Improving Lubrication And Sealing Performance Of Check Valves With Advanced Coatings

NOV 13, 20244 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Technology Background And Goals

The primary objective is to investigate and evaluate advanced coating technologies that can enhance the lubrication and sealing performance of check valves. This involves exploring various coating materials, deposition methods, and surface modification techniques that can improve the tribological properties and durability of valve components.

Key areas of focus include reducing friction and wear, increasing corrosion and erosion resistance, and enhancing compatibility with different working fluids. The research aims to identify promising coating solutions that can extend the service life, improve reliability, and reduce maintenance requirements of check valves across various industrial applications.

Key areas of focus include reducing friction and wear, increasing corrosion and erosion resistance, and enhancing compatibility with different working fluids. The research aims to identify promising coating solutions that can extend the service life, improve reliability, and reduce maintenance requirements of check valves across various industrial applications.

Check Valve Market Demand Analysis

- Market Size and Growth

The global check valve market is expected to witness significant growth, driven by increasing demand from industries like oil and gas, chemical processing, power generation, and water treatment. Factors fueling this growth include infrastructure development, stringent regulations for safety and environmental protection, and the need for efficient fluid handling systems. - Industry Trends

Key trends shaping the check valve market include:- Rising adoption of advanced materials and coatings for improved performance and durability

- Increasing demand for compact and lightweight valve designs

- Growing emphasis on energy-efficient and low-maintenance valve solutions

- Integration of smart technologies for remote monitoring and predictive maintenance

- Application Segments

The check valve market can be segmented based on various applications:- Oil and Gas: Upstream, midstream, and downstream operations

- Chemical Processing: Handling corrosive and hazardous fluids

- Power Generation: Fossil fuel and nuclear power plants

- Water and Wastewater Treatment: Municipal and industrial water systems

- Pharmaceutical and Food & Beverage: Ensuring product purity and hygiene

- Regional Dynamics

The Asia-Pacific region is expected to dominate the check valve market due to rapid industrialization and infrastructure development in countries like China and India. North America and Europe also hold significant market shares, driven by stringent regulations and the presence of established industries.

Technology Status And Challenges

- Valve Lubrication Challenges

Check valves often experience friction and wear due to frequent opening/closing cycles, leading to reduced service life and potential leakage issues. - Sealing Performance Limitations

Conventional sealing materials may degrade over time, compromising the valve's ability to prevent backflow and maintain system integrity. - Harsh Operating Environments

Extreme temperatures, pressures, and corrosive media can accelerate material degradation, posing challenges for valve performance and reliability. - Maintenance and Replacement Costs

Frequent valve maintenance or replacement due to wear and leakage can result in significant operational costs and system downtime.

Current Technical Solutions

01 Check valve lubrication

Lubricating materials, coatings, reservoirs, channels, and self-lubricating materials for smooth operation and wear prevention.- Check valve lubrication: Lubrication techniques for smooth operation and wear prevention, including compatible lubricants, lubrication channels, and reservoirs within valve design.

- Check valve sealing performance: Optimized valve seat and sealing surface designs, specialized sealing materials and coatings for enhanced backflow prevention and leakage control.

- Check valve materials and coatings: Corrosion-resistant alloys, ceramics, and specialized coatings for enhanced durability, wear resistance, and compatibility with operating environment.

- Check valve design and configuration: Innovative designs and configurations for improved flow characteristics, reduced pressure drop, and enhanced reliability, including streamlined flow paths, guided disc/piston designs, and integrated check and relief valve functions.

- Check valve testing and monitoring: Techniques for testing and monitoring performance, including leak testing, flow testing, and condition monitoring, to ensure proper operation, identify issues, and facilitate maintenance and replacement decisions.

02 Check valve sealing performance

Optimized sealing surfaces, specialized sealing materials/coatings, and additional sealing elements/mechanisms for leakage prevention and proper functioning.Expand Specific Solutions03 Check valve design and configuration

Optimized valve geometry, features for turbulence/pressure drop reduction, and designs for specific flow conditions or applications.Expand Specific Solutions04 Materials for check valve components

Durable, corrosion-resistant, and compatible materials for valve body, sealing elements, and moving parts.Expand Specific Solutions05 Check valve maintenance and monitoring

Periodic inspections, condition monitoring systems, and predictive maintenance strategies for reliable operation and failure prevention.Expand Specific Solutions

Check Valve Main Player Analysis

The competitive landscape for improving the lubrication and sealing performance of check valves with advanced coatings is diverse, with players at different stages of development and varying market scales and technology maturity. Leading companies like Chevron Oronite Co. LLC, Baker Hughes Holdings LLC, and Henkel AG & Co. KGaA showcase high maturity in advanced coatings technology, while firms like Yancheng Dafeng Nanya Valve Co., Ltd. and Jiangsu Xingya Marine Valve Co., Ltd. are emerging players focusing on niche applications. The market is expanding due to the demand for enhanced valve performance across various sectors.

Chevron Oronite Co. LLC

Technical Solution: Chevron Oronite has developed advanced coating technologies with high-performance additives to enhance the durability and efficiency of coatings for check valves.

Strength: Proven lubrication technology. Weakness: High cost of proprietary additives.

Baker Hughes Holdings LLC

Technical Solution: Baker Hughes offers advanced coating solutions designed for check valves in harsh environments, enhancing wear resistance and reducing friction to extend valve lifespan.

Strength: Expertise in harsh environment applications. Weakness: Limited application in non-industrial settings.

Key Technology Interpretation

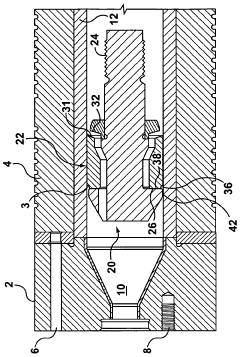

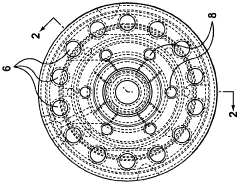

Check valve lip seal for an injection molding machine

PatentWO2006000075A1

Innovation

- 1. The invention provides a lip seal for a check ring of a check valve, with a groove on the interior circumferential surface of the ring that engages with a surface of the valve to block the flow of injection material into the melt passageway.

- 2. The invention features a groove formed in the forward face of the ring portion that receives melt, forcing the outer circumferential portion of the ring radially outward to provide a seal between the ring portion and the machine wall.

- 3. The check valve design is specifically tailored for use in injection molding and die casting machines, addressing the challenges of high temperatures, injection pressures, and corrosive environments.

Check Valve Advanced Coatings Economic Analysis

The economic analysis of advanced coatings for improving the lubrication and sealing performance of check valves involves assessing the potential market demand, cost-benefit analysis, and return on investment. Key factors include the cost of coating materials and application processes, potential performance improvements and associated cost savings, target industries and applications, and market competition. A comprehensive evaluation of the economic viability, scalability, and long-term profitability is crucial for strategic decision-making regarding the adoption and commercialization of these advanced coating technologies.

Check Valve Advanced Coatings Policy And Regulatory Impact

The regulatory landscape surrounding check valve coatings is complex and evolving. Stringent environmental regulations aim to minimize the release of hazardous substances, driving the adoption of eco-friendly coatings. Safety standards mandate the use of non-toxic, corrosion-resistant coatings in critical applications like food processing and pharmaceuticals. Additionally, industry-specific guidelines govern coating selection based on factors like temperature, pressure, and fluid compatibility. Compliance with these regulations is crucial for manufacturers to ensure product safety, environmental sustainability, and market access. Failure to adhere to these regulations can result in hefty fines, product recalls, and reputational damage. Staying abreast of regulatory changes and proactively adapting coating technologies is essential for maintaining a competitive edge in the check valve market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!