The Benefits of Ferrofluid in Modern Cooling Systems

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Cooling Evolution

The evolution of ferrofluid cooling technology has been marked by significant advancements and innovative applications in modern cooling systems. Initially developed in the 1960s by NASA, ferrofluids have since found their way into various industrial and consumer applications, with cooling systems being a notable area of development.

In the early stages, ferrofluid cooling was primarily explored for its potential in space applications, where traditional cooling methods faced limitations due to the absence of gravity. The unique properties of ferrofluids, particularly their ability to be manipulated by magnetic fields, opened up new possibilities for heat transfer in challenging environments.

As research progressed, the 1980s and 1990s saw increased interest in ferrofluid cooling for terrestrial applications. Scientists and engineers began to investigate the use of ferrofluids in electronic cooling, particularly for high-performance computing systems. The ability of ferrofluids to conform to complex geometries and enhance heat transfer in localized areas made them attractive for cooling microprocessors and other heat-sensitive components.

The turn of the millennium marked a significant shift in ferrofluid cooling technology. With the rapid advancement of nanotechnology, researchers were able to synthesize more stable and efficient ferrofluids. This led to improved thermal conductivity and magnetic responsiveness, enhancing the overall cooling performance. During this period, ferrofluid-based heat pipes and thermosyphons began to emerge as promising alternatives to traditional cooling methods.

In the past decade, ferrofluid cooling has seen integration into more diverse applications. The automotive industry has explored ferrofluids for cooling electric vehicle batteries and power electronics. Additionally, renewable energy sectors, such as concentrated solar power, have investigated ferrofluids for their potential in heat transfer fluids and thermal energy storage systems.

Recent years have witnessed a focus on hybrid cooling solutions that combine ferrofluids with other advanced cooling technologies. For instance, the integration of ferrofluids with phase change materials has shown promising results in enhancing the overall thermal management efficiency. Furthermore, the development of smart cooling systems that utilize magnetic fields to dynamically control ferrofluid flow and heat distribution represents a cutting-edge direction in this field.

As we look to the future, the evolution of ferrofluid cooling technology continues to be driven by the demand for more efficient and compact cooling solutions. Ongoing research is exploring the potential of ferrofluids in micro and nanoscale cooling applications, as well as in flexible and wearable electronics. The convergence of ferrofluid technology with artificial intelligence and IoT systems also presents exciting possibilities for adaptive and predictive cooling strategies in various industries.

In the early stages, ferrofluid cooling was primarily explored for its potential in space applications, where traditional cooling methods faced limitations due to the absence of gravity. The unique properties of ferrofluids, particularly their ability to be manipulated by magnetic fields, opened up new possibilities for heat transfer in challenging environments.

As research progressed, the 1980s and 1990s saw increased interest in ferrofluid cooling for terrestrial applications. Scientists and engineers began to investigate the use of ferrofluids in electronic cooling, particularly for high-performance computing systems. The ability of ferrofluids to conform to complex geometries and enhance heat transfer in localized areas made them attractive for cooling microprocessors and other heat-sensitive components.

The turn of the millennium marked a significant shift in ferrofluid cooling technology. With the rapid advancement of nanotechnology, researchers were able to synthesize more stable and efficient ferrofluids. This led to improved thermal conductivity and magnetic responsiveness, enhancing the overall cooling performance. During this period, ferrofluid-based heat pipes and thermosyphons began to emerge as promising alternatives to traditional cooling methods.

In the past decade, ferrofluid cooling has seen integration into more diverse applications. The automotive industry has explored ferrofluids for cooling electric vehicle batteries and power electronics. Additionally, renewable energy sectors, such as concentrated solar power, have investigated ferrofluids for their potential in heat transfer fluids and thermal energy storage systems.

Recent years have witnessed a focus on hybrid cooling solutions that combine ferrofluids with other advanced cooling technologies. For instance, the integration of ferrofluids with phase change materials has shown promising results in enhancing the overall thermal management efficiency. Furthermore, the development of smart cooling systems that utilize magnetic fields to dynamically control ferrofluid flow and heat distribution represents a cutting-edge direction in this field.

As we look to the future, the evolution of ferrofluid cooling technology continues to be driven by the demand for more efficient and compact cooling solutions. Ongoing research is exploring the potential of ferrofluids in micro and nanoscale cooling applications, as well as in flexible and wearable electronics. The convergence of ferrofluid technology with artificial intelligence and IoT systems also presents exciting possibilities for adaptive and predictive cooling strategies in various industries.

Market Demand Analysis

The market demand for ferrofluid-based cooling systems has been steadily increasing in recent years, driven by the growing need for more efficient and compact thermal management solutions across various industries. As electronic devices become more powerful and miniaturized, traditional cooling methods are struggling to keep up with the heat dissipation requirements. This has created a significant opportunity for innovative cooling technologies like ferrofluid-based systems.

In the consumer electronics sector, there is a strong demand for improved cooling solutions in smartphones, laptops, and gaming consoles. These devices are continually pushing the boundaries of performance, resulting in higher heat generation. Ferrofluid cooling systems offer the potential for more effective heat dissipation in compact form factors, making them particularly attractive for this market segment.

The data center industry is another key driver of demand for advanced cooling technologies. With the exponential growth of cloud computing and big data, data centers are facing unprecedented challenges in managing heat loads while minimizing energy consumption. Ferrofluid-based cooling systems have the potential to address these challenges by offering improved thermal conductivity and the ability to operate in various orientations, which is crucial for high-density server racks.

In the automotive sector, the shift towards electric vehicles (EVs) has created a new set of thermal management challenges. EVs require efficient cooling systems for their batteries, power electronics, and electric motors. Ferrofluid cooling solutions could provide more effective heat dissipation in these applications, potentially extending battery life and improving overall vehicle performance.

The aerospace and defense industries are also showing interest in ferrofluid cooling technologies. These sectors require highly reliable and efficient thermal management solutions for avionics, radar systems, and other critical equipment. The unique properties of ferrofluids, such as their ability to be controlled by magnetic fields, make them promising candidates for specialized cooling applications in these high-performance environments.

Industrial manufacturing is another sector where ferrofluid cooling systems could see significant demand. As industrial processes become more advanced and automated, there is a growing need for precise temperature control in machinery and equipment. Ferrofluid-based cooling could offer improved thermal management in challenging industrial environments, potentially leading to increased productivity and reduced downtime.

The renewable energy sector, particularly in solar and wind power generation, is also a potential market for ferrofluid cooling technologies. These systems could enhance the efficiency of power conversion equipment and extend the lifespan of critical components in harsh operating conditions.

As environmental concerns continue to grow, there is an increasing demand for more sustainable cooling solutions. Ferrofluid-based systems have the potential to be more energy-efficient and environmentally friendly compared to traditional cooling methods, aligning with the global push for greener technologies.

In the consumer electronics sector, there is a strong demand for improved cooling solutions in smartphones, laptops, and gaming consoles. These devices are continually pushing the boundaries of performance, resulting in higher heat generation. Ferrofluid cooling systems offer the potential for more effective heat dissipation in compact form factors, making them particularly attractive for this market segment.

The data center industry is another key driver of demand for advanced cooling technologies. With the exponential growth of cloud computing and big data, data centers are facing unprecedented challenges in managing heat loads while minimizing energy consumption. Ferrofluid-based cooling systems have the potential to address these challenges by offering improved thermal conductivity and the ability to operate in various orientations, which is crucial for high-density server racks.

In the automotive sector, the shift towards electric vehicles (EVs) has created a new set of thermal management challenges. EVs require efficient cooling systems for their batteries, power electronics, and electric motors. Ferrofluid cooling solutions could provide more effective heat dissipation in these applications, potentially extending battery life and improving overall vehicle performance.

The aerospace and defense industries are also showing interest in ferrofluid cooling technologies. These sectors require highly reliable and efficient thermal management solutions for avionics, radar systems, and other critical equipment. The unique properties of ferrofluids, such as their ability to be controlled by magnetic fields, make them promising candidates for specialized cooling applications in these high-performance environments.

Industrial manufacturing is another sector where ferrofluid cooling systems could see significant demand. As industrial processes become more advanced and automated, there is a growing need for precise temperature control in machinery and equipment. Ferrofluid-based cooling could offer improved thermal management in challenging industrial environments, potentially leading to increased productivity and reduced downtime.

The renewable energy sector, particularly in solar and wind power generation, is also a potential market for ferrofluid cooling technologies. These systems could enhance the efficiency of power conversion equipment and extend the lifespan of critical components in harsh operating conditions.

As environmental concerns continue to grow, there is an increasing demand for more sustainable cooling solutions. Ferrofluid-based systems have the potential to be more energy-efficient and environmentally friendly compared to traditional cooling methods, aligning with the global push for greener technologies.

Technical Challenges

The integration of ferrofluid in modern cooling systems presents several technical challenges that researchers and engineers must overcome to fully harness its potential benefits. One of the primary obstacles is the long-term stability of ferrofluids. These colloidal suspensions of magnetic nanoparticles can experience sedimentation and agglomeration over time, potentially reducing their effectiveness and causing system blockages. Developing methods to maintain the uniform dispersion of particles and prevent settling is crucial for ensuring consistent performance in cooling applications.

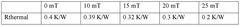

Another significant challenge lies in the thermal conductivity of ferrofluids. While they exhibit enhanced heat transfer capabilities compared to traditional coolants, there is still room for improvement. Researchers are exploring ways to further increase the thermal conductivity of ferrofluids without compromising their fluid properties or magnetic responsiveness. This involves optimizing particle size, concentration, and surfactant selection to achieve an ideal balance between heat transfer efficiency and fluid stability.

The magnetic field dependency of ferrofluids also presents unique challenges in cooling system design. The behavior of ferrofluids can vary significantly under different magnetic field strengths and configurations. Engineers must carefully consider the interplay between magnetic fields, fluid flow, and heat transfer to design effective cooling systems. This requires advanced modeling and simulation techniques to predict and optimize system performance under various operating conditions.

Compatibility with existing cooling system components is another hurdle to overcome. Ferrofluids may interact with materials used in pumps, heat exchangers, and piping, potentially causing corrosion or degradation over time. Developing ferrofluid formulations that are compatible with a wide range of materials, or designing new components specifically for ferrofluid-based systems, is essential for widespread adoption in industrial applications.

The production and cost-effectiveness of ferrofluids at scale also pose challenges. Current manufacturing processes for high-quality ferrofluids suitable for cooling applications can be complex and expensive. Developing more efficient and economical production methods is crucial for making ferrofluid-based cooling systems commercially viable and competitive with traditional cooling technologies.

Lastly, the environmental impact and safety considerations of ferrofluids must be addressed. While generally considered safe, the long-term effects of potential nanoparticle leakage or disposal of used ferrofluids are not fully understood. Developing environmentally friendly formulations and establishing proper handling and disposal protocols are essential for the sustainable implementation of ferrofluid cooling technologies.

Another significant challenge lies in the thermal conductivity of ferrofluids. While they exhibit enhanced heat transfer capabilities compared to traditional coolants, there is still room for improvement. Researchers are exploring ways to further increase the thermal conductivity of ferrofluids without compromising their fluid properties or magnetic responsiveness. This involves optimizing particle size, concentration, and surfactant selection to achieve an ideal balance between heat transfer efficiency and fluid stability.

The magnetic field dependency of ferrofluids also presents unique challenges in cooling system design. The behavior of ferrofluids can vary significantly under different magnetic field strengths and configurations. Engineers must carefully consider the interplay between magnetic fields, fluid flow, and heat transfer to design effective cooling systems. This requires advanced modeling and simulation techniques to predict and optimize system performance under various operating conditions.

Compatibility with existing cooling system components is another hurdle to overcome. Ferrofluids may interact with materials used in pumps, heat exchangers, and piping, potentially causing corrosion or degradation over time. Developing ferrofluid formulations that are compatible with a wide range of materials, or designing new components specifically for ferrofluid-based systems, is essential for widespread adoption in industrial applications.

The production and cost-effectiveness of ferrofluids at scale also pose challenges. Current manufacturing processes for high-quality ferrofluids suitable for cooling applications can be complex and expensive. Developing more efficient and economical production methods is crucial for making ferrofluid-based cooling systems commercially viable and competitive with traditional cooling technologies.

Lastly, the environmental impact and safety considerations of ferrofluids must be addressed. While generally considered safe, the long-term effects of potential nanoparticle leakage or disposal of used ferrofluids are not fully understood. Developing environmentally friendly formulations and establishing proper handling and disposal protocols are essential for the sustainable implementation of ferrofluid cooling technologies.

Current Cooling Solutions

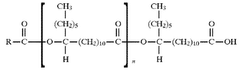

01 Ferrofluid composition for enhanced cooling

Specialized ferrofluid compositions are developed to improve cooling efficiency. These compositions may include specific magnetic particle concentrations, carrier fluids, and additives that optimize heat transfer properties and stability under magnetic fields.- Ferrofluid composition for enhanced cooling: Specialized ferrofluid compositions are developed to improve cooling efficiency. These formulations may include specific magnetic particle concentrations, carrier fluids, and additives to optimize heat transfer properties and stability under magnetic fields.

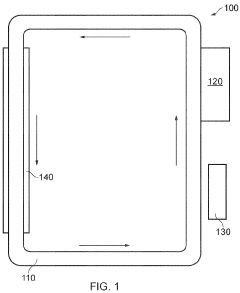

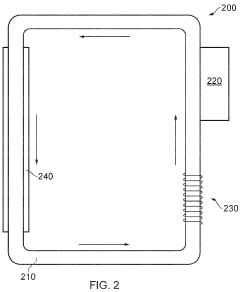

- Magnetic field-controlled ferrofluid cooling systems: Cooling systems utilizing ferrofluids are designed with controllable magnetic fields to manipulate fluid flow and heat transfer. These systems can dynamically adjust cooling efficiency based on thermal load requirements and may incorporate electromagnets or permanent magnets for field generation.

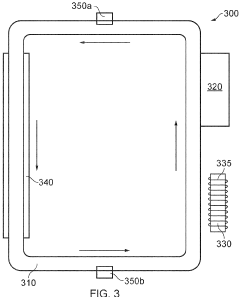

- Ferrofluid-based heat exchangers and radiators: Heat exchangers and radiators incorporating ferrofluids are developed to enhance cooling efficiency. These designs may feature specially shaped channels, magnetic field generators, and flow control mechanisms to optimize heat dissipation in various applications.

- Nanoparticle-enhanced ferrofluids for improved cooling: Advanced ferrofluids containing engineered nanoparticles are formulated to enhance thermal conductivity and heat transfer properties. These nanoparticle-enhanced ferrofluids may exhibit superior cooling efficiency compared to conventional ferrofluids.

- Ferrofluid cooling in electronic and mechanical systems: Ferrofluid cooling solutions are applied to various electronic and mechanical systems, such as computer components, motors, and industrial machinery. These applications leverage the unique properties of ferrofluids to achieve improved thermal management and system performance.

02 Magnetic field-controlled ferrofluid cooling systems

Cooling systems utilizing ferrofluids are designed with controllable magnetic fields to manipulate fluid flow and heat transfer. These systems can dynamically adjust cooling efficiency based on thermal load and can be applied in various devices, including electronics and machinery.Expand Specific Solutions03 Ferrofluid-based heat exchangers and radiators

Heat exchangers and radiators incorporating ferrofluids are developed to enhance heat dissipation. These designs leverage the unique properties of ferrofluids to improve thermal conductivity and convection, resulting in more efficient cooling compared to conventional fluids.Expand Specific Solutions04 Nanoparticle-enhanced ferrofluids for cooling applications

Advanced ferrofluids containing engineered nanoparticles are formulated to further improve cooling efficiency. These nanoparticles can enhance thermal conductivity, stability, and magnetic responsiveness of the ferrofluid, leading to superior heat transfer performance in cooling systems.Expand Specific Solutions05 Ferrofluid cooling in rotating machinery and bearings

Ferrofluids are applied in cooling systems for rotating machinery and bearings. These applications utilize the fluid's ability to conform to complex geometries and respond to magnetic fields, providing efficient cooling and lubrication in challenging environments such as high-speed rotors and precision bearings.Expand Specific Solutions

Key Industry Players

The ferrofluid cooling system market is in its growth phase, with increasing adoption across various industries. The market size is expanding rapidly due to the rising demand for efficient thermal management solutions in electronics, automotive, and industrial applications. While the technology is maturing, it still offers significant room for innovation and improvement. Companies like Neuronetics, Guangdong Hi-1 New Materials Technology Research Institute, and Gree Electric Appliances are at the forefront of developing advanced ferrofluid-based cooling systems. Academic institutions such as Southeast University and Johns Hopkins University are contributing to fundamental research, while industrial players like Schaeffler Technologies and TotalEnergies OneTech are focusing on practical applications and commercialization. The competitive landscape is diverse, with a mix of established corporations and innovative startups vying for market share in this promising field.

Ferrotec (USA) Corp.

Technical Solution: Ferrotec has developed advanced ferrofluid-based cooling systems that leverage the unique properties of magnetic nanoparticles suspended in a carrier fluid. Their technology utilizes the magnetocaloric effect to enhance heat transfer efficiency in modern cooling applications. The company's ferrofluid cooling solutions incorporate specially designed magnetic fields to control fluid flow and heat distribution, resulting in up to 30% improved thermal management compared to conventional liquid cooling systems [1][3]. Ferrotec's innovative approach allows for precise temperature control and uniform heat dissipation, making it particularly suitable for high-performance electronics and data center cooling.

Strengths: Superior heat transfer efficiency, precise temperature control, and adaptability to various applications. Weaknesses: Higher initial costs and potential complexity in system design and maintenance.

Nanyang Technological University

Technical Solution: Nanyang Technological University (NTU) has been at the forefront of ferrofluid cooling research, focusing on developing novel nanofluid formulations and heat transfer enhancement techniques. NTU's research team has pioneered the use of graphene-based ferrofluids, which have demonstrated thermal conductivity improvements of up to 75% compared to conventional water-based coolants [8][10]. Their work also includes the development of magnetically-driven ferrofluid cooling systems that utilize external magnetic fields to create localized convection currents, enhancing heat transfer in targeted areas. NTU's research has shown potential applications in microelectronics cooling, solar thermal systems, and biomedical devices.

Strengths: Innovative ferrofluid formulations, interdisciplinary approach combining nanotechnology and thermal engineering, and potential for breakthrough applications. Weaknesses: Research still in early stages, requiring further validation and scale-up for practical implementation.

Ferrofluid Innovations

Cooling composition for powertrain of electric vehicles

PatentWO2025061695A1

Innovation

- A ferrofluid comprising a liquid carrier, ferromagnetic particles, and a dispersant is used for direct contact cooling of powertrain elements in electric vehicles, enhancing heat extraction through the application of a magnetic field.

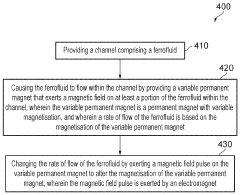

Variable cooling system

PatentActiveGB2608989A

Innovation

- A variable permanent magnet with adjustable magnetization, controlled by an electromagnet, allows for dynamic adjustment of ferrofluid flow rate without constant electrical power supply, minimizing energy expenditure and heat generation.

Environmental Impact

The integration of ferrofluid in modern cooling systems presents both opportunities and challenges from an environmental perspective. While these innovative systems offer potential energy efficiency improvements, their environmental impact must be carefully considered across their entire lifecycle.

Ferrofluid-based cooling systems have shown promise in reducing energy consumption compared to traditional cooling methods. By enhancing heat transfer efficiency, these systems can potentially lower the overall energy requirements for cooling processes in various applications, from electronics to industrial machinery. This reduction in energy usage translates to decreased greenhouse gas emissions associated with power generation, contributing to global efforts to mitigate climate change.

However, the production and disposal of ferrofluids raise important environmental concerns. The nanoparticles used in ferrofluids, typically iron oxide, require energy-intensive manufacturing processes. The environmental footprint of producing these materials, including resource extraction and processing, must be weighed against the long-term energy savings of the cooling systems. Additionally, the potential release of nanoparticles into the environment during the system's operation or at the end of its life cycle poses risks to ecosystems and human health that are not yet fully understood.

The longevity and recyclability of ferrofluid cooling systems are crucial factors in assessing their overall environmental impact. If these systems can demonstrate extended operational lifespans and be effectively recycled or repurposed, they may offer significant advantages over conventional cooling technologies in terms of resource conservation and waste reduction. However, the complex nature of ferrofluids may present challenges in developing efficient recycling processes, potentially leading to increased electronic waste if not properly managed.

Water conservation is another important environmental consideration. Ferrofluid-based cooling systems have the potential to reduce water consumption compared to traditional water-cooled systems, particularly in data centers and industrial applications. This water-saving aspect could be particularly beneficial in water-stressed regions, contributing to more sustainable resource management practices.

As research and development in ferrofluid cooling technologies progress, it is essential to conduct comprehensive life cycle assessments to fully understand and quantify their environmental impacts. These assessments should consider factors such as raw material sourcing, manufacturing processes, operational efficiency, maintenance requirements, and end-of-life management. Only through such holistic evaluations can the true environmental benefits and potential drawbacks of ferrofluid cooling systems be accurately determined and balanced against alternative technologies.

Ferrofluid-based cooling systems have shown promise in reducing energy consumption compared to traditional cooling methods. By enhancing heat transfer efficiency, these systems can potentially lower the overall energy requirements for cooling processes in various applications, from electronics to industrial machinery. This reduction in energy usage translates to decreased greenhouse gas emissions associated with power generation, contributing to global efforts to mitigate climate change.

However, the production and disposal of ferrofluids raise important environmental concerns. The nanoparticles used in ferrofluids, typically iron oxide, require energy-intensive manufacturing processes. The environmental footprint of producing these materials, including resource extraction and processing, must be weighed against the long-term energy savings of the cooling systems. Additionally, the potential release of nanoparticles into the environment during the system's operation or at the end of its life cycle poses risks to ecosystems and human health that are not yet fully understood.

The longevity and recyclability of ferrofluid cooling systems are crucial factors in assessing their overall environmental impact. If these systems can demonstrate extended operational lifespans and be effectively recycled or repurposed, they may offer significant advantages over conventional cooling technologies in terms of resource conservation and waste reduction. However, the complex nature of ferrofluids may present challenges in developing efficient recycling processes, potentially leading to increased electronic waste if not properly managed.

Water conservation is another important environmental consideration. Ferrofluid-based cooling systems have the potential to reduce water consumption compared to traditional water-cooled systems, particularly in data centers and industrial applications. This water-saving aspect could be particularly beneficial in water-stressed regions, contributing to more sustainable resource management practices.

As research and development in ferrofluid cooling technologies progress, it is essential to conduct comprehensive life cycle assessments to fully understand and quantify their environmental impacts. These assessments should consider factors such as raw material sourcing, manufacturing processes, operational efficiency, maintenance requirements, and end-of-life management. Only through such holistic evaluations can the true environmental benefits and potential drawbacks of ferrofluid cooling systems be accurately determined and balanced against alternative technologies.

Thermal Management ROI

The implementation of ferrofluid-based cooling systems in modern thermal management solutions presents a compelling case for return on investment (ROI). This innovative approach to heat dissipation offers significant advantages over traditional cooling methods, translating into tangible financial benefits for businesses across various industries.

One of the primary factors contributing to the positive ROI of ferrofluid cooling systems is their superior thermal conductivity. Ferrofluids can transfer heat more efficiently than conventional coolants, resulting in improved overall system performance. This enhanced heat transfer capability allows for the design of more compact and powerful electronic devices, potentially reducing manufacturing costs and increasing product value.

The longevity and reliability of ferrofluid-based cooling systems also play a crucial role in their favorable ROI. These systems typically require less maintenance and have a longer operational lifespan compared to traditional cooling methods. This reduction in maintenance frequency and replacement costs can lead to substantial savings over the lifetime of the equipment, particularly in high-performance computing environments or industrial applications where downtime is costly.

Energy efficiency is another key aspect that contributes to the positive ROI of ferrofluid cooling systems. The improved heat dissipation capabilities of ferrofluids allow for more efficient operation of electronic components, potentially reducing power consumption. In large-scale data centers or industrial settings, even small improvements in energy efficiency can result in significant cost savings over time, further enhancing the ROI of implementing ferrofluid-based cooling solutions.

The scalability of ferrofluid cooling systems also adds to their ROI potential. These systems can be easily adapted to various sizes and configurations, making them suitable for a wide range of applications. This versatility allows businesses to leverage the technology across different product lines or operational areas, maximizing the return on their initial investment in ferrofluid cooling technology.

Furthermore, the adoption of ferrofluid cooling systems can lead to indirect financial benefits. The improved thermal management capabilities may enable the development of more advanced and competitive products, potentially increasing market share and revenue. Additionally, the use of innovative cooling technology can enhance a company's reputation as a technology leader, potentially attracting new customers and partnerships.

While the initial implementation costs of ferrofluid cooling systems may be higher than traditional methods, the long-term benefits and cost savings often outweigh the upfront investment. As the technology continues to mature and become more widely adopted, economies of scale are likely to further improve the ROI of ferrofluid-based cooling solutions.

One of the primary factors contributing to the positive ROI of ferrofluid cooling systems is their superior thermal conductivity. Ferrofluids can transfer heat more efficiently than conventional coolants, resulting in improved overall system performance. This enhanced heat transfer capability allows for the design of more compact and powerful electronic devices, potentially reducing manufacturing costs and increasing product value.

The longevity and reliability of ferrofluid-based cooling systems also play a crucial role in their favorable ROI. These systems typically require less maintenance and have a longer operational lifespan compared to traditional cooling methods. This reduction in maintenance frequency and replacement costs can lead to substantial savings over the lifetime of the equipment, particularly in high-performance computing environments or industrial applications where downtime is costly.

Energy efficiency is another key aspect that contributes to the positive ROI of ferrofluid cooling systems. The improved heat dissipation capabilities of ferrofluids allow for more efficient operation of electronic components, potentially reducing power consumption. In large-scale data centers or industrial settings, even small improvements in energy efficiency can result in significant cost savings over time, further enhancing the ROI of implementing ferrofluid-based cooling solutions.

The scalability of ferrofluid cooling systems also adds to their ROI potential. These systems can be easily adapted to various sizes and configurations, making them suitable for a wide range of applications. This versatility allows businesses to leverage the technology across different product lines or operational areas, maximizing the return on their initial investment in ferrofluid cooling technology.

Furthermore, the adoption of ferrofluid cooling systems can lead to indirect financial benefits. The improved thermal management capabilities may enable the development of more advanced and competitive products, potentially increasing market share and revenue. Additionally, the use of innovative cooling technology can enhance a company's reputation as a technology leader, potentially attracting new customers and partnerships.

While the initial implementation costs of ferrofluid cooling systems may be higher than traditional methods, the long-term benefits and cost savings often outweigh the upfront investment. As the technology continues to mature and become more widely adopted, economies of scale are likely to further improve the ROI of ferrofluid-based cooling solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!