Analysis of Photovoltaic glass coatings surface engineering and durability optimization

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PV Glass Coating Technology Background and Objectives

Photovoltaic (PV) glass coating technology has evolved significantly over the past three decades, transforming from simple anti-reflective treatments to sophisticated multi-functional coating systems. The development trajectory began in the 1990s with basic single-layer coatings and has progressed to today's advanced nano-engineered surfaces that simultaneously address multiple performance parameters. This technological evolution has been driven by the continuous pursuit of higher solar energy conversion efficiency and longer service life for PV modules.

The global transition toward renewable energy sources has accelerated research and development in PV glass coating technologies. As solar energy installations have grown at a compound annual growth rate of approximately 25% over the past decade, the demand for high-performance, durable PV glass has intensified. This market expansion has catalyzed innovation in coating technologies that can withstand increasingly diverse and challenging environmental conditions while maintaining optimal optical properties.

Current PV glass coating technology faces several critical challenges. Conventional coatings often experience performance degradation due to environmental factors such as UV radiation, temperature cycling, humidity, and airborne pollutants. These degradation mechanisms can reduce light transmission by 2-3% annually in severe environments, directly impacting energy generation capacity. Additionally, the accumulation of dust and organic matter on PV surfaces can further reduce efficiency by up to 40% in arid regions, highlighting the need for self-cleaning properties.

The primary technical objectives in PV glass coating development center on enhancing durability while optimizing optical performance. Specifically, the industry aims to develop coatings that maintain over 95% of their initial performance after 25-30 years of field exposure. This requires innovations in both material science and surface engineering to create coatings that resist mechanical abrasion, chemical degradation, and environmental soiling while maximizing light transmission in the photovoltaically active spectrum.

Emerging research directions include the development of multi-functional coatings that simultaneously provide anti-reflective, self-cleaning, and anti-soiling properties. These advanced coating systems typically employ hierarchical surface structures with both micro and nano-scale features to control light interaction and surface wettability. The integration of hydrophobic and hydrophilic regions creates surfaces that effectively shed water while preventing dust adhesion, representing a significant advancement over traditional single-function coatings.

The ultimate goal of current PV glass coating technology development is to create economically viable solutions that can be scaled to industrial production volumes while delivering measurable improvements in energy yield and system lifetime. This requires balancing advanced performance characteristics with practical considerations such as manufacturing complexity, material costs, and compatibility with existing PV module assembly processes.

The global transition toward renewable energy sources has accelerated research and development in PV glass coating technologies. As solar energy installations have grown at a compound annual growth rate of approximately 25% over the past decade, the demand for high-performance, durable PV glass has intensified. This market expansion has catalyzed innovation in coating technologies that can withstand increasingly diverse and challenging environmental conditions while maintaining optimal optical properties.

Current PV glass coating technology faces several critical challenges. Conventional coatings often experience performance degradation due to environmental factors such as UV radiation, temperature cycling, humidity, and airborne pollutants. These degradation mechanisms can reduce light transmission by 2-3% annually in severe environments, directly impacting energy generation capacity. Additionally, the accumulation of dust and organic matter on PV surfaces can further reduce efficiency by up to 40% in arid regions, highlighting the need for self-cleaning properties.

The primary technical objectives in PV glass coating development center on enhancing durability while optimizing optical performance. Specifically, the industry aims to develop coatings that maintain over 95% of their initial performance after 25-30 years of field exposure. This requires innovations in both material science and surface engineering to create coatings that resist mechanical abrasion, chemical degradation, and environmental soiling while maximizing light transmission in the photovoltaically active spectrum.

Emerging research directions include the development of multi-functional coatings that simultaneously provide anti-reflective, self-cleaning, and anti-soiling properties. These advanced coating systems typically employ hierarchical surface structures with both micro and nano-scale features to control light interaction and surface wettability. The integration of hydrophobic and hydrophilic regions creates surfaces that effectively shed water while preventing dust adhesion, representing a significant advancement over traditional single-function coatings.

The ultimate goal of current PV glass coating technology development is to create economically viable solutions that can be scaled to industrial production volumes while delivering measurable improvements in energy yield and system lifetime. This requires balancing advanced performance characteristics with practical considerations such as manufacturing complexity, material costs, and compatibility with existing PV module assembly processes.

Market Analysis for Advanced PV Glass Coatings

The global market for advanced photovoltaic (PV) glass coatings is experiencing robust growth, driven by increasing solar energy adoption and technological advancements in coating materials. Current market valuation stands at approximately 3.2 billion USD in 2023, with projections indicating a compound annual growth rate of 7.8% through 2030, potentially reaching 5.4 billion USD by the end of the decade.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for over 45% of global demand, with China leading manufacturing capacity. Europe follows with roughly 30% market share, demonstrating strong growth due to aggressive renewable energy targets and sustainability initiatives. North America represents about 20% of the market, with accelerating growth following recent climate-focused legislation.

Consumer demand patterns show increasing preference for high-efficiency coatings that maximize energy conversion while maintaining durability. Anti-reflective coatings currently dominate the market segment with approximately 40% share, followed by anti-soiling (25%) and anti-icing coatings (15%). Emerging demand for self-cleaning and durability-enhancing coatings represents the fastest-growing segment, expanding at nearly 12% annually.

Price sensitivity analysis indicates that while initial cost remains a consideration, buyers increasingly evaluate total lifetime value, with durability becoming a critical purchasing factor. The average price premium for advanced coatings ranges between 15-25% compared to standard options, though this gap is narrowing as manufacturing scales.

Market barriers include high initial R&D investments, technical challenges in balancing optical performance with durability, and regulatory compliance requirements across different regions. Additionally, supply chain constraints for specialized materials and competition from alternative technologies present ongoing challenges.

Future market trajectories suggest integration of multi-functional coatings combining anti-reflective, self-cleaning, and durability properties will capture premium market segments. Building-integrated photovoltaics (BIPV) represents a high-growth application area, with aesthetic coatings gaining importance. The market is also witnessing increased demand for environmentally sustainable coating solutions with reduced environmental footprint and improved end-of-life recyclability.

Competitive landscape analysis reveals traditional glass manufacturers expanding into specialized PV coatings alongside dedicated coating technology companies and chemical suppliers. Strategic partnerships between coating developers and PV module manufacturers are becoming increasingly common to optimize performance and reduce integration costs.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for over 45% of global demand, with China leading manufacturing capacity. Europe follows with roughly 30% market share, demonstrating strong growth due to aggressive renewable energy targets and sustainability initiatives. North America represents about 20% of the market, with accelerating growth following recent climate-focused legislation.

Consumer demand patterns show increasing preference for high-efficiency coatings that maximize energy conversion while maintaining durability. Anti-reflective coatings currently dominate the market segment with approximately 40% share, followed by anti-soiling (25%) and anti-icing coatings (15%). Emerging demand for self-cleaning and durability-enhancing coatings represents the fastest-growing segment, expanding at nearly 12% annually.

Price sensitivity analysis indicates that while initial cost remains a consideration, buyers increasingly evaluate total lifetime value, with durability becoming a critical purchasing factor. The average price premium for advanced coatings ranges between 15-25% compared to standard options, though this gap is narrowing as manufacturing scales.

Market barriers include high initial R&D investments, technical challenges in balancing optical performance with durability, and regulatory compliance requirements across different regions. Additionally, supply chain constraints for specialized materials and competition from alternative technologies present ongoing challenges.

Future market trajectories suggest integration of multi-functional coatings combining anti-reflective, self-cleaning, and durability properties will capture premium market segments. Building-integrated photovoltaics (BIPV) represents a high-growth application area, with aesthetic coatings gaining importance. The market is also witnessing increased demand for environmentally sustainable coating solutions with reduced environmental footprint and improved end-of-life recyclability.

Competitive landscape analysis reveals traditional glass manufacturers expanding into specialized PV coatings alongside dedicated coating technology companies and chemical suppliers. Strategic partnerships between coating developers and PV module manufacturers are becoming increasingly common to optimize performance and reduce integration costs.

Current Challenges in PV Glass Surface Engineering

Despite significant advancements in photovoltaic glass coating technologies, the industry continues to face several critical challenges in surface engineering that impede optimal performance and long-term durability. One of the primary obstacles is achieving consistent anti-reflective coating uniformity across large glass surfaces. Manufacturing processes often struggle to maintain nanometer-level precision across square meters of substrate, resulting in efficiency variations that can reduce overall module performance by 1-3%.

Environmental degradation presents another significant challenge, with coatings exposed to harsh conditions including UV radiation, temperature cycling, humidity, and airborne pollutants. Current anti-reflective coatings typically experience a 5-10% reduction in transmittance over a 25-year service life, directly impacting energy yield. This degradation is particularly pronounced in coastal and industrial areas where salt spray and chemical pollutants accelerate coating deterioration.

Mechanical durability remains problematic, with surface abrasion from cleaning operations, sand particles, and hail impacts compromising coating integrity. Laboratory tests indicate that after simulated weathering equivalent to 10 years of field exposure, microscopic scratches can increase light scattering by up to 4%, reducing module efficiency. The industry standard IEC 61215 testing protocols may not adequately represent real-world abrasion scenarios, creating a disconnect between certification and field performance.

Cost-effectiveness continues to challenge manufacturers, as high-performance coatings often require expensive materials and complex deposition processes. The industry faces a difficult balance between enhancing optical performance and maintaining economically viable production costs. Advanced coatings with superior durability can increase glass costs by 15-25%, affecting the overall economics of PV installations.

Self-cleaning functionality represents an emerging challenge, with current hydrophobic and hydrophilic approaches showing limited effectiveness in diverse environmental conditions. Hydrophobic coatings often lose their water-repellent properties within 3-5 years, while hydrophilic coatings may not perform adequately in low-rainfall regions. The development of truly effective self-cleaning surfaces that maintain performance throughout the module lifetime remains elusive.

Scalability of advanced coating technologies from laboratory to mass production presents significant technical hurdles. Promising technologies demonstrated at research scale, such as multi-layer nanostructured coatings, face challenges in translation to high-throughput manufacturing environments. Production speeds of 10-15 meters per minute required by glass manufacturers can compromise coating quality and uniformity when applying complex surface treatments.

Environmental degradation presents another significant challenge, with coatings exposed to harsh conditions including UV radiation, temperature cycling, humidity, and airborne pollutants. Current anti-reflective coatings typically experience a 5-10% reduction in transmittance over a 25-year service life, directly impacting energy yield. This degradation is particularly pronounced in coastal and industrial areas where salt spray and chemical pollutants accelerate coating deterioration.

Mechanical durability remains problematic, with surface abrasion from cleaning operations, sand particles, and hail impacts compromising coating integrity. Laboratory tests indicate that after simulated weathering equivalent to 10 years of field exposure, microscopic scratches can increase light scattering by up to 4%, reducing module efficiency. The industry standard IEC 61215 testing protocols may not adequately represent real-world abrasion scenarios, creating a disconnect between certification and field performance.

Cost-effectiveness continues to challenge manufacturers, as high-performance coatings often require expensive materials and complex deposition processes. The industry faces a difficult balance between enhancing optical performance and maintaining economically viable production costs. Advanced coatings with superior durability can increase glass costs by 15-25%, affecting the overall economics of PV installations.

Self-cleaning functionality represents an emerging challenge, with current hydrophobic and hydrophilic approaches showing limited effectiveness in diverse environmental conditions. Hydrophobic coatings often lose their water-repellent properties within 3-5 years, while hydrophilic coatings may not perform adequately in low-rainfall regions. The development of truly effective self-cleaning surfaces that maintain performance throughout the module lifetime remains elusive.

Scalability of advanced coating technologies from laboratory to mass production presents significant technical hurdles. Promising technologies demonstrated at research scale, such as multi-layer nanostructured coatings, face challenges in translation to high-throughput manufacturing environments. Production speeds of 10-15 meters per minute required by glass manufacturers can compromise coating quality and uniformity when applying complex surface treatments.

Current Surface Engineering Solutions for PV Glass

01 Anti-reflective coatings for photovoltaic glass

Anti-reflective coatings are applied to photovoltaic glass surfaces to reduce light reflection and increase light transmission, thereby improving solar cell efficiency. These coatings typically consist of multiple layers with varying refractive indices and can be fabricated using methods such as sol-gel processing, vacuum deposition, or chemical vapor deposition. The durability of these coatings is enhanced through surface engineering techniques that improve adhesion and resistance to environmental factors.- Anti-reflective coatings for photovoltaic glass: Anti-reflective coatings can be applied to photovoltaic glass to reduce light reflection and increase light transmission, thereby improving the efficiency of solar cells. These coatings typically consist of multiple layers of materials with different refractive indices. The durability of these coatings can be enhanced through surface engineering techniques such as plasma treatment or the incorporation of hydrophobic compounds that provide self-cleaning properties.

- Self-cleaning and hydrophobic surface treatments: Hydrophobic and self-cleaning surface treatments can be applied to photovoltaic glass to maintain optimal performance over time. These treatments typically involve the application of fluorinated compounds or silicone-based materials that repel water and prevent the accumulation of dust and dirt. By keeping the glass surface clean, these treatments help to maintain the efficiency of solar panels and reduce maintenance requirements.

- Durability enhancement through multi-layer structures: Multi-layer coating structures can significantly enhance the durability of photovoltaic glass. These structures typically consist of a base layer for adhesion, intermediate layers for specific functionalities (such as anti-reflection or conductivity), and a top layer for protection against environmental factors. The combination of different materials in these layers can provide resistance to UV radiation, temperature fluctuations, and mechanical abrasion, thereby extending the service life of photovoltaic modules.

- Transparent conductive oxide coatings: Transparent conductive oxide (TCO) coatings are essential components of many photovoltaic glass applications. These coatings, typically made of materials such as indium tin oxide (ITO) or fluorine-doped tin oxide (FTO), provide electrical conductivity while maintaining high optical transparency. Surface engineering techniques can be employed to enhance the durability of TCO coatings, including the incorporation of dopants or the application of protective overlayers that shield the conductive material from environmental degradation.

- Environmental resistance and weathering protection: Specialized coatings can be applied to photovoltaic glass to provide resistance against environmental factors such as moisture, salt spray, and pollutants. These protective layers often incorporate materials such as silicon dioxide or aluminum oxide that form dense, impermeable barriers. Advanced surface engineering techniques, including sol-gel processes and atomic layer deposition, can be used to create highly uniform and defect-free protective coatings that maintain their integrity under prolonged exposure to outdoor conditions.

02 Self-cleaning and hydrophobic surface treatments

Self-cleaning and hydrophobic surface treatments are applied to photovoltaic glass to maintain optimal performance over time by preventing dust and dirt accumulation. These treatments typically involve the application of nanostructured coatings that create a water-repellent surface, allowing rainwater to easily wash away contaminants. The durability of these coatings is critical for long-term performance and is achieved through advanced formulations that resist degradation from UV exposure, temperature fluctuations, and mechanical abrasion.Expand Specific Solutions03 Transparent conductive oxide (TCO) coatings

Transparent conductive oxide coatings are essential components of photovoltaic glass, providing electrical conductivity while maintaining high optical transparency. These coatings, typically composed of materials such as indium tin oxide (ITO), fluorine-doped tin oxide (FTO), or aluminum-doped zinc oxide (AZO), serve as electrodes in solar cells. Surface engineering techniques are employed to optimize the balance between conductivity and transparency, while enhancing durability against environmental stressors such as humidity, temperature cycling, and mechanical wear.Expand Specific Solutions04 Barrier coatings for moisture and oxygen protection

Barrier coatings are applied to photovoltaic glass to protect sensitive solar cell components from moisture and oxygen penetration, which can cause degradation and reduce efficiency over time. These coatings typically consist of multiple inorganic and organic layers that create a tortuous path for gas molecules, effectively blocking their passage. Surface engineering techniques focus on creating defect-free, dense films with strong adhesion to the substrate, while ensuring long-term durability under various environmental conditions including UV exposure, temperature cycling, and mechanical stress.Expand Specific Solutions05 Abrasion and impact resistant coatings

Abrasion and impact resistant coatings are developed to protect photovoltaic glass surfaces from mechanical damage during installation, maintenance, and exposure to environmental elements such as hail, sand, or debris. These coatings typically incorporate hard materials such as silicon dioxide, aluminum oxide, or diamond-like carbon, often in nanostructured forms. Surface engineering approaches focus on optimizing coating hardness while maintaining flexibility to prevent cracking, ensuring strong adhesion to the substrate, and preserving optical properties essential for solar energy conversion efficiency.Expand Specific Solutions

Key Industry Players in PV Glass Coating Market

The photovoltaic glass coatings market is currently in a growth phase, with increasing adoption driven by the expanding solar energy sector. Market size is projected to grow significantly as solar installations continue to rise globally, particularly in regions with strong renewable energy policies. Technologically, the field is advancing from basic anti-reflective coatings toward multifunctional surface engineering solutions that enhance both performance and longevity. Leading players demonstrate varying levels of technical maturity: established glass manufacturers like AGC, Saint-Gobain, and CSG Holding offer commercial solutions, while specialized companies such as Enki Technology and First Solar focus on proprietary coating innovations. Research institutions including CEA and King Fahd University contribute fundamental advancements, while companies like JinkoSolar and Cardinal IG are integrating these technologies into their product ecosystems to meet growing demand for durable, high-efficiency photovoltaic glass.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has developed advanced anti-reflective (AR) coatings for photovoltaic glass using sol-gel technology. Their approach involves multi-layer porous silica structures with controlled porosity gradients that maximize light transmission while maintaining durability. CEA's research includes innovative surface functionalization techniques that incorporate hydrophobic compounds directly into the coating matrix rather than as a separate layer, creating chemically bonded water-repellent properties that resist degradation. Their technology employs environmentally friendly precursors and low-temperature curing processes, making it compatible with various glass substrates. CEA has also pioneered accelerated aging test protocols specifically designed for PV glass coatings that correlate with real-world performance, allowing for rapid iteration and improvement of coating formulations.

Strengths: Superior integration of anti-reflective and self-cleaning properties through advanced sol-gel chemistry; excellent durability due to chemical bonding rather than physical layering; environmentally sustainable manufacturing process. Weaknesses: Higher initial production costs compared to conventional coatings; requires specialized application equipment; limited commercial-scale implementation data.

First Solar, Inc.

Technical Solution: First Solar has developed proprietary CdTe (Cadmium Telluride) thin-film technology with specialized glass coating systems optimized for their unique semiconductor stack. Their approach includes engineered anti-reflective coatings that are specifically designed to enhance spectral response in the CdTe absorption range. First Solar's glass treatment process incorporates nano-textured surfaces created through controlled etching techniques that scatter light at optimal angles to increase path length through the semiconductor layer. Their coatings feature multi-functional properties including anti-soiling technology that reduces dust adhesion by modifying surface energy characteristics. First Solar has implemented rigorous accelerated lifetime testing protocols that simulate decades of field exposure, including combined UV, temperature cycling, humidity, and mechanical stress tests. Their coating systems are designed for high-volume manufacturing compatibility with roll-to-roll or large-area deposition techniques, enabling cost-effective production at scale.

Strengths: Highly optimized for CdTe technology with proven field performance data; excellent integration with manufacturing processes; demonstrated long-term durability in harsh environments. Weaknesses: Technology is specifically tailored to their proprietary module design and may not transfer well to other PV technologies; contains some environmentally sensitive materials requiring careful handling and disposal.

Critical Patents in PV Glass Coating Durability

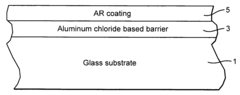

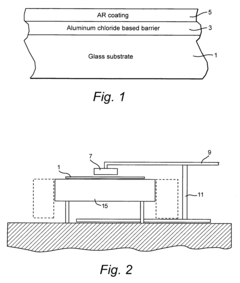

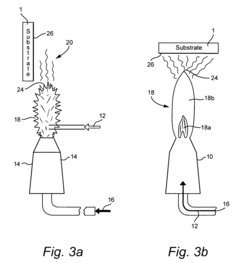

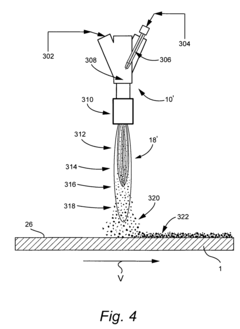

Method of making glass including surface treatment with aluminum chloride using combustion deposition prior to deposition of antireflective coating

PatentInactiveUS20090148709A1

Innovation

- A method involving flame deposition of an aluminum chloride barrier layer on soda-lime-silica glass substrates, followed by an antireflective coating application via sol-gel technique, significantly reduces sodium leaching and enhances the durability of the coatings by creating a protective barrier against environmental stressors.

Material and glazing comprising said material

PatentActiveEP2475626A2

Innovation

- A glass substrate coated with a stack of thin layers including a lower dielectric layer, a functional metal or metal nitride layer, and a partially crystallized titanium oxide layer, which provides excellent climatic durability and combines self-cleaning, anti-soiling, and solar control properties, while avoiding the use of silver or copper layers that degrade performance.

Environmental Impact Assessment of Coating Materials

The environmental impact of photovoltaic glass coating materials represents a critical consideration in the sustainable development of solar energy technologies. Current coating materials, including metal oxides, fluorides, and various nanoparticles, exhibit varying degrees of environmental footprint throughout their lifecycle. Manufacturing processes for these coatings often involve energy-intensive deposition methods such as physical vapor deposition (PVD) and chemical vapor deposition (CVD), contributing significantly to carbon emissions.

Raw material extraction for coating components presents additional environmental challenges. Rare earth elements and precious metals commonly used in high-performance coatings require extensive mining operations that can lead to habitat destruction, soil erosion, and water contamination. The environmental burden is particularly pronounced for indium tin oxide (ITO) and silver-based coatings, which rely on limited natural resources with geographically concentrated reserves.

Toxicity profiles of coating materials vary considerably, with certain compounds posing potential ecological risks. Cadmium-based materials, though effective for specific applications, present significant environmental hazards if improperly managed. Similarly, lead-containing formulations, while decreasing in usage, continue to raise concerns regarding soil and groundwater contamination when products reach end-of-life.

Waste management challenges emerge during manufacturing and at product end-of-life. Chemical waste streams from coating processes require specialized treatment to prevent environmental contamination. Additionally, the complex multi-layer nature of modern photovoltaic coatings complicates recycling efforts, potentially leading to increased landfill disposal of decommissioned solar panels.

Recent advancements in environmentally conscious coating technologies show promising developments. Water-based coating formulations have demonstrated reduced volatile organic compound (VOC) emissions compared to traditional solvent-based alternatives. Bio-inspired coating materials derived from renewable resources represent an emerging frontier with potentially lower environmental impact, though commercial viability remains under investigation.

Life cycle assessment (LCA) studies indicate that despite initial environmental costs, photovoltaic coatings deliver net positive environmental benefits through extended solar panel efficiency and durability. Optimized coatings can increase energy conversion efficiency by 2-5% while extending operational lifespans by up to 25%, significantly improving the environmental return on investment for solar installations.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of coating materials. The European Union's Restriction of Hazardous Substances (RoHS) directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have driven industry innovation toward less hazardous alternatives. Similarly, emerging standards in North America and Asia are establishing more stringent environmental benchmarks for photovoltaic materials.

Raw material extraction for coating components presents additional environmental challenges. Rare earth elements and precious metals commonly used in high-performance coatings require extensive mining operations that can lead to habitat destruction, soil erosion, and water contamination. The environmental burden is particularly pronounced for indium tin oxide (ITO) and silver-based coatings, which rely on limited natural resources with geographically concentrated reserves.

Toxicity profiles of coating materials vary considerably, with certain compounds posing potential ecological risks. Cadmium-based materials, though effective for specific applications, present significant environmental hazards if improperly managed. Similarly, lead-containing formulations, while decreasing in usage, continue to raise concerns regarding soil and groundwater contamination when products reach end-of-life.

Waste management challenges emerge during manufacturing and at product end-of-life. Chemical waste streams from coating processes require specialized treatment to prevent environmental contamination. Additionally, the complex multi-layer nature of modern photovoltaic coatings complicates recycling efforts, potentially leading to increased landfill disposal of decommissioned solar panels.

Recent advancements in environmentally conscious coating technologies show promising developments. Water-based coating formulations have demonstrated reduced volatile organic compound (VOC) emissions compared to traditional solvent-based alternatives. Bio-inspired coating materials derived from renewable resources represent an emerging frontier with potentially lower environmental impact, though commercial viability remains under investigation.

Life cycle assessment (LCA) studies indicate that despite initial environmental costs, photovoltaic coatings deliver net positive environmental benefits through extended solar panel efficiency and durability. Optimized coatings can increase energy conversion efficiency by 2-5% while extending operational lifespans by up to 25%, significantly improving the environmental return on investment for solar installations.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of coating materials. The European Union's Restriction of Hazardous Substances (RoHS) directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have driven industry innovation toward less hazardous alternatives. Similarly, emerging standards in North America and Asia are establishing more stringent environmental benchmarks for photovoltaic materials.

Cost-Performance Analysis of Durability Solutions

The economic viability of durability solutions for photovoltaic glass coatings represents a critical factor in technology adoption across the solar energy sector. Current market analysis indicates that while high-performance anti-soiling and anti-reflective coatings may increase initial manufacturing costs by 15-25%, they can deliver lifetime energy yield improvements of 3-8%, creating a compelling return on investment over the typical 25-30 year lifespan of solar installations.

Advanced hydrophobic coatings with self-cleaning properties demonstrate particularly favorable cost-performance metrics, with implementation costs averaging $8-12 per square meter but reducing cleaning frequency by up to 70% in arid environments. This translates to operational expenditure reductions of approximately $0.15-0.25 per watt over system lifetime, with payback periods typically ranging from 3-5 years depending on installation location and environmental conditions.

Comparative analysis of durability enhancement technologies reveals significant variations in cost-effectiveness. Traditional fluoropolymer-based coatings offer moderate durability at $5-7 per square meter but require replacement every 7-10 years. In contrast, next-generation sol-gel derived nanocomposite coatings command premium pricing of $15-20 per square meter yet maintain performance specifications for 15+ years, resulting in superior lifetime value despite higher initial investment.

Regional economic modeling demonstrates that durability solutions deliver maximum financial benefits in high-irradiance, high-particulate environments such as desert installations, where performance degradation due to soiling can reduce annual energy yield by up to 25% without appropriate coating technologies. In these contexts, premium durability solutions can improve levelized cost of electricity (LCOE) by $0.007-0.015 per kWh.

Manufacturing scale economies significantly impact the cost-performance equation. Production volumes below 50,000 square meters annually typically incur 30-40% higher per-unit costs compared to large-scale operations exceeding 500,000 square meters. This creates market advantages for established coating suppliers and presents barriers to entry for innovative solutions from smaller enterprises, potentially limiting technology diversity and advancement rates.

Sensitivity analysis indicates that durability solution value propositions are highly dependent on installation-specific factors including tilt angle, proximity to pollution sources, precipitation patterns, and labor costs for maintenance operations. This necessitates customized economic modeling rather than one-size-fits-all approaches when evaluating coating technologies for specific photovoltaic projects.

Advanced hydrophobic coatings with self-cleaning properties demonstrate particularly favorable cost-performance metrics, with implementation costs averaging $8-12 per square meter but reducing cleaning frequency by up to 70% in arid environments. This translates to operational expenditure reductions of approximately $0.15-0.25 per watt over system lifetime, with payback periods typically ranging from 3-5 years depending on installation location and environmental conditions.

Comparative analysis of durability enhancement technologies reveals significant variations in cost-effectiveness. Traditional fluoropolymer-based coatings offer moderate durability at $5-7 per square meter but require replacement every 7-10 years. In contrast, next-generation sol-gel derived nanocomposite coatings command premium pricing of $15-20 per square meter yet maintain performance specifications for 15+ years, resulting in superior lifetime value despite higher initial investment.

Regional economic modeling demonstrates that durability solutions deliver maximum financial benefits in high-irradiance, high-particulate environments such as desert installations, where performance degradation due to soiling can reduce annual energy yield by up to 25% without appropriate coating technologies. In these contexts, premium durability solutions can improve levelized cost of electricity (LCOE) by $0.007-0.015 per kWh.

Manufacturing scale economies significantly impact the cost-performance equation. Production volumes below 50,000 square meters annually typically incur 30-40% higher per-unit costs compared to large-scale operations exceeding 500,000 square meters. This creates market advantages for established coating suppliers and presents barriers to entry for innovative solutions from smaller enterprises, potentially limiting technology diversity and advancement rates.

Sensitivity analysis indicates that durability solution value propositions are highly dependent on installation-specific factors including tilt angle, proximity to pollution sources, precipitation patterns, and labor costs for maintenance operations. This necessitates customized economic modeling rather than one-size-fits-all approaches when evaluating coating technologies for specific photovoltaic projects.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!