Hypochlorous Acid in Textile Antimicrobial Finishes

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCl in Textiles: Background and Objectives

Hypochlorous acid (HOCl) has emerged as a promising antimicrobial agent in textile finishes, offering a potent and eco-friendly alternative to traditional chemical treatments. The textile industry has long sought effective methods to impart antimicrobial properties to fabrics, driven by increasing consumer demand for hygienic and odor-resistant textiles. HOCl, a naturally occurring compound produced by the human immune system, has gained attention for its broad-spectrum antimicrobial activity and low toxicity.

The evolution of antimicrobial textile treatments can be traced back to ancient times when natural substances like herbs and plant extracts were used. However, the modern era of antimicrobial textiles began in the mid-20th century with the introduction of synthetic biocides. These early treatments often faced challenges related to durability, environmental impact, and potential health risks. The search for safer and more sustainable alternatives has led to the exploration of HOCl as a viable option for textile antimicrobial finishes.

HOCl's potential in textile applications stems from its unique properties. It is a powerful oxidizing agent capable of destroying a wide range of microorganisms, including bacteria, viruses, and fungi. Unlike many traditional antimicrobial agents, HOCl is non-toxic to humans and animals when used at appropriate concentrations. This safety profile, combined with its effectiveness, makes it an attractive choice for textiles that come into close contact with human skin.

The technological objectives of researching HOCl in textile antimicrobial finishes are multifaceted. Primarily, the goal is to develop stable and long-lasting HOCl-based treatments that can withstand repeated washing and wear. This involves overcoming the inherent instability of HOCl, which tends to degrade rapidly under normal conditions. Researchers aim to create formulations and application methods that preserve HOCl's antimicrobial efficacy throughout the textile's lifecycle.

Another key objective is to optimize the integration of HOCl into various textile substrates, including natural fibers like cotton and wool, as well as synthetic materials. This requires a deep understanding of the interactions between HOCl and different fiber types to ensure effective bonding and uniform distribution of the antimicrobial agent. Additionally, there is a focus on developing scalable and cost-effective production methods that can be implemented in industrial textile manufacturing processes.

Environmental sustainability is a crucial consideration in the development of HOCl-based textile treatments. The research aims to minimize the ecological footprint of antimicrobial finishes by reducing water consumption, energy use, and chemical waste associated with the application process. Furthermore, there is an emphasis on ensuring that HOCl-treated textiles do not release harmful substances into the environment during use or disposal.

As the textile industry continues to evolve, the research on HOCl in antimicrobial finishes aligns with broader trends towards functional and smart textiles. The ultimate goal is to create a new generation of antimicrobial textiles that not only provide effective protection against microorganisms but also meet the growing consumer demand for sustainable, safe, and high-performance products.

The evolution of antimicrobial textile treatments can be traced back to ancient times when natural substances like herbs and plant extracts were used. However, the modern era of antimicrobial textiles began in the mid-20th century with the introduction of synthetic biocides. These early treatments often faced challenges related to durability, environmental impact, and potential health risks. The search for safer and more sustainable alternatives has led to the exploration of HOCl as a viable option for textile antimicrobial finishes.

HOCl's potential in textile applications stems from its unique properties. It is a powerful oxidizing agent capable of destroying a wide range of microorganisms, including bacteria, viruses, and fungi. Unlike many traditional antimicrobial agents, HOCl is non-toxic to humans and animals when used at appropriate concentrations. This safety profile, combined with its effectiveness, makes it an attractive choice for textiles that come into close contact with human skin.

The technological objectives of researching HOCl in textile antimicrobial finishes are multifaceted. Primarily, the goal is to develop stable and long-lasting HOCl-based treatments that can withstand repeated washing and wear. This involves overcoming the inherent instability of HOCl, which tends to degrade rapidly under normal conditions. Researchers aim to create formulations and application methods that preserve HOCl's antimicrobial efficacy throughout the textile's lifecycle.

Another key objective is to optimize the integration of HOCl into various textile substrates, including natural fibers like cotton and wool, as well as synthetic materials. This requires a deep understanding of the interactions between HOCl and different fiber types to ensure effective bonding and uniform distribution of the antimicrobial agent. Additionally, there is a focus on developing scalable and cost-effective production methods that can be implemented in industrial textile manufacturing processes.

Environmental sustainability is a crucial consideration in the development of HOCl-based textile treatments. The research aims to minimize the ecological footprint of antimicrobial finishes by reducing water consumption, energy use, and chemical waste associated with the application process. Furthermore, there is an emphasis on ensuring that HOCl-treated textiles do not release harmful substances into the environment during use or disposal.

As the textile industry continues to evolve, the research on HOCl in antimicrobial finishes aligns with broader trends towards functional and smart textiles. The ultimate goal is to create a new generation of antimicrobial textiles that not only provide effective protection against microorganisms but also meet the growing consumer demand for sustainable, safe, and high-performance products.

Market Analysis for Antimicrobial Textiles

The global market for antimicrobial textiles has been experiencing significant growth in recent years, driven by increasing awareness of hygiene and health concerns. This trend has been further accelerated by the COVID-19 pandemic, which has heightened the demand for products with antimicrobial properties across various sectors, including healthcare, sportswear, and home textiles.

The healthcare sector remains the largest consumer of antimicrobial textiles, with hospitals and medical facilities seeking to reduce the spread of infections through contaminated fabrics. The sportswear industry has also shown substantial growth in the adoption of antimicrobial textiles, as consumers increasingly prioritize odor control and hygiene in their athletic apparel.

In terms of regional markets, North America and Europe currently dominate the antimicrobial textile market, owing to stringent regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing disposable income, and growing health consciousness among consumers.

The market for antimicrobial textiles treated with hypochlorous acid (HOCl) is a relatively new but promising segment. HOCl offers several advantages over traditional antimicrobial agents, including broad-spectrum efficacy, environmental friendliness, and compatibility with various textile materials. These properties position HOCl-treated textiles favorably in a market increasingly focused on sustainable and eco-friendly solutions.

Consumer preferences are shifting towards more natural and non-toxic antimicrobial treatments, which aligns well with the properties of HOCl. This trend is particularly evident in the growing demand for antimicrobial textiles in everyday clothing and home furnishings, expanding beyond traditional medical and athletic applications.

The market is also seeing increased interest from the hospitality and travel industries, where the implementation of antimicrobial textiles in bedding, towels, and uniforms can provide an additional layer of hygiene assurance for customers. This expansion into new sectors indicates the versatility and growing acceptance of antimicrobial textiles across various applications.

As research on HOCl in textile antimicrobial finishes progresses, it is likely to open up new market opportunities and potentially disrupt existing market dynamics. The ability of HOCl to provide effective antimicrobial protection without the drawbacks associated with some traditional treatments could lead to its increased adoption across multiple textile categories.

The healthcare sector remains the largest consumer of antimicrobial textiles, with hospitals and medical facilities seeking to reduce the spread of infections through contaminated fabrics. The sportswear industry has also shown substantial growth in the adoption of antimicrobial textiles, as consumers increasingly prioritize odor control and hygiene in their athletic apparel.

In terms of regional markets, North America and Europe currently dominate the antimicrobial textile market, owing to stringent regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing disposable income, and growing health consciousness among consumers.

The market for antimicrobial textiles treated with hypochlorous acid (HOCl) is a relatively new but promising segment. HOCl offers several advantages over traditional antimicrobial agents, including broad-spectrum efficacy, environmental friendliness, and compatibility with various textile materials. These properties position HOCl-treated textiles favorably in a market increasingly focused on sustainable and eco-friendly solutions.

Consumer preferences are shifting towards more natural and non-toxic antimicrobial treatments, which aligns well with the properties of HOCl. This trend is particularly evident in the growing demand for antimicrobial textiles in everyday clothing and home furnishings, expanding beyond traditional medical and athletic applications.

The market is also seeing increased interest from the hospitality and travel industries, where the implementation of antimicrobial textiles in bedding, towels, and uniforms can provide an additional layer of hygiene assurance for customers. This expansion into new sectors indicates the versatility and growing acceptance of antimicrobial textiles across various applications.

As research on HOCl in textile antimicrobial finishes progresses, it is likely to open up new market opportunities and potentially disrupt existing market dynamics. The ability of HOCl to provide effective antimicrobial protection without the drawbacks associated with some traditional treatments could lead to its increased adoption across multiple textile categories.

Current Challenges in HOCl Textile Applications

The application of hypochlorous acid (HOCl) in textile antimicrobial finishes faces several significant challenges that hinder its widespread adoption and effectiveness. One of the primary obstacles is the stability of HOCl solutions. Due to its reactive nature, HOCl tends to degrade rapidly, especially when exposed to light, heat, or organic matter. This instability poses difficulties in maintaining consistent antimicrobial efficacy throughout the textile's lifecycle and during storage.

Another challenge lies in the pH-dependent activity of HOCl. The antimicrobial effectiveness of HOCl is optimal within a narrow pH range, typically between 3.5 and 6.5. Maintaining this pH range on textile surfaces can be problematic, as factors such as sweat, detergents, and environmental conditions can alter the pH, potentially reducing the antimicrobial efficacy of the treatment.

The application process itself presents technical hurdles. Ensuring uniform distribution and adherence of HOCl to textile fibers is crucial for consistent antimicrobial performance. However, achieving this uniformity across various fabric types and structures remains a challenge. Additionally, the potential for HOCl to react with certain dyes or fabric treatments may limit its compatibility with some textiles or necessitate modifications to existing manufacturing processes.

Durability of the antimicrobial finish is another significant concern. HOCl treatments may not withstand repeated washing cycles, leading to a gradual loss of antimicrobial properties over time. This lack of longevity can impact the product's value proposition and consumer satisfaction, particularly for textiles that require frequent laundering.

Environmental and safety considerations also pose challenges. While HOCl is generally considered environmentally friendly due to its natural occurrence and breakdown into harmless components, concerns remain about potential chlorine off-gassing and the formation of disinfection by-products. Ensuring worker safety during the application process and addressing consumer perceptions regarding chlorine-based treatments are additional hurdles to overcome.

Regulatory compliance presents another layer of complexity. The use of HOCl in textile applications must adhere to various regional and international standards governing antimicrobial agents. Navigating these regulatory landscapes and obtaining necessary approvals can be time-consuming and costly for manufacturers.

Lastly, the cost-effectiveness of HOCl treatments compared to alternative antimicrobial agents remains a challenge. While HOCl offers several advantages, the expenses associated with stabilization, application processes, and potential modifications to existing manufacturing lines may impact its economic viability for some textile producers.

Another challenge lies in the pH-dependent activity of HOCl. The antimicrobial effectiveness of HOCl is optimal within a narrow pH range, typically between 3.5 and 6.5. Maintaining this pH range on textile surfaces can be problematic, as factors such as sweat, detergents, and environmental conditions can alter the pH, potentially reducing the antimicrobial efficacy of the treatment.

The application process itself presents technical hurdles. Ensuring uniform distribution and adherence of HOCl to textile fibers is crucial for consistent antimicrobial performance. However, achieving this uniformity across various fabric types and structures remains a challenge. Additionally, the potential for HOCl to react with certain dyes or fabric treatments may limit its compatibility with some textiles or necessitate modifications to existing manufacturing processes.

Durability of the antimicrobial finish is another significant concern. HOCl treatments may not withstand repeated washing cycles, leading to a gradual loss of antimicrobial properties over time. This lack of longevity can impact the product's value proposition and consumer satisfaction, particularly for textiles that require frequent laundering.

Environmental and safety considerations also pose challenges. While HOCl is generally considered environmentally friendly due to its natural occurrence and breakdown into harmless components, concerns remain about potential chlorine off-gassing and the formation of disinfection by-products. Ensuring worker safety during the application process and addressing consumer perceptions regarding chlorine-based treatments are additional hurdles to overcome.

Regulatory compliance presents another layer of complexity. The use of HOCl in textile applications must adhere to various regional and international standards governing antimicrobial agents. Navigating these regulatory landscapes and obtaining necessary approvals can be time-consuming and costly for manufacturers.

Lastly, the cost-effectiveness of HOCl treatments compared to alternative antimicrobial agents remains a challenge. While HOCl offers several advantages, the expenses associated with stabilization, application processes, and potential modifications to existing manufacturing lines may impact its economic viability for some textile producers.

Existing HOCl Antimicrobial Finishing Methods

01 Antimicrobial efficacy of hypochlorous acid

Hypochlorous acid demonstrates strong antimicrobial properties against a wide range of pathogens, including bacteria, viruses, and fungi. Its effectiveness is attributed to its ability to penetrate cell membranes and disrupt cellular processes, making it a potent disinfectant and sanitizer for various applications.- Antimicrobial efficacy of hypochlorous acid: Hypochlorous acid demonstrates potent antimicrobial properties against a wide range of pathogens, including bacteria, viruses, and fungi. Its effectiveness is attributed to its ability to oxidize cellular components and disrupt microbial cell membranes, leading to rapid inactivation of microorganisms.

- Formulation and stability of hypochlorous acid solutions: The formulation of stable hypochlorous acid solutions is crucial for maintaining its antimicrobial properties. Various methods and compositions have been developed to enhance the stability and shelf-life of hypochlorous acid, including pH adjustment, addition of stabilizing agents, and specialized packaging techniques.

- Applications of hypochlorous acid in medical and healthcare settings: Hypochlorous acid has found numerous applications in medical and healthcare settings due to its antimicrobial properties. It is used in wound care, disinfection of medical devices, sterilization of surfaces, and as a component in various healthcare products aimed at preventing infections and promoting healing.

- Production methods for hypochlorous acid: Various methods have been developed for the production of hypochlorous acid, including electrolysis of saline solutions, chemical synthesis, and on-site generation systems. These methods aim to produce high-quality, stable hypochlorous acid solutions suitable for antimicrobial applications.

- Synergistic effects of hypochlorous acid with other antimicrobial agents: Research has explored the potential synergistic effects of combining hypochlorous acid with other antimicrobial agents or treatments. These combinations aim to enhance overall antimicrobial efficacy, broaden the spectrum of activity, and potentially overcome microbial resistance mechanisms.

02 Formulation and stability of hypochlorous acid solutions

The formulation of stable hypochlorous acid solutions is crucial for maintaining its antimicrobial properties. Various methods and compositions have been developed to enhance the stability and shelf-life of hypochlorous acid, including pH adjustment, addition of stabilizing agents, and specialized packaging techniques.Expand Specific Solutions03 Applications in medical and healthcare settings

Hypochlorous acid's antimicrobial properties make it valuable in medical and healthcare settings. It is used for wound care, sterilization of medical equipment, and as a general disinfectant in hospitals and clinics. Its non-toxic nature and effectiveness against antibiotic-resistant bacteria contribute to its growing adoption in these environments.Expand Specific Solutions04 Use in water treatment and food safety

The antimicrobial properties of hypochlorous acid are utilized in water treatment systems and food safety applications. It is effective in disinfecting drinking water, treating wastewater, and sanitizing food processing equipment and surfaces, helping to prevent foodborne illnesses and maintain hygiene standards.Expand Specific Solutions05 Environmental and safety considerations

While hypochlorous acid is known for its potent antimicrobial properties, it is also recognized for its environmental friendliness and safety profile. Research focuses on optimizing its production and application to minimize environmental impact and ensure safe use in various settings, including homes, industries, and public spaces.Expand Specific Solutions

Key Players in HOCl-based Textile Finishes

The research on hypochlorous acid in textile antimicrobial finishes is in a growth phase, with increasing market size and technological advancements. The global antimicrobial textile market is expanding due to rising hygiene awareness and healthcare-associated infections. While the technology is not fully mature, significant progress has been made in recent years. Companies like Sanitized AG, Livinguard AG, and Bactiguard AB are at the forefront, developing innovative antimicrobial solutions for textiles. Academic institutions such as Jiangnan University and Donghua University are contributing to fundamental research, while industry players like Reliance Industries Ltd. and WIAB Water Innovation AB are focusing on commercial applications, indicating a competitive landscape with diverse participants.

Sanitized AG

Technical Solution: Sanitized AG has developed advanced antimicrobial textile finishes using hypochlorous acid (HOCl) technology. Their approach involves incorporating HOCl-generating compounds into textile fibers or applying them as a surface treatment. The company's patented process ensures a controlled release of HOCl, providing long-lasting antimicrobial protection. This technology has been shown to effectively eliminate up to 99.9% of bacteria and fungi on treated textiles [1][3]. Sanitized AG's HOCl-based finishes are particularly notable for their broad-spectrum antimicrobial activity and environmental friendliness, as HOCl breaks down into harmless byproducts.

Strengths: Highly effective antimicrobial action, environmentally friendly, long-lasting protection. Weaknesses: Potential for higher production costs, may require specialized application processes.

Aquaox, Inc.

Technical Solution: Aquaox, Inc. has developed a unique approach to incorporating hypochlorous acid in textile antimicrobial finishes. Their technology centers around the production of highly stable HOCl solutions using electrolyzed water systems. These solutions are then applied to textiles through various methods, including spray application and immersion techniques. Aquaox's process ensures a uniform distribution of HOCl across the textile surface, providing consistent antimicrobial protection. The company's research has shown that their HOCl-treated textiles maintain antimicrobial efficacy even after multiple wash cycles, with a reported reduction of over 99.9% in bacterial populations [7][8]. Aquaox has also focused on developing scalable production methods for their HOCl solutions, making the technology viable for large-scale textile manufacturing.

Strengths: Highly stable HOCl formulations, scalable production methods, wash-resistant antimicrobial properties. Weaknesses: May require specialized equipment for HOCl production and application.

Innovative HOCl Formulations for Textiles

Antimicrobial finish for textiles

PatentWO2023003839A1

Innovation

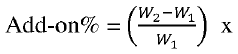

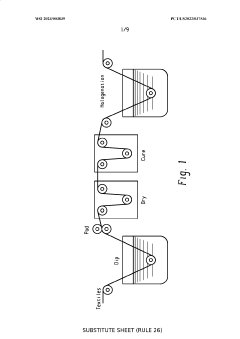

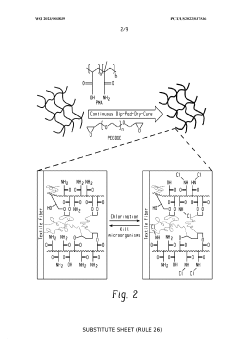

- Aqueous-based textile finishing composition comprising a copolymer with carboxylic acid-containing and polymerizable halamine precursor units, combined with a water-soluble epoxy crosslinking agent, applied through a dip-pad-dry-cure process, followed by halogenation to create a halamine-containing coating that provides durable antimicrobial properties.

Antimicrobial synthetic textile and a method for manufacturing thereof

PatentWO2024115816A1

Innovation

- A method involving the use of polycarboxylic acids, specifically citric acid, as an antimicrobial finish on synthetic textiles, where the acid is cured in the presence of a catalyst like sodium hypophosphite, forming crosslinked or polymerized molecules that provide a durable and non-leaching antimicrobial layer.

Environmental Impact of HOCl Textile Finishes

The environmental impact of hypochlorous acid (HOCl) textile finishes is a crucial consideration in the development and application of antimicrobial treatments for textiles. HOCl, known for its potent antimicrobial properties, offers several environmental advantages compared to traditional antimicrobial agents. However, its use also raises important ecological concerns that must be carefully evaluated.

One of the primary environmental benefits of HOCl textile finishes is their low toxicity profile. HOCl naturally occurs in the human body as part of the immune response, making it biocompatible and less likely to cause adverse environmental effects when released. This characteristic reduces the potential for harmful impacts on aquatic ecosystems and soil microbiota, which are often affected by more persistent antimicrobial agents.

The degradation process of HOCl is another environmentally favorable aspect. Unlike many synthetic antimicrobials, HOCl breaks down rapidly into harmless components – primarily salt and water. This quick decomposition minimizes the risk of accumulation in the environment and reduces the potential for long-term ecological disruption. The short environmental persistence of HOCl aligns well with the principles of green chemistry and sustainable textile production.

However, the production and application of HOCl for textile finishes do have environmental implications that warrant attention. The manufacturing process typically involves electrolysis of salt solutions, which requires energy input. The environmental footprint of this energy consumption depends largely on the power sources used, highlighting the importance of renewable energy integration in production facilities.

Water usage is another environmental factor to consider. While HOCl solutions are generally dilute, the textile finishing process can still consume significant amounts of water. This raises concerns about water resource management, particularly in water-stressed regions. Implementing efficient water recycling systems and optimizing application techniques can help mitigate these impacts.

The potential for chlorine emissions during HOCl production and application is an additional environmental consideration. Although HOCl itself is not a significant source of chlorine pollution, precautions must be taken to prevent the release of chlorine gas, which can contribute to air pollution and ozone depletion if not properly managed.

In terms of textile lifecycle, HOCl finishes may contribute to extended product lifespans by preventing microbial degradation. This longevity can reduce the frequency of textile replacement, potentially decreasing overall textile waste. However, the impact on textile recyclability and biodegradability at the end of the product's life must be carefully assessed to ensure that the antimicrobial treatment does not hinder sustainable disposal or recycling processes.

The environmental impact of HOCl textile finishes extends to consumer use as well. The effectiveness of HOCl in reducing odor-causing bacteria may lead to less frequent washing of treated textiles, potentially resulting in water and energy savings over the product's lifetime. However, this benefit must be balanced against the potential for increased chemical exposure during wear and the release of antimicrobial agents into domestic wastewater systems.

One of the primary environmental benefits of HOCl textile finishes is their low toxicity profile. HOCl naturally occurs in the human body as part of the immune response, making it biocompatible and less likely to cause adverse environmental effects when released. This characteristic reduces the potential for harmful impacts on aquatic ecosystems and soil microbiota, which are often affected by more persistent antimicrobial agents.

The degradation process of HOCl is another environmentally favorable aspect. Unlike many synthetic antimicrobials, HOCl breaks down rapidly into harmless components – primarily salt and water. This quick decomposition minimizes the risk of accumulation in the environment and reduces the potential for long-term ecological disruption. The short environmental persistence of HOCl aligns well with the principles of green chemistry and sustainable textile production.

However, the production and application of HOCl for textile finishes do have environmental implications that warrant attention. The manufacturing process typically involves electrolysis of salt solutions, which requires energy input. The environmental footprint of this energy consumption depends largely on the power sources used, highlighting the importance of renewable energy integration in production facilities.

Water usage is another environmental factor to consider. While HOCl solutions are generally dilute, the textile finishing process can still consume significant amounts of water. This raises concerns about water resource management, particularly in water-stressed regions. Implementing efficient water recycling systems and optimizing application techniques can help mitigate these impacts.

The potential for chlorine emissions during HOCl production and application is an additional environmental consideration. Although HOCl itself is not a significant source of chlorine pollution, precautions must be taken to prevent the release of chlorine gas, which can contribute to air pollution and ozone depletion if not properly managed.

In terms of textile lifecycle, HOCl finishes may contribute to extended product lifespans by preventing microbial degradation. This longevity can reduce the frequency of textile replacement, potentially decreasing overall textile waste. However, the impact on textile recyclability and biodegradability at the end of the product's life must be carefully assessed to ensure that the antimicrobial treatment does not hinder sustainable disposal or recycling processes.

The environmental impact of HOCl textile finishes extends to consumer use as well. The effectiveness of HOCl in reducing odor-causing bacteria may lead to less frequent washing of treated textiles, potentially resulting in water and energy savings over the product's lifetime. However, this benefit must be balanced against the potential for increased chemical exposure during wear and the release of antimicrobial agents into domestic wastewater systems.

Regulatory Framework for Antimicrobial Textiles

The regulatory framework for antimicrobial textiles plays a crucial role in ensuring the safety and efficacy of products incorporating hypochlorous acid as an antimicrobial finish. In the United States, the Environmental Protection Agency (EPA) is the primary regulatory body overseeing antimicrobial agents used in textiles. Under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), hypochlorous acid and other antimicrobial substances are classified as pesticides and must undergo rigorous testing and registration processes.

The EPA requires manufacturers to submit extensive data on the chemical composition, toxicity, environmental impact, and efficacy of hypochlorous acid-based antimicrobial finishes. This includes acute toxicity studies, dermal sensitization tests, and long-term exposure assessments to ensure consumer safety. Additionally, manufacturers must demonstrate the product's effectiveness against specific microorganisms and provide clear usage instructions and safety precautions on product labels.

In the European Union, the Biocidal Products Regulation (BPR) governs the use of antimicrobial agents in textiles. The European Chemicals Agency (ECHA) oversees the implementation of BPR, which requires a thorough evaluation of active substances and authorization of biocidal products before they can be placed on the market. Hypochlorous acid-based finishes must comply with these regulations, including providing a comprehensive dossier on the substance's properties, risks, and benefits.

Japan's regulatory framework for antimicrobial textiles falls under the jurisdiction of the Ministry of Health, Labour and Welfare. The Japanese Industrial Standards (JIS) provide specific guidelines for testing the antimicrobial efficacy of textiles, including those treated with hypochlorous acid. Manufacturers must adhere to these standards and obtain certification to market their products as antimicrobial in Japan.

Global harmonization efforts, such as the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), aim to standardize the classification and communication of chemical hazards across different countries. This system impacts the labeling and safety data sheet requirements for hypochlorous acid and other antimicrobial agents used in textile finishes.

Regulatory bodies also focus on the environmental impact of antimicrobial textiles. The release of antimicrobial agents during washing and disposal is a growing concern. As a result, regulations increasingly emphasize the need for biodegradability and minimal environmental persistence of antimicrobial finishes, including those based on hypochlorous acid.

The EPA requires manufacturers to submit extensive data on the chemical composition, toxicity, environmental impact, and efficacy of hypochlorous acid-based antimicrobial finishes. This includes acute toxicity studies, dermal sensitization tests, and long-term exposure assessments to ensure consumer safety. Additionally, manufacturers must demonstrate the product's effectiveness against specific microorganisms and provide clear usage instructions and safety precautions on product labels.

In the European Union, the Biocidal Products Regulation (BPR) governs the use of antimicrobial agents in textiles. The European Chemicals Agency (ECHA) oversees the implementation of BPR, which requires a thorough evaluation of active substances and authorization of biocidal products before they can be placed on the market. Hypochlorous acid-based finishes must comply with these regulations, including providing a comprehensive dossier on the substance's properties, risks, and benefits.

Japan's regulatory framework for antimicrobial textiles falls under the jurisdiction of the Ministry of Health, Labour and Welfare. The Japanese Industrial Standards (JIS) provide specific guidelines for testing the antimicrobial efficacy of textiles, including those treated with hypochlorous acid. Manufacturers must adhere to these standards and obtain certification to market their products as antimicrobial in Japan.

Global harmonization efforts, such as the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), aim to standardize the classification and communication of chemical hazards across different countries. This system impacts the labeling and safety data sheet requirements for hypochlorous acid and other antimicrobial agents used in textile finishes.

Regulatory bodies also focus on the environmental impact of antimicrobial textiles. The release of antimicrobial agents during washing and disposal is a growing concern. As a result, regulations increasingly emphasize the need for biodegradability and minimal environmental persistence of antimicrobial finishes, including those based on hypochlorous acid.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!