Key Applications of Ferrofluid for Cutting-Edge Nanotechnology Projects

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Nanotechnology Background and Objectives

Ferrofluids, a remarkable class of magnetic nanomaterials, have emerged as a cornerstone in cutting-edge nanotechnology projects. These unique liquids, composed of nanoscale ferromagnetic particles suspended in a carrier fluid, exhibit extraordinary properties that bridge the gap between fluid dynamics and magnetism. The development of ferrofluids can be traced back to the 1960s when NASA scientists sought to control liquids in zero gravity environments. Since then, the field has experienced significant advancements, driven by the growing demand for innovative solutions in various technological domains.

The evolution of ferrofluid technology has been marked by continuous improvements in synthesis methods, particle stability, and magnetic responsiveness. Early ferrofluids faced challenges related to particle aggregation and limited magnetic properties. However, recent breakthroughs in nanoparticle engineering and surface functionalization have led to the creation of more stable and efficient ferrofluids, expanding their potential applications across multiple industries.

As we delve into the key applications of ferrofluids in cutting-edge nanotechnology projects, it is crucial to understand the overarching technological objectives. The primary goal is to harness the unique properties of ferrofluids to develop novel solutions for complex engineering challenges. These objectives include enhancing the performance of existing systems, creating new functionalities in devices, and enabling previously unattainable technological capabilities.

One of the most promising areas of ferrofluid application is in the field of microfluidics and lab-on-a-chip technologies. Here, the aim is to leverage the magnetic responsiveness of ferrofluids to manipulate and control fluid flow at the microscale, potentially revolutionizing diagnostic and analytical processes. In the realm of energy harvesting, researchers are exploring ferrofluids as a means to improve the efficiency of heat transfer systems and develop innovative energy conversion devices.

Another significant objective is the integration of ferrofluids into advanced materials and smart systems. This includes the development of adaptive structures that can change their properties in response to magnetic fields, opening up new possibilities in fields such as robotics, aerospace, and biomedical engineering. In the medical sector, ferrofluids are being investigated for targeted drug delivery, magnetic hyperthermia treatments, and as contrast agents for magnetic resonance imaging (MRI).

As we look towards the future, the technological trajectory of ferrofluids points towards even more sophisticated applications. The ongoing research aims to push the boundaries of what is possible with these remarkable materials, exploring their potential in quantum computing, spintronics, and next-generation data storage devices. The ultimate goal is to unlock the full potential of ferrofluids, transforming them from a niche scientific curiosity into a ubiquitous technology that underpins numerous advanced systems and devices across various industries.

The evolution of ferrofluid technology has been marked by continuous improvements in synthesis methods, particle stability, and magnetic responsiveness. Early ferrofluids faced challenges related to particle aggregation and limited magnetic properties. However, recent breakthroughs in nanoparticle engineering and surface functionalization have led to the creation of more stable and efficient ferrofluids, expanding their potential applications across multiple industries.

As we delve into the key applications of ferrofluids in cutting-edge nanotechnology projects, it is crucial to understand the overarching technological objectives. The primary goal is to harness the unique properties of ferrofluids to develop novel solutions for complex engineering challenges. These objectives include enhancing the performance of existing systems, creating new functionalities in devices, and enabling previously unattainable technological capabilities.

One of the most promising areas of ferrofluid application is in the field of microfluidics and lab-on-a-chip technologies. Here, the aim is to leverage the magnetic responsiveness of ferrofluids to manipulate and control fluid flow at the microscale, potentially revolutionizing diagnostic and analytical processes. In the realm of energy harvesting, researchers are exploring ferrofluids as a means to improve the efficiency of heat transfer systems and develop innovative energy conversion devices.

Another significant objective is the integration of ferrofluids into advanced materials and smart systems. This includes the development of adaptive structures that can change their properties in response to magnetic fields, opening up new possibilities in fields such as robotics, aerospace, and biomedical engineering. In the medical sector, ferrofluids are being investigated for targeted drug delivery, magnetic hyperthermia treatments, and as contrast agents for magnetic resonance imaging (MRI).

As we look towards the future, the technological trajectory of ferrofluids points towards even more sophisticated applications. The ongoing research aims to push the boundaries of what is possible with these remarkable materials, exploring their potential in quantum computing, spintronics, and next-generation data storage devices. The ultimate goal is to unlock the full potential of ferrofluids, transforming them from a niche scientific curiosity into a ubiquitous technology that underpins numerous advanced systems and devices across various industries.

Market Analysis for Ferrofluid Applications

The ferrofluid market has been experiencing significant growth in recent years, driven by the increasing demand for advanced nanotechnology applications across various industries. The global ferrofluid market size was valued at approximately $57 million in 2020 and is projected to reach $73 million by 2025, growing at a CAGR of 5.1% during the forecast period.

One of the key factors contributing to this growth is the rising adoption of ferrofluids in the healthcare sector. Ferrofluids are being extensively used in targeted drug delivery systems, magnetic hyperthermia for cancer treatment, and magnetic resonance imaging (MRI) contrast agents. The healthcare segment is expected to witness the highest growth rate in the coming years, with a projected CAGR of 6.8% from 2020 to 2025.

In the electronics industry, ferrofluids are finding applications in loudspeakers, hard disk drives, and electronic cooling systems. The increasing demand for high-performance electronic devices is driving the growth of ferrofluids in this sector. The electronics segment accounted for 28% of the total ferrofluid market share in 2020 and is expected to maintain its dominance throughout the forecast period.

The automotive industry is another significant consumer of ferrofluids, utilizing them in shock absorbers, dampers, and sealing systems. With the growing trend towards electric vehicles and advanced automotive technologies, the demand for ferrofluids in this sector is expected to increase substantially. The automotive segment is projected to grow at a CAGR of 5.5% from 2020 to 2025.

Geographically, North America held the largest market share in 2020, accounting for 35% of the global ferrofluid market. This can be attributed to the presence of major players, advanced research facilities, and high adoption rates of nanotechnology in the region. However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, with a CAGR of 6.2%, driven by rapid industrialization and increasing investments in research and development activities.

Key players in the ferrofluid market include Ferrotec Holdings Corporation, Liquid Research Limited, American Elements, Ioniqa Technologies, and Ferrofluidics Corporation. These companies are focusing on product innovation, strategic partnerships, and mergers and acquisitions to strengthen their market position and expand their product portfolio.

In conclusion, the ferrofluid market shows promising growth potential across various industries, with healthcare, electronics, and automotive sectors being the primary drivers. As research and development activities continue to uncover new applications for ferrofluids in cutting-edge nanotechnology projects, the market is expected to witness sustained growth in the coming years.

One of the key factors contributing to this growth is the rising adoption of ferrofluids in the healthcare sector. Ferrofluids are being extensively used in targeted drug delivery systems, magnetic hyperthermia for cancer treatment, and magnetic resonance imaging (MRI) contrast agents. The healthcare segment is expected to witness the highest growth rate in the coming years, with a projected CAGR of 6.8% from 2020 to 2025.

In the electronics industry, ferrofluids are finding applications in loudspeakers, hard disk drives, and electronic cooling systems. The increasing demand for high-performance electronic devices is driving the growth of ferrofluids in this sector. The electronics segment accounted for 28% of the total ferrofluid market share in 2020 and is expected to maintain its dominance throughout the forecast period.

The automotive industry is another significant consumer of ferrofluids, utilizing them in shock absorbers, dampers, and sealing systems. With the growing trend towards electric vehicles and advanced automotive technologies, the demand for ferrofluids in this sector is expected to increase substantially. The automotive segment is projected to grow at a CAGR of 5.5% from 2020 to 2025.

Geographically, North America held the largest market share in 2020, accounting for 35% of the global ferrofluid market. This can be attributed to the presence of major players, advanced research facilities, and high adoption rates of nanotechnology in the region. However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, with a CAGR of 6.2%, driven by rapid industrialization and increasing investments in research and development activities.

Key players in the ferrofluid market include Ferrotec Holdings Corporation, Liquid Research Limited, American Elements, Ioniqa Technologies, and Ferrofluidics Corporation. These companies are focusing on product innovation, strategic partnerships, and mergers and acquisitions to strengthen their market position and expand their product portfolio.

In conclusion, the ferrofluid market shows promising growth potential across various industries, with healthcare, electronics, and automotive sectors being the primary drivers. As research and development activities continue to uncover new applications for ferrofluids in cutting-edge nanotechnology projects, the market is expected to witness sustained growth in the coming years.

Current Challenges in Ferrofluid Technology

Despite the promising potential of ferrofluids in nanotechnology applications, several significant challenges persist in their development and implementation. One of the primary obstacles is the long-term stability of ferrofluids. Over time, these magnetic nanofluids tend to agglomerate, leading to a loss of their unique properties. This instability limits their practical use in long-duration applications and necessitates the development of more robust stabilization techniques.

Another critical challenge lies in the precise control of ferrofluid behavior under varying magnetic fields. While ferrofluids respond to external magnetic fields, achieving fine-tuned control over their movement, shape, and properties remains difficult. This limitation hinders their application in areas requiring high precision, such as targeted drug delivery or microfluidic devices.

The biocompatibility of ferrofluids presents another significant hurdle, particularly for biomedical applications. Many ferrofluids contain materials that may be toxic or cause adverse reactions in biological systems. Developing ferrofluids that are both functionally effective and biologically safe is a complex task that requires extensive research and testing.

Manufacturing scalability is also a major concern in ferrofluid technology. Current production methods often struggle to maintain consistent quality and properties when scaled up to industrial levels. This challenge impedes the widespread adoption of ferrofluids in commercial applications and increases their cost.

Furthermore, the environmental impact of ferrofluids is an emerging concern. The potential release of nanoparticles into the environment and their long-term effects on ecosystems are not fully understood. This uncertainty calls for comprehensive studies on the ecological footprint of ferrofluids and the development of environmentally friendly alternatives.

Lastly, the integration of ferrofluids with existing technologies and systems poses significant engineering challenges. Adapting current equipment and processes to accommodate the unique properties of ferrofluids often requires substantial modifications and innovations. This integration challenge slows down the adoption of ferrofluid technology across various industries.

Addressing these challenges requires a multidisciplinary approach, combining advances in materials science, nanotechnology, bioengineering, and environmental studies. Overcoming these hurdles will be crucial for unlocking the full potential of ferrofluids in cutting-edge nanotechnology projects and expanding their applications across diverse fields.

Another critical challenge lies in the precise control of ferrofluid behavior under varying magnetic fields. While ferrofluids respond to external magnetic fields, achieving fine-tuned control over their movement, shape, and properties remains difficult. This limitation hinders their application in areas requiring high precision, such as targeted drug delivery or microfluidic devices.

The biocompatibility of ferrofluids presents another significant hurdle, particularly for biomedical applications. Many ferrofluids contain materials that may be toxic or cause adverse reactions in biological systems. Developing ferrofluids that are both functionally effective and biologically safe is a complex task that requires extensive research and testing.

Manufacturing scalability is also a major concern in ferrofluid technology. Current production methods often struggle to maintain consistent quality and properties when scaled up to industrial levels. This challenge impedes the widespread adoption of ferrofluids in commercial applications and increases their cost.

Furthermore, the environmental impact of ferrofluids is an emerging concern. The potential release of nanoparticles into the environment and their long-term effects on ecosystems are not fully understood. This uncertainty calls for comprehensive studies on the ecological footprint of ferrofluids and the development of environmentally friendly alternatives.

Lastly, the integration of ferrofluids with existing technologies and systems poses significant engineering challenges. Adapting current equipment and processes to accommodate the unique properties of ferrofluids often requires substantial modifications and innovations. This integration challenge slows down the adoption of ferrofluid technology across various industries.

Addressing these challenges requires a multidisciplinary approach, combining advances in materials science, nanotechnology, bioengineering, and environmental studies. Overcoming these hurdles will be crucial for unlocking the full potential of ferrofluids in cutting-edge nanotechnology projects and expanding their applications across diverse fields.

Existing Ferrofluid Application Solutions

01 Composition and preparation of ferrofluids

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with a surfactant to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with a surfactant to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals and bearings. Their unique properties allow them to form liquid seals that can be controlled by magnetic fields, providing effective containment of gases and liquids while reducing friction and wear.

- Thermal management and heat transfer: Ferrofluids have excellent heat transfer properties and are used in various thermal management applications. They can be employed in cooling systems for electronic devices, transformers, and other heat-generating equipment. The magnetic properties of ferrofluids allow for enhanced heat transfer and improved thermal conductivity.

- Magnetic field sensing and measurement: Ferrofluids are utilized in various sensing and measurement applications involving magnetic fields. They can be used to visualize magnetic field lines, measure field strength, and detect small changes in magnetic fields. This makes them valuable in scientific research, industrial testing, and quality control processes.

- Biomedical and therapeutic applications: Ferrofluids have emerging applications in biomedicine and therapeutics. They can be used as contrast agents in magnetic resonance imaging (MRI), targeted drug delivery systems, and hyperthermia treatment for cancer. The ability to control ferrofluids with external magnetic fields makes them promising for various medical interventions.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals and bearings. Their unique properties allow them to form liquid seals that can be controlled by magnetic fields, providing effective containment of gases and liquids while reducing friction and wear in mechanical systems.Expand Specific Solutions03 Thermal management and heat transfer

Ferrofluids exhibit enhanced heat transfer properties due to their magnetic nature. They are used in cooling systems for electronic devices, transformers, and other heat-generating equipment. The ability to manipulate ferrofluids with magnetic fields allows for targeted cooling and improved thermal management in various applications.Expand Specific Solutions04 Magnetic field sensing and measurement

Ferrofluids are employed in various sensing and measurement devices that rely on magnetic field detection. These applications include accelerometers, inclinometers, and magnetic field sensors. The response of ferrofluids to magnetic fields allows for precise measurements and detection of changes in orientation or field strength.Expand Specific Solutions05 Medical and biomedical applications

Ferrofluids have emerging applications in the medical and biomedical fields. They are being researched for use in targeted drug delivery, magnetic hyperthermia for cancer treatment, and as contrast agents in magnetic resonance imaging (MRI). The ability to control ferrofluids with external magnetic fields makes them promising for various therapeutic and diagnostic applications.Expand Specific Solutions

Key Players in Ferrofluid Industry

The field of ferrofluid applications in cutting-edge nanotechnology projects is in a growth phase, with increasing market potential and technological advancements. The global market for ferrofluids is expanding, driven by diverse applications in electronics, biomedical, and energy sectors. While the technology has matured in certain areas, ongoing research by key players indicates significant room for innovation. Yale University, MIT, and CNRS are leading academic institutions pushing the boundaries of ferrofluid research. Companies like Ferrotec (USA) Corp. are commercializing ferrofluid technologies, while research organizations such as Raman Research Institute and CSIR are exploring novel applications. The involvement of diverse players across academia, industry, and research institutions suggests a competitive landscape with ample opportunities for breakthrough developments in nanotechnology utilizing ferrofluids.

Midatech Ltd.

Technical Solution: Midatech specializes in the development of nanoparticle-based drug delivery systems, including ferrofluid-inspired technologies. Their approach combines gold nanoparticles with biocompatible coatings to create hybrid systems that can be magnetically guided to target tissues. Midatech's technology platform allows for the precise engineering of nanoparticle size, shape, and surface properties to optimize drug delivery for various therapeutic applications. The company has made significant progress in developing treatments for brain tumors and rare cancers, leveraging the ability of their nanoparticles to cross the blood-brain barrier when subjected to external magnetic fields[12][13]. Midatech is also exploring the use of their nanoparticle technology in combination with other treatment modalities, such as photodynamic therapy, to enhance therapeutic efficacy[14].

Strengths: Focused expertise in nanoparticle-based drug delivery with potential for breakthrough treatments. Weaknesses: Faces regulatory hurdles and competition from larger pharmaceutical companies.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced ferrofluid-based nanoparticle systems for targeted drug delivery in cancer treatment. Their approach utilizes magnetic nanoparticles coated with biocompatible polymers to create a ferrofluid that can be precisely controlled using external magnetic fields. This allows for highly localized drug delivery to tumor sites, minimizing side effects on healthy tissues. The nanoparticles are engineered to respond to specific stimuli, such as pH changes or enzyme activity, triggering controlled release of therapeutic agents[1][3]. MIT researchers have also explored using ferrofluids for enhanced heat transfer in microfluidic cooling systems, potentially revolutionizing thermal management in electronics and energy systems[2].

Strengths: Cutting-edge research in targeted drug delivery and thermal management. Weaknesses: Potential challenges in scaling up production and regulatory approval for medical applications.

Breakthrough Ferrofluid Patents and Research

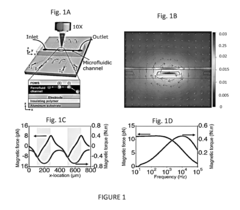

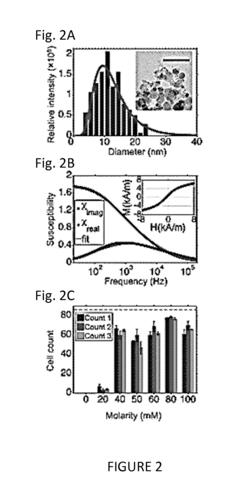

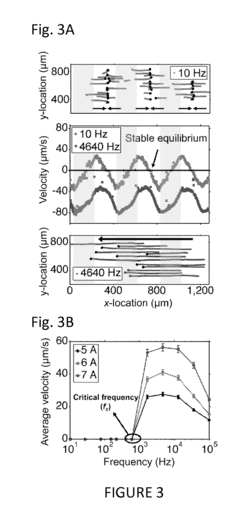

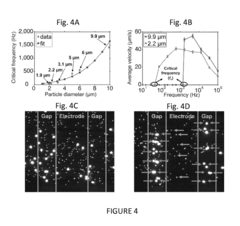

Label-Free Cellular Manipulation and Sorting Via Biocompatible Ferrofluids

PatentActiveUS20180128729A1

Innovation

- A microfluidic platform using biocompatible ferrofluids with a microfluidic channel and electrodes that generate a magnetic field pattern, allowing for the controlled manipulation and separation of microparticles and live cells based on size, shape, and elasticity, with high efficiency and rapid separation capabilities.

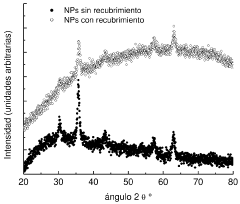

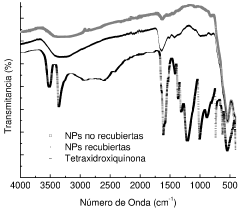

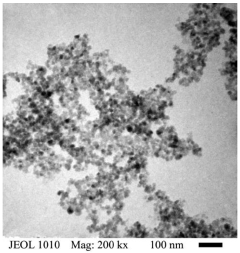

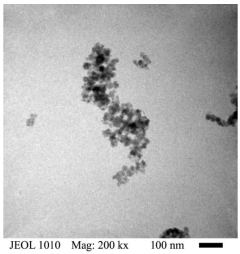

A ferrofluid of iron oxide nanoparticles covered with tetrahydroxyquinone that does not produce reactive oxygen species.

PatentPendingMX2022005740A

Innovation

- Development of a ferrofluid composed of iron oxide nanoparticles coated with tetrahydroxyquinone, with diameters less than 15 nm, providing high magnetic saturation, low cytotoxicity, and the ability to absorb energy from alternating magnetic fields without producing reactive oxygen species, enhancing tumor reduction through combined anti-keloid and magnetic hyperthermia effects.

Environmental Impact of Ferrofluid Usage

The environmental impact of ferrofluid usage in cutting-edge nanotechnology projects is a critical consideration that requires careful assessment. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, have unique properties that make them valuable in various applications. However, their potential environmental consequences must be thoroughly evaluated.

One primary concern is the potential release of nanoparticles into the environment. The magnetic nanoparticles in ferrofluids, typically iron oxides, may pose risks to ecosystems if not properly contained or disposed of. These particles can potentially accumulate in soil and water systems, affecting microbial communities and aquatic organisms. Long-term exposure to these nanoparticles could lead to bioaccumulation in food chains, potentially impacting higher-level organisms.

The production process of ferrofluids also raises environmental concerns. The synthesis of magnetic nanoparticles often involves chemical reactions that may generate hazardous byproducts. Proper waste management and treatment protocols are essential to mitigate the environmental impact of these manufacturing processes. Additionally, the energy consumption associated with ferrofluid production and purification should be considered in the overall environmental assessment.

On the positive side, ferrofluids have the potential to contribute to environmental protection in certain applications. For instance, their use in advanced water treatment technologies can help remove contaminants more efficiently, potentially reducing the environmental footprint of water purification processes. Similarly, ferrofluid-based magnetic separation techniques can aid in the recovery of valuable materials from waste streams, promoting resource conservation and recycling.

The lifecycle analysis of ferrofluid-based technologies is crucial for understanding their net environmental impact. This includes evaluating the sourcing of raw materials, production processes, usage phase, and end-of-life disposal or recycling. Developing sustainable practices for the entire lifecycle of ferrofluid applications is essential to minimize negative environmental consequences.

Research into biodegradable or bio-based ferrofluids is an emerging area that could significantly reduce the environmental risks associated with these materials. By developing ferrofluids with environmentally friendly carrier fluids and biodegradable nanoparticles, the potential for long-term environmental persistence and accumulation could be minimized.

Regulatory frameworks and guidelines for the safe use and disposal of ferrofluids in nanotechnology applications are necessary to ensure environmental protection. These should address proper handling, containment, and disposal methods to prevent unintended release into the environment. Additionally, ongoing monitoring and assessment of the environmental fate of ferrofluids in various applications will be crucial for identifying and mitigating any unforeseen ecological impacts.

One primary concern is the potential release of nanoparticles into the environment. The magnetic nanoparticles in ferrofluids, typically iron oxides, may pose risks to ecosystems if not properly contained or disposed of. These particles can potentially accumulate in soil and water systems, affecting microbial communities and aquatic organisms. Long-term exposure to these nanoparticles could lead to bioaccumulation in food chains, potentially impacting higher-level organisms.

The production process of ferrofluids also raises environmental concerns. The synthesis of magnetic nanoparticles often involves chemical reactions that may generate hazardous byproducts. Proper waste management and treatment protocols are essential to mitigate the environmental impact of these manufacturing processes. Additionally, the energy consumption associated with ferrofluid production and purification should be considered in the overall environmental assessment.

On the positive side, ferrofluids have the potential to contribute to environmental protection in certain applications. For instance, their use in advanced water treatment technologies can help remove contaminants more efficiently, potentially reducing the environmental footprint of water purification processes. Similarly, ferrofluid-based magnetic separation techniques can aid in the recovery of valuable materials from waste streams, promoting resource conservation and recycling.

The lifecycle analysis of ferrofluid-based technologies is crucial for understanding their net environmental impact. This includes evaluating the sourcing of raw materials, production processes, usage phase, and end-of-life disposal or recycling. Developing sustainable practices for the entire lifecycle of ferrofluid applications is essential to minimize negative environmental consequences.

Research into biodegradable or bio-based ferrofluids is an emerging area that could significantly reduce the environmental risks associated with these materials. By developing ferrofluids with environmentally friendly carrier fluids and biodegradable nanoparticles, the potential for long-term environmental persistence and accumulation could be minimized.

Regulatory frameworks and guidelines for the safe use and disposal of ferrofluids in nanotechnology applications are necessary to ensure environmental protection. These should address proper handling, containment, and disposal methods to prevent unintended release into the environment. Additionally, ongoing monitoring and assessment of the environmental fate of ferrofluids in various applications will be crucial for identifying and mitigating any unforeseen ecological impacts.

Ferrofluid Safety and Regulatory Compliance

Ferrofluid safety and regulatory compliance are critical considerations for the implementation of this innovative nanotechnology in cutting-edge projects. As ferrofluids gain prominence in various applications, it is essential to address potential risks and adhere to established guidelines to ensure safe handling and usage.

The primary safety concern with ferrofluids stems from their nanoparticle composition. These magnetic nanoparticles, typically iron oxides, can pose health risks if inhaled or ingested. Prolonged exposure may lead to respiratory issues or accumulation in organs. To mitigate these risks, proper personal protective equipment (PPE) such as gloves, goggles, and respiratory protection should be mandatory when handling ferrofluids.

Environmental considerations are equally important. The potential release of nanoparticles into ecosystems could have unforeseen consequences on wildlife and aquatic systems. Proper disposal protocols must be established and followed to prevent environmental contamination. This includes treating ferrofluid waste as hazardous material and employing specialized disposal methods.

Regulatory compliance for ferrofluids varies across jurisdictions but generally falls under broader nanotechnology regulations. In the United States, the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) provide guidelines for nanomaterials. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation also covers nanoparticles, including those found in ferrofluids.

Manufacturers and researchers working with ferrofluids must conduct thorough risk assessments and implement appropriate safety measures. This includes developing standard operating procedures (SOPs) for handling, storage, and disposal. Regular safety training for personnel working with ferrofluids is crucial to maintain a safe working environment and ensure compliance with regulations.

Quality control measures are essential to ensure the consistency and safety of ferrofluids used in nanotechnology projects. This involves rigorous testing of physical and chemical properties, as well as monitoring for potential contaminants. Manufacturers should provide detailed safety data sheets (SDS) outlining the composition, hazards, and proper handling procedures for their ferrofluid products.

As the field of nanotechnology evolves, regulations surrounding ferrofluids are likely to become more specific and stringent. Staying informed about regulatory changes and participating in industry discussions can help organizations anticipate and adapt to new compliance requirements. Collaboration between industry, academia, and regulatory bodies is crucial for developing comprehensive safety standards that balance innovation with risk mitigation.

The primary safety concern with ferrofluids stems from their nanoparticle composition. These magnetic nanoparticles, typically iron oxides, can pose health risks if inhaled or ingested. Prolonged exposure may lead to respiratory issues or accumulation in organs. To mitigate these risks, proper personal protective equipment (PPE) such as gloves, goggles, and respiratory protection should be mandatory when handling ferrofluids.

Environmental considerations are equally important. The potential release of nanoparticles into ecosystems could have unforeseen consequences on wildlife and aquatic systems. Proper disposal protocols must be established and followed to prevent environmental contamination. This includes treating ferrofluid waste as hazardous material and employing specialized disposal methods.

Regulatory compliance for ferrofluids varies across jurisdictions but generally falls under broader nanotechnology regulations. In the United States, the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) provide guidelines for nanomaterials. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation also covers nanoparticles, including those found in ferrofluids.

Manufacturers and researchers working with ferrofluids must conduct thorough risk assessments and implement appropriate safety measures. This includes developing standard operating procedures (SOPs) for handling, storage, and disposal. Regular safety training for personnel working with ferrofluids is crucial to maintain a safe working environment and ensure compliance with regulations.

Quality control measures are essential to ensure the consistency and safety of ferrofluids used in nanotechnology projects. This involves rigorous testing of physical and chemical properties, as well as monitoring for potential contaminants. Manufacturers should provide detailed safety data sheets (SDS) outlining the composition, hazards, and proper handling procedures for their ferrofluid products.

As the field of nanotechnology evolves, regulations surrounding ferrofluids are likely to become more specific and stringent. Staying informed about regulatory changes and participating in industry discussions can help organizations anticipate and adapt to new compliance requirements. Collaboration between industry, academia, and regulatory bodies is crucial for developing comprehensive safety standards that balance innovation with risk mitigation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!