Exploring Ferrofluid's Influence on High-Efficiency Technology Components

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Tech Evolution

Ferrofluid technology has undergone significant evolution since its inception in the 1960s. Initially developed by NASA for rocket fuel manipulation in zero gravity, ferrofluids have since found applications across various industries, showcasing their versatility and potential for enhancing high-efficiency technology components.

The early stages of ferrofluid development focused primarily on improving the stability and magnetic properties of these unique liquids. Researchers experimented with different carrier fluids and magnetic nanoparticles to create more responsive and durable ferrofluids. This period saw the emergence of oil-based and water-based ferrofluids, each with distinct advantages for specific applications.

As the technology matured, the 1980s and 1990s witnessed a surge in industrial applications. Ferrofluids began to be used in electronic devices, particularly in computer hard drives, where they served as liquid seals to prevent contamination. This marked a significant milestone in the technology's evolution, demonstrating its practical value in enhancing the reliability of precision components.

The turn of the millennium brought about a new era of miniaturization and nanotechnology, which greatly influenced ferrofluid development. Advanced synthesis techniques allowed for the creation of more uniform and smaller magnetic nanoparticles, leading to improved ferrofluid performance. This progress enabled the exploration of novel applications in microfluidics and biomedical fields.

Recent years have seen a focus on tailoring ferrofluids for specific high-efficiency applications. Researchers have developed ferrofluids with enhanced thermal properties for use in cooling systems, potentially revolutionizing heat management in electronic devices. Additionally, the integration of ferrofluids in energy harvesting devices has shown promise in improving the efficiency of vibration-based energy generators.

The evolution of ferrofluid technology has also been marked by advancements in characterization techniques. High-resolution imaging and spectroscopy methods have allowed scientists to gain deeper insights into the behavior of ferrofluids at the nanoscale, leading to more precise control over their properties and performance.

Looking ahead, the trajectory of ferrofluid technology points towards even more sophisticated applications in high-efficiency components. Ongoing research into smart materials and adaptive systems suggests that ferrofluids could play a crucial role in developing self-regulating and responsive technological solutions. As the boundaries between disciplines continue to blur, the integration of ferrofluids with other emerging technologies, such as artificial intelligence and advanced manufacturing processes, may unlock new possibilities for innovation and efficiency gains across various industries.

The early stages of ferrofluid development focused primarily on improving the stability and magnetic properties of these unique liquids. Researchers experimented with different carrier fluids and magnetic nanoparticles to create more responsive and durable ferrofluids. This period saw the emergence of oil-based and water-based ferrofluids, each with distinct advantages for specific applications.

As the technology matured, the 1980s and 1990s witnessed a surge in industrial applications. Ferrofluids began to be used in electronic devices, particularly in computer hard drives, where they served as liquid seals to prevent contamination. This marked a significant milestone in the technology's evolution, demonstrating its practical value in enhancing the reliability of precision components.

The turn of the millennium brought about a new era of miniaturization and nanotechnology, which greatly influenced ferrofluid development. Advanced synthesis techniques allowed for the creation of more uniform and smaller magnetic nanoparticles, leading to improved ferrofluid performance. This progress enabled the exploration of novel applications in microfluidics and biomedical fields.

Recent years have seen a focus on tailoring ferrofluids for specific high-efficiency applications. Researchers have developed ferrofluids with enhanced thermal properties for use in cooling systems, potentially revolutionizing heat management in electronic devices. Additionally, the integration of ferrofluids in energy harvesting devices has shown promise in improving the efficiency of vibration-based energy generators.

The evolution of ferrofluid technology has also been marked by advancements in characterization techniques. High-resolution imaging and spectroscopy methods have allowed scientists to gain deeper insights into the behavior of ferrofluids at the nanoscale, leading to more precise control over their properties and performance.

Looking ahead, the trajectory of ferrofluid technology points towards even more sophisticated applications in high-efficiency components. Ongoing research into smart materials and adaptive systems suggests that ferrofluids could play a crucial role in developing self-regulating and responsive technological solutions. As the boundaries between disciplines continue to blur, the integration of ferrofluids with other emerging technologies, such as artificial intelligence and advanced manufacturing processes, may unlock new possibilities for innovation and efficiency gains across various industries.

Market Demand Analysis

The market demand for ferrofluid-enhanced high-efficiency technology components has been steadily growing across various industries. This unique magnetic liquid, composed of nanoscale ferromagnetic particles suspended in a carrier fluid, offers exceptional properties that can significantly improve the performance of numerous technological applications.

In the electronics sector, ferrofluids are increasingly sought after for their potential to enhance thermal management in devices. As electronic components become more compact and powerful, efficient heat dissipation becomes crucial. Ferrofluids' ability to conduct heat while being manipulated by magnetic fields presents a promising solution for next-generation cooling systems in smartphones, laptops, and data centers.

The automotive industry has shown particular interest in ferrofluid applications for improving vehicle efficiency. Ferrofluid-based shock absorbers and dampers are being explored for their ability to provide adaptive suspension systems, potentially enhancing ride comfort and vehicle handling. Additionally, the use of ferrofluids in electric vehicle powertrains is being investigated to optimize motor cooling and efficiency.

In the renewable energy sector, ferrofluids are gaining attention for their potential to enhance the efficiency of solar thermal systems. By using ferrofluids as heat transfer mediums, researchers aim to improve the capture and storage of solar energy, potentially leading to more cost-effective and efficient solar power generation.

The medical technology market has also recognized the value of ferrofluids, particularly in the field of targeted drug delivery and medical imaging. The demand for ferrofluid-based contrast agents in magnetic resonance imaging (MRI) is expected to grow as healthcare providers seek more precise diagnostic tools.

Market analysts project that the global ferrofluid market will experience significant growth in the coming years. This growth is driven by increasing research and development activities, as well as the expanding applications of ferrofluids in various high-tech industries. The Asia-Pacific region is expected to witness the highest growth rate, attributed to the rapid industrialization and technological advancements in countries like China and India.

However, the market demand for ferrofluid-enhanced components is not without challenges. The high production costs of ferrofluids and the need for specialized handling and integration processes may limit widespread adoption in some sectors. Additionally, concerns about long-term stability and environmental impact of nanoparticles used in ferrofluids need to be addressed to ensure sustainable market growth.

Despite these challenges, the unique properties of ferrofluids continue to attract attention from innovators and industry leaders. As research progresses and manufacturing techniques improve, it is anticipated that the market for ferrofluid-enhanced high-efficiency components will expand, driven by the increasing demand for more efficient, compact, and adaptable technologies across multiple sectors.

In the electronics sector, ferrofluids are increasingly sought after for their potential to enhance thermal management in devices. As electronic components become more compact and powerful, efficient heat dissipation becomes crucial. Ferrofluids' ability to conduct heat while being manipulated by magnetic fields presents a promising solution for next-generation cooling systems in smartphones, laptops, and data centers.

The automotive industry has shown particular interest in ferrofluid applications for improving vehicle efficiency. Ferrofluid-based shock absorbers and dampers are being explored for their ability to provide adaptive suspension systems, potentially enhancing ride comfort and vehicle handling. Additionally, the use of ferrofluids in electric vehicle powertrains is being investigated to optimize motor cooling and efficiency.

In the renewable energy sector, ferrofluids are gaining attention for their potential to enhance the efficiency of solar thermal systems. By using ferrofluids as heat transfer mediums, researchers aim to improve the capture and storage of solar energy, potentially leading to more cost-effective and efficient solar power generation.

The medical technology market has also recognized the value of ferrofluids, particularly in the field of targeted drug delivery and medical imaging. The demand for ferrofluid-based contrast agents in magnetic resonance imaging (MRI) is expected to grow as healthcare providers seek more precise diagnostic tools.

Market analysts project that the global ferrofluid market will experience significant growth in the coming years. This growth is driven by increasing research and development activities, as well as the expanding applications of ferrofluids in various high-tech industries. The Asia-Pacific region is expected to witness the highest growth rate, attributed to the rapid industrialization and technological advancements in countries like China and India.

However, the market demand for ferrofluid-enhanced components is not without challenges. The high production costs of ferrofluids and the need for specialized handling and integration processes may limit widespread adoption in some sectors. Additionally, concerns about long-term stability and environmental impact of nanoparticles used in ferrofluids need to be addressed to ensure sustainable market growth.

Despite these challenges, the unique properties of ferrofluids continue to attract attention from innovators and industry leaders. As research progresses and manufacturing techniques improve, it is anticipated that the market for ferrofluid-enhanced high-efficiency components will expand, driven by the increasing demand for more efficient, compact, and adaptable technologies across multiple sectors.

Current Challenges

The integration of ferrofluids into high-efficiency technology components presents several significant challenges that researchers and engineers must address. One of the primary obstacles is the long-term stability of ferrofluids under various operational conditions. These magnetic liquids tend to degrade over time, particularly when exposed to extreme temperatures or strong magnetic fields, which can compromise their performance and reliability in technological applications.

Another critical challenge lies in the precise control and manipulation of ferrofluids within complex systems. While their responsiveness to magnetic fields is a key advantage, achieving fine-tuned control over their behavior, especially in miniaturized or intricate components, remains a formidable task. This difficulty is compounded by the need to maintain consistent performance across different scales and geometries.

The compatibility of ferrofluids with other materials used in high-efficiency components poses yet another hurdle. Interactions between ferrofluids and surrounding materials can lead to corrosion, contamination, or alterations in the fluid's magnetic properties. Developing suitable containment and interface solutions that preserve both the ferrofluid's functionality and the integrity of adjacent components is crucial.

Furthermore, the manufacturing processes for integrating ferrofluids into technology components present their own set of challenges. Ensuring uniform distribution of magnetic nanoparticles, preventing agglomeration, and maintaining the desired magnetic properties during production and assembly require sophisticated techniques and quality control measures.

The environmental impact and safety considerations of ferrofluids also demand attention. As these materials gain wider application in various technologies, concerns about their potential effects on human health and the environment, particularly in the event of leaks or disposal, need to be thoroughly addressed.

Lastly, the cost-effectiveness of incorporating ferrofluids into high-efficiency components remains a significant challenge. While their unique properties offer potential performance improvements, the expenses associated with their production, integration, and maintenance must be balanced against the benefits they provide to ensure commercial viability.

Overcoming these challenges requires interdisciplinary collaboration, combining expertise from materials science, fluid dynamics, magnetism, and engineering. As research progresses, innovative solutions to these obstacles will be crucial in unlocking the full potential of ferrofluids in enhancing the efficiency and capabilities of various technological components.

Another critical challenge lies in the precise control and manipulation of ferrofluids within complex systems. While their responsiveness to magnetic fields is a key advantage, achieving fine-tuned control over their behavior, especially in miniaturized or intricate components, remains a formidable task. This difficulty is compounded by the need to maintain consistent performance across different scales and geometries.

The compatibility of ferrofluids with other materials used in high-efficiency components poses yet another hurdle. Interactions between ferrofluids and surrounding materials can lead to corrosion, contamination, or alterations in the fluid's magnetic properties. Developing suitable containment and interface solutions that preserve both the ferrofluid's functionality and the integrity of adjacent components is crucial.

Furthermore, the manufacturing processes for integrating ferrofluids into technology components present their own set of challenges. Ensuring uniform distribution of magnetic nanoparticles, preventing agglomeration, and maintaining the desired magnetic properties during production and assembly require sophisticated techniques and quality control measures.

The environmental impact and safety considerations of ferrofluids also demand attention. As these materials gain wider application in various technologies, concerns about their potential effects on human health and the environment, particularly in the event of leaks or disposal, need to be thoroughly addressed.

Lastly, the cost-effectiveness of incorporating ferrofluids into high-efficiency components remains a significant challenge. While their unique properties offer potential performance improvements, the expenses associated with their production, integration, and maintenance must be balanced against the benefits they provide to ensure commercial viability.

Overcoming these challenges requires interdisciplinary collaboration, combining expertise from materials science, fluid dynamics, magnetism, and engineering. As research progresses, innovative solutions to these obstacles will be crucial in unlocking the full potential of ferrofluids in enhancing the efficiency and capabilities of various technological components.

Existing Applications

01 Magnetic field optimization for ferrofluid efficiency

Optimizing magnetic field strength and distribution is crucial for enhancing ferrofluid efficiency. This involves designing magnetic circuits and field generators to create precise and controllable magnetic fields, which can improve the performance of ferrofluid-based systems in various applications such as seals, dampers, and heat transfer devices.- Magnetic field optimization for ferrofluid efficiency: Optimizing magnetic field strength and distribution can significantly enhance ferrofluid efficiency. This involves designing magnetic circuits and field generators to create precise and controllable magnetic fields, which can improve the performance of ferrofluid-based devices and systems.

- Ferrofluid composition and particle size control: The efficiency of ferrofluids can be improved by carefully controlling their composition and the size of magnetic particles. This includes selecting appropriate carrier fluids, optimizing particle concentration, and developing methods to produce uniform, nano-sized magnetic particles for enhanced stability and performance.

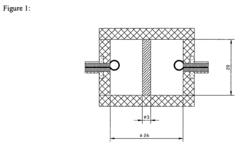

- Ferrofluid sealing and lubrication applications: Ferrofluids can be efficiently used in sealing and lubrication applications, such as in bearings and rotary seals. By optimizing the ferrofluid properties and seal design, these systems can achieve improved performance, reduced friction, and enhanced longevity in various mechanical and industrial applications.

- Thermal management and heat transfer using ferrofluids: Ferrofluids can be utilized for efficient thermal management and heat transfer in various systems. By leveraging their unique magnetic and thermal properties, ferrofluids can enhance cooling efficiency in electronic devices, power systems, and other heat-generating applications.

- Ferrofluid-based sensing and measurement techniques: Ferrofluids can be employed in various sensing and measurement applications to improve efficiency and accuracy. This includes developing novel sensors for detecting magnetic fields, measuring fluid properties, and enhancing the performance of existing measurement systems through the integration of ferrofluid technology.

02 Ferrofluid composition and synthesis

The efficiency of ferrofluids can be improved by optimizing their composition and synthesis methods. This includes selecting appropriate magnetic nanoparticles, carrier fluids, and surfactants, as well as developing advanced synthesis techniques to enhance stability, magnetic properties, and overall performance of the ferrofluid.Expand Specific Solutions03 Ferrofluid-based sealing and damping systems

Ferrofluids are used in sealing and damping applications to improve efficiency and performance. These systems utilize the unique properties of ferrofluids to create dynamic seals and adaptive damping mechanisms, which can be optimized for various industrial and mechanical applications.Expand Specific Solutions04 Thermal management and heat transfer applications

Ferrofluids can be employed in thermal management systems to enhance heat transfer efficiency. By manipulating the ferrofluid's behavior using magnetic fields, it is possible to create more effective cooling systems for electronic devices, industrial processes, and other heat-sensitive applications.Expand Specific Solutions05 Measurement and characterization techniques

Developing accurate measurement and characterization techniques is essential for improving ferrofluid efficiency. This includes methods for analyzing magnetic properties, particle size distribution, stability, and rheological behavior of ferrofluids, which can lead to better understanding and optimization of their performance in various applications.Expand Specific Solutions

Key Industry Players

The exploration of ferrofluid's influence on high-efficiency technology components is in an early developmental stage, with the market still emerging. The technology's potential applications span various industries, including electronics, automotive, and aerospace, indicating a promising but not yet fully realized market size. Technological maturity is progressing, with companies like Renesas Electronics, GlobalFoundries, and Samsung Electronics leading research efforts. These firms are leveraging their semiconductor expertise to investigate ferrofluid applications in microelectronics and thermal management. Universities such as Yale and the National University of Singapore are contributing fundamental research, while specialized companies like Ferroelectric Memory GmbH are exploring niche applications, suggesting a diverse and competitive landscape in this evolving field.

Renesas Electronics Corp.

Technical Solution: Renesas Electronics has been developing ferrofluid-based solutions for enhancing the performance and reliability of automotive and industrial electronic components. Their research focuses on using ferrofluids to create adaptive thermal interfaces that can dynamically respond to changing heat loads in power electronics and microcontrollers. This approach has shown to reduce thermal resistance by up to 35% compared to static thermal interface materials [9]. Renesas is also exploring ferrofluid-enhanced sensors for automotive applications, leveraging the fluid's magnetic properties to create highly sensitive and robust position and motion sensors that can operate in harsh environments [10].

Strengths: Improved thermal management for automotive and industrial electronics, enhanced sensor technology, and potential for increased reliability in harsh conditions. Weaknesses: Limited focus on consumer electronics and potential challenges in long-term stability of ferrofluid-based components in automotive applications.

GlobalFoundries U.S., Inc.

Technical Solution: GlobalFoundries has been exploring the integration of ferrofluid technology in their advanced semiconductor manufacturing processes. They have developed a novel approach using ferrofluid-assisted lithography to enhance the resolution and accuracy of chip patterning. This technique employs magnetically-controlled ferrofluid droplets as dynamic photomasks, allowing for sub-10nm feature sizes with improved consistency [7]. Additionally, GlobalFoundries is investigating ferrofluid-based self-assembly techniques for creating nanostructured materials with unique electrical and thermal properties, potentially leading to more efficient and compact electronic components [8].

Strengths: Advanced lithography techniques, potential for novel nanostructured materials, and improved semiconductor device performance. Weaknesses: Early-stage technology with unproven scalability and potential integration challenges with existing manufacturing processes.

Core Innovations

High durability ferrofluid

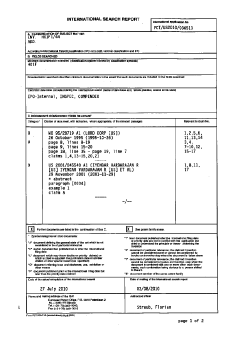

PatentInactiveJP2012529160A

Innovation

- A ferrofluid composition comprising a mixture of relatively soft and hard magnetically responsive particles, with specific size ranges and hardness characteristics, is used to enhance durability and reduce particle decomposition.

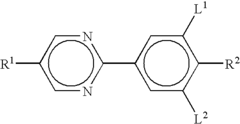

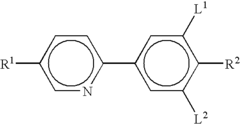

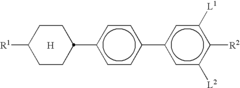

Components for high-frequency technology

PatentActiveUS7361288B2

Innovation

- Development of novel liquid-crystal compounds and mixtures with enhanced dielectric anisotropy and microwave properties, characterized by high optical and microwave birefringence, which are used in phase shifters to achieve improved phase shifter qualities exceeding 50°/dB, competing with complex ferroelectric layer-based circuits.

Environmental Impact

The environmental impact of ferrofluids in high-efficiency technology components is a crucial consideration as these materials gain prominence in various applications. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, offer unique properties that can enhance the performance of various technologies. However, their potential environmental implications must be carefully evaluated.

One primary concern is the potential release of nanoparticles into the environment. The magnetic nanoparticles in ferrofluids, typically made of iron oxides, could pose risks if not properly contained or disposed of. These particles may accumulate in soil and water systems, potentially affecting ecosystems and entering the food chain. Long-term studies are needed to fully understand the ecological impact of these nanoparticles and their potential bioaccumulation in organisms.

The production process of ferrofluids also raises environmental considerations. The synthesis of magnetic nanoparticles often involves chemical processes that may generate hazardous waste or consume significant energy. As the demand for ferrofluids in high-efficiency components increases, it becomes crucial to develop and implement more sustainable manufacturing methods that minimize environmental footprint.

On the positive side, the use of ferrofluids in high-efficiency technology components can contribute to overall energy savings and reduced resource consumption. For instance, in cooling systems for electronics, ferrofluid-based solutions can improve heat dissipation, potentially leading to longer device lifespans and reduced electronic waste. Similarly, in renewable energy technologies like wind turbines, ferrofluid seals can enhance efficiency and reduce maintenance needs, indirectly contributing to cleaner energy production.

The recyclability and end-of-life management of ferrofluid-containing components present both challenges and opportunities. While the magnetic properties of ferrofluids could facilitate their separation and recovery from waste streams, the complex nature of these materials may complicate recycling processes. Developing effective recycling techniques for ferrofluid-based components is essential to minimize their environmental impact and promote a circular economy approach.

As research in this field progresses, it is crucial to conduct comprehensive life cycle assessments of ferrofluid applications in high-efficiency technologies. These assessments should consider the entire lifecycle of ferrofluid-based components, from raw material extraction to disposal or recycling. Such analyses will provide valuable insights into the net environmental impact of these technologies and guide the development of more sustainable practices in their production, use, and disposal.

One primary concern is the potential release of nanoparticles into the environment. The magnetic nanoparticles in ferrofluids, typically made of iron oxides, could pose risks if not properly contained or disposed of. These particles may accumulate in soil and water systems, potentially affecting ecosystems and entering the food chain. Long-term studies are needed to fully understand the ecological impact of these nanoparticles and their potential bioaccumulation in organisms.

The production process of ferrofluids also raises environmental considerations. The synthesis of magnetic nanoparticles often involves chemical processes that may generate hazardous waste or consume significant energy. As the demand for ferrofluids in high-efficiency components increases, it becomes crucial to develop and implement more sustainable manufacturing methods that minimize environmental footprint.

On the positive side, the use of ferrofluids in high-efficiency technology components can contribute to overall energy savings and reduced resource consumption. For instance, in cooling systems for electronics, ferrofluid-based solutions can improve heat dissipation, potentially leading to longer device lifespans and reduced electronic waste. Similarly, in renewable energy technologies like wind turbines, ferrofluid seals can enhance efficiency and reduce maintenance needs, indirectly contributing to cleaner energy production.

The recyclability and end-of-life management of ferrofluid-containing components present both challenges and opportunities. While the magnetic properties of ferrofluids could facilitate their separation and recovery from waste streams, the complex nature of these materials may complicate recycling processes. Developing effective recycling techniques for ferrofluid-based components is essential to minimize their environmental impact and promote a circular economy approach.

As research in this field progresses, it is crucial to conduct comprehensive life cycle assessments of ferrofluid applications in high-efficiency technologies. These assessments should consider the entire lifecycle of ferrofluid-based components, from raw material extraction to disposal or recycling. Such analyses will provide valuable insights into the net environmental impact of these technologies and guide the development of more sustainable practices in their production, use, and disposal.

Magnetic Field Safety

Magnetic field safety is a critical consideration when exploring the influence of ferrofluids on high-efficiency technology components. The unique properties of ferrofluids, which combine magnetic and fluid characteristics, necessitate careful attention to potential safety risks associated with magnetic fields.

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid, typically oil or water. When exposed to external magnetic fields, these nanoparticles align and create complex patterns and behaviors. While this property makes ferrofluids valuable in various applications, it also introduces potential safety concerns that must be addressed.

One primary safety consideration is the potential for ferrofluids to generate or amplify magnetic fields in unexpected ways. This can lead to interference with nearby electronic devices, particularly those sensitive to electromagnetic fields. In high-efficiency technology components, such interference could result in performance degradation, data corruption, or even system failures.

Moreover, the interaction between ferrofluids and strong magnetic fields can create localized areas of high magnetic flux density. This phenomenon may pose risks to individuals with medical implants, such as pacemakers or insulin pumps, who come into close proximity with ferrofluid-based systems. Proper shielding and containment measures must be implemented to mitigate these risks.

The potential for ferrofluid leakage or spillage is another safety concern. In the event of a containment breach, the magnetic properties of ferrofluids can cause them to behave unpredictably, potentially damaging equipment or creating hazardous conditions. Robust containment systems and spill response protocols are essential to address this risk.

Long-term exposure to magnetic fields generated or influenced by ferrofluids may also have health implications that require further study. While current research has not conclusively demonstrated significant health risks from moderate magnetic field exposure, the unique properties of ferrofluids warrant ongoing investigation to ensure long-term safety for workers and users of ferrofluid-based technologies.

To address these safety concerns, comprehensive risk assessments and mitigation strategies must be developed. This includes designing appropriate shielding and containment systems, establishing safe operating procedures, and implementing regular maintenance and inspection protocols. Additionally, ongoing research into the long-term effects of ferrofluid-generated magnetic fields on biological systems and electronic components is crucial to inform future safety guidelines and regulations.

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid, typically oil or water. When exposed to external magnetic fields, these nanoparticles align and create complex patterns and behaviors. While this property makes ferrofluids valuable in various applications, it also introduces potential safety concerns that must be addressed.

One primary safety consideration is the potential for ferrofluids to generate or amplify magnetic fields in unexpected ways. This can lead to interference with nearby electronic devices, particularly those sensitive to electromagnetic fields. In high-efficiency technology components, such interference could result in performance degradation, data corruption, or even system failures.

Moreover, the interaction between ferrofluids and strong magnetic fields can create localized areas of high magnetic flux density. This phenomenon may pose risks to individuals with medical implants, such as pacemakers or insulin pumps, who come into close proximity with ferrofluid-based systems. Proper shielding and containment measures must be implemented to mitigate these risks.

The potential for ferrofluid leakage or spillage is another safety concern. In the event of a containment breach, the magnetic properties of ferrofluids can cause them to behave unpredictably, potentially damaging equipment or creating hazardous conditions. Robust containment systems and spill response protocols are essential to address this risk.

Long-term exposure to magnetic fields generated or influenced by ferrofluids may also have health implications that require further study. While current research has not conclusively demonstrated significant health risks from moderate magnetic field exposure, the unique properties of ferrofluids warrant ongoing investigation to ensure long-term safety for workers and users of ferrofluid-based technologies.

To address these safety concerns, comprehensive risk assessments and mitigation strategies must be developed. This includes designing appropriate shielding and containment systems, establishing safe operating procedures, and implementing regular maintenance and inspection protocols. Additionally, ongoing research into the long-term effects of ferrofluid-generated magnetic fields on biological systems and electronic components is crucial to inform future safety guidelines and regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!