintenance of electrolysis system needed.

Jiangsu Tengchuang Environmental Protection Technology Co., Ltd.

Technical Solution: Jiangsu Tengchuang has developed a comprehensive HOCl-based odor control system for industrial applications. Their approach combines HOCl generation technology with advanced dispersion methods to effectively neutralize a wide range of industrial odors. The company's system uses a membrane electrolysis process to produce high-purity HOCl solutions with concentrations up to 200 ppm[4]. They have also developed proprietary misting and fogging systems that allow for efficient distribution of HOCl in large industrial spaces, such as waste treatment facilities and food processing plants[5]. Additionally, Jiangsu Tengchuang has integrated real-time monitoring and automated dosing controls to optimize HOCl usage based on odor levels and environmental conditions[6].

Strengths: Integrated system approach combining generation and distribution; Suitable for large-scale industrial applications; Advanced monitoring and control systems. Weaknesses: May require significant customization for different industrial settings; Higher initial cost compared to traditional odor control methods.

Core HOCl Odor Control Innovations

Hypochlorous acid aqueous solution, and material impregnated with hypochlorous acid water

PatentInactiveJP2017160174A

Innovation

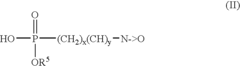

- Aqueous hypochlorous acid solution and impregnated products containing microcapsules with perfume as a core material, maintaining a pH of 3.0 to 7.0 and hypochlorous acid concentration of 1 mg/kg, which prevents direct contact between hypochlorous acid and perfume, thereby suppressing deactivation and generating a pleasant scent upon capsule rupture.

Odor reduction for agents containing hypochlorite

PatentInactiveUS20080261839A1

Innovation

- A combination of specific odorants, such as diphenylmethane, diphenyl oxide, and 2-methyl naphthyl ether, is used to reduce the odor of chlorine bleach on skin, applied either post-exposure or incorporated into the bleaching agent composition, with preferred weight ratios and concentrations to effectively mask the chlorine scent.

Environmental Impact of HOCl Odor Control

The environmental impact of using hypochlorous acid (HOCl) for industrial odor control is generally considered to be positive, with several key advantages over traditional methods. HOCl is a naturally occurring compound that breaks down into harmless components, making it an environmentally friendly option for odor management.

One of the primary environmental benefits of HOCl is its rapid decomposition. When released into the environment, HOCl quickly breaks down into water and salt, leaving no harmful residues or by-products. This characteristic significantly reduces the risk of long-term environmental contamination associated with other chemical odor control methods.

HOCl's effectiveness in neutralizing a wide range of odor-causing compounds also contributes to its positive environmental impact. By efficiently eliminating odors at their source, HOCl reduces the need for masking agents or stronger chemicals that may have more significant environmental consequences. This targeted approach minimizes the overall chemical load released into the environment.

The production and use of HOCl for odor control typically require less energy and fewer resources compared to traditional chemical manufacturing processes. This reduced carbon footprint aligns with sustainability goals and helps minimize the overall environmental impact of industrial odor control operations.

Furthermore, HOCl's non-toxic nature means it poses minimal risk to aquatic life and ecosystems if accidentally released into water bodies. This is particularly important for industries located near sensitive environmental areas or those with stringent discharge regulations.

However, it is essential to consider the potential for chlorine emissions during HOCl production and use. While these emissions are generally low, proper monitoring and control measures should be implemented to ensure compliance with air quality regulations and minimize any potential negative impacts on local air quality.

The use of HOCl in odor control applications may also lead to reduced reliance on other chemical treatments or air scrubbing systems, which can be energy-intensive and generate waste products. This shift towards a more environmentally friendly solution can contribute to overall improvements in industrial sustainability practices.

In conclusion, the environmental impact of HOCl as an odor control solution is predominantly positive. Its rapid decomposition, non-toxic nature, and effectiveness in odor neutralization make it a promising alternative to more environmentally harmful methods. However, ongoing research and monitoring are necessary to fully understand and optimize its long-term environmental effects in various industrial applications.

One of the primary environmental benefits of HOCl is its rapid decomposition. When released into the environment, HOCl quickly breaks down into water and salt, leaving no harmful residues or by-products. This characteristic significantly reduces the risk of long-term environmental contamination associated with other chemical odor control methods.

HOCl's effectiveness in neutralizing a wide range of odor-causing compounds also contributes to its positive environmental impact. By efficiently eliminating odors at their source, HOCl reduces the need for masking agents or stronger chemicals that may have more significant environmental consequences. This targeted approach minimizes the overall chemical load released into the environment.

The production and use of HOCl for odor control typically require less energy and fewer resources compared to traditional chemical manufacturing processes. This reduced carbon footprint aligns with sustainability goals and helps minimize the overall environmental impact of industrial odor control operations.

Furthermore, HOCl's non-toxic nature means it poses minimal risk to aquatic life and ecosystems if accidentally released into water bodies. This is particularly important for industries located near sensitive environmental areas or those with stringent discharge regulations.

However, it is essential to consider the potential for chlorine emissions during HOCl production and use. While these emissions are generally low, proper monitoring and control measures should be implemented to ensure compliance with air quality regulations and minimize any potential negative impacts on local air quality.

The use of HOCl in odor control applications may also lead to reduced reliance on other chemical treatments or air scrubbing systems, which can be energy-intensive and generate waste products. This shift towards a more environmentally friendly solution can contribute to overall improvements in industrial sustainability practices.

In conclusion, the environmental impact of HOCl as an odor control solution is predominantly positive. Its rapid decomposition, non-toxic nature, and effectiveness in odor neutralization make it a promising alternative to more environmentally harmful methods. However, ongoing research and monitoring are necessary to fully understand and optimize its long-term environmental effects in various industrial applications.

Regulatory Framework for HOCl Use in Industry

The regulatory framework for the use of hypochlorous acid (HOCl) in industrial odor control is complex and varies across different regions and countries. In the United States, the Environmental Protection Agency (EPA) regulates HOCl under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) as an antimicrobial pesticide. The EPA has approved HOCl for use in various applications, including water treatment and surface disinfection, which can indirectly contribute to odor control in industrial settings.

The Occupational Safety and Health Administration (OSHA) sets guidelines for worker exposure to HOCl in industrial environments. These guidelines include permissible exposure limits (PELs) and recommended safety measures for handling and storage. OSHA requires employers to provide appropriate personal protective equipment (PPE) and implement safety protocols when workers are exposed to HOCl.

In the European Union, the use of HOCl is regulated under the Biocidal Products Regulation (BPR). The European Chemicals Agency (ECHA) oversees the registration and authorization of HOCl for various applications, including industrial use. The BPR requires manufacturers and importers to demonstrate the safety and efficacy of HOCl-based products before they can be placed on the market.

The Food and Drug Administration (FDA) in the United States has approved HOCl for use in food processing facilities as an antimicrobial agent. This approval extends to its application in odor control within these environments, provided that specific concentration and application guidelines are followed.

Many countries have adopted the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), which provides standardized hazard communication for chemicals, including HOCl. This system ensures consistent labeling and safety data sheets across different regions, facilitating international trade and use of HOCl-based products.

Local and state regulations may impose additional requirements for the use of HOCl in industrial odor control. These can include specific permitting processes, emission standards, and monitoring requirements. Industries must carefully navigate these local regulations in addition to federal and international standards.

The regulatory landscape for HOCl use in industry is dynamic, with ongoing research and assessments potentially leading to updates in guidelines and restrictions. Companies utilizing HOCl for odor control must stay informed about regulatory changes and adapt their practices accordingly to ensure compliance and maintain operational efficiency.

The Occupational Safety and Health Administration (OSHA) sets guidelines for worker exposure to HOCl in industrial environments. These guidelines include permissible exposure limits (PELs) and recommended safety measures for handling and storage. OSHA requires employers to provide appropriate personal protective equipment (PPE) and implement safety protocols when workers are exposed to HOCl.

In the European Union, the use of HOCl is regulated under the Biocidal Products Regulation (BPR). The European Chemicals Agency (ECHA) oversees the registration and authorization of HOCl for various applications, including industrial use. The BPR requires manufacturers and importers to demonstrate the safety and efficacy of HOCl-based products before they can be placed on the market.

The Food and Drug Administration (FDA) in the United States has approved HOCl for use in food processing facilities as an antimicrobial agent. This approval extends to its application in odor control within these environments, provided that specific concentration and application guidelines are followed.

Many countries have adopted the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), which provides standardized hazard communication for chemicals, including HOCl. This system ensures consistent labeling and safety data sheets across different regions, facilitating international trade and use of HOCl-based products.

Local and state regulations may impose additional requirements for the use of HOCl in industrial odor control. These can include specific permitting processes, emission standards, and monitoring requirements. Industries must carefully navigate these local regulations in addition to federal and international standards.

The regulatory landscape for HOCl use in industry is dynamic, with ongoing research and assessments potentially leading to updates in guidelines and restrictions. Companies utilizing HOCl for odor control must stay informed about regulatory changes and adapt their practices accordingly to ensure compliance and maintain operational efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!