How to Harness Ferrofluid for Efficient Industrial Processes?

Ferrofluid Technology Evolution and Objectives

Ferrofluid technology has undergone significant evolution since its inception in the 1960s. Initially developed by NASA for rocket fuel management in zero gravity, ferrofluids have since found applications across various industries. The technology's progression has been marked by advancements in synthesis methods, particle size control, and stability enhancement.

Early ferrofluids faced challenges with long-term stability and limited magnetic responsiveness. However, continuous research has led to the development of more stable and responsive formulations. The introduction of surfactant coatings and improved dispersion techniques has greatly enhanced the colloidal stability of ferrofluids, extending their shelf life and expanding potential applications.

The evolution of ferrofluid technology has been closely tied to advancements in nanotechnology. As manufacturing processes for nanoparticles have improved, so too has the quality and performance of ferrofluids. Modern ferrofluids can be tailored with precise magnetic properties, viscosity, and thermal characteristics to suit specific industrial needs.

One of the key objectives in ferrofluid technology development has been to harness its unique properties for efficient industrial processes. This includes leveraging its magnetic responsiveness for precision control in various applications, such as sealing, damping, and heat transfer. The ability of ferrofluids to change viscosity in response to magnetic fields has opened up possibilities for adaptive fluid systems in manufacturing and automation.

Another important goal has been to expand the range of base fluids compatible with magnetic nanoparticles. This has led to the creation of oil-based, water-based, and even specialized ferrofluids for extreme environments. Such versatility has enabled the technology to penetrate diverse industrial sectors, from electronics cooling to biomedical applications.

The ongoing evolution of ferrofluid technology aims to address several key objectives. These include improving the magnetic saturation of ferrofluids to enhance their responsiveness, developing environmentally friendly and biocompatible formulations, and scaling up production processes for industrial-scale applications. Additionally, there is a focus on integrating ferrofluids with other emerging technologies, such as microfluidics and smart materials, to create novel hybrid systems.

As industrial processes increasingly demand precision, efficiency, and adaptability, the objectives for ferrofluid technology continue to evolve. Current research is exploring ways to fine-tune the rheological properties of ferrofluids, enhance their thermal conductivity, and improve their long-term stability under various operating conditions. These advancements are crucial for realizing the full potential of ferrofluids in efficient industrial processes across a wide range of applications.

Industrial Demand for Ferrofluid Applications

The industrial demand for ferrofluid applications has been steadily growing across various sectors due to its unique properties and versatile nature. Ferrofluids, which are colloidal liquids containing magnetic nanoparticles suspended in a carrier fluid, offer a range of potential applications in industrial processes. The market for ferrofluid-based technologies is driven by the increasing need for efficient and innovative solutions in manufacturing, energy, and environmental sectors.

In the manufacturing industry, ferrofluids are gaining traction in precision engineering and machining processes. They are used in damping systems for high-precision equipment, such as computer-controlled cutting machines and optical devices, where vibration control is crucial. The automotive sector has shown particular interest in ferrofluid-based shock absorbers and sealing systems, which can enhance vehicle performance and durability.

The energy sector presents significant opportunities for ferrofluid applications, especially in renewable energy technologies. Wind turbines, for instance, can benefit from ferrofluid-based cooling systems and seals, improving efficiency and reducing maintenance requirements. In solar energy, ferrofluids are being explored for heat transfer applications in concentrated solar power systems, potentially increasing energy conversion rates.

Environmental applications of ferrofluids are also on the rise, particularly in wastewater treatment and oil spill cleanup operations. The magnetic properties of ferrofluids allow for efficient separation of contaminants from water, offering a more effective and environmentally friendly alternative to traditional methods. This has led to increased demand from municipal water treatment facilities and industrial wastewater management systems.

The electronics industry has shown growing interest in ferrofluid technology for thermal management solutions. As electronic devices become more compact and powerful, the need for efficient cooling systems becomes critical. Ferrofluid-based cooling systems offer the potential for improved heat dissipation in high-performance computing and telecommunications equipment.

In the biomedical field, there is an emerging demand for ferrofluids in targeted drug delivery systems and medical imaging technologies. While still in the research and development phase, these applications show promise for revolutionizing certain medical procedures and treatments, driving investment in ferrofluid technology from pharmaceutical and medical device companies.

The global market for ferrofluid applications is expected to expand as industries seek more efficient and sustainable processes. However, challenges such as the high cost of production and the need for specialized handling and storage facilities currently limit widespread adoption. As research progresses and manufacturing techniques improve, it is anticipated that these barriers will be reduced, leading to broader industrial implementation of ferrofluid-based solutions.

Ferrofluid Properties and Current Limitations

Ferrofluids are unique colloidal suspensions of magnetic nanoparticles in a carrier fluid, typically oil or water. These nanoparticles, usually made of magnetite or hematite, are coated with surfactants to prevent agglomeration. The most striking property of ferrofluids is their ability to become strongly magnetized in the presence of a magnetic field while retaining their liquid characteristics.

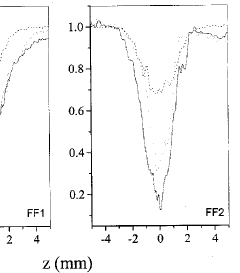

One of the key properties of ferrofluids is their high magnetic permeability, which allows them to be precisely controlled and manipulated using external magnetic fields. This property makes them valuable in various industrial applications, such as sealing, damping, and heat transfer. Ferrofluids also exhibit excellent thermal conductivity, making them useful in cooling systems for electronic devices and industrial machinery.

However, despite their unique properties, ferrofluids face several limitations that hinder their widespread adoption in industrial processes. One significant challenge is the long-term stability of the colloidal suspension. Over time, the magnetic nanoparticles tend to agglomerate, leading to a loss of the fluid's magnetic properties and overall performance degradation. This instability is particularly problematic in high-temperature or high-stress environments, limiting the use of ferrofluids in certain industrial applications.

Another limitation is the relatively low saturation magnetization of current ferrofluids. While they respond well to magnetic fields, the maximum magnetic strength they can achieve is limited by the concentration of magnetic particles that can be suspended in the carrier fluid without compromising its stability. This constraint restricts the force and precision with which ferrofluids can be manipulated in industrial processes.

The viscosity of ferrofluids also presents challenges in some applications. While their ability to change viscosity in response to magnetic fields is advantageous in certain scenarios, it can be a limitation in others where consistent flow properties are required. Additionally, the change in viscosity under strong magnetic fields can lead to increased power consumption in pumping and flow control systems.

Ferrofluids are also sensitive to oxidation, particularly those based on iron oxide nanoparticles. This susceptibility to oxidation can lead to degradation of the fluid's properties over time, especially in environments with high oxygen content or elevated temperatures. This limitation necessitates careful handling and storage procedures, which can increase operational costs in industrial settings.

Lastly, the cost of producing high-quality ferrofluids remains a significant barrier to their widespread industrial adoption. The process of synthesizing stable, uniform magnetic nanoparticles and dispersing them effectively in a carrier fluid is complex and expensive. This high production cost makes ferrofluids less economically viable for large-scale industrial processes compared to conventional fluids.

Current Ferrofluid Industrial Solutions

01 Ferrofluid seal design and optimization

Improving the efficiency of ferrofluid seals through optimized design and configuration. This includes enhancing the magnetic field distribution, selecting appropriate ferrofluid compositions, and optimizing seal geometry to minimize leakage and maximize sealing performance in various applications such as rotary shafts and bearings.- Ferrofluid sealing systems: Ferrofluid seals are used to improve efficiency in various mechanical systems. These seals utilize the unique properties of ferrofluids to create a barrier that prevents leakage while reducing friction. The sealing systems can be applied in rotating shafts, bearings, and other moving parts to enhance overall system performance and longevity.

- Ferrofluid-based heat transfer systems: Ferrofluids are employed in heat transfer applications to improve thermal management efficiency. These systems utilize the magnetic properties of ferrofluids to enhance heat dissipation in electronic devices, cooling systems, and thermal management solutions. The controlled movement of ferrofluids under magnetic fields allows for more effective heat transfer and temperature regulation.

- Ferrofluid-enhanced bearings and lubricants: Ferrofluids are used to improve the efficiency of bearings and lubrication systems. By incorporating ferrofluids into these components, friction can be reduced, and load-bearing capacity can be increased. This results in improved performance, reduced wear, and extended lifespan of mechanical systems utilizing ferrofluid-enhanced bearings and lubricants.

- Ferrofluid-based sensors and measurement devices: Ferrofluids are utilized in various sensing and measurement applications to improve efficiency and accuracy. These devices leverage the magnetic properties of ferrofluids to detect changes in position, orientation, or other physical parameters. Examples include accelerometers, gyroscopes, and liquid level sensors that offer enhanced sensitivity and reliability compared to conventional alternatives.

- Ferrofluid-enhanced energy harvesting systems: Ferrofluids are employed in energy harvesting applications to improve the efficiency of power generation from various sources. These systems utilize the unique properties of ferrofluids to enhance the conversion of mechanical energy, vibrations, or thermal gradients into electrical energy. The incorporation of ferrofluids can lead to increased power output and improved overall system performance in energy harvesting devices.

02 Thermal management using ferrofluids

Utilizing ferrofluids for efficient heat transfer and thermal management in various systems. This involves designing cooling systems that leverage the unique properties of ferrofluids to enhance heat dissipation, improve temperature control, and increase overall system efficiency in applications such as electronics cooling and energy conversion devices.Expand Specific Solutions03 Ferrofluid-based energy harvesting and conversion

Developing efficient energy harvesting and conversion systems using ferrofluids. This includes designing generators, actuators, and other devices that exploit the magnetic and fluid properties of ferrofluids to convert mechanical energy into electrical energy or vice versa, improving overall energy efficiency in various applications.Expand Specific Solutions04 Ferrofluid-enhanced lubrication systems

Improving the efficiency of lubrication systems by incorporating ferrofluids. This involves developing novel lubricant formulations and delivery mechanisms that utilize the magnetic properties of ferrofluids to enhance lubricant retention, reduce friction, and improve wear resistance in mechanical systems such as bearings and gears.Expand Specific Solutions05 Ferrofluid-based measurement and sensing techniques

Enhancing the efficiency and accuracy of measurement and sensing systems using ferrofluids. This includes developing novel sensors and measurement devices that leverage the unique properties of ferrofluids to improve sensitivity, response time, and reliability in applications such as accelerometers, gyroscopes, and fluid level sensors.Expand Specific Solutions

Key Ferrofluid Industry Players

The ferrofluid industry is in a growth phase, with increasing applications across various sectors driving market expansion. The global ferrofluid market size is projected to reach significant value in the coming years, fueled by advancements in nanotechnology and growing demand in electronics, medical, and mechanical engineering fields. While the technology is maturing, there's still room for innovation and efficiency improvements. Key players like Ferrotec GmbH and Hengdian Group DMEGC Magnetics Co., Ltd. are at the forefront, developing advanced ferrofluid solutions. Research institutions such as Delft University of Technology and University of Malaya are contributing to technological advancements, while companies like TotalEnergies OneTech SAS and Air Liquide SA are exploring industrial applications, indicating a competitive and diverse landscape in ferrofluid technology.

Delft University of Technology

Ferrotec GmbH

Breakthrough Ferrofluid Patents and Research

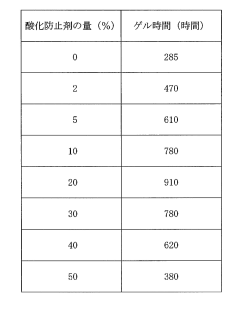

- A ferrofluid composition with improved oxidation resistance is achieved by incorporating 5-50% by weight of an antioxidant, such as alkylarylamines, into the carrier liquid to stabilize the colloidal suspension and extend the gelation time.

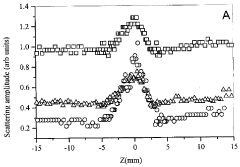

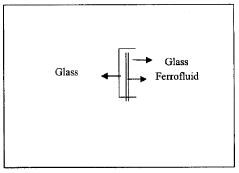

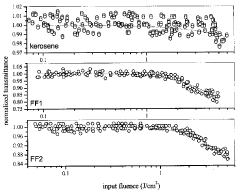

- Synthesizing ferromagnetic nanoparticles of specific sizes (4-6 nm) using an optimized co-precipitation technique and incorporating them into a ferrofluid, which is then encapsulated between glass plates without air gaps for enhanced thermal stability and optical limiting performance.

Environmental Impact of Ferrofluid Use

The use of ferrofluids in industrial processes presents both opportunities and challenges from an environmental perspective. While these magnetic nanofluids offer potential benefits in terms of efficiency and precision, their environmental impact must be carefully considered and managed.

One of the primary environmental concerns associated with ferrofluids is the potential for nanoparticle release into ecosystems. The magnetic nanoparticles in ferrofluids, typically composed of iron oxides, can persist in the environment and may have unforeseen effects on aquatic and terrestrial organisms. Studies have shown that nanoparticles can accumulate in living tissues, potentially disrupting biological processes and food chains.

However, the controlled use of ferrofluids in closed industrial systems can significantly mitigate these risks. When properly contained and recycled, ferrofluids can contribute to more efficient processes that reduce overall resource consumption and waste generation. For instance, in magnetic separation techniques, ferrofluids can enhance the recovery of valuable materials from waste streams, thereby reducing the environmental footprint of mining and manufacturing operations.

The production of ferrofluids itself requires careful consideration of environmental factors. The synthesis of magnetic nanoparticles often involves chemical processes that may generate hazardous byproducts. Sustainable manufacturing practices, such as green chemistry approaches and closed-loop production systems, can help minimize the environmental impact of ferrofluid production.

Energy efficiency is another important aspect of ferrofluid use in industrial processes. The unique properties of ferrofluids, such as their ability to change viscosity in response to magnetic fields, can lead to more energy-efficient operations in various applications. This can result in reduced power consumption and, consequently, lower greenhouse gas emissions associated with energy production.

In terms of waste management, the disposal of ferrofluids at the end of their lifecycle presents challenges. Proper treatment and disposal methods must be developed to prevent the release of nanoparticles into the environment. Recycling and reclamation of ferrofluids can help extend their useful life and reduce the need for new production, further minimizing environmental impact.

The potential for ferrofluids to contribute to environmental remediation efforts should also be noted. Research has shown promise in using functionalized ferrofluids for the removal of contaminants from water and soil, offering a novel approach to environmental cleanup that could have significant positive impacts.

As industrial applications of ferrofluids continue to expand, it is crucial to conduct comprehensive life cycle assessments to fully understand their environmental implications. This will enable the development of best practices and regulations to ensure that the benefits of ferrofluid technology are realized while minimizing negative environmental consequences.

Ferrofluid Safety and Handling Protocols

Ferrofluid safety and handling protocols are crucial for the efficient and responsible use of this unique material in industrial processes. The magnetic nanoparticles suspended in a carrier fluid require specific precautions to ensure worker safety and environmental protection. Personal protective equipment (PPE) is essential when handling ferrofluids, including chemical-resistant gloves, safety goggles, and appropriate clothing to prevent skin contact or inhalation of vapors.

Proper storage of ferrofluids is vital to maintain their stability and prevent contamination. They should be kept in sealed containers away from strong magnetic fields, extreme temperatures, and direct sunlight. Labeling containers with clear hazard information and storage instructions is necessary for safe handling and to comply with regulatory requirements.

Spill management procedures must be established and communicated to all personnel working with ferrofluids. In the event of a spill, immediate containment using non-magnetic absorbent materials is crucial. The affected area should be cordoned off to prevent the spread of the material, and cleanup should be conducted using appropriate tools and disposal methods.

Environmental considerations are paramount when working with ferrofluids. Proper disposal methods must be implemented to prevent contamination of water sources or soil. Used ferrofluids and contaminated materials should be treated as hazardous waste and disposed of according to local regulations and industry best practices.

Training programs for personnel handling ferrofluids are essential to ensure compliance with safety protocols. These programs should cover proper handling techniques, emergency procedures, and the potential health and environmental risks associated with ferrofluid exposure. Regular refresher courses and safety audits can help maintain a high level of awareness and adherence to protocols.

When integrating ferrofluids into industrial processes, engineering controls such as ventilation systems and enclosed handling areas should be implemented to minimize exposure risks. Regular equipment maintenance and integrity checks are necessary to prevent leaks or unexpected releases of ferrofluid during operation.

Monitoring and documentation of ferrofluid use, including inventory tracking and exposure records, are important aspects of a comprehensive safety program. This data can be valuable for continuous improvement of handling protocols and for addressing any long-term health or environmental concerns that may arise.

By implementing and strictly adhering to these safety and handling protocols, industries can harness the unique properties of ferrofluids while minimizing risks to personnel and the environment, thereby ensuring efficient and responsible use of this innovative material in various industrial applications.