Leading Ferrofluid Techniques in Nanotechnology Research

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Evolution

Ferrofluids have undergone a remarkable evolution since their inception in the 1960s, marking significant milestones in the field of nanotechnology. Initially developed by NASA for controlling liquids in zero gravity, these magnetic nanofluids have since found applications across various industries, showcasing their versatility and potential.

The early stages of ferrofluid development focused primarily on their magnetic properties and basic composition. Scientists worked on perfecting the suspension of magnetic nanoparticles in carrier fluids, ensuring stability and responsiveness to external magnetic fields. This period saw the establishment of fundamental principles that would guide future research and applications.

As research progressed, the 1980s and 1990s witnessed a surge in exploring the unique properties of ferrofluids. Scientists began to understand and manipulate their rheological behavior, thermal properties, and optical characteristics. This era marked the transition from purely theoretical studies to practical applications, with ferrofluids finding their way into industrial settings, particularly in electronic devices and mechanical engineering.

The turn of the millennium brought about a new phase in ferrofluid evolution, characterized by the integration of advanced materials science and nanotechnology. Researchers started experimenting with different types of magnetic nanoparticles, carrier fluids, and surfactants to enhance the performance and stability of ferrofluids. This period saw the development of biocompatible ferrofluids, opening up possibilities in biomedical applications such as targeted drug delivery and magnetic hyperthermia for cancer treatment.

In recent years, the focus has shifted towards developing smart ferrofluids with programmable properties. Scientists are now exploring ways to create ferrofluids that can change their characteristics in response to multiple stimuli, not just magnetic fields. This includes research into thermo-responsive and pH-sensitive ferrofluids, which could revolutionize fields like microfluidics and adaptive optics.

The latest frontier in ferrofluid evolution involves the integration of ferrofluids with other emerging technologies. For instance, researchers are investigating the potential of ferrofluids in energy harvesting, utilizing their unique properties to convert mechanical energy into electrical energy. Additionally, there's growing interest in combining ferrofluids with advanced manufacturing techniques like 3D printing to create novel structures and devices with unprecedented magnetic and fluidic properties.

As we look to the future, the evolution of ferrofluids continues to push the boundaries of what's possible in nanotechnology. With ongoing research into new materials, fabrication techniques, and applications, ferrofluids are poised to play an increasingly important role in solving complex technological challenges across various fields, from healthcare to energy to advanced computing.

The early stages of ferrofluid development focused primarily on their magnetic properties and basic composition. Scientists worked on perfecting the suspension of magnetic nanoparticles in carrier fluids, ensuring stability and responsiveness to external magnetic fields. This period saw the establishment of fundamental principles that would guide future research and applications.

As research progressed, the 1980s and 1990s witnessed a surge in exploring the unique properties of ferrofluids. Scientists began to understand and manipulate their rheological behavior, thermal properties, and optical characteristics. This era marked the transition from purely theoretical studies to practical applications, with ferrofluids finding their way into industrial settings, particularly in electronic devices and mechanical engineering.

The turn of the millennium brought about a new phase in ferrofluid evolution, characterized by the integration of advanced materials science and nanotechnology. Researchers started experimenting with different types of magnetic nanoparticles, carrier fluids, and surfactants to enhance the performance and stability of ferrofluids. This period saw the development of biocompatible ferrofluids, opening up possibilities in biomedical applications such as targeted drug delivery and magnetic hyperthermia for cancer treatment.

In recent years, the focus has shifted towards developing smart ferrofluids with programmable properties. Scientists are now exploring ways to create ferrofluids that can change their characteristics in response to multiple stimuli, not just magnetic fields. This includes research into thermo-responsive and pH-sensitive ferrofluids, which could revolutionize fields like microfluidics and adaptive optics.

The latest frontier in ferrofluid evolution involves the integration of ferrofluids with other emerging technologies. For instance, researchers are investigating the potential of ferrofluids in energy harvesting, utilizing their unique properties to convert mechanical energy into electrical energy. Additionally, there's growing interest in combining ferrofluids with advanced manufacturing techniques like 3D printing to create novel structures and devices with unprecedented magnetic and fluidic properties.

As we look to the future, the evolution of ferrofluids continues to push the boundaries of what's possible in nanotechnology. With ongoing research into new materials, fabrication techniques, and applications, ferrofluids are poised to play an increasingly important role in solving complex technological challenges across various fields, from healthcare to energy to advanced computing.

Nanotech Market Demand

The market demand for nanotechnology, particularly in the field of ferrofluid techniques, has been experiencing significant growth in recent years. This surge is driven by the increasing applications of ferrofluids across various industries, including healthcare, electronics, mechanical engineering, and aerospace.

In the healthcare sector, ferrofluids are gaining traction in targeted drug delivery systems and magnetic hyperthermia for cancer treatment. The ability to manipulate these nanoscale magnetic particles with external magnetic fields offers precise control in medical procedures, leading to improved patient outcomes and reduced side effects. This application alone is expected to drive substantial market growth in the coming years.

The electronics industry is another major contributor to the rising demand for ferrofluid-based nanotechnology. Ferrofluids are being utilized in advanced cooling systems for high-performance computing and data centers, addressing the critical need for efficient heat dissipation in increasingly powerful and compact electronic devices. Additionally, their unique properties make them valuable in the development of next-generation display technologies and haptic feedback systems.

In mechanical engineering, ferrofluids are finding applications in smart damping systems, seals, and bearings. These innovations are particularly relevant in industries requiring high-precision equipment, such as semiconductor manufacturing and robotics. The ability of ferrofluids to adapt to changing conditions and provide dynamic responses to external stimuli makes them invaluable in these contexts.

The aerospace industry is also driving demand for ferrofluid techniques, with applications ranging from advanced propulsion systems to adaptive control surfaces. The potential for ferrofluids to enhance the performance and efficiency of spacecraft and aircraft is significant, leading to increased investment in research and development in this area.

Market analysts project that the global ferrofluid market will continue to expand at a compound annual growth rate (CAGR) of over 5% in the next five years. This growth is underpinned by the increasing adoption of ferrofluid-based technologies across diverse sectors and the ongoing research into novel applications.

However, challenges remain in scaling up production and reducing costs to meet the growing demand. The complexity of synthesizing high-quality ferrofluids and the need for specialized manufacturing processes currently limit widespread adoption. Overcoming these hurdles will be crucial for realizing the full market potential of ferrofluid techniques in nanotechnology.

As research progresses and new applications emerge, the market demand for ferrofluid-based nanotechnology is expected to diversify further. This trend underscores the importance of continued investment in research and development to unlock new possibilities and meet evolving industry needs.

In the healthcare sector, ferrofluids are gaining traction in targeted drug delivery systems and magnetic hyperthermia for cancer treatment. The ability to manipulate these nanoscale magnetic particles with external magnetic fields offers precise control in medical procedures, leading to improved patient outcomes and reduced side effects. This application alone is expected to drive substantial market growth in the coming years.

The electronics industry is another major contributor to the rising demand for ferrofluid-based nanotechnology. Ferrofluids are being utilized in advanced cooling systems for high-performance computing and data centers, addressing the critical need for efficient heat dissipation in increasingly powerful and compact electronic devices. Additionally, their unique properties make them valuable in the development of next-generation display technologies and haptic feedback systems.

In mechanical engineering, ferrofluids are finding applications in smart damping systems, seals, and bearings. These innovations are particularly relevant in industries requiring high-precision equipment, such as semiconductor manufacturing and robotics. The ability of ferrofluids to adapt to changing conditions and provide dynamic responses to external stimuli makes them invaluable in these contexts.

The aerospace industry is also driving demand for ferrofluid techniques, with applications ranging from advanced propulsion systems to adaptive control surfaces. The potential for ferrofluids to enhance the performance and efficiency of spacecraft and aircraft is significant, leading to increased investment in research and development in this area.

Market analysts project that the global ferrofluid market will continue to expand at a compound annual growth rate (CAGR) of over 5% in the next five years. This growth is underpinned by the increasing adoption of ferrofluid-based technologies across diverse sectors and the ongoing research into novel applications.

However, challenges remain in scaling up production and reducing costs to meet the growing demand. The complexity of synthesizing high-quality ferrofluids and the need for specialized manufacturing processes currently limit widespread adoption. Overcoming these hurdles will be crucial for realizing the full market potential of ferrofluid techniques in nanotechnology.

As research progresses and new applications emerge, the market demand for ferrofluid-based nanotechnology is expected to diversify further. This trend underscores the importance of continued investment in research and development to unlock new possibilities and meet evolving industry needs.

Ferrofluid Challenges

Despite the promising potential of ferrofluids in nanotechnology research, several significant challenges persist in their development and application. One of the primary obstacles is the long-term stability of ferrofluids. Over time, these colloidal suspensions tend to aggregate and settle, compromising their unique properties and functionality. This instability limits their practical use in long-term applications and necessitates frequent replacement or maintenance.

Another critical challenge lies in the precise control of ferrofluid behavior under varying magnetic field strengths and configurations. While ferrofluids respond readily to magnetic fields, achieving fine-tuned control for specific applications, such as targeted drug delivery or microfluidic devices, remains complex. The non-linear response of ferrofluids to magnetic fields adds another layer of difficulty in predicting and managing their behavior in intricate systems.

The biocompatibility of ferrofluids presents a significant hurdle, particularly in biomedical applications. Many ferrofluids contain materials that may be toxic or trigger immune responses when introduced into biological systems. Developing ferrofluids that are both functionally effective and biologically inert is a ongoing challenge that requires extensive research and testing.

Scalability and cost-effectiveness in production represent additional challenges. While ferrofluids can be synthesized in laboratory settings, scaling up production for industrial applications while maintaining consistent quality and properties is problematic. The high costs associated with producing high-quality ferrofluids also limit their widespread adoption in commercial applications.

Furthermore, the environmental impact of ferrofluids is a growing concern. The potential release of nanoparticles into the environment, either during production or application, raises questions about their long-term effects on ecosystems. Developing environmentally friendly ferrofluids and establishing proper disposal protocols are crucial challenges that need to be addressed.

Lastly, the integration of ferrofluids with other nanotechnologies and materials presents both opportunities and challenges. While combining ferrofluids with other nanomaterials could lead to novel applications, ensuring compatibility and maintaining the desired properties of both components is complex. This integration challenge extends to incorporating ferrofluids into existing systems and devices, requiring careful engineering and often redesign of established technologies.

Another critical challenge lies in the precise control of ferrofluid behavior under varying magnetic field strengths and configurations. While ferrofluids respond readily to magnetic fields, achieving fine-tuned control for specific applications, such as targeted drug delivery or microfluidic devices, remains complex. The non-linear response of ferrofluids to magnetic fields adds another layer of difficulty in predicting and managing their behavior in intricate systems.

The biocompatibility of ferrofluids presents a significant hurdle, particularly in biomedical applications. Many ferrofluids contain materials that may be toxic or trigger immune responses when introduced into biological systems. Developing ferrofluids that are both functionally effective and biologically inert is a ongoing challenge that requires extensive research and testing.

Scalability and cost-effectiveness in production represent additional challenges. While ferrofluids can be synthesized in laboratory settings, scaling up production for industrial applications while maintaining consistent quality and properties is problematic. The high costs associated with producing high-quality ferrofluids also limit their widespread adoption in commercial applications.

Furthermore, the environmental impact of ferrofluids is a growing concern. The potential release of nanoparticles into the environment, either during production or application, raises questions about their long-term effects on ecosystems. Developing environmentally friendly ferrofluids and establishing proper disposal protocols are crucial challenges that need to be addressed.

Lastly, the integration of ferrofluids with other nanotechnologies and materials presents both opportunities and challenges. While combining ferrofluids with other nanomaterials could lead to novel applications, ensuring compatibility and maintaining the desired properties of both components is complex. This integration challenge extends to incorporating ferrofluids into existing systems and devices, requiring careful engineering and often redesign of established technologies.

Current Ferrofluid Tech

01 Composition and preparation of ferrofluids

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They typically consist of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals and bearings. Their unique properties allow them to form liquid seals that can be controlled by magnetic fields, providing effective containment of gases and liquids while reducing friction and wear in mechanical systems.

- Thermal management and heat transfer: Ferrofluids exhibit enhanced heat transfer properties due to their magnetic nature. They are used in cooling systems for electronic devices, transformers, and other heat-generating equipment. The ability to manipulate ferrofluids with magnetic fields allows for targeted and efficient heat dissipation in various applications.

- Magnetic field sensing and measurement: Ferrofluids are employed in various sensing and measurement devices that rely on magnetic field detection. These applications include accelerometers, inclinometers, and magnetic field sensors. The response of ferrofluids to magnetic fields allows for precise measurements and detection of changes in orientation or field strength.

- Medical and biomedical applications: Ferrofluids have emerging applications in the medical and biomedical fields. They are being researched for use in targeted drug delivery, magnetic hyperthermia for cancer treatment, and as contrast agents in magnetic resonance imaging (MRI). The ability to control ferrofluids with external magnetic fields makes them promising for various therapeutic and diagnostic purposes.

02 Applications in sealing and lubrication

Ferrofluids are used in various sealing and lubrication applications, particularly in rotating shaft seals and bearings. They provide low-friction, contamination-resistant barriers that can be controlled by magnetic fields, improving the performance and longevity of mechanical systems.Expand Specific Solutions03 Thermal management and cooling systems

Ferrofluids are employed in thermal management solutions, particularly for electronic devices and power systems. Their unique properties allow for efficient heat transfer and cooling when subjected to magnetic fields, enabling the development of novel cooling systems and heat sinks.Expand Specific Solutions04 Sensor and actuator technologies

Ferrofluids are utilized in various sensor and actuator applications, including accelerometers, tilt sensors, and haptic feedback devices. Their responsiveness to magnetic fields and ability to change shape or position allows for precise control and measurement in these systems.Expand Specific Solutions05 Medical and biomedical applications

Ferrofluids have potential applications in medical and biomedical fields, including targeted drug delivery, magnetic hyperthermia for cancer treatment, and contrast agents for magnetic resonance imaging (MRI). Their magnetic properties and biocompatibility make them suitable for various therapeutic and diagnostic purposes.Expand Specific Solutions

Key Ferrofluid Players

The field of ferrofluid techniques in nanotechnology research is in a dynamic growth phase, with significant market potential and ongoing technological advancements. The global market for ferrofluids is expanding, driven by applications in electronics, biomedical, and energy sectors. While the technology is maturing, there's still room for innovation. Key players like Consejo Superior de Investigaciones Científicas, Midatech Ltd., and The Regents of the University of California are at the forefront, contributing to research and development. Universities such as Yale, Southeast University, and Shenzhen University are also actively involved, indicating a strong academic-industry collaboration. The competitive landscape is diverse, with both established institutions and emerging companies vying for breakthroughs in this promising field.

Consejo Superior de Investigaciones Científicas

Technical Solution: CSIC has developed advanced ferrofluid techniques for nanotechnology research, focusing on the synthesis and characterization of magnetic nanoparticles. Their approach involves using surfactant-coated iron oxide nanoparticles suspended in carrier fluids to create stable ferrofluids[1]. These ferrofluids exhibit unique magnetic and rheological properties, allowing for precise control in various applications. CSIC has also pioneered the use of ferrofluids in biomedical applications, such as targeted drug delivery and magnetic hyperthermia for cancer treatment[2]. Their research extends to the development of novel ferrofluid-based sensors and actuators for microfluidic devices, leveraging the magnetic responsiveness of ferrofluids to create highly sensitive and controllable systems[3].

Strengths: Extensive experience in nanoparticle synthesis and characterization, strong focus on biomedical applications. Weaknesses: May face challenges in scaling up production for industrial applications, potential regulatory hurdles for biomedical use.

Midatech Ltd.

Technical Solution: Midatech Ltd. has developed innovative ferrofluid techniques in nanotechnology research, focusing on their proprietary gold nanoparticle (GNP) technology. Their approach involves creating ferrofluids using gold nanoparticles functionalized with specific ligands, allowing for precise control of particle size and surface properties[1]. These gold-based ferrofluids exhibit unique optical and magnetic properties, making them ideal for applications in targeted drug delivery and diagnostic imaging. Midatech's technology enables the creation of multifunctional nanoparticles that can be loaded with therapeutic agents and guided to specific targets using external magnetic fields[2]. They have also explored the use of their GNP-based ferrofluids in theranostic applications, combining diagnostic and therapeutic capabilities in a single nanoparticle system[3].

Strengths: Proprietary gold nanoparticle technology, strong focus on pharmaceutical applications. Weaknesses: Limited to gold-based systems, potentially higher production costs compared to iron oxide-based ferrofluids.

Ferrofluid Innovations

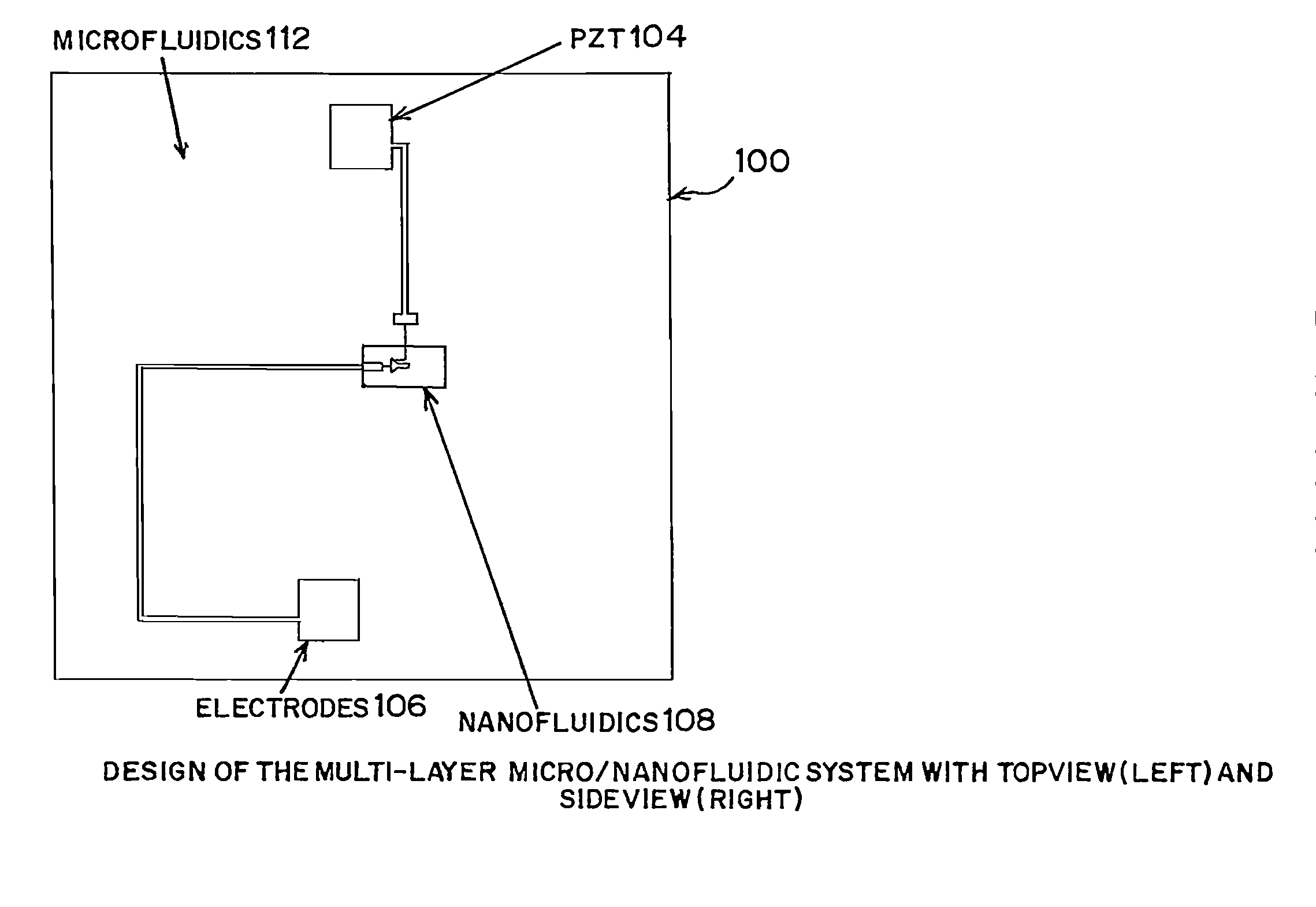

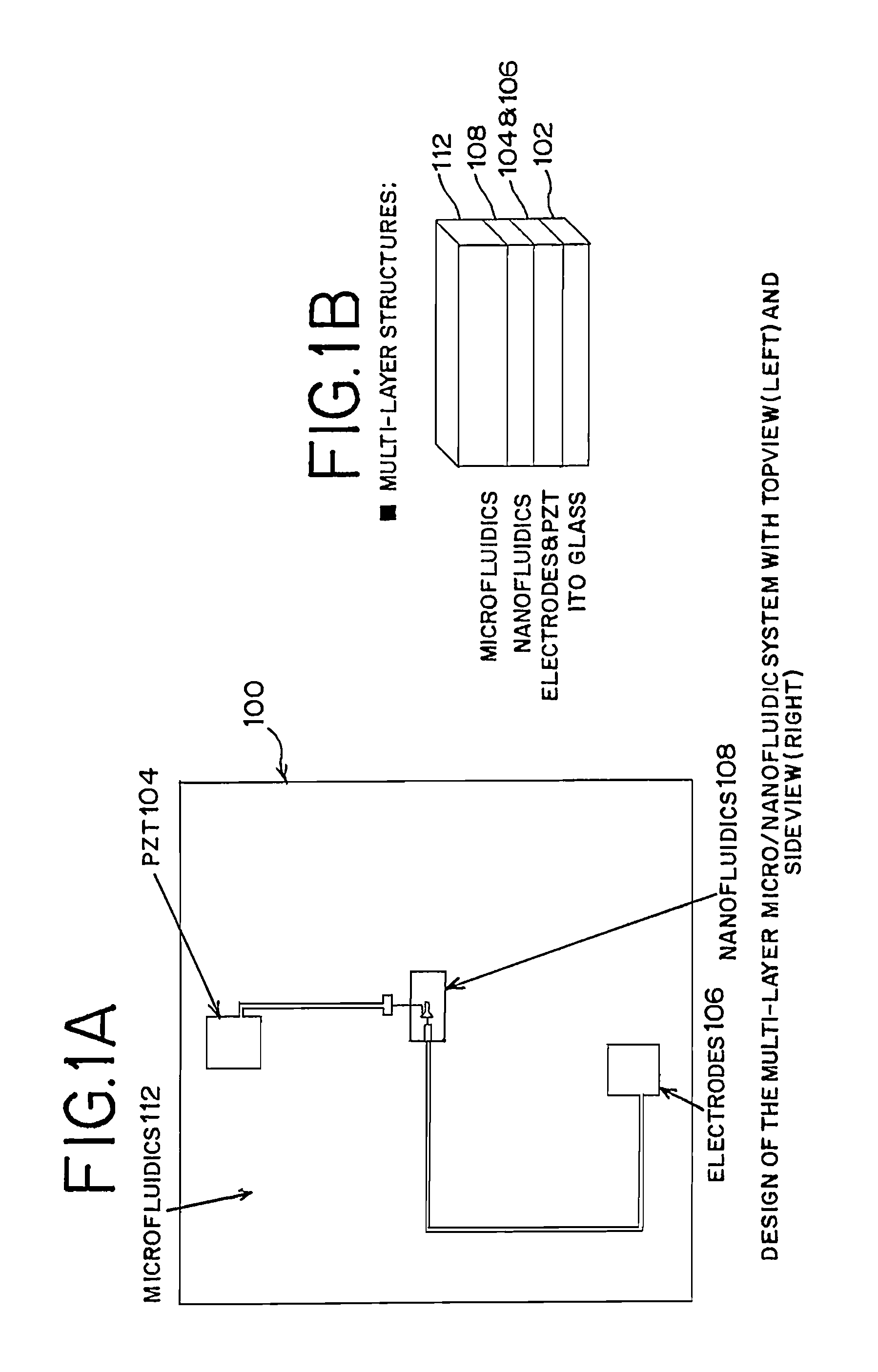

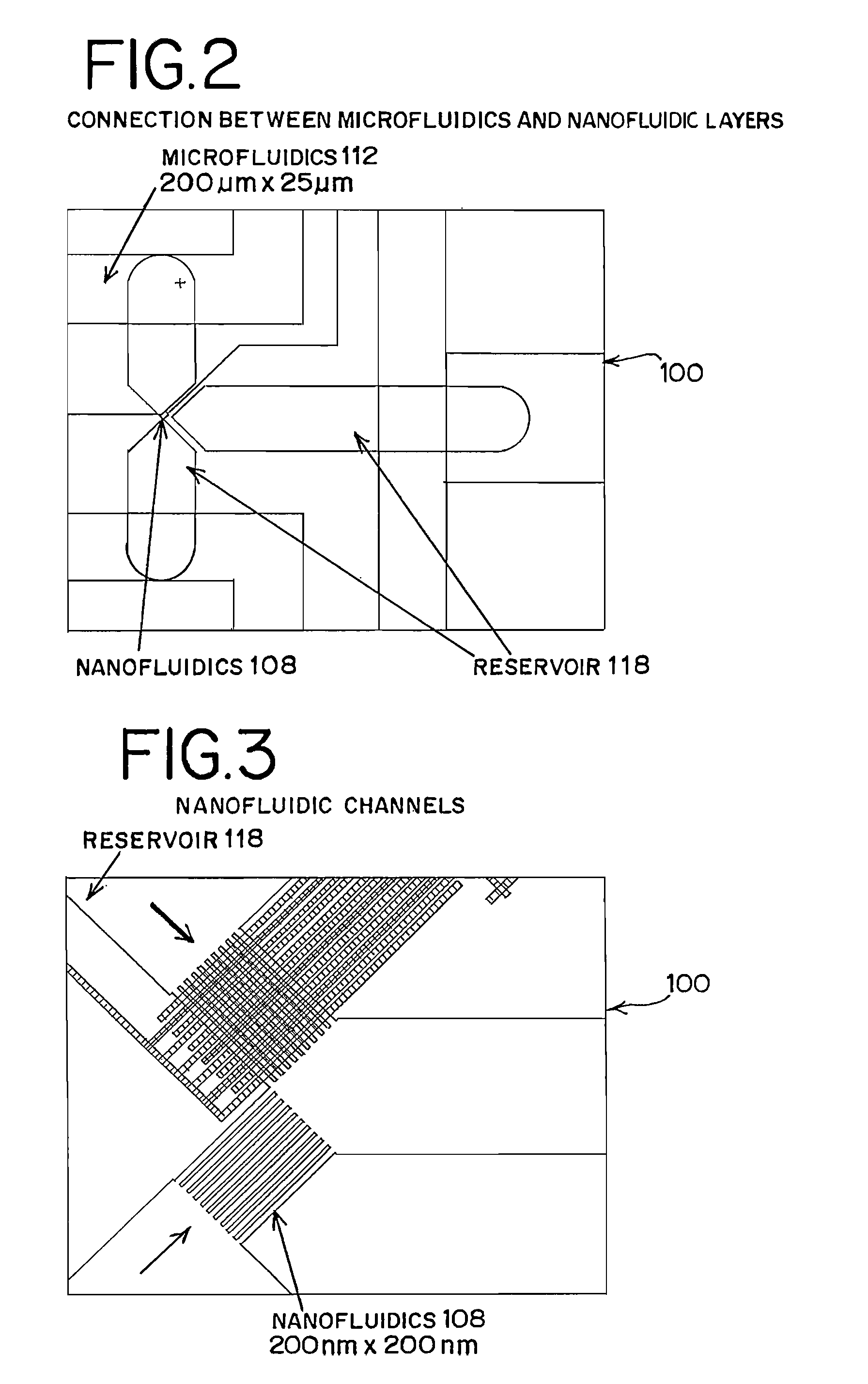

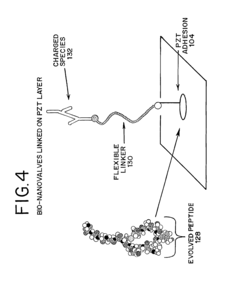

Multi-layer micro/nanofluid devices with bio-nanovalves

PatentInactiveUS20130000764A1

Innovation

- A multi-layer micro/nanofluidic flow device is developed, incorporating a ferroelectric material layer and bio-nanovalves that use microfluidic flow as a driving force to overcome pressure challenges, allowing for controlled nanofluidic flow and mixing, with the ferroelectric material's polarization activating the bio-nanovalves to open and close nanochannels.

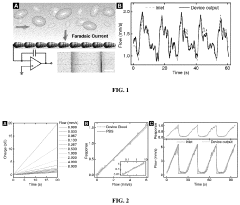

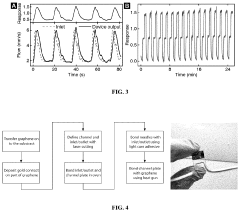

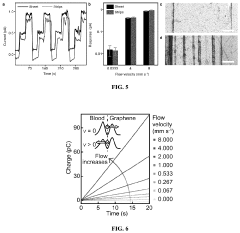

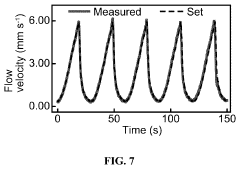

Nanodevices and methods for measuring biofluidic flow using a graphene-based microelectrode

PatentPendingUS20240000330A1

Innovation

- A graphene microsheet-based flow meter that measures microfluidic flow velocity by quantifying contact electrification-induced current variations in real-time, immune to biofouling and requiring no gate voltage or source-drain bias, utilizing a monolayer graphene sheet as a single microelectrode across a microfluidic channel for continuous and in vivo monitoring.

Nanotech Safety Regs

As nanotechnology continues to advance, the development of comprehensive safety regulations becomes increasingly crucial. The field of nanotech safety regulations encompasses a wide range of considerations, from environmental impact to human health risks. Current regulatory frameworks are evolving to address the unique challenges posed by nanomaterials, including their small size, high reactivity, and potential for bioaccumulation.

Key areas of focus in nanotech safety regulations include exposure assessment, toxicology studies, and risk management strategies. Regulatory bodies worldwide are working to establish standardized protocols for evaluating the safety of nanomaterials throughout their lifecycle, from production to disposal. This includes developing guidelines for handling, storage, and transportation of nanomaterials, as well as protocols for assessing their potential environmental and health impacts.

One of the primary challenges in nanotech safety regulation is the rapid pace of technological advancement, which often outpaces regulatory processes. To address this, many regulatory agencies are adopting adaptive approaches that allow for flexibility in response to new scientific findings. This includes the implementation of tiered testing strategies and the use of alternative testing methods to expedite safety assessments while maintaining rigorous standards.

International collaboration plays a vital role in the development of nanotech safety regulations. Organizations such as the OECD and ISO are working to harmonize standards and testing methodologies across different countries, facilitating global trade and ensuring consistent safety measures. These efforts aim to create a unified approach to nanotech safety, balancing innovation with precautionary principles.

In the context of ferrofluid techniques in nanotechnology research, safety regulations are particularly relevant. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, present unique safety considerations due to their magnetic properties and potential for environmental dispersion. Regulatory frameworks must address the specific risks associated with ferrofluid production, handling, and application, including potential magnetic field interactions and the long-term stability of these materials in various environments.

As research in ferrofluid techniques advances, safety regulations will need to evolve to encompass new applications and potential risks. This may include developing specific guidelines for the use of ferrofluids in biomedical applications, environmental remediation, or advanced manufacturing processes. The integration of these safety considerations into the research and development process is essential for ensuring the responsible advancement of ferrofluid technology within the broader field of nanotechnology.

Key areas of focus in nanotech safety regulations include exposure assessment, toxicology studies, and risk management strategies. Regulatory bodies worldwide are working to establish standardized protocols for evaluating the safety of nanomaterials throughout their lifecycle, from production to disposal. This includes developing guidelines for handling, storage, and transportation of nanomaterials, as well as protocols for assessing their potential environmental and health impacts.

One of the primary challenges in nanotech safety regulation is the rapid pace of technological advancement, which often outpaces regulatory processes. To address this, many regulatory agencies are adopting adaptive approaches that allow for flexibility in response to new scientific findings. This includes the implementation of tiered testing strategies and the use of alternative testing methods to expedite safety assessments while maintaining rigorous standards.

International collaboration plays a vital role in the development of nanotech safety regulations. Organizations such as the OECD and ISO are working to harmonize standards and testing methodologies across different countries, facilitating global trade and ensuring consistent safety measures. These efforts aim to create a unified approach to nanotech safety, balancing innovation with precautionary principles.

In the context of ferrofluid techniques in nanotechnology research, safety regulations are particularly relevant. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, present unique safety considerations due to their magnetic properties and potential for environmental dispersion. Regulatory frameworks must address the specific risks associated with ferrofluid production, handling, and application, including potential magnetic field interactions and the long-term stability of these materials in various environments.

As research in ferrofluid techniques advances, safety regulations will need to evolve to encompass new applications and potential risks. This may include developing specific guidelines for the use of ferrofluids in biomedical applications, environmental remediation, or advanced manufacturing processes. The integration of these safety considerations into the research and development process is essential for ensuring the responsible advancement of ferrofluid technology within the broader field of nanotechnology.

Ferrofluid Eco Impact

Ferrofluids, while offering significant advancements in nanotechnology research, also present potential environmental concerns that warrant careful consideration. The ecological impact of ferrofluids primarily stems from their composition and potential for release into the environment. These magnetic nanofluids typically consist of nanoscale ferromagnetic particles suspended in a carrier fluid, often containing surfactants to prevent agglomeration.

One of the primary environmental concerns is the potential toxicity of ferrofluid components to aquatic ecosystems. If released into water bodies, the nanoparticles may interact with aquatic organisms, potentially causing adverse effects on their health and behavior. Studies have shown that some magnetic nanoparticles can accumulate in the tissues of fish and other aquatic life, potentially leading to bioaccumulation up the food chain.

The long-term persistence of ferrofluid nanoparticles in the environment is another area of concern. Unlike larger particles, these nanoscale materials may remain suspended in water or air for extended periods, increasing their potential for widespread distribution. This persistence could lead to chronic exposure for various organisms, with yet unknown long-term ecological consequences.

Soil contamination is another potential impact of ferrofluid use. If spilled or improperly disposed of, these materials could alter soil properties, affecting plant growth and soil microbial communities. The magnetic properties of ferrofluids might also interfere with the natural magnetic fields that some organisms use for navigation, potentially disrupting migration patterns or other behaviors.

However, it's important to note that the environmental impact of ferrofluids is highly dependent on their specific composition and the context of their use. Many research efforts are focused on developing more environmentally friendly ferrofluids, using biodegradable carrier fluids and less toxic nanoparticles. These eco-friendly alternatives aim to maintain the beneficial properties of ferrofluids while minimizing their potential environmental risks.

Furthermore, the controlled use of ferrofluids in laboratory and industrial settings, with proper containment and disposal protocols, can significantly mitigate their environmental impact. As research in this field progresses, it is crucial to continue assessing the long-term ecological effects of ferrofluids and to develop sustainable practices for their production, use, and disposal.

One of the primary environmental concerns is the potential toxicity of ferrofluid components to aquatic ecosystems. If released into water bodies, the nanoparticles may interact with aquatic organisms, potentially causing adverse effects on their health and behavior. Studies have shown that some magnetic nanoparticles can accumulate in the tissues of fish and other aquatic life, potentially leading to bioaccumulation up the food chain.

The long-term persistence of ferrofluid nanoparticles in the environment is another area of concern. Unlike larger particles, these nanoscale materials may remain suspended in water or air for extended periods, increasing their potential for widespread distribution. This persistence could lead to chronic exposure for various organisms, with yet unknown long-term ecological consequences.

Soil contamination is another potential impact of ferrofluid use. If spilled or improperly disposed of, these materials could alter soil properties, affecting plant growth and soil microbial communities. The magnetic properties of ferrofluids might also interfere with the natural magnetic fields that some organisms use for navigation, potentially disrupting migration patterns or other behaviors.

However, it's important to note that the environmental impact of ferrofluids is highly dependent on their specific composition and the context of their use. Many research efforts are focused on developing more environmentally friendly ferrofluids, using biodegradable carrier fluids and less toxic nanoparticles. These eco-friendly alternatives aim to maintain the beneficial properties of ferrofluids while minimizing their potential environmental risks.

Furthermore, the controlled use of ferrofluids in laboratory and industrial settings, with proper containment and disposal protocols, can significantly mitigate their environmental impact. As research in this field progresses, it is crucial to continue assessing the long-term ecological effects of ferrofluids and to develop sustainable practices for their production, use, and disposal.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!