Ferrofluid's Contribution to Revolutionary Electromagnetic Research

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Tech Evolution

Ferrofluids have undergone a remarkable evolution since their inception in the 1960s, revolutionizing electromagnetic research and applications. Initially developed by NASA for fuel control in zero-gravity environments, these magnetic liquids have since found their way into various fields, including engineering, medicine, and materials science.

The early stages of ferrofluid technology focused primarily on basic composition and stability. Scientists worked to perfect the colloidal suspension of magnetic nanoparticles in a carrier fluid, ensuring long-term stability and uniform magnetic response. This period saw the development of various surfactants to prevent particle agglomeration, a crucial step in maintaining the fluid's unique properties.

As research progressed, the 1980s and 1990s witnessed significant advancements in ferrofluid synthesis and characterization techniques. Improved methods for producing monodisperse magnetic nanoparticles led to more consistent and predictable ferrofluid behavior. This era also saw the expansion of ferrofluid applications, particularly in sealing and damping technologies.

The turn of the millennium marked a new phase in ferrofluid evolution, with a focus on enhancing magnetic properties and exploring novel applications. Researchers began experimenting with different magnetic materials, such as cobalt and manganese ferrites, to create ferrofluids with tailored magnetic responses. This period also saw the integration of ferrofluids into microfluidic devices, opening up new possibilities in lab-on-a-chip technologies.

Recent years have witnessed a surge in biomedical applications of ferrofluids. The development of biocompatible ferrofluids has enabled their use in targeted drug delivery, magnetic hyperthermia for cancer treatment, and contrast agents for magnetic resonance imaging. These advancements have significantly expanded the potential of ferrofluids in healthcare and diagnostics.

Concurrently, the field of magneto-rheological devices has seen substantial growth, with ferrofluids playing a crucial role. Adaptive damping systems, precision polishing techniques, and tunable optical devices have all benefited from the unique properties of ferrofluids. The ability to control fluid properties in real-time through external magnetic fields has opened up new avenues for dynamic and responsive systems.

The latest frontier in ferrofluid technology involves the development of smart materials and systems. Researchers are exploring self-assembling ferrofluid structures, magnetically actuated soft robots, and responsive surfaces that can change properties on demand. These innovations are pushing the boundaries of what's possible with magnetic fluids, promising transformative applications in fields ranging from energy harvesting to adaptive architecture.

The early stages of ferrofluid technology focused primarily on basic composition and stability. Scientists worked to perfect the colloidal suspension of magnetic nanoparticles in a carrier fluid, ensuring long-term stability and uniform magnetic response. This period saw the development of various surfactants to prevent particle agglomeration, a crucial step in maintaining the fluid's unique properties.

As research progressed, the 1980s and 1990s witnessed significant advancements in ferrofluid synthesis and characterization techniques. Improved methods for producing monodisperse magnetic nanoparticles led to more consistent and predictable ferrofluid behavior. This era also saw the expansion of ferrofluid applications, particularly in sealing and damping technologies.

The turn of the millennium marked a new phase in ferrofluid evolution, with a focus on enhancing magnetic properties and exploring novel applications. Researchers began experimenting with different magnetic materials, such as cobalt and manganese ferrites, to create ferrofluids with tailored magnetic responses. This period also saw the integration of ferrofluids into microfluidic devices, opening up new possibilities in lab-on-a-chip technologies.

Recent years have witnessed a surge in biomedical applications of ferrofluids. The development of biocompatible ferrofluids has enabled their use in targeted drug delivery, magnetic hyperthermia for cancer treatment, and contrast agents for magnetic resonance imaging. These advancements have significantly expanded the potential of ferrofluids in healthcare and diagnostics.

Concurrently, the field of magneto-rheological devices has seen substantial growth, with ferrofluids playing a crucial role. Adaptive damping systems, precision polishing techniques, and tunable optical devices have all benefited from the unique properties of ferrofluids. The ability to control fluid properties in real-time through external magnetic fields has opened up new avenues for dynamic and responsive systems.

The latest frontier in ferrofluid technology involves the development of smart materials and systems. Researchers are exploring self-assembling ferrofluid structures, magnetically actuated soft robots, and responsive surfaces that can change properties on demand. These innovations are pushing the boundaries of what's possible with magnetic fluids, promising transformative applications in fields ranging from energy harvesting to adaptive architecture.

Electromagnetic Market Demand

The electromagnetic market has witnessed significant growth in recent years, driven by the increasing demand for advanced technologies across various industries. The integration of ferrofluids in electromagnetic research has opened up new possibilities, further expanding the market potential. The global electromagnetic market is expected to reach substantial value in the coming years, with a compound annual growth rate surpassing industry averages.

The automotive sector represents a major driver for electromagnetic technologies, particularly in the development of electric and hybrid vehicles. The demand for efficient electric motors, regenerative braking systems, and electromagnetic suspension systems has surged, creating a robust market for ferrofluid-based electromagnetic solutions. Additionally, the aerospace industry has shown keen interest in leveraging ferrofluids for improved electromagnetic shielding and advanced propulsion systems.

In the consumer electronics sector, the miniaturization trend has led to increased demand for compact and efficient electromagnetic components. Ferrofluids offer unique properties that can enhance the performance of speakers, haptic feedback systems, and cooling solutions in smartphones, tablets, and wearable devices. This has created a substantial market opportunity for ferrofluid-based electromagnetic technologies in the consumer electronics industry.

The healthcare sector has also emerged as a significant market for electromagnetic technologies, with applications in medical imaging, drug delivery systems, and minimally invasive surgical procedures. Ferrofluids show promise in enhancing the precision and effectiveness of these applications, driving demand for research and development in this area.

Industrial automation and robotics represent another key market segment for electromagnetic technologies. The need for precise control and positioning in manufacturing processes has led to increased adoption of electromagnetic actuators and sensors. Ferrofluids can potentially improve the performance and reliability of these systems, creating a growing market for advanced electromagnetic solutions in the industrial sector.

The energy sector, particularly in renewable energy generation and smart grid technologies, has shown a rising demand for electromagnetic components. Ferrofluids can contribute to the development of more efficient generators, transformers, and energy storage systems, aligning with the global push towards sustainable energy solutions.

As the Internet of Things (IoT) continues to expand, the demand for electromagnetic sensors and actuators in smart home devices, wearables, and industrial IoT applications is expected to grow significantly. This presents a substantial market opportunity for ferrofluid-based electromagnetic technologies that can offer improved performance and energy efficiency in these applications.

The automotive sector represents a major driver for electromagnetic technologies, particularly in the development of electric and hybrid vehicles. The demand for efficient electric motors, regenerative braking systems, and electromagnetic suspension systems has surged, creating a robust market for ferrofluid-based electromagnetic solutions. Additionally, the aerospace industry has shown keen interest in leveraging ferrofluids for improved electromagnetic shielding and advanced propulsion systems.

In the consumer electronics sector, the miniaturization trend has led to increased demand for compact and efficient electromagnetic components. Ferrofluids offer unique properties that can enhance the performance of speakers, haptic feedback systems, and cooling solutions in smartphones, tablets, and wearable devices. This has created a substantial market opportunity for ferrofluid-based electromagnetic technologies in the consumer electronics industry.

The healthcare sector has also emerged as a significant market for electromagnetic technologies, with applications in medical imaging, drug delivery systems, and minimally invasive surgical procedures. Ferrofluids show promise in enhancing the precision and effectiveness of these applications, driving demand for research and development in this area.

Industrial automation and robotics represent another key market segment for electromagnetic technologies. The need for precise control and positioning in manufacturing processes has led to increased adoption of electromagnetic actuators and sensors. Ferrofluids can potentially improve the performance and reliability of these systems, creating a growing market for advanced electromagnetic solutions in the industrial sector.

The energy sector, particularly in renewable energy generation and smart grid technologies, has shown a rising demand for electromagnetic components. Ferrofluids can contribute to the development of more efficient generators, transformers, and energy storage systems, aligning with the global push towards sustainable energy solutions.

As the Internet of Things (IoT) continues to expand, the demand for electromagnetic sensors and actuators in smart home devices, wearables, and industrial IoT applications is expected to grow significantly. This presents a substantial market opportunity for ferrofluid-based electromagnetic technologies that can offer improved performance and energy efficiency in these applications.

Ferrofluid Challenges

Despite the promising potential of ferrofluids in electromagnetic research, several significant challenges hinder their widespread application and further development. These challenges span across multiple domains, including material properties, stability, and practical implementation.

One of the primary challenges is the long-term stability of ferrofluids. Over time, these fluids tend to experience particle agglomeration and sedimentation, which can significantly alter their magnetic properties and overall performance. This instability poses a major obstacle for applications requiring consistent and reliable magnetic responses over extended periods.

The thermal stability of ferrofluids presents another critical challenge. Many electromagnetic applications involve exposure to varying temperatures, and ferrofluids often exhibit changes in their magnetic properties and viscosity with temperature fluctuations. Developing ferrofluids that maintain consistent performance across a wide temperature range remains a significant hurdle for researchers.

Controlling the precise magnetic behavior of ferrofluids in complex electromagnetic fields is another area of difficulty. The non-linear response of ferrofluids to external magnetic fields can lead to unpredictable behaviors, making it challenging to design and optimize systems that rely on their unique properties. This unpredictability is particularly problematic in applications requiring high precision and repeatability.

The scalability of ferrofluid production and application presents both technical and economic challenges. While small-scale laboratory demonstrations have shown promising results, scaling up these processes for industrial applications often encounters unforeseen difficulties. These can include issues with maintaining uniform properties across larger volumes of ferrofluids and the increased costs associated with large-scale production of high-quality magnetic nanoparticles.

Environmental and health concerns also pose significant challenges to the widespread adoption of ferrofluids. The potential toxicity of nanoparticles used in ferrofluids, particularly when exposed to living organisms or released into the environment, necessitates careful consideration and extensive safety studies. This aspect is crucial for applications in biomedical fields or in consumer products where human exposure is likely.

Lastly, the integration of ferrofluids with existing electromagnetic technologies and systems presents its own set of challenges. Adapting current designs and manufacturing processes to incorporate ferrofluids often requires significant modifications and investments. This integration challenge is further complicated by the need for specialized handling and containment systems to prevent leakage or contamination of the ferrofluid.

One of the primary challenges is the long-term stability of ferrofluids. Over time, these fluids tend to experience particle agglomeration and sedimentation, which can significantly alter their magnetic properties and overall performance. This instability poses a major obstacle for applications requiring consistent and reliable magnetic responses over extended periods.

The thermal stability of ferrofluids presents another critical challenge. Many electromagnetic applications involve exposure to varying temperatures, and ferrofluids often exhibit changes in their magnetic properties and viscosity with temperature fluctuations. Developing ferrofluids that maintain consistent performance across a wide temperature range remains a significant hurdle for researchers.

Controlling the precise magnetic behavior of ferrofluids in complex electromagnetic fields is another area of difficulty. The non-linear response of ferrofluids to external magnetic fields can lead to unpredictable behaviors, making it challenging to design and optimize systems that rely on their unique properties. This unpredictability is particularly problematic in applications requiring high precision and repeatability.

The scalability of ferrofluid production and application presents both technical and economic challenges. While small-scale laboratory demonstrations have shown promising results, scaling up these processes for industrial applications often encounters unforeseen difficulties. These can include issues with maintaining uniform properties across larger volumes of ferrofluids and the increased costs associated with large-scale production of high-quality magnetic nanoparticles.

Environmental and health concerns also pose significant challenges to the widespread adoption of ferrofluids. The potential toxicity of nanoparticles used in ferrofluids, particularly when exposed to living organisms or released into the environment, necessitates careful consideration and extensive safety studies. This aspect is crucial for applications in biomedical fields or in consumer products where human exposure is likely.

Lastly, the integration of ferrofluids with existing electromagnetic technologies and systems presents its own set of challenges. Adapting current designs and manufacturing processes to incorporate ferrofluids often requires significant modifications and investments. This integration challenge is further complicated by the need for specialized handling and containment systems to prevent leakage or contamination of the ferrofluid.

Current Ferrofluid Solutions

01 Composition and preparation of ferrofluids

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication systems, particularly in rotating shaft seals. They provide effective sealing against pressure differentials while reducing friction. These applications leverage the fluid's ability to be held in place by magnetic fields, creating dynamic seals that adapt to various operating conditions.

- Thermal management and heat transfer: Ferrofluids exhibit enhanced heat transfer properties due to their magnetic nature. They are used in cooling systems for electronic devices and in thermal management applications. The ability to control the fluid's movement using magnetic fields allows for targeted cooling and improved thermal efficiency in various systems.

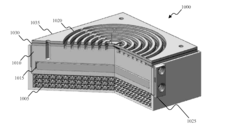

- Damping and vibration control: The unique properties of ferrofluids make them effective in damping and vibration control applications. They can be used in shock absorbers, vibration isolators, and inertial dampers. The fluid's response to magnetic fields allows for adaptive damping characteristics, improving performance in various mechanical systems.

- Sensing and measurement applications: Ferrofluids are employed in various sensing and measurement devices. They are used in accelerometers, inclinometers, and position sensors. The fluid's response to magnetic fields and gravity enables precise measurements and detection of motion or orientation changes, making them valuable in instrumentation and control systems.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication systems, particularly in rotating shaft seals. They provide effective sealing against pressure differentials and contaminants while reducing friction. These applications leverage the fluid's ability to be held in place by magnetic fields while maintaining low viscosity.Expand Specific Solutions03 Thermal management and heat transfer

Ferrofluids exhibit enhanced heat transfer properties due to their magnetic nature. They are used in cooling systems for electronic devices, transformers, and other heat-generating equipment. The fluid's movement can be controlled by magnetic fields, allowing for targeted cooling and improved thermal management.Expand Specific Solutions04 Damping and vibration control

The unique properties of ferrofluids make them effective in damping and vibration control applications. They can be used in shock absorbers, inertial dampers, and acoustic devices. The fluid's response to magnetic fields allows for adaptive damping characteristics and improved system performance.Expand Specific Solutions05 Sensing and measurement applications

Ferrofluids are employed in various sensing and measurement devices. They are used in accelerometers, inclinometers, and pressure sensors. The fluid's response to magnetic fields and its ability to change shape or position under external forces make it suitable for detecting and measuring physical parameters.Expand Specific Solutions

Key Ferrofluid Players

The ferrofluid electromagnetic research field is in a dynamic growth phase, with increasing market potential and technological advancements. The global market for ferrofluids is expanding, driven by applications in electronics, medical devices, and energy sectors. While the technology is maturing, it still offers significant room for innovation. Key players like Teledyne Scientific & Imaging, Koninklijke Philips, and MIT are at the forefront, leveraging their research capabilities to develop novel applications. Universities such as Yale, Michigan Tech, and Delft University of Technology are contributing fundamental research, while companies like Boeing and Western Digital are exploring practical implementations. This competitive landscape suggests a blend of academic and industrial efforts driving the field forward.

Massachusetts Institute of Technology

Technical Solution: MIT has made significant contributions to ferrofluid research and its applications in electromagnetic systems. Their approach involves developing novel ferrofluid compositions with enhanced magnetic properties and stability. MIT researchers have created ferrofluids with nanoparticles that exhibit improved magnetic saturation and reduced agglomeration[1]. They have also explored the use of ferrofluids in adaptive optical systems, where the fluid's shape can be precisely controlled by electromagnetic fields to create tunable lenses or mirrors[2]. Additionally, MIT has investigated the potential of ferrofluids in energy harvesting applications, developing devices that can convert mechanical energy into electricity using the unique properties of ferrofluids[3].

Strengths: Cutting-edge research in nanoparticle synthesis and ferrofluid composition. Strong focus on practical applications in optics and energy. Weaknesses: Some technologies may be at early stages of development and require further optimization for commercial use.

Delft University of Technology

Technical Solution: Delft University of Technology has been at the forefront of ferrofluid research, particularly in the field of microfluidics and nanofluidics. Their approach involves developing novel ferrofluid-based microfluidic devices for various applications, including biosensing and drug delivery. Researchers at Delft have created ferrofluid-actuated microvalves and micropumps that can be precisely controlled using external magnetic fields[7]. They have also explored the use of ferrofluids in creating adaptive surfaces with tunable wettability, which have potential applications in self-cleaning materials and anti-fouling coatings[8]. Additionally, Delft has investigated the behavior of ferrofluids under extreme conditions, such as in high-frequency electromagnetic fields, to develop new applications in telecommunications and energy harvesting[9].

Strengths: Strong expertise in microfluidics and nanofluidics. Focus on interdisciplinary applications combining physics, chemistry, and engineering. Weaknesses: Some research may be more theoretical and require further development for practical implementation.

Ferrofluid Breakthroughs

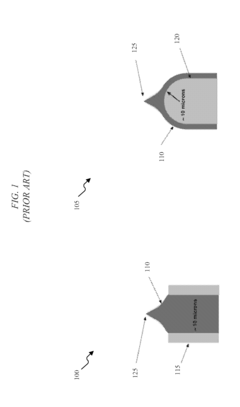

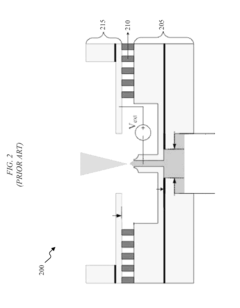

Generating electrospray from a ferrofluid

PatentActiveUS20160010631A1

Innovation

- The use of a ferrofluidic liquid that exploits Rosensweig instability to form sharp peaks without the need for microfabricated solid emitters, allowing for the generation of electrospray through a magnetic field and electric field combination, eliminating the reliance on solid structural scaffolding and addressing issues of fragility and wetting sensitivity.

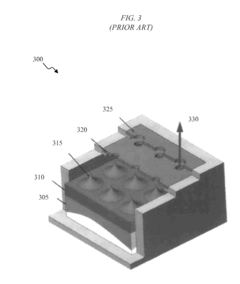

Label-free cellular manipulation and sorting via biocompatible ferrofluids

PatentActiveUS20120237997A1

Innovation

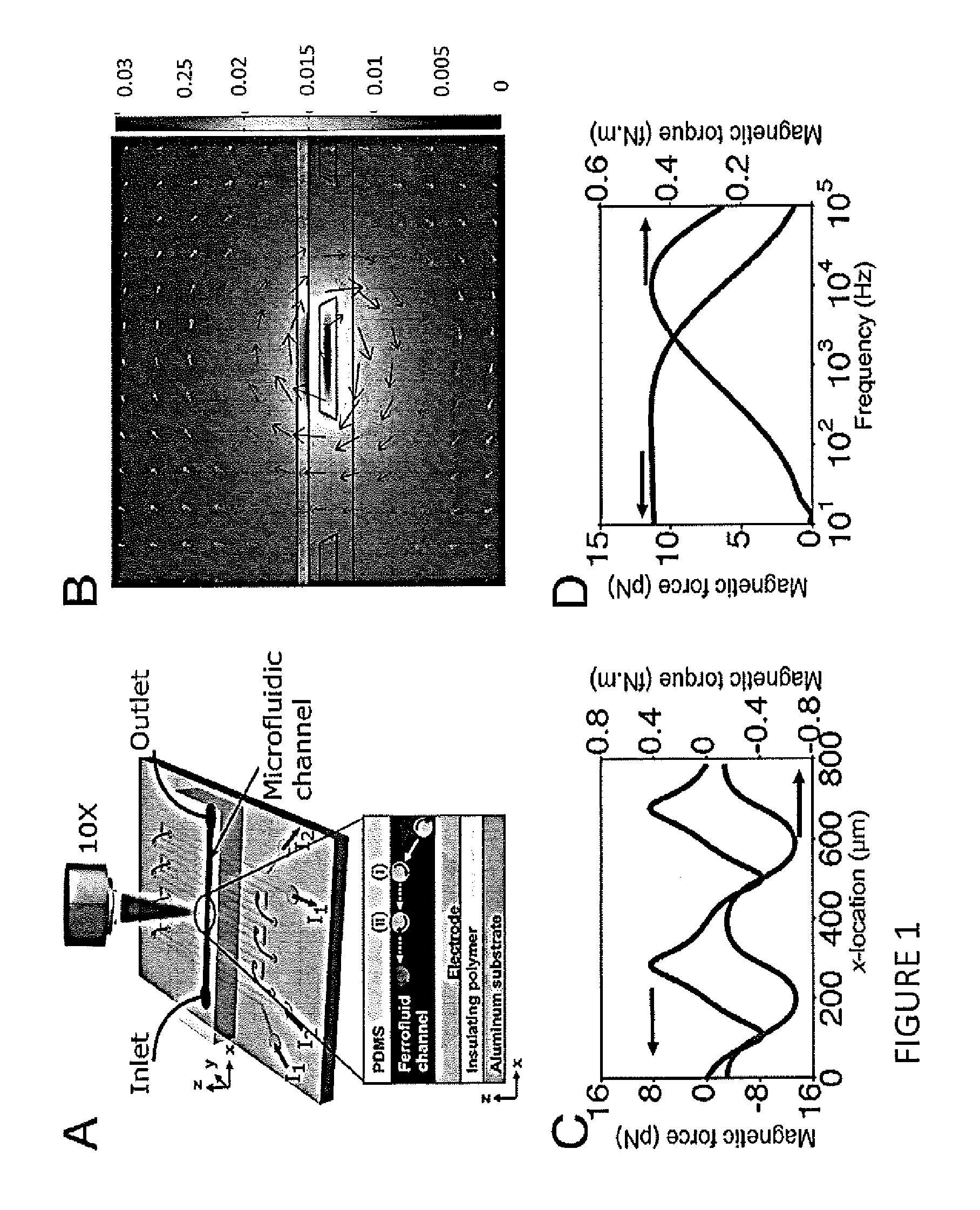

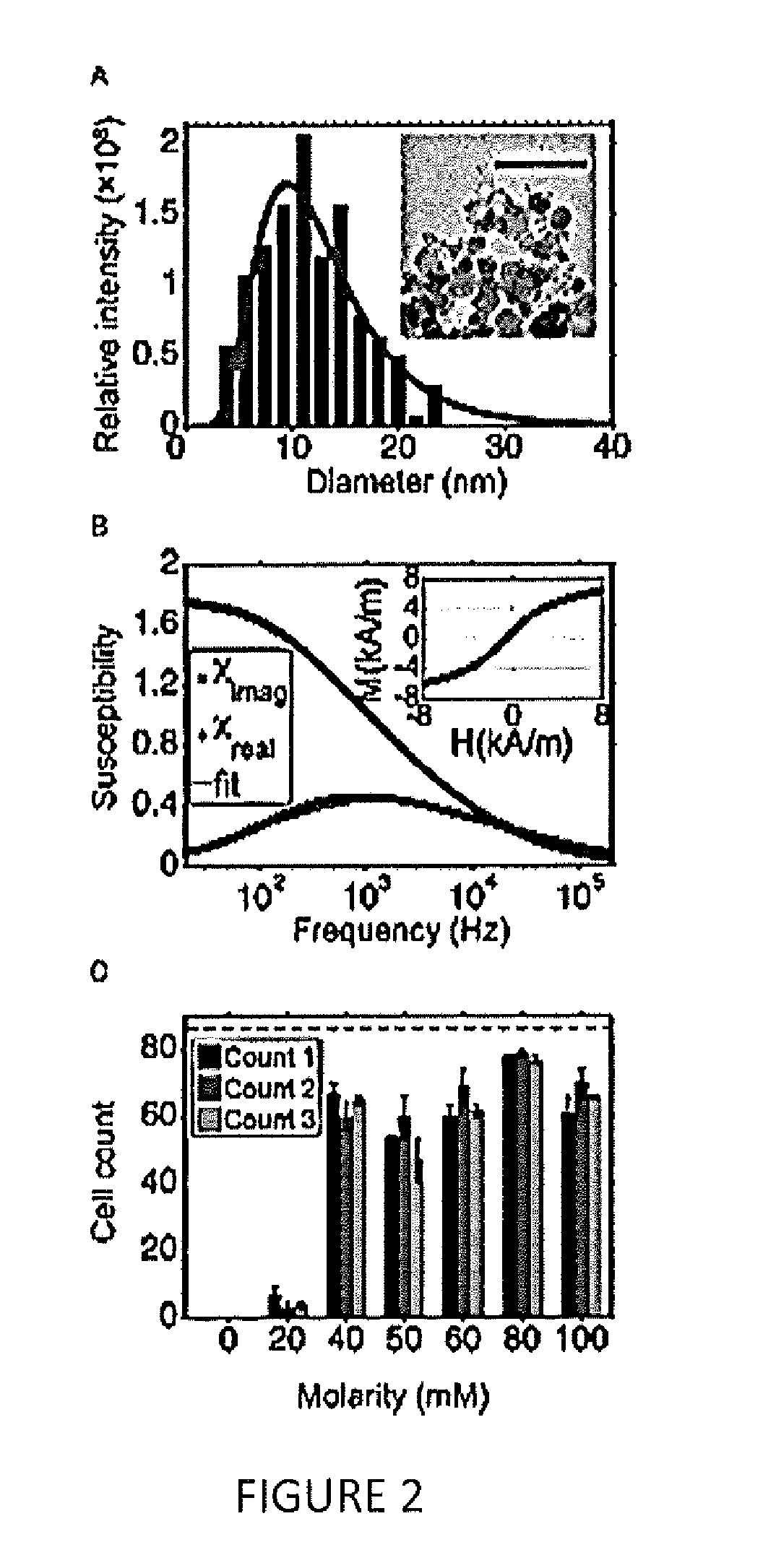

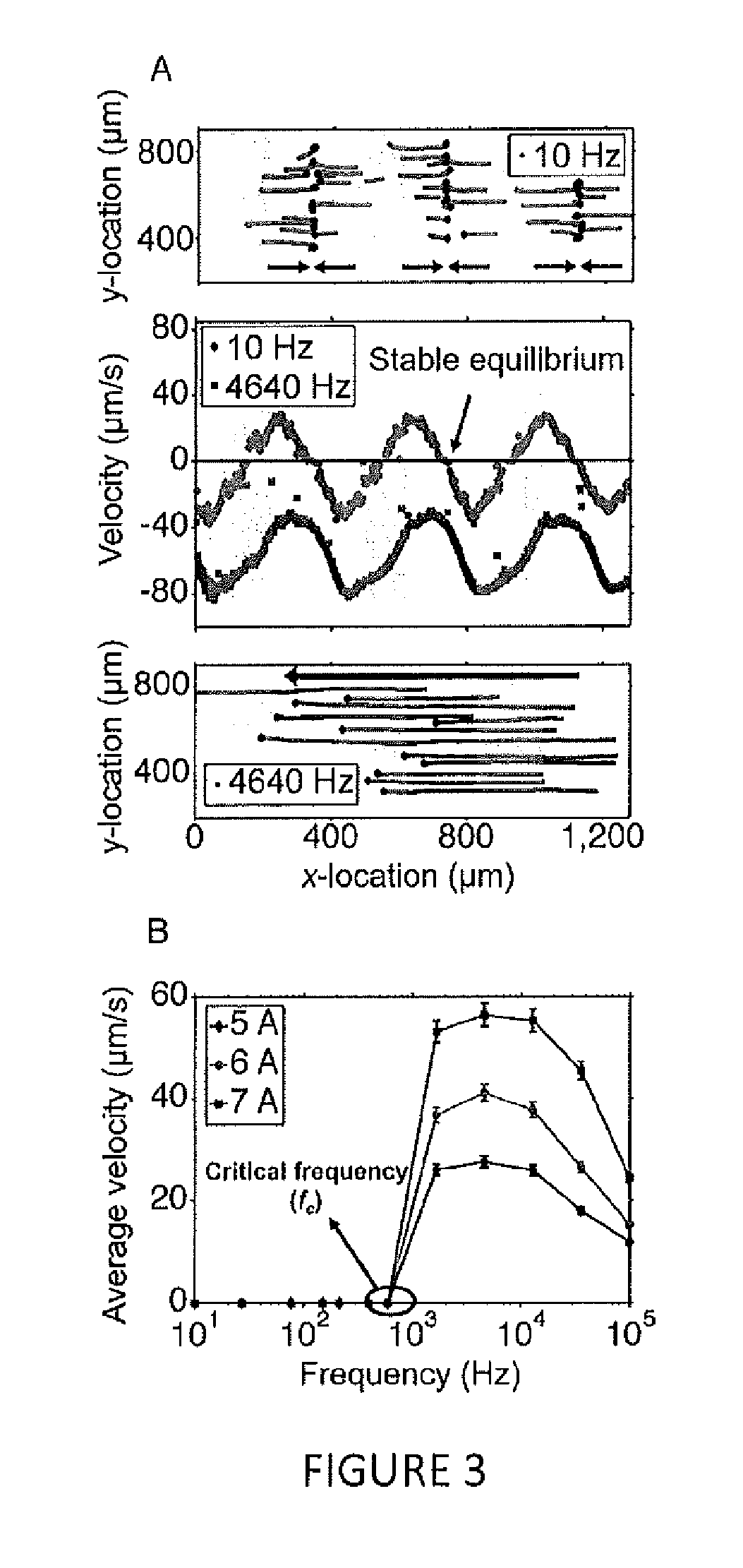

- A microfluidic platform using biocompatible ferrofluids with a microfluidic channel and electrodes that generate a magnetic field pattern, allowing for the controlled manipulation and separation of microparticles and live cells based on size, shape, and elasticity, with high efficiency and rapid separation capabilities.

Environmental Impact

The environmental impact of ferrofluid research in electromagnetic applications is a critical aspect that requires careful consideration. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, have shown promising potential in various electromagnetic applications. However, their widespread use and production raise concerns about potential environmental consequences.

One of the primary environmental considerations is the production process of ferrofluids. The synthesis of magnetic nanoparticles often involves chemical reactions that may generate hazardous byproducts. Proper waste management and treatment protocols are essential to mitigate the risk of environmental contamination. Additionally, the use of rare earth elements in some ferrofluid compositions could lead to increased mining activities, potentially causing habitat disruption and soil degradation.

The disposal of ferrofluid-containing devices and equipment presents another environmental challenge. As these materials become more prevalent in electromagnetic research and applications, proper end-of-life management becomes crucial. Recycling and safe disposal methods need to be developed to prevent the release of nanoparticles into ecosystems, where they could potentially accumulate and affect wildlife.

On the positive side, ferrofluids have the potential to contribute to more energy-efficient electromagnetic systems. Their unique properties allow for improved heat dissipation and enhanced performance in various applications, potentially reducing overall energy consumption. This could indirectly lead to a decrease in greenhouse gas emissions associated with power generation.

The long-term effects of ferrofluids on aquatic and terrestrial ecosystems remain an area of ongoing research. While the magnetic nanoparticles are typically encapsulated within a carrier fluid, there is concern about potential leakage or degradation over time. Studies are needed to assess the bioaccumulation and toxicity of these particles in different organisms and food chains.

As research in this field progresses, it is imperative to develop environmentally friendly ferrofluid formulations. This includes exploring biodegradable carrier fluids and non-toxic magnetic particles. Furthermore, the implementation of closed-loop systems in manufacturing and application processes could significantly reduce the environmental footprint of ferrofluid technologies.

In conclusion, while ferrofluids offer exciting possibilities in electromagnetic research, their environmental impact must be carefully managed. Balancing technological advancement with ecological responsibility will be key to ensuring the sustainable development and application of ferrofluid-based technologies in the future.

One of the primary environmental considerations is the production process of ferrofluids. The synthesis of magnetic nanoparticles often involves chemical reactions that may generate hazardous byproducts. Proper waste management and treatment protocols are essential to mitigate the risk of environmental contamination. Additionally, the use of rare earth elements in some ferrofluid compositions could lead to increased mining activities, potentially causing habitat disruption and soil degradation.

The disposal of ferrofluid-containing devices and equipment presents another environmental challenge. As these materials become more prevalent in electromagnetic research and applications, proper end-of-life management becomes crucial. Recycling and safe disposal methods need to be developed to prevent the release of nanoparticles into ecosystems, where they could potentially accumulate and affect wildlife.

On the positive side, ferrofluids have the potential to contribute to more energy-efficient electromagnetic systems. Their unique properties allow for improved heat dissipation and enhanced performance in various applications, potentially reducing overall energy consumption. This could indirectly lead to a decrease in greenhouse gas emissions associated with power generation.

The long-term effects of ferrofluids on aquatic and terrestrial ecosystems remain an area of ongoing research. While the magnetic nanoparticles are typically encapsulated within a carrier fluid, there is concern about potential leakage or degradation over time. Studies are needed to assess the bioaccumulation and toxicity of these particles in different organisms and food chains.

As research in this field progresses, it is imperative to develop environmentally friendly ferrofluid formulations. This includes exploring biodegradable carrier fluids and non-toxic magnetic particles. Furthermore, the implementation of closed-loop systems in manufacturing and application processes could significantly reduce the environmental footprint of ferrofluid technologies.

In conclusion, while ferrofluids offer exciting possibilities in electromagnetic research, their environmental impact must be carefully managed. Balancing technological advancement with ecological responsibility will be key to ensuring the sustainable development and application of ferrofluid-based technologies in the future.

Ferrofluid Safety Regulations

The safety regulations surrounding ferrofluids are crucial for their responsible use in electromagnetic research and applications. These regulations primarily focus on handling, storage, disposal, and potential environmental impacts. When working with ferrofluids, researchers and technicians must adhere to strict safety protocols to prevent exposure and contamination.

Personal protective equipment (PPE) is mandatory when handling ferrofluids. This includes wearing chemical-resistant gloves, safety goggles, and lab coats. Respiratory protection may be necessary when working with aerosolized ferrofluids or in poorly ventilated areas. Proper training on the safe handling of ferrofluids is essential for all personnel involved in their use.

Storage of ferrofluids requires special considerations. They must be kept in sealed, non-reactive containers away from strong magnetic fields, which can alter their properties. Temperature control is also important, as extreme temperatures can affect the stability of the fluid. Proper labeling of containers with hazard information and storage instructions is mandatory.

Disposal of ferrofluids must follow specific guidelines to prevent environmental contamination. They cannot be disposed of through regular waste streams or poured down drains. Instead, they should be treated as hazardous waste and disposed of through authorized facilities equipped to handle magnetic materials and nanoparticles.

Environmental regulations surrounding ferrofluids are becoming increasingly stringent. Concerns about the potential release of nanoparticles into ecosystems have led to more comprehensive risk assessments and containment measures. Researchers must demonstrate that their use of ferrofluids does not pose a threat to local flora and fauna.

In electromagnetic research applications, additional safety measures are necessary. Strong magnetic fields used in conjunction with ferrofluids can pose risks to individuals with medical implants or devices. Clear signage and restricted access to areas with high magnetic field strength are essential.

Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) in the United States provide guidelines for the safe use of nanomaterials, including ferrofluids. Similar agencies in other countries have developed their own sets of regulations. Compliance with these regulations is mandatory for research institutions and industries working with ferrofluids.

As the applications of ferrofluids in electromagnetic research continue to expand, safety regulations are likely to evolve. Ongoing research into the long-term effects of exposure to ferrofluids and their nanoparticles will inform future regulatory decisions. It is crucial for researchers and institutions to stay informed about the latest safety guidelines and adapt their practices accordingly to ensure the responsible advancement of ferrofluid technology in electromagnetic research.

Personal protective equipment (PPE) is mandatory when handling ferrofluids. This includes wearing chemical-resistant gloves, safety goggles, and lab coats. Respiratory protection may be necessary when working with aerosolized ferrofluids or in poorly ventilated areas. Proper training on the safe handling of ferrofluids is essential for all personnel involved in their use.

Storage of ferrofluids requires special considerations. They must be kept in sealed, non-reactive containers away from strong magnetic fields, which can alter their properties. Temperature control is also important, as extreme temperatures can affect the stability of the fluid. Proper labeling of containers with hazard information and storage instructions is mandatory.

Disposal of ferrofluids must follow specific guidelines to prevent environmental contamination. They cannot be disposed of through regular waste streams or poured down drains. Instead, they should be treated as hazardous waste and disposed of through authorized facilities equipped to handle magnetic materials and nanoparticles.

Environmental regulations surrounding ferrofluids are becoming increasingly stringent. Concerns about the potential release of nanoparticles into ecosystems have led to more comprehensive risk assessments and containment measures. Researchers must demonstrate that their use of ferrofluids does not pose a threat to local flora and fauna.

In electromagnetic research applications, additional safety measures are necessary. Strong magnetic fields used in conjunction with ferrofluids can pose risks to individuals with medical implants or devices. Clear signage and restricted access to areas with high magnetic field strength are essential.

Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) in the United States provide guidelines for the safe use of nanomaterials, including ferrofluids. Similar agencies in other countries have developed their own sets of regulations. Compliance with these regulations is mandatory for research institutions and industries working with ferrofluids.

As the applications of ferrofluids in electromagnetic research continue to expand, safety regulations are likely to evolve. Ongoing research into the long-term effects of exposure to ferrofluids and their nanoparticles will inform future regulatory decisions. It is crucial for researchers and institutions to stay informed about the latest safety guidelines and adapt their practices accordingly to ensure the responsible advancement of ferrofluid technology in electromagnetic research.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!