Research on Photovoltaic glass coatings for corrosion and weather resistance

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PV Glass Coating Technology Background and Objectives

Photovoltaic (PV) glass coatings have evolved significantly since the early development of solar technology in the 1950s. Initially, these coatings were primarily focused on enhancing light transmission properties, with minimal consideration for durability against environmental factors. The technological trajectory shifted dramatically in the 1990s when researchers began recognizing the critical importance of protective coatings to extend the operational lifespan of PV installations.

The evolution of PV glass coating technology has been driven by the increasing deployment of solar panels in diverse and often harsh environments. From desert installations facing sandstorms and extreme temperature fluctuations to coastal arrays exposed to salt spray and high humidity, the need for resilient coating solutions has become paramount. This has catalyzed research into multi-functional coatings that can simultaneously address corrosion resistance, UV stability, and weather protection.

Current technological trends in PV glass coatings are moving toward nano-engineered materials that offer superior protection while maintaining optimal light transmission properties. These advanced coatings incorporate elements such as titanium dioxide, silicon dioxide, and various fluoropolymers, often in multi-layer configurations designed to address specific environmental challenges. The integration of self-cleaning properties has emerged as a significant innovation, reducing maintenance requirements while preserving energy conversion efficiency.

The primary objective of contemporary research in this field is to develop coating systems that can provide comprehensive protection against multiple degradation mechanisms simultaneously. This includes resistance to moisture ingress, prevention of alkali leaching from the glass substrate, mitigation of UV-induced degradation, and protection against physical abrasion from airborne particles. Additionally, these coatings must maintain their protective properties for 25-30 years, matching the expected operational lifespan of modern PV installations.

Another critical goal is the development of cost-effective coating technologies that can be implemented in large-scale manufacturing processes without significantly increasing the overall cost of PV modules. This economic consideration is essential for maintaining the competitive position of solar energy in the broader energy market. Researchers are exploring various deposition methods, including sol-gel processes, physical vapor deposition, and plasma-enhanced chemical vapor deposition, to identify optimal approaches for industrial-scale implementation.

The ultimate technological objective is to create a new generation of protective coatings that can extend PV module lifespans beyond current expectations, potentially reaching 40-50 years of reliable operation even in extreme environments. This would significantly improve the lifecycle economics of solar installations and accelerate the global transition to renewable energy sources.

The evolution of PV glass coating technology has been driven by the increasing deployment of solar panels in diverse and often harsh environments. From desert installations facing sandstorms and extreme temperature fluctuations to coastal arrays exposed to salt spray and high humidity, the need for resilient coating solutions has become paramount. This has catalyzed research into multi-functional coatings that can simultaneously address corrosion resistance, UV stability, and weather protection.

Current technological trends in PV glass coatings are moving toward nano-engineered materials that offer superior protection while maintaining optimal light transmission properties. These advanced coatings incorporate elements such as titanium dioxide, silicon dioxide, and various fluoropolymers, often in multi-layer configurations designed to address specific environmental challenges. The integration of self-cleaning properties has emerged as a significant innovation, reducing maintenance requirements while preserving energy conversion efficiency.

The primary objective of contemporary research in this field is to develop coating systems that can provide comprehensive protection against multiple degradation mechanisms simultaneously. This includes resistance to moisture ingress, prevention of alkali leaching from the glass substrate, mitigation of UV-induced degradation, and protection against physical abrasion from airborne particles. Additionally, these coatings must maintain their protective properties for 25-30 years, matching the expected operational lifespan of modern PV installations.

Another critical goal is the development of cost-effective coating technologies that can be implemented in large-scale manufacturing processes without significantly increasing the overall cost of PV modules. This economic consideration is essential for maintaining the competitive position of solar energy in the broader energy market. Researchers are exploring various deposition methods, including sol-gel processes, physical vapor deposition, and plasma-enhanced chemical vapor deposition, to identify optimal approaches for industrial-scale implementation.

The ultimate technological objective is to create a new generation of protective coatings that can extend PV module lifespans beyond current expectations, potentially reaching 40-50 years of reliable operation even in extreme environments. This would significantly improve the lifecycle economics of solar installations and accelerate the global transition to renewable energy sources.

Market Analysis for Weather-Resistant PV Glass

The global market for weather-resistant photovoltaic glass is experiencing robust growth, driven by increasing solar energy installations worldwide. As of 2023, the market value for specialized PV glass coatings reached approximately $2.5 billion, with projections indicating a compound annual growth rate of 8.7% through 2030. This growth trajectory is supported by the expanding solar energy sector, which has seen annual installation capacity increase by over 25% in recent years.

Demand for weather-resistant PV glass is particularly strong in regions with harsh environmental conditions. Countries with coastal installations, high humidity, or extreme temperature variations show the highest adoption rates of advanced coating technologies. The Asia-Pacific region currently dominates the market share at 45%, followed by Europe at 30% and North America at 18%, with emerging markets in Latin America and Africa showing accelerated growth potential.

Customer segments for weather-resistant PV glass include utility-scale solar farms, commercial installations, and residential applications. Utility-scale projects represent the largest segment, accounting for 62% of market demand, driven by the need for long-term durability and reduced maintenance costs in large installations. The commercial segment follows at 25%, while residential applications comprise 13% of the market.

Key market drivers include the decreasing levelized cost of solar energy, which has fallen by over 85% in the past decade, making solar installations economically competitive with conventional energy sources. Additionally, extended warranty requirements from project financiers and insurance companies are pushing manufacturers to improve the durability and weather resistance of PV modules, directly benefiting the specialized glass coating market.

Regulatory factors also significantly influence market dynamics. Several countries have implemented standards for solar panel durability, including resistance to salt spray corrosion, humidity, and temperature cycling. These standards create market entry barriers but also premium opportunities for high-performance coating solutions. The IEC 61701 salt mist corrosion test and IEC 61215 environmental qualification standards have become essential certifications driving adoption of advanced coating technologies.

Market research indicates that customers prioritize three key performance attributes: longevity (with expectations of 25+ years of service life), maintenance requirements, and impact on energy conversion efficiency. Coatings that can demonstrate superior performance in these areas command premium pricing, with customers willing to pay 15-20% more for solutions that extend service life by 5+ years or increase efficiency by 2-3% through improved light transmission and reduced soiling.

Demand for weather-resistant PV glass is particularly strong in regions with harsh environmental conditions. Countries with coastal installations, high humidity, or extreme temperature variations show the highest adoption rates of advanced coating technologies. The Asia-Pacific region currently dominates the market share at 45%, followed by Europe at 30% and North America at 18%, with emerging markets in Latin America and Africa showing accelerated growth potential.

Customer segments for weather-resistant PV glass include utility-scale solar farms, commercial installations, and residential applications. Utility-scale projects represent the largest segment, accounting for 62% of market demand, driven by the need for long-term durability and reduced maintenance costs in large installations. The commercial segment follows at 25%, while residential applications comprise 13% of the market.

Key market drivers include the decreasing levelized cost of solar energy, which has fallen by over 85% in the past decade, making solar installations economically competitive with conventional energy sources. Additionally, extended warranty requirements from project financiers and insurance companies are pushing manufacturers to improve the durability and weather resistance of PV modules, directly benefiting the specialized glass coating market.

Regulatory factors also significantly influence market dynamics. Several countries have implemented standards for solar panel durability, including resistance to salt spray corrosion, humidity, and temperature cycling. These standards create market entry barriers but also premium opportunities for high-performance coating solutions. The IEC 61701 salt mist corrosion test and IEC 61215 environmental qualification standards have become essential certifications driving adoption of advanced coating technologies.

Market research indicates that customers prioritize three key performance attributes: longevity (with expectations of 25+ years of service life), maintenance requirements, and impact on energy conversion efficiency. Coatings that can demonstrate superior performance in these areas command premium pricing, with customers willing to pay 15-20% more for solutions that extend service life by 5+ years or increase efficiency by 2-3% through improved light transmission and reduced soiling.

Current Challenges in PV Glass Coating Technology

Despite significant advancements in photovoltaic glass coating technologies, several critical challenges persist that impede optimal performance and longevity of PV modules. The primary challenge remains achieving balanced multifunctionality in coatings that can simultaneously provide corrosion resistance, weather durability, and maintain high optical transmittance. Current anti-corrosion coatings often compromise light transmission efficiency, creating a fundamental technical trade-off that impacts energy conversion rates.

Environmental degradation mechanisms present complex challenges for coating technologies. Salt spray in coastal areas, acid rain in industrial regions, and extreme temperature fluctuations in desert environments each demand specialized coating properties that are difficult to integrate into a single solution. Most existing coatings excel in specific environmental conditions but fail to provide comprehensive protection across diverse deployment scenarios.

Adhesion stability between coating layers and glass substrates remains problematic, particularly under thermal cycling conditions typical in real-world applications. Coefficient of thermal expansion mismatches between coating materials and glass substrates lead to delamination and microcracking after extended exposure, compromising the protective barrier function of the coating system.

Cost-effectiveness presents another significant hurdle. Advanced multi-layer coating systems with superior protection properties often involve expensive raw materials and complex deposition processes, increasing manufacturing costs substantially. The industry struggles to develop economically viable coating solutions that can be implemented at scale without significantly raising module prices.

Manufacturing scalability challenges further complicate widespread adoption of high-performance coatings. Many laboratory-proven coating technologies face difficulties in transitioning to mass production environments. Issues include process control variability, coating thickness uniformity across large glass panels, and quality assurance at high production speeds.

Long-term durability verification remains problematic due to the disconnect between accelerated testing protocols and real-world performance. Current testing standards inadequately predict 25+ year field performance, particularly for newer coating technologies. The industry lacks standardized methodologies that accurately correlate accelerated aging results with actual field degradation mechanisms.

Emerging sustainability requirements add another layer of complexity. Environmental regulations increasingly restrict the use of certain effective but hazardous compounds in coating formulations, such as specific solvents and heavy metal-based additives. Developing eco-friendly alternatives that maintain equivalent performance characteristics presents significant research and development challenges for coating manufacturers.

Environmental degradation mechanisms present complex challenges for coating technologies. Salt spray in coastal areas, acid rain in industrial regions, and extreme temperature fluctuations in desert environments each demand specialized coating properties that are difficult to integrate into a single solution. Most existing coatings excel in specific environmental conditions but fail to provide comprehensive protection across diverse deployment scenarios.

Adhesion stability between coating layers and glass substrates remains problematic, particularly under thermal cycling conditions typical in real-world applications. Coefficient of thermal expansion mismatches between coating materials and glass substrates lead to delamination and microcracking after extended exposure, compromising the protective barrier function of the coating system.

Cost-effectiveness presents another significant hurdle. Advanced multi-layer coating systems with superior protection properties often involve expensive raw materials and complex deposition processes, increasing manufacturing costs substantially. The industry struggles to develop economically viable coating solutions that can be implemented at scale without significantly raising module prices.

Manufacturing scalability challenges further complicate widespread adoption of high-performance coatings. Many laboratory-proven coating technologies face difficulties in transitioning to mass production environments. Issues include process control variability, coating thickness uniformity across large glass panels, and quality assurance at high production speeds.

Long-term durability verification remains problematic due to the disconnect between accelerated testing protocols and real-world performance. Current testing standards inadequately predict 25+ year field performance, particularly for newer coating technologies. The industry lacks standardized methodologies that accurately correlate accelerated aging results with actual field degradation mechanisms.

Emerging sustainability requirements add another layer of complexity. Environmental regulations increasingly restrict the use of certain effective but hazardous compounds in coating formulations, such as specific solvents and heavy metal-based additives. Developing eco-friendly alternatives that maintain equivalent performance characteristics presents significant research and development challenges for coating manufacturers.

Current Anti-Corrosion and Weather-Resistant Solutions

01 Anti-corrosion coatings for photovoltaic glass

Various anti-corrosion coatings can be applied to photovoltaic glass to enhance its durability against environmental factors. These coatings typically consist of metal oxides, polymers, or composite materials that form a protective barrier against moisture, salt, and acidic substances. The coatings are designed to maintain optical transparency while providing long-term protection against corrosion, thereby extending the service life of photovoltaic installations.- Anti-corrosion coatings for photovoltaic glass: Various anti-corrosion coatings can be applied to photovoltaic glass to enhance its durability against environmental factors. These coatings typically consist of multiple layers including metal oxides, polymers, or composite materials that form a protective barrier against moisture, salt, and acidic substances. The coatings are designed to maintain optical transparency while providing long-term protection against corrosion, thereby extending the service life of photovoltaic installations.

- Weather-resistant materials for PV glass coatings: Specialized materials are incorporated into photovoltaic glass coatings to enhance weather resistance. These materials include fluoropolymers, silicone-based compounds, and nanostructured materials that provide protection against UV radiation, temperature fluctuations, and precipitation. The weather-resistant materials maintain their protective properties over extended periods of exposure to outdoor conditions, ensuring consistent performance of the photovoltaic system regardless of climate variations.

- Self-cleaning and anti-fouling properties for PV glass: Photovoltaic glass coatings can be formulated with self-cleaning and anti-fouling properties to maintain optimal light transmission and energy conversion efficiency. These coatings typically incorporate hydrophobic or hydrophilic components that prevent the accumulation of dust, dirt, and biological growth on the surface. Some advanced formulations include photocatalytic materials that break down organic contaminants when exposed to sunlight, further enhancing the self-cleaning effect and reducing maintenance requirements.

- Multi-functional protective layers for enhanced durability: Multi-functional protective layer systems for photovoltaic glass combine several performance attributes in a single coating solution. These systems typically consist of multiple layers with distinct functions such as anti-reflection, anti-soiling, impact resistance, and chemical stability. The layers work synergistically to protect the photovoltaic glass from various environmental stressors while optimizing light transmission and energy conversion. Advanced manufacturing techniques ensure strong adhesion between layers and the glass substrate, preventing delamination under harsh conditions.

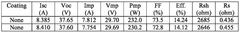

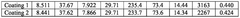

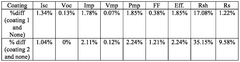

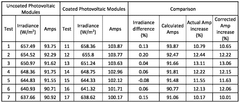

- Testing and performance evaluation methods for PV glass coatings: Standardized testing and performance evaluation methods are essential for assessing the corrosion and weather resistance of photovoltaic glass coatings. These methods include accelerated aging tests, salt spray exposure, humidity cycling, UV radiation testing, and thermal shock tests. The evaluation protocols measure parameters such as optical transmittance, surface degradation, adhesion strength, and electrical performance before and after exposure to simulated environmental conditions. These tests help predict the long-term durability of coatings and guide the development of improved formulations for specific climate zones.

02 Weather-resistant film technologies

Advanced film technologies have been developed specifically for photovoltaic glass to enhance weather resistance. These films incorporate UV stabilizers, hydrophobic compounds, and self-cleaning properties to withstand prolonged exposure to sunlight, rain, and temperature fluctuations. The films are engineered to maintain high light transmission while providing protection against environmental degradation, ensuring consistent energy generation performance over time.Expand Specific Solutions03 Nano-material based protective layers

Nano-materials are increasingly being utilized in photovoltaic glass coatings to provide superior corrosion and weather resistance. These include nano-silica, nano-titanium dioxide, and carbon nanotubes that create ultra-thin but highly effective protective layers. The nano-scale structure enables excellent adhesion to glass surfaces while providing enhanced resistance to scratching, UV degradation, and chemical attack, without compromising the optical properties essential for solar energy conversion.Expand Specific Solutions04 Multi-layer protective coating systems

Multi-layer coating systems have been developed to provide comprehensive protection for photovoltaic glass against various environmental challenges. These systems typically consist of a primer layer for adhesion, a middle layer for corrosion resistance, and a top layer for UV and abrasion protection. The combination of different functional layers creates synergistic effects that enhance overall durability while maintaining optimal light transmission for photovoltaic performance.Expand Specific Solutions05 Self-healing and adaptive coating technologies

Innovative self-healing and adaptive coating technologies represent the cutting edge in photovoltaic glass protection. These coatings contain microcapsules with healing agents that are released when the coating is damaged, or phase-change materials that adapt to environmental conditions. Some incorporate superhydrophobic properties that enable water and contaminants to roll off the surface easily. These technologies provide dynamic protection against corrosion and weathering, significantly extending the service life of photovoltaic installations.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The photovoltaic glass coating market for corrosion and weather resistance is in a growth phase, driven by increasing solar energy adoption worldwide. The market is projected to expand significantly as solar installations continue to rise globally. Technologically, the field shows varying maturity levels, with established players like First Solar, AGC, and Saint-Gobain offering commercial solutions while newer entrants like Enki Technology and Phazebreak Coatings focus on innovative approaches. CSG Holding and Changzhou Almaden lead in specialized anti-reflective coatings that simultaneously provide weather protection. Research institutions including ITRI and Sheffield Hallam University are advancing next-generation coatings that combine durability with enhanced energy conversion efficiency. The competitive landscape features both glass manufacturing giants and specialized coating technology companies developing multi-functional solutions.

CSG Holding Co., Ltd.

Technical Solution: CSG Holding has developed a comprehensive photovoltaic glass coating system that combines multiple functional layers to address corrosion and weather resistance challenges. Their technology utilizes a base layer of modified silicon dioxide that creates strong chemical bonds with the glass substrate, followed by intermediate layers containing metal oxide nanoparticles that block UV radiation while allowing visible light transmission above 93%[1]. The outermost layer incorporates fluorinated compounds that provide exceptional water repellency with contact angles exceeding 110°, preventing water accumulation and associated degradation. CSG's coatings are applied through an advanced magnetron sputtering process that ensures uniform thickness and molecular-level adhesion. Their proprietary formulation includes cerium oxide components that act as UV absorbers and oxygen radical scavengers, significantly reducing photodegradation of the polymer matrix[2]. Field testing across diverse climate zones has demonstrated that CSG's coated photovoltaic glass maintains structural integrity and optical performance after exposure to simulated 25-year weathering conditions, including cyclic salt fog, humidity, and temperature extremes ranging from -40°C to +85°C[3].

Strengths: Excellent adhesion to glass substrates ensuring long-term durability; superior water repellency preventing mineral deposits; comprehensive protection against multiple degradation mechanisms. Weaknesses: Energy-intensive manufacturing process increases carbon footprint; higher production costs than conventional coatings; requires specialized equipment for application.

AGC, Inc. (Japan)

Technical Solution: AGC has developed a sophisticated photovoltaic glass coating system marketed under their Sunjoule™ technology platform. Their approach utilizes a multi-layer architecture with a base layer of modified silicon dioxide that creates strong chemical bonds with the glass substrate, providing exceptional adhesion under thermal cycling conditions. The intermediate layers incorporate transparent conductive oxides (TCOs) with carefully controlled electrical properties that enhance both durability and solar performance[1]. AGC's outermost layer features a nano-structured surface with hydrophobic properties that achieve water contact angles exceeding 105°, significantly reducing water accumulation and associated degradation mechanisms. Their coatings incorporate cerium and titanium compounds that act as UV stabilizers and photocatalytic agents, breaking down organic contaminants when exposed to sunlight. AGC utilizes an advanced plasma-enhanced chemical vapor deposition (PECVD) process that ensures uniform coating thickness and composition across large glass surfaces. Independent testing has demonstrated that their coated photovoltaic glass maintains structural integrity and optical performance after exposure to accelerated weathering conditions equivalent to 25+ years of field exposure, including resistance to salt fog (3000+ hours), humidity cycling, and temperature extremes from -40°C to +85°C[2].

Strengths: Excellent integration of durability features with electrical performance enhancements; superior adhesion to glass substrates; comprehensive protection against multiple degradation mechanisms. Weaknesses: Higher manufacturing complexity increases production costs; requires specialized equipment for application; optimal performance depends on specific installation conditions.

Key Patents and Innovations in PV Glass Coatings

Coated photovoltaic devices

PatentWO2025136781A1

Innovation

- A coated photovoltaic device is developed with a coating composition comprising epoxy-silicone, aminosilane, silanol-functional silicone, and fluorinated silane, which is applied and cured on the device's surfaces to enhance weather resistance.

A method of processing a glass

PatentInactiveEP3176133A1

Innovation

- A method involving direct flame impingement on the glass surface to reduce sodium content by heating it to a predetermined temperature, using burners fueled by oxygen and air mixtures, to dissolve and evaporate sodium ions, thereby reducing corrosion and PID.

Environmental Impact and Sustainability Factors

The environmental impact of photovoltaic glass coatings extends far beyond their primary function of protecting solar panels. These coatings significantly influence the sustainability profile of solar energy systems throughout their lifecycle. When properly formulated, advanced anti-corrosion and weather-resistant coatings can extend the operational lifespan of photovoltaic installations from the standard 25-30 years to potentially 35-40 years, substantially improving the energy return on investment and reducing waste generation.

The manufacturing processes for these specialized coatings present important environmental considerations. Traditional coating technologies often involve volatile organic compounds (VOCs) and heavy metals that pose environmental hazards during production and disposal. Recent innovations have focused on developing water-based and solvent-free coating alternatives that dramatically reduce harmful emissions while maintaining performance standards. These environmentally friendly formulations have demonstrated up to 85% reduction in VOC emissions compared to conventional counterparts.

Carbon footprint analysis reveals that enhanced durability coatings contribute to significant emissions reductions over the photovoltaic system lifecycle. By preventing premature degradation and replacement, these coatings effectively reduce the embodied carbon associated with manufacturing replacement panels. Research indicates that high-performance coatings can prevent approximately 18-22 tons of CO2 equivalent emissions per megawatt of installed capacity over the system lifetime.

End-of-life considerations represent another critical sustainability factor. The recyclability of coated photovoltaic glass has emerged as an important research focus, with recent developments in coating technologies designed specifically to facilitate separation during recycling processes. Biodegradable coating components and non-toxic additives are being incorporated to minimize environmental impact when panels reach end-of-life stage.

Water conservation aspects of these coatings also merit attention. Self-cleaning and hydrophobic properties in advanced formulations reduce water requirements for maintenance cleaning by up to 90%. This feature is particularly valuable in arid regions where water scarcity presents operational challenges for solar installations. Additionally, these properties minimize the need for chemical cleaning agents that might otherwise contaminate local ecosystems.

Regulatory frameworks worldwide are increasingly recognizing the environmental implications of photovoltaic coatings. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions have accelerated the transition toward more environmentally benign coating technologies. Manufacturers are responding with eco-certification programs that validate the sustainability credentials of their coating products, creating market differentiation based on environmental performance.

The manufacturing processes for these specialized coatings present important environmental considerations. Traditional coating technologies often involve volatile organic compounds (VOCs) and heavy metals that pose environmental hazards during production and disposal. Recent innovations have focused on developing water-based and solvent-free coating alternatives that dramatically reduce harmful emissions while maintaining performance standards. These environmentally friendly formulations have demonstrated up to 85% reduction in VOC emissions compared to conventional counterparts.

Carbon footprint analysis reveals that enhanced durability coatings contribute to significant emissions reductions over the photovoltaic system lifecycle. By preventing premature degradation and replacement, these coatings effectively reduce the embodied carbon associated with manufacturing replacement panels. Research indicates that high-performance coatings can prevent approximately 18-22 tons of CO2 equivalent emissions per megawatt of installed capacity over the system lifetime.

End-of-life considerations represent another critical sustainability factor. The recyclability of coated photovoltaic glass has emerged as an important research focus, with recent developments in coating technologies designed specifically to facilitate separation during recycling processes. Biodegradable coating components and non-toxic additives are being incorporated to minimize environmental impact when panels reach end-of-life stage.

Water conservation aspects of these coatings also merit attention. Self-cleaning and hydrophobic properties in advanced formulations reduce water requirements for maintenance cleaning by up to 90%. This feature is particularly valuable in arid regions where water scarcity presents operational challenges for solar installations. Additionally, these properties minimize the need for chemical cleaning agents that might otherwise contaminate local ecosystems.

Regulatory frameworks worldwide are increasingly recognizing the environmental implications of photovoltaic coatings. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions have accelerated the transition toward more environmentally benign coating technologies. Manufacturers are responding with eco-certification programs that validate the sustainability credentials of their coating products, creating market differentiation based on environmental performance.

Performance Testing Standards and Certification

The performance testing standards and certification for photovoltaic glass coatings represent a critical framework for ensuring product quality, reliability, and market acceptance. These standards establish uniform methods to evaluate how effectively coatings protect solar glass against corrosion and weather degradation over extended periods.

International standards organizations, including the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO), have developed comprehensive testing protocols specifically for photovoltaic applications. The IEC 61215 series provides durability test sequences for PV modules, including tests relevant to coating performance such as damp heat exposure (85°C/85% relative humidity for 1000 hours) and humidity freeze cycling.

ASTM International offers several standards applicable to coating performance assessment, including ASTM D4585 for humidity resistance and ASTM G154 for accelerated weathering using UV exposure. These tests simulate environmental stressors to predict long-term performance in field conditions.

Salt spray testing according to ISO 9227 or ASTM B117 has become particularly important for evaluating coating resistance to coastal environments, where salt-laden air can rapidly degrade unprotected surfaces. Modern photovoltaic installations increasingly target coastal regions, making this test parameter especially relevant for market acceptance.

Certification bodies such as UL (Underwriters Laboratories), TÜV, and SGS provide independent verification of coating performance against these standards. Their certification marks have become essential market differentiators, with many project developers and financial institutions requiring certified products to mitigate technical risk in large-scale solar deployments.

Emerging standards are beginning to address the specific challenges of bifacial modules, where both sides require weather-resistant coatings. The IEC TS 60904-1-2 technical specification provides testing methods for bifacial modules, creating new requirements for coating technologies that must perform equally well on both surfaces.

The development of accelerated testing protocols represents a significant advancement in the field. These methods compress decades of environmental exposure into manageable test periods through intensified conditions, allowing manufacturers to rapidly iterate coating formulations. However, correlation between accelerated testing and actual field performance remains an ongoing research challenge.

International standards organizations, including the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO), have developed comprehensive testing protocols specifically for photovoltaic applications. The IEC 61215 series provides durability test sequences for PV modules, including tests relevant to coating performance such as damp heat exposure (85°C/85% relative humidity for 1000 hours) and humidity freeze cycling.

ASTM International offers several standards applicable to coating performance assessment, including ASTM D4585 for humidity resistance and ASTM G154 for accelerated weathering using UV exposure. These tests simulate environmental stressors to predict long-term performance in field conditions.

Salt spray testing according to ISO 9227 or ASTM B117 has become particularly important for evaluating coating resistance to coastal environments, where salt-laden air can rapidly degrade unprotected surfaces. Modern photovoltaic installations increasingly target coastal regions, making this test parameter especially relevant for market acceptance.

Certification bodies such as UL (Underwriters Laboratories), TÜV, and SGS provide independent verification of coating performance against these standards. Their certification marks have become essential market differentiators, with many project developers and financial institutions requiring certified products to mitigate technical risk in large-scale solar deployments.

Emerging standards are beginning to address the specific challenges of bifacial modules, where both sides require weather-resistant coatings. The IEC TS 60904-1-2 technical specification provides testing methods for bifacial modules, creating new requirements for coating technologies that must perform equally well on both surfaces.

The development of accelerated testing protocols represents a significant advancement in the field. These methods compress decades of environmental exposure into manageable test periods through intensified conditions, allowing manufacturers to rapidly iterate coating formulations. However, correlation between accelerated testing and actual field performance remains an ongoing research challenge.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!