Integrated Lubrication Systems For Efficient Check Valves

Technology Background And Goals

The analysis will cover the evolution of this technology, highlighting major milestones and breakthroughs. It will also examine the competitive landscape, profiling major industry players and their respective strengths. By synthesizing insights from patents, research papers, and industry trends, potential avenues for innovation and disruptive solutions will be explored.

Market Demand Analysis

- Market Size and Growth

Analyze the current and projected market size for check valves with integrated lubrication systems across various industries. Provide estimates for market value and unit shipments, along with growth rates and forecasts. - Application Segments

Identify key application areas driving demand, such as oil and gas, chemical processing, power generation, and water treatment. Assess the specific requirements and adoption trends in each segment. - Regional Demand Patterns

Examine regional variations in market demand, highlighting regions with high growth potential and factors influencing demand, such as industrialization, infrastructure development, and regulatory environment. - Customer Preferences

Understand customer preferences and priorities when selecting check valves with integrated lubrication systems. Factors may include performance, reliability, maintenance requirements, and cost-effectiveness. - Competitive Landscape

Analyze the competitive landscape, including major players, their market shares, and product offerings. Identify key differentiators and competitive advantages driving customer choices.

Technology Status And Challenges

- Valve Design Evolution

Tracing the development of check valve designs, from traditional swing and lift types to advanced configurations like tilting disc and double-door valves, highlighting key milestones and innovations. - Sealing Challenges

Discussing common sealing issues faced by check valves, such as wear, leakage, and sticking, and the need for effective lubrication systems to mitigate these problems. - Lubrication System Integration

Exploring the integration of lubrication systems into check valve designs, including grease injection ports, self-lubricating materials, and automated lubrication systems. - Performance Enhancements

Analyzing how integrated lubrication systems can improve check valve performance, such as reducing friction, extending service life, and minimizing maintenance requirements.

Current Technical Solutions

01 Grease or Oil Lubrication

Check valves can be lubricated using grease or oil to reduce friction and wear between moving parts, ensuring smooth operation and extending service life. Suitable lubricants include petroleum-based greases, synthetic greases, or lubricating oils.- Lubrication Methods for Check Valves: Various techniques are disclosed for lubricating check valves to ensure smooth operation and prevent sticking or seizing. These methods involve applying lubricants to specific components or surfaces of the valve, such as the valve seat, disc, or hinge mechanism.

- Specialized Lubricant Compositions: Specialized lubricant compositions are described for use in check valves. These compositions are designed to withstand harsh conditions like high temperatures, pressures, or chemical environments, and provide enhanced lubricity, wear resistance, or compatibility with valve materials.

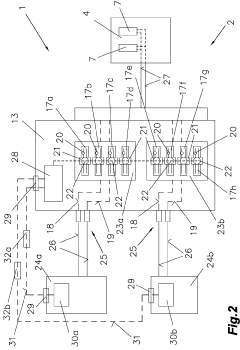

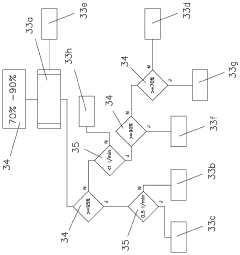

- Integrated Lubrication Systems: Integrated lubrication systems are disclosed for automatically or periodically lubricating check valves during operation. These systems may involve pumps, reservoirs, or distribution mechanisms to deliver lubricant to critical valve components.

- Lubricant-Impregnated Components: Certain components of check valves, such as seals, bearings, or bushings, may be designed to be impregnated or coated with lubricants, providing long-lasting lubrication and reducing the need for frequent relubrication.

- Type-Specific Lubrication Techniques: Specialized lubrication techniques may be tailored for different types of check valves, such as swing, lift, or ball check valves, addressing the unique design and operating conditions of each valve type.

02 Self-Lubricating Valve Designs

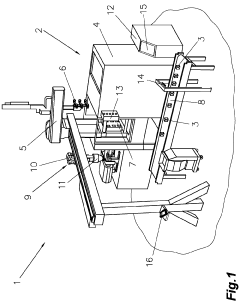

Some check valve designs incorporate self-lubricating features, such as using materials with inherent lubricity or incorporating lubricant reservoirs, minimizing the need for external lubrication and reducing maintenance requirements.Expand Specific Solutions03 Dedicated Lubrication Systems

Dedicated lubrication systems can be employed to ensure proper lubrication of check valves, especially in critical applications. These systems may include pumps, reservoirs, and distribution lines to deliver lubricant to valve components.Expand Specific Solutions04 Material-Specific Lubrication Considerations

The choice of lubricant and lubrication method may depend on the materials used in the check valve construction, considering factors such as compatibility, temperature range, and chemical resistance to ensure proper lubrication and prevent degradation.Expand Specific Solutions05 Lubrication-Free Valve Designs

In some applications, lubrication-free check valve designs may be preferred to eliminate the need for regular lubrication and maintenance. These designs may use specialized materials or coatings to reduce friction and wear without external lubrication.Expand Specific Solutions

Technology Main Player Analysis

The market for check valves with integrated lubrication systems is emerging, with significant growth potential as the technology matures. Key players like Honeywell International Technologies Ltd., Robert Bosch GmbH, and Continental Automotive Systems, Inc. are leading in technological advancements and market presence, while HL Mando Co., Ltd., Pierburg GmbH, and Vitesco Technologies GmbH are also making notable innovations.

HL Mando Co., Ltd.

Honeywell International Technologies Ltd.

Key Technology Interpretation

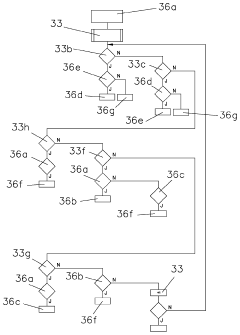

- The integrated valve allows data exchange with connected means, enabling better control and monitoring of the temperature control process.

- The temperature control process is applicable to various applications, including injection molding, die casting, and extrusion, providing a versatile solution.

- The integrated valve design integrates temperature control functionality into a single component, potentially simplifying the overall system architecture.

Technology Economic Analysis

The integration of lubrication systems into check valves could significantly impact the economic landscape across several industries. By reducing maintenance costs and increasing the lifespan of valves, this technology has the potential to enhance operational efficiency and reduce operational expenditures. In sectors such as oil and gas, water treatment, and manufacturing, where check valves are extensively used, the cost savings from ensuring smooth operations without frequent manual lubrication could be substantial.

Furthermore, the implementation of such integrated systems can lead to a decrease in downtime due to equipment failure, which is often costly in industries reliant on continuous operations. As the technology matures, there may also be a reduction in labor costs by minimizing the need for specialized maintenance personnel to perform routine lubrication.

The adoption of check valves with integrated lubrication systems could also stimulate innovation, as manufacturers strive to develop more efficient, reliable, and cost-effective solutions. This could drive competitive advantages and lead to increased market shares for early adopters. Overall, this advancement might encourage further investments in smarter, technology-driven infrastructure, aligning with broader industry trends towards automation and intelligent maintenance solutions.