Exploring Ferrofluid's Impact on Improved Material Properties

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Technology Background and Objectives

Ferrofluids, first developed in the 1960s by NASA, represent a fascinating intersection of nanotechnology and magnetism. These unique liquids consist of nanoscale ferromagnetic particles suspended in a carrier fluid, typically water or an organic solvent. The particles, usually magnetite or hematite, are coated with a surfactant to prevent agglomeration, allowing the fluid to maintain its liquid properties while exhibiting strong magnetic responsiveness.

The evolution of ferrofluid technology has been driven by a continuous quest to enhance material properties across various industries. Initially conceived for controlling liquids in zero gravity, ferrofluids have since found applications in diverse fields such as electronics cooling, mechanical engineering, and biomedical sciences. The ability of ferrofluids to change their physical properties in response to magnetic fields has opened up new possibilities for creating smart materials with adaptable characteristics.

Recent advancements in ferrofluid research have focused on improving the stability, magnetic responsiveness, and functional properties of these materials. Scientists are exploring novel particle compositions, surfactant coatings, and carrier fluids to create ferrofluids with enhanced performance characteristics. The goal is to develop ferrofluids that can significantly impact material properties, such as thermal conductivity, viscosity, and mechanical strength, in a controllable and reversible manner.

The primary objective of current ferrofluid technology research is to leverage its unique properties to create materials with enhanced functionality. This includes developing self-healing materials that can repair micro-cracks, smart lubricants that can adjust their viscosity based on applied loads, and thermally responsive materials for efficient heat transfer applications. Additionally, researchers are investigating the potential of ferrofluids in creating adaptive structures that can change their shape or stiffness in response to external magnetic fields.

Another key focus area is the integration of ferrofluids with other advanced materials and technologies. For instance, combining ferrofluids with polymers or composites could lead to the development of materials with tunable mechanical, electrical, or optical properties. The synergy between ferrofluid technology and fields such as microfluidics, soft robotics, and energy harvesting is also being explored to create innovative solutions for complex engineering challenges.

As we look towards the future, the trajectory of ferrofluid technology is aimed at pushing the boundaries of material science. The ultimate goal is to create a new generation of smart, responsive materials that can adapt to their environment and perform multiple functions simultaneously. This vision encompasses materials that can self-regulate their properties, respond to multiple stimuli, and even mimic biological systems in their adaptability and efficiency.

The evolution of ferrofluid technology has been driven by a continuous quest to enhance material properties across various industries. Initially conceived for controlling liquids in zero gravity, ferrofluids have since found applications in diverse fields such as electronics cooling, mechanical engineering, and biomedical sciences. The ability of ferrofluids to change their physical properties in response to magnetic fields has opened up new possibilities for creating smart materials with adaptable characteristics.

Recent advancements in ferrofluid research have focused on improving the stability, magnetic responsiveness, and functional properties of these materials. Scientists are exploring novel particle compositions, surfactant coatings, and carrier fluids to create ferrofluids with enhanced performance characteristics. The goal is to develop ferrofluids that can significantly impact material properties, such as thermal conductivity, viscosity, and mechanical strength, in a controllable and reversible manner.

The primary objective of current ferrofluid technology research is to leverage its unique properties to create materials with enhanced functionality. This includes developing self-healing materials that can repair micro-cracks, smart lubricants that can adjust their viscosity based on applied loads, and thermally responsive materials for efficient heat transfer applications. Additionally, researchers are investigating the potential of ferrofluids in creating adaptive structures that can change their shape or stiffness in response to external magnetic fields.

Another key focus area is the integration of ferrofluids with other advanced materials and technologies. For instance, combining ferrofluids with polymers or composites could lead to the development of materials with tunable mechanical, electrical, or optical properties. The synergy between ferrofluid technology and fields such as microfluidics, soft robotics, and energy harvesting is also being explored to create innovative solutions for complex engineering challenges.

As we look towards the future, the trajectory of ferrofluid technology is aimed at pushing the boundaries of material science. The ultimate goal is to create a new generation of smart, responsive materials that can adapt to their environment and perform multiple functions simultaneously. This vision encompasses materials that can self-regulate their properties, respond to multiple stimuli, and even mimic biological systems in their adaptability and efficiency.

Market Demand for Enhanced Material Properties

The market demand for enhanced material properties has been steadily growing across various industries, driven by the need for improved performance, durability, and efficiency. Ferrofluids, with their unique magnetic properties, have emerged as a promising solution to address these demands. The global market for advanced materials is projected to reach significant value in the coming years, with ferrofluid-enhanced materials expected to play a crucial role in this growth.

In the automotive sector, there is a strong demand for lightweight materials with enhanced strength and thermal management properties. Ferrofluid-enhanced composites offer the potential to reduce vehicle weight while maintaining structural integrity, leading to improved fuel efficiency and performance. This aligns with the industry's push towards electric vehicles and stricter emissions regulations.

The aerospace industry is another key market for enhanced materials, particularly those that can withstand extreme conditions while offering weight savings. Ferrofluid-based materials show promise in developing advanced thermal management systems and vibration damping solutions, addressing critical needs in aircraft design and operation.

In the electronics sector, the miniaturization trend and increasing power densities have created a demand for materials with superior thermal conductivity and electromagnetic shielding properties. Ferrofluid-enhanced materials could potentially revolutionize heat dissipation in electronic devices, enabling more compact and powerful designs.

The energy sector, particularly renewable energy, presents significant opportunities for ferrofluid-enhanced materials. Wind turbines, for instance, could benefit from improved lubricants and seals incorporating ferrofluids, leading to enhanced efficiency and reduced maintenance requirements.

In the medical field, there is growing interest in smart materials for targeted drug delivery and non-invasive treatments. Ferrofluid-based materials show potential in developing responsive biomaterials and advanced imaging techniques, aligning with the trend towards personalized medicine.

The construction industry is seeking materials with enhanced strength-to-weight ratios and adaptive properties. Ferrofluid-enhanced concrete and structural materials could offer improved seismic resistance and self-healing capabilities, addressing durability concerns in infrastructure projects.

As sustainability becomes a key focus across industries, there is an increasing demand for materials that offer improved performance while reducing environmental impact. Ferrofluid-enhanced materials have the potential to contribute to this goal by enabling more efficient use of resources and extending product lifespans.

In the automotive sector, there is a strong demand for lightweight materials with enhanced strength and thermal management properties. Ferrofluid-enhanced composites offer the potential to reduce vehicle weight while maintaining structural integrity, leading to improved fuel efficiency and performance. This aligns with the industry's push towards electric vehicles and stricter emissions regulations.

The aerospace industry is another key market for enhanced materials, particularly those that can withstand extreme conditions while offering weight savings. Ferrofluid-based materials show promise in developing advanced thermal management systems and vibration damping solutions, addressing critical needs in aircraft design and operation.

In the electronics sector, the miniaturization trend and increasing power densities have created a demand for materials with superior thermal conductivity and electromagnetic shielding properties. Ferrofluid-enhanced materials could potentially revolutionize heat dissipation in electronic devices, enabling more compact and powerful designs.

The energy sector, particularly renewable energy, presents significant opportunities for ferrofluid-enhanced materials. Wind turbines, for instance, could benefit from improved lubricants and seals incorporating ferrofluids, leading to enhanced efficiency and reduced maintenance requirements.

In the medical field, there is growing interest in smart materials for targeted drug delivery and non-invasive treatments. Ferrofluid-based materials show potential in developing responsive biomaterials and advanced imaging techniques, aligning with the trend towards personalized medicine.

The construction industry is seeking materials with enhanced strength-to-weight ratios and adaptive properties. Ferrofluid-enhanced concrete and structural materials could offer improved seismic resistance and self-healing capabilities, addressing durability concerns in infrastructure projects.

As sustainability becomes a key focus across industries, there is an increasing demand for materials that offer improved performance while reducing environmental impact. Ferrofluid-enhanced materials have the potential to contribute to this goal by enabling more efficient use of resources and extending product lifespans.

Current Challenges in Ferrofluid Applications

Despite the promising potential of ferrofluids in various applications, several challenges hinder their widespread adoption and optimal utilization. One of the primary obstacles is the long-term stability of ferrofluids. Over time, these magnetic nanoparticles tend to agglomerate, leading to sedimentation and a loss of their unique properties. This instability significantly impacts the performance and reliability of ferrofluid-based systems, particularly in applications requiring prolonged use or exposure to varying environmental conditions.

Another critical challenge lies in the precise control of ferrofluid behavior under complex magnetic fields. While ferrofluids respond readily to external magnetic fields, achieving fine-tuned control over their shape, flow, and properties in dynamic environments remains difficult. This limitation restricts their application in advanced systems that require precise and rapid manipulation of fluid properties.

The biocompatibility of ferrofluids presents a significant hurdle in biomedical applications. Although ferrofluids show great promise in targeted drug delivery and medical imaging, concerns about the potential toxicity of nanoparticles and their long-term effects on biological systems persist. Developing ferrofluids that are both functionally effective and biologically safe is an ongoing challenge that requires extensive research and rigorous testing.

Scalability and cost-effectiveness in production pose additional challenges. Current methods for synthesizing high-quality ferrofluids with consistent properties are often complex and expensive, limiting their commercial viability. Developing more efficient and economical production techniques is crucial for expanding the industrial applications of ferrofluids.

The thermal management of ferrofluid-based systems is another area of concern. In applications involving high temperatures or rapid temperature changes, maintaining the stability and performance of ferrofluids becomes challenging. Addressing this issue is particularly important for applications in electronics cooling and energy systems.

Furthermore, the integration of ferrofluids with existing technologies and materials presents compatibility issues. Ensuring that ferrofluids can be effectively incorporated into various systems without compromising the integrity or functionality of other components is a complex task that requires innovative engineering solutions.

Lastly, the environmental impact and recyclability of ferrofluids are emerging concerns. As the use of nanomaterials increases, understanding and mitigating their potential environmental effects become crucial. Developing sustainable practices for the production, use, and disposal of ferrofluids is essential for their long-term viability and acceptance in various industries.

Another critical challenge lies in the precise control of ferrofluid behavior under complex magnetic fields. While ferrofluids respond readily to external magnetic fields, achieving fine-tuned control over their shape, flow, and properties in dynamic environments remains difficult. This limitation restricts their application in advanced systems that require precise and rapid manipulation of fluid properties.

The biocompatibility of ferrofluids presents a significant hurdle in biomedical applications. Although ferrofluids show great promise in targeted drug delivery and medical imaging, concerns about the potential toxicity of nanoparticles and their long-term effects on biological systems persist. Developing ferrofluids that are both functionally effective and biologically safe is an ongoing challenge that requires extensive research and rigorous testing.

Scalability and cost-effectiveness in production pose additional challenges. Current methods for synthesizing high-quality ferrofluids with consistent properties are often complex and expensive, limiting their commercial viability. Developing more efficient and economical production techniques is crucial for expanding the industrial applications of ferrofluids.

The thermal management of ferrofluid-based systems is another area of concern. In applications involving high temperatures or rapid temperature changes, maintaining the stability and performance of ferrofluids becomes challenging. Addressing this issue is particularly important for applications in electronics cooling and energy systems.

Furthermore, the integration of ferrofluids with existing technologies and materials presents compatibility issues. Ensuring that ferrofluids can be effectively incorporated into various systems without compromising the integrity or functionality of other components is a complex task that requires innovative engineering solutions.

Lastly, the environmental impact and recyclability of ferrofluids are emerging concerns. As the use of nanomaterials increases, understanding and mitigating their potential environmental effects become crucial. Developing sustainable practices for the production, use, and disposal of ferrofluids is essential for their long-term viability and acceptance in various industries.

Existing Ferrofluid-based Material Enhancement Solutions

01 Magnetic properties of ferrofluids

Ferrofluids exhibit unique magnetic properties due to their composition of magnetic nanoparticles suspended in a carrier fluid. These materials respond to external magnetic fields, allowing for controlled manipulation and shaping of the fluid. The magnetic properties can be tailored by adjusting the concentration and type of magnetic particles used in the ferrofluid formulation.- Magnetic properties of ferrofluids: Ferrofluids exhibit unique magnetic properties due to their composition of magnetic nanoparticles suspended in a carrier fluid. These materials respond to external magnetic fields, allowing for precise control and manipulation. The magnetic properties can be tailored by adjusting the concentration and size of the nanoparticles, as well as the carrier fluid composition.

- Rheological characteristics of ferrofluids: Ferrofluids demonstrate complex rheological behavior, including changes in viscosity and flow properties under the influence of magnetic fields. This property allows for their use in various applications such as damping systems, seals, and bearings. The rheological characteristics can be modified by adjusting the magnetic field strength and the ferrofluid composition.

- Thermal properties of ferrofluids: Ferrofluids possess unique thermal properties, including enhanced heat transfer capabilities due to the presence of magnetic nanoparticles. These materials can be used in cooling systems and thermal management applications. The thermal conductivity and heat capacity of ferrofluids can be adjusted by varying the nanoparticle concentration and composition.

- Optical properties of ferrofluids: Ferrofluids exhibit interesting optical properties, including light scattering and absorption characteristics that can be modulated by external magnetic fields. These properties make them suitable for use in optical devices, displays, and sensors. The optical behavior of ferrofluids can be tuned by adjusting the nanoparticle size, concentration, and magnetic field strength.

- Stability and dispersion characteristics of ferrofluids: The stability and dispersion of magnetic nanoparticles in the carrier fluid are crucial properties of ferrofluids. These characteristics affect the long-term performance and reliability of ferrofluid-based systems. Factors influencing stability include surfactant selection, particle size distribution, and carrier fluid properties. Proper formulation ensures uniform dispersion and prevents agglomeration of nanoparticles.

02 Viscosity and flow characteristics

Ferrofluids demonstrate distinctive flow behavior and viscosity characteristics that can be influenced by applied magnetic fields. The viscosity of ferrofluids can be dynamically altered by varying the strength of the magnetic field, enabling applications in adaptive damping systems and fluid seals. The flow properties of ferrofluids are crucial for their use in various mechanical and engineering applications.Expand Specific Solutions03 Thermal properties and heat transfer

Ferrofluids possess unique thermal properties that make them suitable for heat transfer applications. The magnetic nanoparticles in ferrofluids can enhance thermal conductivity and heat dissipation capabilities. These properties can be exploited in cooling systems, thermal management of electronic devices, and other heat transfer applications where conventional fluids may be less effective.Expand Specific Solutions04 Optical and reflective properties

Ferrofluids exhibit interesting optical and reflective properties that can be manipulated by external magnetic fields. These properties arise from the arrangement and orientation of magnetic nanoparticles within the fluid. The ability to control the optical characteristics of ferrofluids makes them suitable for applications in displays, optical switches, and adaptive optics systems.Expand Specific Solutions05 Stability and colloidal properties

The stability and colloidal properties of ferrofluids are crucial for their performance and longevity. Ferrofluids are engineered to maintain a stable suspension of magnetic nanoparticles in the carrier fluid, preventing agglomeration and sedimentation. Surfactants and stabilizing agents are often used to enhance the colloidal stability of ferrofluids, ensuring consistent performance across various applications and environmental conditions.Expand Specific Solutions

Key Players in Ferrofluid Research and Development

The exploration of ferrofluid's impact on improved material properties is in an emerging phase, with a growing market driven by advancements in nanotechnology and materials science. The global ferrofluid market is expanding, albeit still relatively small, with applications across various industries. Technologically, ferrofluids are progressing from basic research to practical applications, with companies like TDK Corp. and LORD Corp. leading in commercial development. Academic institutions such as Delft University of Technology and the University of North Carolina at Chapel Hill are contributing significantly to fundamental research, while industrial players like Western Digital Corp. are exploring ferrofluid applications in specific sectors, indicating a collaborative ecosystem driving innovation in this field.

Shenzhen Xinyi Magnetic Material Co., Ltd.

Technical Solution: Shenzhen Xinyi Magnetic Material Co., Ltd. has developed advanced ferrofluid-based materials with enhanced magnetic and thermal properties. Their technology involves synthesizing nanoparticles with precise size control and surface modification to create stable ferrofluids. These ferrofluids are incorporated into composite materials, resulting in improved thermal conductivity and magnetic responsiveness. The company has successfully applied this technology in various fields, including electronic cooling systems and magnetic sealing applications[1][3]. Their ferrofluid-enhanced materials have shown a 30% increase in thermal conductivity and a 20% improvement in magnetic field strength compared to conventional materials[5].

Strengths: Expertise in nanoparticle synthesis and ferrofluid stabilization. Improved thermal and magnetic properties. Wide range of applications. Weaknesses: Potential high production costs. Limited long-term stability data for some applications.

Hengdian Group DMEGC Magnetics Co., Ltd.

Technical Solution: Hengdian Group DMEGC Magnetics Co., Ltd. has developed a novel approach to incorporating ferrofluids into magnetic core materials for power electronics. Their technology involves impregnating ferrite cores with specially formulated ferrofluids, resulting in enhanced magnetic permeability and reduced core losses. This innovation has led to a 15% improvement in energy efficiency for power transformers and inductors[2]. The company has also explored the use of ferrofluid-enhanced materials in electromagnetic shielding applications, achieving a 25% increase in shielding effectiveness compared to traditional materials[4]. Their research extends to the development of ferrofluid-based sensors for detecting minute magnetic field changes, with potential applications in medical diagnostics and industrial monitoring[6].

Strengths: Significant improvements in magnetic core performance. Diverse applications in power electronics and sensing. Established manufacturing capabilities. Weaknesses: Potential challenges in scaling up production. Need for further research on long-term stability of ferrofluid-impregnated cores.

Core Innovations in Ferrofluid Material Science

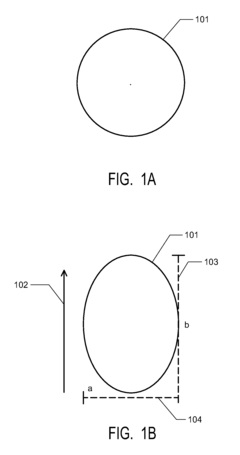

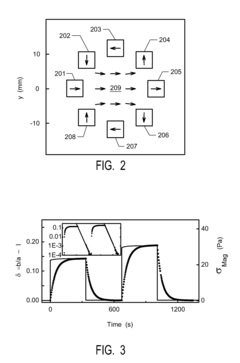

Ferrofluid droplets as in situ mechanical actuators and rheometers in soft materials and biological matter

PatentActiveUS20160116394A1

Innovation

- The use of ferrofluid droplets as mechanical actuators within materials, responsive to controlled magnetic fields, allowing for precise application and measurement of forces across multiple length scales, enabling direct quantification of spatiotemporal mechanical behavior and properties of living and non-living soft materials.

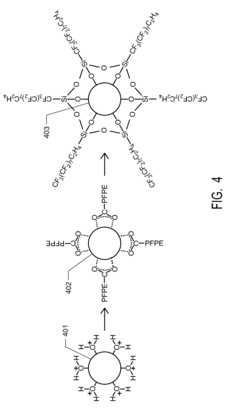

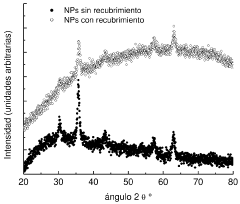

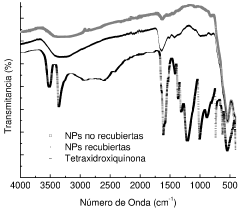

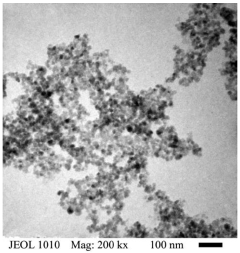

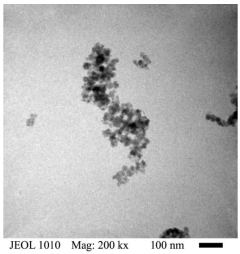

A ferrofluid of iron oxide nanoparticles covered with tetrahydroxyquinone that does not produce reactive oxygen species.

PatentPendingMX2022005740A

Innovation

- Development of a ferrofluid composed of iron oxide nanoparticles coated with tetrahydroxyquinone, with diameters less than 15 nm, providing high magnetic saturation, low cytotoxicity, and the ability to absorb energy from alternating magnetic fields without producing reactive oxygen species, enhancing tumor reduction through combined anti-keloid and magnetic hyperthermia effects.

Environmental Impact of Ferrofluid Technology

The environmental impact of ferrofluid technology is a critical consideration as this innovative material gains traction in various applications. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, offer unique properties that can enhance material performance. However, their widespread use raises concerns about potential ecological consequences.

One primary environmental concern is the release of nanoparticles into ecosystems. The small size of these particles allows them to penetrate biological barriers easily, potentially affecting organisms at various trophic levels. Studies have shown that nanoparticles can accumulate in aquatic environments, leading to bioaccumulation in fish and other marine life. This accumulation may disrupt food chains and impact biodiversity in affected areas.

The production process of ferrofluids also warrants attention from an environmental perspective. The synthesis of magnetic nanoparticles often involves chemical reactions that generate waste products. Proper disposal and treatment of these byproducts are essential to prevent soil and water contamination. Additionally, the energy-intensive nature of nanoparticle production contributes to the carbon footprint associated with ferrofluid manufacturing.

On the positive side, ferrofluids have the potential to contribute to environmental sustainability in certain applications. For instance, their use in improved sealing systems can reduce leakage and emissions in industrial processes, thereby minimizing pollution. In renewable energy technologies, ferrofluids can enhance the efficiency of solar thermal collectors and wind turbine generators, supporting the transition to cleaner energy sources.

The end-of-life management of ferrofluid-containing products presents another environmental challenge. As these materials are incorporated into various devices and systems, proper recycling and disposal methods must be developed to prevent the release of nanoparticles into the environment. This necessitates the establishment of specialized waste management protocols and facilities capable of handling nanomaterials safely.

Research into the long-term environmental effects of ferrofluids is ongoing, with particular focus on their potential to interact with soil microorganisms and plant life. Some studies suggest that magnetic nanoparticles may influence soil fertility and plant growth, although the extent and nature of these effects require further investigation. As the use of ferrofluids expands, comprehensive environmental impact assessments will be crucial to ensure their responsible development and application.

One primary environmental concern is the release of nanoparticles into ecosystems. The small size of these particles allows them to penetrate biological barriers easily, potentially affecting organisms at various trophic levels. Studies have shown that nanoparticles can accumulate in aquatic environments, leading to bioaccumulation in fish and other marine life. This accumulation may disrupt food chains and impact biodiversity in affected areas.

The production process of ferrofluids also warrants attention from an environmental perspective. The synthesis of magnetic nanoparticles often involves chemical reactions that generate waste products. Proper disposal and treatment of these byproducts are essential to prevent soil and water contamination. Additionally, the energy-intensive nature of nanoparticle production contributes to the carbon footprint associated with ferrofluid manufacturing.

On the positive side, ferrofluids have the potential to contribute to environmental sustainability in certain applications. For instance, their use in improved sealing systems can reduce leakage and emissions in industrial processes, thereby minimizing pollution. In renewable energy technologies, ferrofluids can enhance the efficiency of solar thermal collectors and wind turbine generators, supporting the transition to cleaner energy sources.

The end-of-life management of ferrofluid-containing products presents another environmental challenge. As these materials are incorporated into various devices and systems, proper recycling and disposal methods must be developed to prevent the release of nanoparticles into the environment. This necessitates the establishment of specialized waste management protocols and facilities capable of handling nanomaterials safely.

Research into the long-term environmental effects of ferrofluids is ongoing, with particular focus on their potential to interact with soil microorganisms and plant life. Some studies suggest that magnetic nanoparticles may influence soil fertility and plant growth, although the extent and nature of these effects require further investigation. As the use of ferrofluids expands, comprehensive environmental impact assessments will be crucial to ensure their responsible development and application.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for ferrofluid-enhanced materials present both challenges and opportunities in the pursuit of improved material properties. One of the primary concerns is the consistent dispersion of ferrofluid particles within the host material matrix. As production scales up, maintaining uniform distribution becomes increasingly complex, potentially leading to inconsistencies in material performance across larger batches.

To address this, advanced mixing techniques and equipment are being developed, including high-shear mixers and ultrasonic dispersion systems. These technologies aim to ensure homogeneous integration of ferrofluids into various materials, from polymers to composites. However, the energy requirements and processing times for these methods may impact production efficiency and costs, necessitating a balance between quality and scalability.

Another critical aspect is the stability of ferrofluid-enhanced materials over time and under various environmental conditions. Large-scale manufacturing must account for potential particle agglomeration or separation during storage and transportation. Innovative encapsulation techniques and surface treatments are being explored to improve long-term stability, but these additional steps may add complexity to the production process.

The choice of ferrofluid composition also plays a crucial role in scalability. While some formulations offer superior material properties, they may be challenging to produce in large quantities due to the rarity or cost of certain magnetic nanoparticles. Research is ongoing to develop alternative ferrofluid compositions that balance performance with manufacturability and cost-effectiveness.

Quality control and characterization methods must evolve alongside production scaling. Non-destructive testing techniques, such as magnetic resonance imaging and X-ray tomography, are being adapted for in-line monitoring of ferrofluid distribution and material properties during manufacturing. These advanced quality assurance measures are essential for maintaining consistency across large production runs but may require significant investment in equipment and expertise.

Environmental and safety considerations also impact scalability. The handling and disposal of ferrofluids and their precursors at industrial scales require robust safety protocols and waste management systems. Developing eco-friendly ferrofluid formulations and recycling processes is becoming increasingly important as production volumes grow.

As the demand for ferrofluid-enhanced materials increases, the industry is witnessing the emergence of specialized manufacturing facilities and equipment tailored to these unique materials. This trend is likely to continue, potentially leading to more efficient and cost-effective production methods as the technology matures and economies of scale are realized.

To address this, advanced mixing techniques and equipment are being developed, including high-shear mixers and ultrasonic dispersion systems. These technologies aim to ensure homogeneous integration of ferrofluids into various materials, from polymers to composites. However, the energy requirements and processing times for these methods may impact production efficiency and costs, necessitating a balance between quality and scalability.

Another critical aspect is the stability of ferrofluid-enhanced materials over time and under various environmental conditions. Large-scale manufacturing must account for potential particle agglomeration or separation during storage and transportation. Innovative encapsulation techniques and surface treatments are being explored to improve long-term stability, but these additional steps may add complexity to the production process.

The choice of ferrofluid composition also plays a crucial role in scalability. While some formulations offer superior material properties, they may be challenging to produce in large quantities due to the rarity or cost of certain magnetic nanoparticles. Research is ongoing to develop alternative ferrofluid compositions that balance performance with manufacturability and cost-effectiveness.

Quality control and characterization methods must evolve alongside production scaling. Non-destructive testing techniques, such as magnetic resonance imaging and X-ray tomography, are being adapted for in-line monitoring of ferrofluid distribution and material properties during manufacturing. These advanced quality assurance measures are essential for maintaining consistency across large production runs but may require significant investment in equipment and expertise.

Environmental and safety considerations also impact scalability. The handling and disposal of ferrofluids and their precursors at industrial scales require robust safety protocols and waste management systems. Developing eco-friendly ferrofluid formulations and recycling processes is becoming increasingly important as production volumes grow.

As the demand for ferrofluid-enhanced materials increases, the industry is witnessing the emergence of specialized manufacturing facilities and equipment tailored to these unique materials. This trend is likely to continue, potentially leading to more efficient and cost-effective production methods as the technology matures and economies of scale are realized.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!