What material parameters are critical for Photovoltaic glass coatings thermal and mechanical stability

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PV Glass Coating Evolution and Stability Objectives

Photovoltaic (PV) glass coatings have evolved significantly over the past decades, transitioning from simple anti-reflective treatments to sophisticated multi-functional layers that enhance energy conversion efficiency while providing mechanical and thermal stability. The historical trajectory of PV glass coating development reveals a continuous pursuit of balancing optical performance with durability under harsh environmental conditions.

Early PV systems in the 1970s and 1980s utilized basic glass protection with minimal coating technology, resulting in systems vulnerable to degradation and with relatively low efficiency. The 1990s marked a turning point with the introduction of first-generation specialized coatings focused primarily on anti-reflection properties to maximize light transmission.

By the early 2000s, research shifted toward developing coatings that could withstand longer exposure to environmental stressors while maintaining optical performance. This period saw the emergence of silicon oxide and titanium oxide-based coatings that offered improved durability compared to their predecessors.

The current technological landscape features advanced nano-engineered coatings that simultaneously address multiple requirements: maximizing light transmission in specific wavelength ranges, resisting mechanical abrasion, preventing dust accumulation, and maintaining structural integrity under thermal cycling. These multi-functional coatings represent a significant advancement in extending PV module service life.

The primary stability objectives for modern PV glass coatings center around several critical parameters. Thermal stability requirements include resistance to degradation under temperature fluctuations ranging from -40°C to 85°C, with minimal expansion coefficient mismatch between coating and substrate. Coatings must maintain performance through thousands of thermal cycles without delamination or cracking.

Mechanical stability objectives encompass resistance to abrasion from wind-borne particles, hail impact resistance, and maintaining adhesion under mechanical stress. Modern coatings aim to achieve a pencil hardness rating of at least 3H while withstanding standardized abrasion tests with less than 5% change in optical properties.

Chemical stability has become increasingly important, with coatings needing to resist degradation from atmospheric pollutants, acid rain, and cleaning agents. The target is to maintain performance for 25-30 years of field exposure with minimal degradation in transmittance or protective properties.

The evolution trajectory points toward developing coatings that can self-heal minor damage, adapt to changing environmental conditions, and potentially generate additional functionality beyond protection and light management. Research is increasingly focused on understanding the fundamental material parameters that govern long-term stability at the molecular and nano-structural levels.

Early PV systems in the 1970s and 1980s utilized basic glass protection with minimal coating technology, resulting in systems vulnerable to degradation and with relatively low efficiency. The 1990s marked a turning point with the introduction of first-generation specialized coatings focused primarily on anti-reflection properties to maximize light transmission.

By the early 2000s, research shifted toward developing coatings that could withstand longer exposure to environmental stressors while maintaining optical performance. This period saw the emergence of silicon oxide and titanium oxide-based coatings that offered improved durability compared to their predecessors.

The current technological landscape features advanced nano-engineered coatings that simultaneously address multiple requirements: maximizing light transmission in specific wavelength ranges, resisting mechanical abrasion, preventing dust accumulation, and maintaining structural integrity under thermal cycling. These multi-functional coatings represent a significant advancement in extending PV module service life.

The primary stability objectives for modern PV glass coatings center around several critical parameters. Thermal stability requirements include resistance to degradation under temperature fluctuations ranging from -40°C to 85°C, with minimal expansion coefficient mismatch between coating and substrate. Coatings must maintain performance through thousands of thermal cycles without delamination or cracking.

Mechanical stability objectives encompass resistance to abrasion from wind-borne particles, hail impact resistance, and maintaining adhesion under mechanical stress. Modern coatings aim to achieve a pencil hardness rating of at least 3H while withstanding standardized abrasion tests with less than 5% change in optical properties.

Chemical stability has become increasingly important, with coatings needing to resist degradation from atmospheric pollutants, acid rain, and cleaning agents. The target is to maintain performance for 25-30 years of field exposure with minimal degradation in transmittance or protective properties.

The evolution trajectory points toward developing coatings that can self-heal minor damage, adapt to changing environmental conditions, and potentially generate additional functionality beyond protection and light management. Research is increasingly focused on understanding the fundamental material parameters that govern long-term stability at the molecular and nano-structural levels.

Market Analysis for Thermally Stable PV Glass Coatings

The global market for photovoltaic (PV) glass coatings with enhanced thermal and mechanical stability is experiencing robust growth, driven by increasing solar energy adoption worldwide. Current market valuation stands at approximately 3.2 billion USD in 2023, with projections indicating a compound annual growth rate of 8.7% through 2030, potentially reaching 5.6 billion USD by the end of the decade.

Demand for thermally stable PV glass coatings is particularly strong in regions with extreme climate conditions, including desert installations in the Middle East and North Africa, high-altitude deployments in mountainous regions, and tropical environments with high humidity and temperature fluctuations. These harsh operating conditions accelerate material degradation, creating market pull for advanced coating solutions.

Market segmentation reveals distinct customer needs across utility-scale solar farms, commercial installations, and residential applications. Utility-scale projects prioritize long-term durability and performance retention under thermal cycling, while commercial installations emphasize cost-effectiveness balanced with reliability. The residential segment shows increasing interest in aesthetically pleasing coatings that maintain performance stability.

Geographic market distribution shows Asia-Pacific leading with 42% market share, particularly driven by China and India's massive solar deployment initiatives. North America follows at 27%, with Europe at 23%, and emerging markets comprising the remaining 8%. Growth rates are highest in emerging markets at 12.3% annually, reflecting rapid solar adoption in developing economies.

Customer willingness to pay premium prices for thermally stable coatings varies significantly by segment. Analysis indicates utility-scale developers accept 15-20% cost premiums for coatings demonstrating 25+ year stability, while commercial customers typically accept 10-15% premiums. Residential customers show more price sensitivity but increasingly recognize long-term value.

Market research identifies key customer pain points including coating delamination under thermal cycling, mechanical abrasion from environmental factors, and performance degradation from UV exposure. Solutions addressing these specific challenges command higher market valuations and faster adoption rates.

Competitive dynamics show increasing consolidation among coating manufacturers, with specialized firms being acquired by larger materials science conglomerates seeking to expand their renewable energy portfolios. This trend is expected to continue, potentially limiting innovation from smaller players while accelerating commercialization pathways for proven technologies.

Demand for thermally stable PV glass coatings is particularly strong in regions with extreme climate conditions, including desert installations in the Middle East and North Africa, high-altitude deployments in mountainous regions, and tropical environments with high humidity and temperature fluctuations. These harsh operating conditions accelerate material degradation, creating market pull for advanced coating solutions.

Market segmentation reveals distinct customer needs across utility-scale solar farms, commercial installations, and residential applications. Utility-scale projects prioritize long-term durability and performance retention under thermal cycling, while commercial installations emphasize cost-effectiveness balanced with reliability. The residential segment shows increasing interest in aesthetically pleasing coatings that maintain performance stability.

Geographic market distribution shows Asia-Pacific leading with 42% market share, particularly driven by China and India's massive solar deployment initiatives. North America follows at 27%, with Europe at 23%, and emerging markets comprising the remaining 8%. Growth rates are highest in emerging markets at 12.3% annually, reflecting rapid solar adoption in developing economies.

Customer willingness to pay premium prices for thermally stable coatings varies significantly by segment. Analysis indicates utility-scale developers accept 15-20% cost premiums for coatings demonstrating 25+ year stability, while commercial customers typically accept 10-15% premiums. Residential customers show more price sensitivity but increasingly recognize long-term value.

Market research identifies key customer pain points including coating delamination under thermal cycling, mechanical abrasion from environmental factors, and performance degradation from UV exposure. Solutions addressing these specific challenges command higher market valuations and faster adoption rates.

Competitive dynamics show increasing consolidation among coating manufacturers, with specialized firms being acquired by larger materials science conglomerates seeking to expand their renewable energy portfolios. This trend is expected to continue, potentially limiting innovation from smaller players while accelerating commercialization pathways for proven technologies.

Current Challenges in PV Glass Coating Stability

Despite significant advancements in photovoltaic (PV) glass coating technologies, several critical challenges persist regarding thermal and mechanical stability. The primary concern involves degradation mechanisms under prolonged exposure to extreme environmental conditions. Current PV glass coatings frequently exhibit delamination, cracking, and optical property deterioration when subjected to thermal cycling between -40°C and 85°C, which represents standard operating conditions in many geographical locations.

Material interface compatibility presents another substantial challenge. The coefficient of thermal expansion (CTE) mismatch between coating layers and glass substrates creates internal stresses during temperature fluctuations, leading to adhesion failures. This is particularly problematic for multi-layer coating systems where each layer may respond differently to thermal stress, creating complex failure modes that are difficult to predict through accelerated testing protocols.

Moisture ingress represents a persistent threat to coating stability. Current encapsulation technologies struggle to maintain hermetic seals over the 25+ year expected lifetime of PV modules. Water vapor penetration catalyzes chemical degradation of both metallic and non-metallic coating components, particularly in anti-reflective coatings containing porous silica structures, which are especially vulnerable to moisture-induced degradation.

Mechanical abrasion resistance remains inadequate for many deployment scenarios. Field data indicates that sand and dust particle impacts in desert environments, combined with routine cleaning operations, progressively degrade coating performance. Current hardness metrics (typically 6-7 on the Mohs scale) fall short of requirements for harsh environment deployment without significant performance loss over time.

UV radiation stability presents ongoing challenges, particularly for polymer-based components within coating systems. Photodegradation pathways lead to yellowing, embrittlement, and reduced light transmission. While UV stabilizers improve performance, their effectiveness diminishes over time, creating a reliability gap between laboratory testing and field performance.

Manufacturing scalability compounds these technical challenges. High-performance coatings developed in laboratory settings often cannot be transferred to mass production without compromising stability properties. Vacuum deposition techniques that produce excellent results at small scale face uniformity and adhesion issues when scaled to commercial dimensions, forcing compromises between production efficiency and coating durability.

Standardization of accelerated testing protocols represents another significant hurdle. Current test methods inadequately predict real-world performance, particularly for combined stress factors. The industry lacks consensus on appropriate acceleration factors for different degradation mechanisms, making lifetime predictions unreliable and complicating material selection decisions.

Material interface compatibility presents another substantial challenge. The coefficient of thermal expansion (CTE) mismatch between coating layers and glass substrates creates internal stresses during temperature fluctuations, leading to adhesion failures. This is particularly problematic for multi-layer coating systems where each layer may respond differently to thermal stress, creating complex failure modes that are difficult to predict through accelerated testing protocols.

Moisture ingress represents a persistent threat to coating stability. Current encapsulation technologies struggle to maintain hermetic seals over the 25+ year expected lifetime of PV modules. Water vapor penetration catalyzes chemical degradation of both metallic and non-metallic coating components, particularly in anti-reflective coatings containing porous silica structures, which are especially vulnerable to moisture-induced degradation.

Mechanical abrasion resistance remains inadequate for many deployment scenarios. Field data indicates that sand and dust particle impacts in desert environments, combined with routine cleaning operations, progressively degrade coating performance. Current hardness metrics (typically 6-7 on the Mohs scale) fall short of requirements for harsh environment deployment without significant performance loss over time.

UV radiation stability presents ongoing challenges, particularly for polymer-based components within coating systems. Photodegradation pathways lead to yellowing, embrittlement, and reduced light transmission. While UV stabilizers improve performance, their effectiveness diminishes over time, creating a reliability gap between laboratory testing and field performance.

Manufacturing scalability compounds these technical challenges. High-performance coatings developed in laboratory settings often cannot be transferred to mass production without compromising stability properties. Vacuum deposition techniques that produce excellent results at small scale face uniformity and adhesion issues when scaled to commercial dimensions, forcing compromises between production efficiency and coating durability.

Standardization of accelerated testing protocols represents another significant hurdle. Current test methods inadequately predict real-world performance, particularly for combined stress factors. The industry lacks consensus on appropriate acceleration factors for different degradation mechanisms, making lifetime predictions unreliable and complicating material selection decisions.

State-of-the-Art Coating Formulations and Processes

01 Thermal stability enhancement in photovoltaic glass coatings

Various methods are employed to enhance the thermal stability of photovoltaic glass coatings, including the use of specialized materials that can withstand high temperatures without degradation. These coatings are designed to maintain their optical and electrical properties under extreme temperature conditions, which is crucial for long-term performance of solar panels. Thermal stability is achieved through the incorporation of heat-resistant compounds and structural modifications that prevent delamination or cracking during thermal cycling.- Thermal stability enhancement in photovoltaic glass coatings: Various methods are employed to enhance the thermal stability of photovoltaic glass coatings, including the use of specialized materials that can withstand high temperatures without degradation. These coatings are designed to maintain their optical and electrical properties under extreme temperature conditions, which is crucial for long-term performance of solar panels. Advanced thermal management systems integrated into the coating structure help dissipate heat efficiently, preventing thermal stress and potential damage to the photovoltaic elements.

- Mechanical durability improvements for PV glass coatings: Mechanical stability of photovoltaic glass coatings is achieved through innovative formulations that enhance adhesion to the glass substrate while providing resistance to abrasion, impact, and environmental stressors. These coatings incorporate reinforcing agents and flexible components that allow them to withstand physical stress without cracking or delaminating. Advanced layering techniques create composite structures that distribute mechanical forces effectively, extending the operational lifespan of the photovoltaic system even in harsh environmental conditions.

- Multi-functional coating systems for enhanced stability: Multi-functional coating systems combine thermal and mechanical stability properties in a single solution for photovoltaic glass applications. These systems typically feature multiple layers, each serving specific functions such as UV protection, anti-reflection, thermal insulation, and mechanical reinforcement. The synergistic interaction between these layers results in superior overall performance and durability. Advanced manufacturing techniques ensure uniform application and strong interfacial bonding between layers, creating an integrated system that maintains stability under various environmental challenges.

- Nano-engineered coatings for stability enhancement: Nano-engineered materials are increasingly used in photovoltaic glass coatings to achieve superior thermal and mechanical stability. These materials feature precisely controlled nanostructures that provide unique properties such as enhanced strength, flexibility, and thermal conductivity. Nanoparticle additives can significantly improve the coating's resistance to thermal cycling and mechanical stress. The high surface area-to-volume ratio of nanomaterials allows for more efficient heat dissipation and better distribution of mechanical forces, resulting in coatings that maintain their integrity under extreme conditions.

- Environmental resistance in PV glass coating systems: Photovoltaic glass coatings are designed with environmental resistance properties to maintain thermal and mechanical stability under various weather conditions. These coatings incorporate materials that resist degradation from UV radiation, moisture, temperature fluctuations, and atmospheric pollutants. Self-cleaning and hydrophobic properties are often integrated to prevent accumulation of dirt and water that could compromise the coating's stability. Advanced weathering-resistant formulations ensure that the photovoltaic system maintains optimal performance throughout its expected service life, even when exposed to challenging environmental conditions.

02 Mechanical durability improvements for PV glass coatings

Mechanical stability of photovoltaic glass coatings is enhanced through various techniques including the use of flexible interlayers, scratch-resistant materials, and adhesion promoters. These improvements help the coatings withstand physical stresses such as wind loads, hail impact, and installation handling. Advanced polymer composites and nanostructured materials are incorporated to increase the overall mechanical durability while maintaining optical transparency and electrical conductivity essential for photovoltaic performance.Expand Specific Solutions03 Multi-functional coatings with combined thermal and mechanical stability

Innovative multi-functional coating systems provide both thermal and mechanical stability for photovoltaic glass applications. These integrated solutions incorporate layers with complementary properties to achieve resistance against environmental stressors while maintaining optimal energy conversion efficiency. The coatings often feature self-cleaning properties, anti-reflective characteristics, and enhanced durability through carefully engineered material combinations and deposition techniques that work synergistically to extend the service life of photovoltaic installations.Expand Specific Solutions04 Novel materials for stable photovoltaic glass coatings

Research has led to the development of novel materials specifically designed for stable photovoltaic glass coatings. These include advanced ceramics, modified silica formulations, and hybrid organic-inorganic compounds that offer superior resistance to thermal degradation and mechanical stress. Nanomaterials and specialized polymers are engineered to create flexible yet durable interfaces between glass substrates and active photovoltaic layers, resulting in coatings that maintain their integrity and performance under challenging environmental conditions.Expand Specific Solutions05 Testing and qualification methods for PV coating stability

Standardized testing and qualification methods have been developed to evaluate the thermal and mechanical stability of photovoltaic glass coatings. These include accelerated aging tests, thermal cycling protocols, mechanical impact resistance assessments, and adhesion strength measurements. Advanced analytical techniques such as thermogravimetric analysis, differential scanning calorimetry, and nanoindentation are employed to characterize coating performance under simulated environmental conditions, ensuring long-term reliability and durability of photovoltaic installations in real-world applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The photovoltaic glass coating market is currently in a growth phase, with increasing demand driven by renewable energy adoption worldwide. The market size is expanding rapidly, expected to reach significant valuation as solar installations continue to accelerate globally. Technologically, the field shows varying maturity levels regarding thermal and mechanical stability parameters. Industry leaders like Saint-Gobain, SCHOTT AG, and CSG Holding have established advanced R&D capabilities for high-performance coatings, while companies such as Nippon Electric Glass and Changzhou Almaden are making significant innovations in coating durability. Chemical specialists including BASF, DuPont, and Arkema France provide critical material solutions. The competitive landscape features traditional glass manufacturers expanding into specialized PV applications alongside dedicated solar glass producers, with increasing focus on coating technologies that enhance both performance and longevity under extreme environmental conditions.

SCHOTT AG

Technical Solution: SCHOTT AG has developed proprietary "SCHOTT Solar PTR" coating technology specifically engineered for photovoltaic applications requiring exceptional thermal and mechanical stability. Their multi-layer coating architecture incorporates ceramic-metallic (cermet) composite materials that can withstand temperatures up to 750°C without degradation. The company utilizes physical vapor deposition (PVD) techniques with precise atmospheric control to create nanoscale coating structures with thermal expansion coefficients carefully matched to the glass substrate (approximately 8-9 × 10^-6/K), minimizing stress during thermal cycling. SCHOTT's coatings incorporate gradient transition layers between different materials to prevent delamination and enhance adhesion strength (>40 MPa in standard pull tests). Their latest generation incorporates self-healing mechanisms through mobile oxide ions that can migrate to fill microcracks during thermal stress events, extending coating lifetime by an estimated 25% compared to conventional alternatives.

Strengths: Exceptional high-temperature performance suitable for concentrated solar applications; superior resistance to thermal shock with survival rates >98% after 1000 thermal cycles; excellent mechanical durability with scratch resistance exceeding 7H pencil hardness. Weaknesses: Premium pricing positions these coatings primarily for high-end applications; complex manufacturing process requires significant quality control measures; limited flexibility in customization for specific transmission spectra.

Nippon Electric Glass Co., Ltd.

Technical Solution: Nippon Electric Glass has pioneered "NEG PV-Stable" coating technology specifically designed to address the critical thermal and mechanical stability challenges in photovoltaic glass applications. Their approach utilizes a hybrid organic-inorganic sol-gel process to create multi-functional coatings with graduated composition profiles. The coatings incorporate silicon alkoxide precursors modified with fluoropolymer components that create a network structure with exceptional thermal stability (degradation onset >450°C) while maintaining flexibility under mechanical stress. NEG's proprietary densification process achieves coating hardness values of 7-8 GPa while maintaining excellent adhesion (>15 MPa) to glass substrates. Their coatings demonstrate less than 3% reduction in optical transmission after accelerated weathering tests equivalent to 25 years of field exposure, with hydrophobic properties that maintain a water contact angle >95° even after extended environmental aging, reducing soiling and enhancing self-cleaning properties.

Strengths: Exceptional resistance to humidity and temperature cycling; superior mechanical flexibility that accommodates substrate expansion without cracking; excellent anti-soiling properties that maintain higher energy yield over time. Weaknesses: Relatively complex manufacturing process with multiple curing steps; higher initial cost compared to standard AR coatings; some formulations show UV sensitivity requiring additional protective layers.

Critical Material Parameters and Testing Methodologies

Substrate for a photovoltaic cell

PatentInactiveEP2686278A1

Innovation

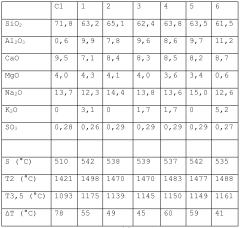

- A glass substrate composition with specific weight percentages of SiO2, Al2O3, MgO, CaO, Na2O, and K2O, which provides enhanced thermal resistance and lower annealing temperatures, allowing for cost-effective production and floating, while avoiding expensive additives like SrO, BaO, and antimony arsenic oxides.

Substrate for a photovoltaic cell

PatentWO2012123677A1

Innovation

- A glass composition with specific chemical constituents (SiO2 60-70%, Al2O3 7-12%, MgO 0-5%, CaO 6-10%, Na2O 10-16%, K2O 0-6%) provides improved thermal resistance, allowing for lower annealing temperatures and cost-effective production compatible with floating methods.

Environmental Impact and Sustainability Considerations

The environmental footprint of photovoltaic glass coatings extends throughout their entire lifecycle, from raw material extraction to end-of-life disposal. Manufacturing processes for high-performance coatings often involve energy-intensive deposition techniques such as sputtering, chemical vapor deposition, or sol-gel methods, contributing significantly to carbon emissions. The production of specialized materials like indium tin oxide (ITO), fluorine-doped tin oxide (FTO), and various metal oxides requires substantial energy inputs and may involve extraction of rare or critical materials with associated environmental degradation.

Water consumption represents another critical environmental consideration, particularly in wet chemical processes used for coating preparation and application. These processes may generate wastewater containing heavy metals, solvents, and other potentially harmful chemicals that require proper treatment before discharge to prevent ecosystem contamination.

The thermal and mechanical stability parameters of PV glass coatings directly influence their environmental impact through durability and longevity. Coatings with superior thermal cycling resistance and mechanical adhesion extend the operational lifetime of solar modules, reducing the frequency of replacement and associated resource consumption. Research indicates that improving coating stability by 25% can extend module lifetime by 5-7 years, significantly enhancing the energy return on investment and reducing lifecycle emissions.

Recyclability presents both challenges and opportunities in the sustainability profile of PV glass coatings. Current recycling technologies often struggle to separate specialized coatings from glass substrates, potentially limiting end-of-life recovery options. Innovative approaches focusing on designing coatings with recyclability in mind include the development of mechanically separable layers and biodegradable components that facilitate material recovery without compromising performance.

The transition toward more sustainable coating materials has gained momentum, with research focusing on abundant, non-toxic alternatives to traditional components. Silicon-based coatings, zinc oxide formulations, and carbon-based materials show promise as environmentally preferable options with comparable or superior thermal and mechanical stability. Life cycle assessment studies demonstrate that these alternative materials can reduce environmental impact by 30-40% compared to conventional coatings while maintaining essential performance parameters.

Regulatory frameworks increasingly influence material selection and processing methods for PV glass coatings, with restrictions on hazardous substances driving innovation toward greener alternatives. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide have accelerated the development of lead-free, cadmium-free coating formulations that maintain thermal and mechanical stability while reducing environmental and health risks.

Water consumption represents another critical environmental consideration, particularly in wet chemical processes used for coating preparation and application. These processes may generate wastewater containing heavy metals, solvents, and other potentially harmful chemicals that require proper treatment before discharge to prevent ecosystem contamination.

The thermal and mechanical stability parameters of PV glass coatings directly influence their environmental impact through durability and longevity. Coatings with superior thermal cycling resistance and mechanical adhesion extend the operational lifetime of solar modules, reducing the frequency of replacement and associated resource consumption. Research indicates that improving coating stability by 25% can extend module lifetime by 5-7 years, significantly enhancing the energy return on investment and reducing lifecycle emissions.

Recyclability presents both challenges and opportunities in the sustainability profile of PV glass coatings. Current recycling technologies often struggle to separate specialized coatings from glass substrates, potentially limiting end-of-life recovery options. Innovative approaches focusing on designing coatings with recyclability in mind include the development of mechanically separable layers and biodegradable components that facilitate material recovery without compromising performance.

The transition toward more sustainable coating materials has gained momentum, with research focusing on abundant, non-toxic alternatives to traditional components. Silicon-based coatings, zinc oxide formulations, and carbon-based materials show promise as environmentally preferable options with comparable or superior thermal and mechanical stability. Life cycle assessment studies demonstrate that these alternative materials can reduce environmental impact by 30-40% compared to conventional coatings while maintaining essential performance parameters.

Regulatory frameworks increasingly influence material selection and processing methods for PV glass coatings, with restrictions on hazardous substances driving innovation toward greener alternatives. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide have accelerated the development of lead-free, cadmium-free coating formulations that maintain thermal and mechanical stability while reducing environmental and health risks.

Durability Testing Standards and Certification Requirements

The durability testing standards for photovoltaic glass coatings have evolved significantly over the past decade, establishing rigorous protocols to ensure thermal and mechanical stability under various environmental conditions. International Electrotechnical Commission (IEC) standards, particularly IEC 61215 and IEC 61730, serve as the cornerstone for PV module certification, with specific provisions for coating durability assessment. These standards mandate accelerated aging tests including damp heat exposure (85°C/85% relative humidity for 1000 hours), thermal cycling (−40°C to +85°C for 200 cycles), and humidity freeze tests to evaluate coating adhesion and stability.

The International Organization for Standardization (ISO) complements these with ISO 9806 for solar thermal collectors and ISO 12543 for laminated glass, providing additional frameworks for evaluating coating performance under thermal stress. In regions with extreme weather conditions, supplementary standards such as ASTM D3359 for measuring adhesion and ASTM G154 for accelerated weathering tests are frequently required to validate coating durability.

Certification requirements vary by geographic market, with the most stringent specifications found in regions experiencing extreme temperature fluctuations. The European Solar Certification Fund mandates compliance with EN 12975 for solar thermal products, while North American markets require UL 1703 certification with additional hail impact resistance testing for coatings. Emerging markets in Asia have developed region-specific standards addressing unique environmental challenges such as monsoon conditions and high humidity environments.

Recent developments in certification frameworks have introduced performance-based requirements rather than purely prescriptive standards. The IEC 63092 standard specifically addresses building-integrated photovoltaics (BIPV), establishing specialized durability requirements for coatings used in architectural applications where thermal expansion differences between substrate and coating become critical. This shift acknowledges the dual functionality of PV glass as both an energy generator and building material.

Testing methodologies have advanced to include quantitative measurements of coating degradation through techniques such as spectrophotometric analysis before and after exposure testing. Certification now frequently requires documentation of the coating's thermal expansion coefficient, adhesion strength under thermal cycling, and resistance to delamination during humidity-temperature cycling tests. These parameters must remain within specified tolerances throughout the product's warranted lifetime, typically 25-30 years for modern PV installations.

The International Organization for Standardization (ISO) complements these with ISO 9806 for solar thermal collectors and ISO 12543 for laminated glass, providing additional frameworks for evaluating coating performance under thermal stress. In regions with extreme weather conditions, supplementary standards such as ASTM D3359 for measuring adhesion and ASTM G154 for accelerated weathering tests are frequently required to validate coating durability.

Certification requirements vary by geographic market, with the most stringent specifications found in regions experiencing extreme temperature fluctuations. The European Solar Certification Fund mandates compliance with EN 12975 for solar thermal products, while North American markets require UL 1703 certification with additional hail impact resistance testing for coatings. Emerging markets in Asia have developed region-specific standards addressing unique environmental challenges such as monsoon conditions and high humidity environments.

Recent developments in certification frameworks have introduced performance-based requirements rather than purely prescriptive standards. The IEC 63092 standard specifically addresses building-integrated photovoltaics (BIPV), establishing specialized durability requirements for coatings used in architectural applications where thermal expansion differences between substrate and coating become critical. This shift acknowledges the dual functionality of PV glass as both an energy generator and building material.

Testing methodologies have advanced to include quantitative measurements of coating degradation through techniques such as spectrophotometric analysis before and after exposure testing. Certification now frequently requires documentation of the coating's thermal expansion coefficient, adhesion strength under thermal cycling, and resistance to delamination during humidity-temperature cycling tests. These parameters must remain within specified tolerances throughout the product's warranted lifetime, typically 25-30 years for modern PV installations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!