Photovoltaic glass coatings for aerospace and high performance energy devices

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace PV Glass Coating Evolution & Objectives

Photovoltaic glass coatings for aerospace applications have evolved significantly over the past five decades, transitioning from simple protective layers to sophisticated multi-functional systems. The journey began in the 1970s with basic anti-reflective coatings designed to maximize light absorption for early satellite solar arrays. These rudimentary solutions provided minimal efficiency improvements while offering basic protection against the harsh space environment.

The 1980s marked a pivotal shift with the introduction of radiation-hardened coatings capable of withstanding prolonged exposure to cosmic radiation and solar flares. This development extended the operational lifespan of space-based solar systems from months to years, revolutionizing the economics of space missions and enabling longer-duration applications.

By the early 2000s, technological breakthroughs in nanomaterials science facilitated the development of self-healing coatings that could repair minor damage caused by micrometeoroid impacts. Concurrently, advances in thin-film deposition techniques enabled the creation of ultra-lightweight coatings that significantly reduced the mass-to-power ratio of space solar arrays, a critical factor in launch economics.

Today's state-of-the-art aerospace photovoltaic glass coatings incorporate multiple functionalities within layers often less than a micron thick. These include spectral selectivity to optimize energy harvesting across different orbital positions, thermal management properties to regulate operating temperatures, and electrostatic discharge protection to prevent damaging charge accumulation in various space environments.

The primary objective of current research is to develop next-generation coatings that can achieve conversion efficiencies exceeding 40% under space conditions while maintaining operational integrity for 20+ years. This represents a significant challenge given the extreme temperature fluctuations, radiation exposure, and vacuum conditions encountered in space.

Secondary objectives include developing coatings that can be applied to flexible substrates for deployable solar arrays, creating self-cleaning surfaces that mitigate dust accumulation for lunar and Martian applications, and engineering coatings with integrated health monitoring capabilities to provide real-time performance data.

The ultimate goal is to create multifunctional, adaptive coating systems that can dynamically respond to changing environmental conditions, potentially incorporating phase-change materials or electrochromic elements that adjust their properties based on temperature, radiation levels, or power requirements. Such innovations would dramatically enhance the resilience and efficiency of aerospace energy systems, enabling more ambitious deep space missions and permanent extraterrestrial installations.

The 1980s marked a pivotal shift with the introduction of radiation-hardened coatings capable of withstanding prolonged exposure to cosmic radiation and solar flares. This development extended the operational lifespan of space-based solar systems from months to years, revolutionizing the economics of space missions and enabling longer-duration applications.

By the early 2000s, technological breakthroughs in nanomaterials science facilitated the development of self-healing coatings that could repair minor damage caused by micrometeoroid impacts. Concurrently, advances in thin-film deposition techniques enabled the creation of ultra-lightweight coatings that significantly reduced the mass-to-power ratio of space solar arrays, a critical factor in launch economics.

Today's state-of-the-art aerospace photovoltaic glass coatings incorporate multiple functionalities within layers often less than a micron thick. These include spectral selectivity to optimize energy harvesting across different orbital positions, thermal management properties to regulate operating temperatures, and electrostatic discharge protection to prevent damaging charge accumulation in various space environments.

The primary objective of current research is to develop next-generation coatings that can achieve conversion efficiencies exceeding 40% under space conditions while maintaining operational integrity for 20+ years. This represents a significant challenge given the extreme temperature fluctuations, radiation exposure, and vacuum conditions encountered in space.

Secondary objectives include developing coatings that can be applied to flexible substrates for deployable solar arrays, creating self-cleaning surfaces that mitigate dust accumulation for lunar and Martian applications, and engineering coatings with integrated health monitoring capabilities to provide real-time performance data.

The ultimate goal is to create multifunctional, adaptive coating systems that can dynamically respond to changing environmental conditions, potentially incorporating phase-change materials or electrochromic elements that adjust their properties based on temperature, radiation levels, or power requirements. Such innovations would dramatically enhance the resilience and efficiency of aerospace energy systems, enabling more ambitious deep space missions and permanent extraterrestrial installations.

Market Analysis for Space-Grade PV Glass Applications

The space-grade photovoltaic glass market represents a specialized segment within the broader aerospace and energy sectors, characterized by stringent performance requirements and high-value applications. Current market valuations indicate that the global space solar panel market exceeds $500 million annually, with photovoltaic glass coatings constituting approximately 15-20% of this value chain.

Market demand for advanced PV glass coatings in aerospace applications is primarily driven by satellite deployments, space stations, and emerging space tourism ventures. The commercial satellite sector, particularly the deployment of mega-constellations for global internet coverage, has created unprecedented demand for high-efficiency, radiation-resistant PV solutions. Companies like SpaceX, OneWeb, and Amazon's Project Kuiper collectively plan to deploy over 40,000 satellites in the coming decade, creating sustained demand for specialized PV technologies.

The defense and government space sectors represent another significant market segment, with NASA, ESA, CNSA, and other space agencies investing heavily in long-duration missions requiring ultra-reliable power systems. These applications demand coatings that can withstand extreme temperature cycling, atomic oxygen exposure, and micrometeoroid impacts while maintaining optimal performance.

Market analysis reveals geographic concentration of demand in North America (38%), Europe (27%), and Asia-Pacific (24%), with emerging markets accounting for the remainder. The United States maintains leadership due to its robust commercial space sector and defense priorities, while China is experiencing the fastest growth rate at approximately 14% annually.

Price sensitivity varies significantly by application segment. Commercial satellite operators prioritize cost-effectiveness and standardization, while scientific missions and defense applications emphasize performance and reliability over cost considerations. This market stratification has created distinct product categories with varying price-performance ratios.

Supply chain analysis indicates potential vulnerabilities in rare earth elements and specialized manufacturing capabilities. Several critical coating materials face supply constraints, with over 70% of production concentrated in China. This geopolitical dimension adds complexity to market dynamics and creates opportunities for suppliers who can develop alternative material systems or secure diversified supply chains.

The market outlook remains strongly positive, with projected compound annual growth rates of 8-10% through 2030. Key growth drivers include increasing satellite deployments, expanding space exploration initiatives, and technology transfer to terrestrial high-performance applications such as high-altitude UAVs and extreme-environment energy systems.

Market demand for advanced PV glass coatings in aerospace applications is primarily driven by satellite deployments, space stations, and emerging space tourism ventures. The commercial satellite sector, particularly the deployment of mega-constellations for global internet coverage, has created unprecedented demand for high-efficiency, radiation-resistant PV solutions. Companies like SpaceX, OneWeb, and Amazon's Project Kuiper collectively plan to deploy over 40,000 satellites in the coming decade, creating sustained demand for specialized PV technologies.

The defense and government space sectors represent another significant market segment, with NASA, ESA, CNSA, and other space agencies investing heavily in long-duration missions requiring ultra-reliable power systems. These applications demand coatings that can withstand extreme temperature cycling, atomic oxygen exposure, and micrometeoroid impacts while maintaining optimal performance.

Market analysis reveals geographic concentration of demand in North America (38%), Europe (27%), and Asia-Pacific (24%), with emerging markets accounting for the remainder. The United States maintains leadership due to its robust commercial space sector and defense priorities, while China is experiencing the fastest growth rate at approximately 14% annually.

Price sensitivity varies significantly by application segment. Commercial satellite operators prioritize cost-effectiveness and standardization, while scientific missions and defense applications emphasize performance and reliability over cost considerations. This market stratification has created distinct product categories with varying price-performance ratios.

Supply chain analysis indicates potential vulnerabilities in rare earth elements and specialized manufacturing capabilities. Several critical coating materials face supply constraints, with over 70% of production concentrated in China. This geopolitical dimension adds complexity to market dynamics and creates opportunities for suppliers who can develop alternative material systems or secure diversified supply chains.

The market outlook remains strongly positive, with projected compound annual growth rates of 8-10% through 2030. Key growth drivers include increasing satellite deployments, expanding space exploration initiatives, and technology transfer to terrestrial high-performance applications such as high-altitude UAVs and extreme-environment energy systems.

Technical Barriers in Aerospace PV Glass Coatings

The development of photovoltaic glass coatings for aerospace applications faces significant technical barriers that must be overcome to achieve optimal performance in extreme environments. One of the primary challenges is the development of coatings that can withstand the harsh conditions of space, including extreme temperature fluctuations ranging from -150°C to +150°C, high-energy radiation exposure, and atomic oxygen erosion in low Earth orbit. These environmental factors can cause degradation of coating materials, reducing their efficiency and operational lifespan.

Material compatibility presents another substantial hurdle. Aerospace PV glass coatings must adhere perfectly to various substrate materials while maintaining thermal expansion compatibility to prevent delamination during thermal cycling. The mismatch between thermal expansion coefficients of different materials in multilayer coating systems often leads to mechanical stress, cracking, and eventual failure of the coating structure.

Weight constraints in aerospace applications demand ultra-thin coatings that maintain high performance. Current technology struggles to achieve the necessary balance between thickness reduction and maintaining optical, electrical, and protective properties. Most high-performance coatings require thicknesses that add significant weight to spacecraft systems, directly impacting launch costs and payload capacity.

Optical performance optimization remains challenging, particularly in achieving both high transmittance in the photovoltaic active spectrum and effective reflection of non-useful radiation. Engineers must develop coatings that maximize energy conversion efficiency while minimizing heat absorption, a delicate balance that current materials science has yet to perfect.

Manufacturing scalability presents significant barriers to widespread implementation. Advanced aerospace PV coatings typically require highly controlled deposition processes such as atomic layer deposition or plasma-enhanced chemical vapor deposition, which are difficult to scale for large-area applications. The precision required for uniform, defect-free coatings across large surfaces significantly increases production costs and complexity.

Long-term stability verification poses both technical and methodological challenges. Accelerated testing protocols often fail to accurately predict real-world performance in space environments over 15+ year missions. The industry lacks standardized testing methodologies that reliably correlate with actual in-orbit performance, making it difficult to validate new coating technologies without expensive and time-consuming space flight testing.

Self-cleaning and anti-dust capabilities represent an emerging challenge, particularly for applications on lunar or Martian surfaces where dust accumulation can severely impact performance. Current coating technologies have limited ability to repel or shed dust particles in low-gravity environments without external energy input.

Material compatibility presents another substantial hurdle. Aerospace PV glass coatings must adhere perfectly to various substrate materials while maintaining thermal expansion compatibility to prevent delamination during thermal cycling. The mismatch between thermal expansion coefficients of different materials in multilayer coating systems often leads to mechanical stress, cracking, and eventual failure of the coating structure.

Weight constraints in aerospace applications demand ultra-thin coatings that maintain high performance. Current technology struggles to achieve the necessary balance between thickness reduction and maintaining optical, electrical, and protective properties. Most high-performance coatings require thicknesses that add significant weight to spacecraft systems, directly impacting launch costs and payload capacity.

Optical performance optimization remains challenging, particularly in achieving both high transmittance in the photovoltaic active spectrum and effective reflection of non-useful radiation. Engineers must develop coatings that maximize energy conversion efficiency while minimizing heat absorption, a delicate balance that current materials science has yet to perfect.

Manufacturing scalability presents significant barriers to widespread implementation. Advanced aerospace PV coatings typically require highly controlled deposition processes such as atomic layer deposition or plasma-enhanced chemical vapor deposition, which are difficult to scale for large-area applications. The precision required for uniform, defect-free coatings across large surfaces significantly increases production costs and complexity.

Long-term stability verification poses both technical and methodological challenges. Accelerated testing protocols often fail to accurately predict real-world performance in space environments over 15+ year missions. The industry lacks standardized testing methodologies that reliably correlate with actual in-orbit performance, making it difficult to validate new coating technologies without expensive and time-consuming space flight testing.

Self-cleaning and anti-dust capabilities represent an emerging challenge, particularly for applications on lunar or Martian surfaces where dust accumulation can severely impact performance. Current coating technologies have limited ability to repel or shed dust particles in low-gravity environments without external energy input.

Current PV Glass Coating Solutions for Aerospace

01 Transparent conductive oxide coatings for photovoltaic glass

Transparent conductive oxide (TCO) coatings are applied to glass substrates to create electrodes for photovoltaic applications. These coatings allow light to pass through while providing electrical conductivity, which is essential for solar cell operation. Common materials include indium tin oxide (ITO), fluorine-doped tin oxide (FTO), and aluminum-doped zinc oxide (AZO). These coatings are typically deposited using methods such as sputtering, chemical vapor deposition, or sol-gel processes to achieve optimal transparency and conductivity.- Transparent conductive coatings for photovoltaic glass: Transparent conductive coatings are applied to glass substrates to create electrodes for photovoltaic applications while maintaining high light transmission. These coatings typically consist of transparent conductive oxides (TCOs) such as indium tin oxide (ITO), fluorine-doped tin oxide (FTO), or aluminum-doped zinc oxide (AZO). The coatings provide electrical conductivity while allowing sunlight to pass through to the active photovoltaic layers, optimizing energy conversion efficiency.

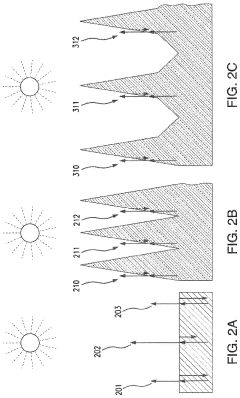

- Anti-reflective coatings for improved light absorption: Anti-reflective coatings are applied to photovoltaic glass to minimize light reflection and maximize light transmission into the solar cell. These coatings typically consist of multiple thin film layers with precisely controlled thicknesses and refractive indices. By reducing reflection losses at the air-glass interface, these coatings can significantly increase the amount of light reaching the photovoltaic material, thereby improving overall energy conversion efficiency of the solar module.

- Self-cleaning and hydrophobic coatings for photovoltaic glass: Self-cleaning and hydrophobic coatings are applied to photovoltaic glass surfaces to prevent dust, dirt, and water accumulation that can reduce light transmission and energy output. These coatings typically utilize titanium dioxide or silica-based materials that create a water-repellent surface. When exposed to sunlight and rain, these coatings facilitate the breakdown of organic contaminants and allow water to sheet off the surface, carrying away dirt particles and maintaining optimal performance of the solar panels over time.

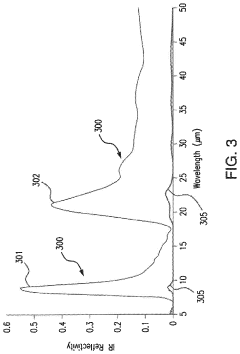

- Heat-reflective and insulating coatings for temperature management: Heat-reflective and insulating coatings are applied to photovoltaic glass to manage operating temperatures of solar panels. These coatings selectively filter infrared radiation while allowing visible light to pass through, reducing heat buildup in the photovoltaic cells. By maintaining lower operating temperatures, these coatings help improve the efficiency and longevity of solar panels, as photovoltaic efficiency typically decreases with increasing temperature. The coatings often incorporate materials such as metal oxides or specialized polymers with infrared-reflecting properties.

- Multi-functional nanocomposite coatings for enhanced performance: Multi-functional nanocomposite coatings combine several beneficial properties in a single layer applied to photovoltaic glass. These advanced coatings typically incorporate nanomaterials such as carbon nanotubes, graphene, or metal nanoparticles to simultaneously provide anti-reflection, self-cleaning, electrical conductivity, and durability benefits. The nanostructured surface can be engineered to trap light through multiple internal reflections, increasing the optical path length and improving light absorption in the photovoltaic material, while also providing resistance to environmental degradation.

02 Anti-reflective coatings for improved light absorption

Anti-reflective coatings are applied to photovoltaic glass to minimize light reflection and maximize the amount of solar radiation entering the solar cell. These coatings typically consist of multiple layers with carefully controlled thicknesses and refractive indices. By reducing reflection losses at the air-glass interface, these coatings can significantly improve the overall efficiency of photovoltaic modules. The coatings may be composed of materials such as silicon nitride, titanium dioxide, or silicon dioxide, and are designed to work across the solar spectrum.Expand Specific Solutions03 Self-cleaning and hydrophobic coatings for photovoltaic glass

Self-cleaning and hydrophobic coatings help maintain the performance of photovoltaic glass by preventing the accumulation of dust, dirt, and water droplets on the surface. These coatings typically utilize materials with hydrophobic properties, such as fluoropolymers or silicones, or photocatalytic materials like titanium dioxide that can break down organic contaminants when exposed to sunlight. By keeping the glass surface clean, these coatings ensure maximum light transmission to the photovoltaic cells and reduce maintenance requirements.Expand Specific Solutions04 Heat-reflective and insulating coatings for temperature management

Heat-reflective and insulating coatings are designed to manage the temperature of photovoltaic modules by selectively reflecting infrared radiation while allowing visible light to pass through. These coatings help prevent overheating, which can reduce the efficiency and lifespan of photovoltaic cells. The coatings may incorporate materials such as metal oxides or specialized polymers that reflect infrared radiation. By maintaining optimal operating temperatures, these coatings contribute to improved energy conversion efficiency and extended service life of photovoltaic systems.Expand Specific Solutions05 Integrated photovoltaic glass coating systems

Integrated photovoltaic glass coating systems combine multiple functional layers to address various requirements simultaneously. These systems may include transparent conductive layers, anti-reflective coatings, encapsulation materials, and protective barriers, all integrated into a single glass product. The integration of these functions can improve manufacturing efficiency, reduce costs, and enhance overall performance. These systems are designed to optimize light transmission, electrical conductivity, durability, and aesthetics, making them suitable for building-integrated photovoltaics and other applications where appearance and functionality are equally important.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The photovoltaic glass coating market for aerospace and high-performance energy devices is in a growth phase, with increasing adoption driven by renewable energy demands and space technology advancements. The market is projected to expand significantly as aerospace applications require specialized high-efficiency coatings. Leading players demonstrate varying levels of technical maturity: established companies like SCHOTT AG, Corning, and CSG Holding possess advanced manufacturing capabilities for specialized glass coatings, while Arkema and SABIC contribute innovative materials science expertise. Research-focused entities like Fraunhofer-Gesellschaft and SolAero Technologies are developing next-generation solutions with enhanced radiation resistance and efficiency. Emerging players like Forge Nano are introducing novel nanocoating technologies that could disrupt traditional manufacturing processes in this specialized sector.

SCHOTT AG

Technical Solution: SCHOTT AG has pioneered specialized glass coatings for aerospace photovoltaics through their SCHOTT Solar® technology platform. Their approach centers on ultra-thin borosilicate glass substrates with proprietary coating systems designed to withstand extreme temperature fluctuations (-150°C to +400°C) encountered in space environments. SCHOTT's coating technology incorporates nanoscale transparent conductive oxide (TCO) layers that provide electrical conductivity while maintaining over 95% optical transparency. Their multi-layer coating architecture includes specialized barrier films that prevent atomic oxygen erosion—a significant degradation factor in low Earth orbit. SCHOTT has developed a vacuum deposition process that creates hermetically sealed glass-to-glass bonds, protecting sensitive photovoltaic materials from space vacuum conditions. Their coatings also incorporate engineered dopants that prevent radiation-induced color center formation, maintaining optical performance throughout the mission lifetime.

Strengths: Exceptional thermal stability and resistance to thermal cycling; superior hermeticity for component protection; extensive experience in space-qualified materials. Weaknesses: Higher weight compared to polymer-based alternatives; more brittle than flexible substrate options; requires specialized handling during integration.

Corning, Inc.

Technical Solution: Corning has developed Willow® Glass, an ultra-thin (100 microns) flexible glass substrate with specialized coatings for high-performance aerospace photovoltaics. Their technology combines the thermal stability and hermeticity of glass with flexibility previously only available in polymer substrates. Corning's coating system incorporates multi-functional layers including anti-reflective coatings that reduce surface reflection to below 1% across the solar spectrum, significantly improving light capture efficiency. Their proprietary ion-exchange strengthening process creates a compressive surface layer that dramatically improves impact and scratch resistance without affecting optical properties. For aerospace applications, Corning has developed specialized transparent conductive oxide coatings with self-healing properties that can recover from micrometeoroid impacts. Their glass also features engineered thermal emissivity coatings on the non-sun-facing side that help regulate operating temperature in the vacuum of space, keeping photovoltaic cells within optimal operating temperature ranges.

Strengths: Unique combination of flexibility and glass properties; excellent barrier properties against moisture and gases; established manufacturing infrastructure for large-scale production. Weaknesses: Higher cost compared to conventional glass; requires specialized handling equipment; more limited deployment heritage in space applications compared to traditional rigid solutions.

Key Patents and Innovations in High-Performance Coatings

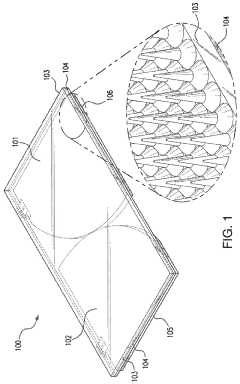

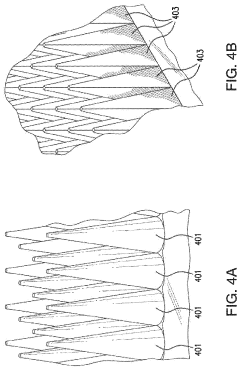

Antireflective structures for cover glasses in single or multijunction solar cells

PatentPendingUS20240162362A1

Innovation

- The implementation of a cover glass with an array of geometrical structures on its surface, designed to increase emissivity and transmissivity of infrared radiation, allowing for enhanced thermodynamic radiative cooling and reduced heat retention, thereby improving the efficiency of solar energy conversion.

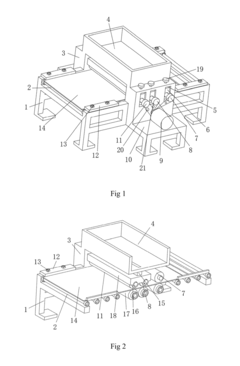

Roller coating device for photovoltaic glass coated with AR coating liquid

PatentInactiveUS20180346373A1

Innovation

- A roller coating device with a rack, support roller, and adjustable components, including a screw-driven column and rollers with matching glue tanks and rubber coatings, allows for precise adjustment of the front, rear, and compaction rollers to form a uniform glue film on the glass, enhancing coating uniformity and preventing droplets.

Environmental Durability and Space Qualification Standards

Photovoltaic glass coatings for aerospace applications must withstand extreme environmental conditions that far exceed terrestrial requirements. These coatings face intense radiation, thermal cycling between -150°C and +150°C, atomic oxygen exposure, and micrometeoroid impacts, necessitating rigorous qualification standards to ensure long-term performance.

The aerospace industry has established comprehensive testing protocols such as ASTM E512 and NASA-STD-5001 specifically for space materials. These standards evaluate radiation resistance, thermal stability, and vacuum compatibility of PV coatings. Recent advancements have led to the development of accelerated testing methods that simulate years of space exposure in laboratory settings, significantly reducing qualification timelines while maintaining reliability.

Qualification testing typically includes radiation exposure using particle accelerators to simulate solar wind and cosmic rays. Coatings must demonstrate less than 5% degradation in optical transmittance and electrical conductivity after exposure to 10^15 electrons/cm² at energies of 1 MeV. Thermal cycling tests require materials to withstand 10,000+ cycles without delamination or cracking, while atomic oxygen exposure tests evaluate erosion resistance in low Earth orbit environments.

Space-qualified coatings incorporate multi-layered protection systems with specialized materials like cerium oxide and indium tin oxide that provide radiation shielding while maintaining optical transparency. Self-healing coating technologies have emerged as promising solutions, incorporating microencapsulated healing agents that activate upon microcrack formation, extending operational lifetimes by up to 40%.

The qualification process also addresses outgassing concerns, as volatile compounds released in vacuum can condense on optical surfaces and degrade performance. ASTM E595 standard requires total mass loss below 1% and collected volatile condensable materials below 0.1% for space-qualified materials. Advanced coatings now incorporate vacuum-stable polymers and inorganic matrices that virtually eliminate outgassing concerns.

Industry leaders have established collaborative testing networks to share qualification data and standardize testing protocols. The European Space Agency's Materials and Electrical Components Laboratory and NASA's Space Environment Effects program provide valuable resources for coating developers seeking qualification pathways. These collaborative efforts have reduced qualification costs by approximately 30% while improving testing thoroughness.

Recent qualification standards have expanded to include resilience against space debris impacts, requiring coatings to maintain functionality even after micrometeoroid penetration. This has driven innovation in self-supporting coating architectures that can isolate damage and prevent catastrophic failure propagation across the entire photovoltaic system.

The aerospace industry has established comprehensive testing protocols such as ASTM E512 and NASA-STD-5001 specifically for space materials. These standards evaluate radiation resistance, thermal stability, and vacuum compatibility of PV coatings. Recent advancements have led to the development of accelerated testing methods that simulate years of space exposure in laboratory settings, significantly reducing qualification timelines while maintaining reliability.

Qualification testing typically includes radiation exposure using particle accelerators to simulate solar wind and cosmic rays. Coatings must demonstrate less than 5% degradation in optical transmittance and electrical conductivity after exposure to 10^15 electrons/cm² at energies of 1 MeV. Thermal cycling tests require materials to withstand 10,000+ cycles without delamination or cracking, while atomic oxygen exposure tests evaluate erosion resistance in low Earth orbit environments.

Space-qualified coatings incorporate multi-layered protection systems with specialized materials like cerium oxide and indium tin oxide that provide radiation shielding while maintaining optical transparency. Self-healing coating technologies have emerged as promising solutions, incorporating microencapsulated healing agents that activate upon microcrack formation, extending operational lifetimes by up to 40%.

The qualification process also addresses outgassing concerns, as volatile compounds released in vacuum can condense on optical surfaces and degrade performance. ASTM E595 standard requires total mass loss below 1% and collected volatile condensable materials below 0.1% for space-qualified materials. Advanced coatings now incorporate vacuum-stable polymers and inorganic matrices that virtually eliminate outgassing concerns.

Industry leaders have established collaborative testing networks to share qualification data and standardize testing protocols. The European Space Agency's Materials and Electrical Components Laboratory and NASA's Space Environment Effects program provide valuable resources for coating developers seeking qualification pathways. These collaborative efforts have reduced qualification costs by approximately 30% while improving testing thoroughness.

Recent qualification standards have expanded to include resilience against space debris impacts, requiring coatings to maintain functionality even after micrometeoroid penetration. This has driven innovation in self-supporting coating architectures that can isolate damage and prevent catastrophic failure propagation across the entire photovoltaic system.

Weight-to-Efficiency Optimization Strategies

In the aerospace and high-performance energy device sectors, weight-to-efficiency optimization represents a critical engineering challenge for photovoltaic glass coatings. Current research focuses on developing ultra-thin coating architectures that minimize mass while maximizing energy conversion capabilities, essential for spacecraft power systems where every gram impacts launch costs significantly.

Nanoscale material engineering has emerged as a primary strategy, with researchers developing multi-functional coatings under 100nm thickness that simultaneously provide high transmissivity, electrical conductivity, and radiation resistance. These advanced thin films utilize precisely controlled deposition techniques such as atomic layer deposition (ALD) and pulsed laser deposition to achieve atomic-level precision in material layering.

Composite materials incorporating carbon nanotubes and graphene derivatives have demonstrated exceptional promise, reducing coating weight by up to 40% compared to traditional materials while maintaining or improving electrical performance. These materials exhibit strength-to-weight ratios approximately 200 times greater than conventional glass coatings, enabling significant mass reduction without compromising structural integrity.

Computational modeling has accelerated optimization processes through machine learning algorithms that predict performance characteristics based on material composition and structural arrangements. These models have identified novel material combinations that traditional experimental approaches might have overlooked, resulting in weight reductions of 15-30% while improving efficiency by 5-12% in laboratory conditions.

Metamaterial structures engineered at the nanoscale have revolutionized light management capabilities, enabling selective wavelength transmission and reflection patterns that maximize photon capture while minimizing thermal absorption. This approach has yielded efficiency improvements of up to 18% in space-optimized photovoltaic systems without adding significant mass.

Vacuum plasma spraying techniques have been adapted to create gradient-index coatings that eliminate discrete layer interfaces, reducing delamination risks in extreme aerospace environments while minimizing material usage. These seamless transitions between functional layers have demonstrated superior durability in thermal cycling tests between -150°C and +150°C, typical of orbital conditions.

Industry-academic partnerships have accelerated commercialization pathways, with several aerospace contractors now implementing third-generation lightweight coating technologies that achieve power-to-weight ratios exceeding 1kW/kg, representing a threefold improvement over systems deployed just five years ago. These advancements are rapidly transitioning from experimental to operational status in both government and commercial space programs.

Nanoscale material engineering has emerged as a primary strategy, with researchers developing multi-functional coatings under 100nm thickness that simultaneously provide high transmissivity, electrical conductivity, and radiation resistance. These advanced thin films utilize precisely controlled deposition techniques such as atomic layer deposition (ALD) and pulsed laser deposition to achieve atomic-level precision in material layering.

Composite materials incorporating carbon nanotubes and graphene derivatives have demonstrated exceptional promise, reducing coating weight by up to 40% compared to traditional materials while maintaining or improving electrical performance. These materials exhibit strength-to-weight ratios approximately 200 times greater than conventional glass coatings, enabling significant mass reduction without compromising structural integrity.

Computational modeling has accelerated optimization processes through machine learning algorithms that predict performance characteristics based on material composition and structural arrangements. These models have identified novel material combinations that traditional experimental approaches might have overlooked, resulting in weight reductions of 15-30% while improving efficiency by 5-12% in laboratory conditions.

Metamaterial structures engineered at the nanoscale have revolutionized light management capabilities, enabling selective wavelength transmission and reflection patterns that maximize photon capture while minimizing thermal absorption. This approach has yielded efficiency improvements of up to 18% in space-optimized photovoltaic systems without adding significant mass.

Vacuum plasma spraying techniques have been adapted to create gradient-index coatings that eliminate discrete layer interfaces, reducing delamination risks in extreme aerospace environments while minimizing material usage. These seamless transitions between functional layers have demonstrated superior durability in thermal cycling tests between -150°C and +150°C, typical of orbital conditions.

Industry-academic partnerships have accelerated commercialization pathways, with several aerospace contractors now implementing third-generation lightweight coating technologies that achieve power-to-weight ratios exceeding 1kW/kg, representing a threefold improvement over systems deployed just five years ago. These advancements are rapidly transitioning from experimental to operational status in both government and commercial space programs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!