How to Apply Ferrofluid in Surface Coating Techniques?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Coating Background and Objectives

Ferrofluids, a unique class of magnetic nanomaterials, have garnered significant attention in the field of surface coating techniques over the past few decades. These colloidal suspensions of magnetic nanoparticles in a carrier fluid exhibit remarkable properties that bridge the gap between liquid and solid states, offering unprecedented opportunities for innovative coating applications.

The evolution of ferrofluid technology can be traced back to the 1960s when NASA scientists first developed them for controlling liquids in space. Since then, the technology has undergone substantial advancements, with researchers and engineers exploring its potential in various industries, including electronics, biomedical, and materials science.

In the context of surface coating techniques, ferrofluids present a promising avenue for creating smart, responsive, and multifunctional coatings. The ability to manipulate these fluids using external magnetic fields opens up new possibilities for precise control over coating thickness, distribution, and patterning. This characteristic sets ferrofluids apart from conventional coating materials and methods.

The primary objective of applying ferrofluids in surface coating techniques is to harness their unique magnetic and fluid properties to enhance coating performance and functionality. Researchers aim to develop coatings that can respond to external stimuli, self-heal, or adapt to changing environmental conditions. These goals align with the broader trends in materials science towards creating more intelligent and adaptive surfaces.

Another key objective is to overcome the limitations of traditional coating methods, such as uneven coverage, poor adhesion, or limited durability. Ferrofluid-based coatings have the potential to address these issues by offering improved control over the coating process and the ability to create layered or gradient structures within the coating.

Furthermore, the integration of ferrofluids into surface coating techniques aims to expand the range of applications for coated surfaces. From self-cleaning and anti-fouling coatings to thermally responsive and electrically conductive surfaces, the versatility of ferrofluids presents numerous opportunities for innovation across various industries.

As research in this field progresses, scientists and engineers are focusing on optimizing the composition and properties of ferrofluids for specific coating applications. This includes tailoring the size and composition of magnetic nanoparticles, selecting appropriate carrier fluids, and developing novel methods for stabilizing the ferrofluid suspensions to ensure long-term performance and reliability.

The exploration of ferrofluid coatings also aligns with the growing emphasis on sustainable and environmentally friendly materials. By enabling more efficient and targeted coating processes, ferrofluids have the potential to reduce material waste and energy consumption in manufacturing, contributing to more sustainable production practices.

The evolution of ferrofluid technology can be traced back to the 1960s when NASA scientists first developed them for controlling liquids in space. Since then, the technology has undergone substantial advancements, with researchers and engineers exploring its potential in various industries, including electronics, biomedical, and materials science.

In the context of surface coating techniques, ferrofluids present a promising avenue for creating smart, responsive, and multifunctional coatings. The ability to manipulate these fluids using external magnetic fields opens up new possibilities for precise control over coating thickness, distribution, and patterning. This characteristic sets ferrofluids apart from conventional coating materials and methods.

The primary objective of applying ferrofluids in surface coating techniques is to harness their unique magnetic and fluid properties to enhance coating performance and functionality. Researchers aim to develop coatings that can respond to external stimuli, self-heal, or adapt to changing environmental conditions. These goals align with the broader trends in materials science towards creating more intelligent and adaptive surfaces.

Another key objective is to overcome the limitations of traditional coating methods, such as uneven coverage, poor adhesion, or limited durability. Ferrofluid-based coatings have the potential to address these issues by offering improved control over the coating process and the ability to create layered or gradient structures within the coating.

Furthermore, the integration of ferrofluids into surface coating techniques aims to expand the range of applications for coated surfaces. From self-cleaning and anti-fouling coatings to thermally responsive and electrically conductive surfaces, the versatility of ferrofluids presents numerous opportunities for innovation across various industries.

As research in this field progresses, scientists and engineers are focusing on optimizing the composition and properties of ferrofluids for specific coating applications. This includes tailoring the size and composition of magnetic nanoparticles, selecting appropriate carrier fluids, and developing novel methods for stabilizing the ferrofluid suspensions to ensure long-term performance and reliability.

The exploration of ferrofluid coatings also aligns with the growing emphasis on sustainable and environmentally friendly materials. By enabling more efficient and targeted coating processes, ferrofluids have the potential to reduce material waste and energy consumption in manufacturing, contributing to more sustainable production practices.

Market Analysis for Ferrofluid Coatings

The market for ferrofluid coatings is experiencing significant growth, driven by the increasing demand for advanced surface treatment technologies across various industries. Ferrofluids, which are colloidal liquids containing magnetic nanoparticles, offer unique properties that make them attractive for coating applications. These properties include controllable viscosity, magnetic responsiveness, and the ability to form intricate patterns when subjected to magnetic fields.

In the automotive sector, ferrofluid coatings are gaining traction for their potential to enhance corrosion resistance and provide self-healing capabilities to vehicle surfaces. The aerospace industry is also showing interest in these coatings for their ability to reduce drag and improve fuel efficiency. Additionally, the electronics industry is exploring ferrofluid coatings for their electromagnetic shielding properties, which are becoming increasingly important in the era of 5G and IoT devices.

The construction industry represents another significant market for ferrofluid coatings. These coatings can be used to create self-cleaning surfaces on buildings and infrastructure, reducing maintenance costs and improving longevity. The medical field is also investigating the use of ferrofluid coatings for antimicrobial applications in healthcare settings.

Market research indicates that the global ferrofluid market, including coating applications, is expected to grow at a compound annual growth rate (CAGR) of over 5% in the coming years. This growth is attributed to the increasing adoption of ferrofluid-based technologies in emerging economies and the continuous development of new applications in established markets.

The Asia-Pacific region is anticipated to be the fastest-growing market for ferrofluid coatings, driven by rapid industrialization and increasing investments in research and development. North America and Europe are also significant markets, with a focus on high-tech applications in aerospace and electronics.

Key factors influencing market growth include advancements in nanotechnology, which are enabling the production of more stable and efficient ferrofluids, and the growing emphasis on sustainable and environmentally friendly coating solutions. Ferrofluid coatings have the potential to reduce the use of harmful solvents and improve the overall environmental footprint of surface treatment processes.

However, challenges remain in scaling up production and reducing costs to make ferrofluid coatings more competitive with traditional coating technologies. Overcoming these hurdles will be crucial for wider market adoption and realizing the full potential of ferrofluid coatings across various industries.

In the automotive sector, ferrofluid coatings are gaining traction for their potential to enhance corrosion resistance and provide self-healing capabilities to vehicle surfaces. The aerospace industry is also showing interest in these coatings for their ability to reduce drag and improve fuel efficiency. Additionally, the electronics industry is exploring ferrofluid coatings for their electromagnetic shielding properties, which are becoming increasingly important in the era of 5G and IoT devices.

The construction industry represents another significant market for ferrofluid coatings. These coatings can be used to create self-cleaning surfaces on buildings and infrastructure, reducing maintenance costs and improving longevity. The medical field is also investigating the use of ferrofluid coatings for antimicrobial applications in healthcare settings.

Market research indicates that the global ferrofluid market, including coating applications, is expected to grow at a compound annual growth rate (CAGR) of over 5% in the coming years. This growth is attributed to the increasing adoption of ferrofluid-based technologies in emerging economies and the continuous development of new applications in established markets.

The Asia-Pacific region is anticipated to be the fastest-growing market for ferrofluid coatings, driven by rapid industrialization and increasing investments in research and development. North America and Europe are also significant markets, with a focus on high-tech applications in aerospace and electronics.

Key factors influencing market growth include advancements in nanotechnology, which are enabling the production of more stable and efficient ferrofluids, and the growing emphasis on sustainable and environmentally friendly coating solutions. Ferrofluid coatings have the potential to reduce the use of harmful solvents and improve the overall environmental footprint of surface treatment processes.

However, challenges remain in scaling up production and reducing costs to make ferrofluid coatings more competitive with traditional coating technologies. Overcoming these hurdles will be crucial for wider market adoption and realizing the full potential of ferrofluid coatings across various industries.

Current Challenges in Ferrofluid Surface Coating

The application of ferrofluid in surface coating techniques faces several significant challenges that hinder its widespread adoption and effectiveness. One of the primary obstacles is the stability of ferrofluid coatings over time. Ferrofluids are colloidal suspensions of magnetic nanoparticles, and maintaining their uniform distribution within the coating matrix is crucial for consistent performance. However, these particles tend to agglomerate or settle due to gravitational forces and magnetic interactions, leading to inhomogeneous coatings and reduced functionality.

Another major challenge lies in controlling the rheological properties of ferrofluid coatings. The viscosity and flow characteristics of these coatings can change dramatically under the influence of magnetic fields, making it difficult to achieve uniform thickness and coverage during application. This variability can result in inconsistent surface properties and compromised coating integrity, especially in complex geometries or large surface areas.

The compatibility of ferrofluids with various substrate materials presents an additional hurdle. Ensuring strong adhesion between the ferrofluid coating and the underlying surface is critical for durability and longevity. However, the unique composition of ferrofluids, which includes surfactants and carrier fluids, can interfere with traditional bonding mechanisms, necessitating the development of specialized primers or surface treatments.

Environmental factors also pose significant challenges to ferrofluid surface coatings. Exposure to UV radiation, moisture, and temperature fluctuations can degrade the coating's performance over time. The magnetic nanoparticles may oxidize, leading to changes in magnetic properties and potential discoloration. Moreover, the potential leaching of nanoparticles from the coating raises environmental and health concerns, particularly in applications where the coated surfaces come into contact with food, water, or biological systems.

The scalability of ferrofluid coating processes for industrial applications remains a considerable challenge. Current methods for applying ferrofluid coatings are often limited to small-scale or laboratory settings. Developing cost-effective and efficient techniques for large-scale production and application of ferrofluid coatings is essential for their commercial viability. This includes addressing issues related to material handling, uniform magnetic field application during curing, and quality control measures.

Lastly, the long-term performance and reliability of ferrofluid coatings under various operating conditions are not yet fully understood. The dynamic nature of these coatings, which respond to magnetic fields, makes it challenging to predict their behavior over extended periods. This uncertainty can deter potential adopters, especially in industries where long-term stability and predictable performance are critical.

Another major challenge lies in controlling the rheological properties of ferrofluid coatings. The viscosity and flow characteristics of these coatings can change dramatically under the influence of magnetic fields, making it difficult to achieve uniform thickness and coverage during application. This variability can result in inconsistent surface properties and compromised coating integrity, especially in complex geometries or large surface areas.

The compatibility of ferrofluids with various substrate materials presents an additional hurdle. Ensuring strong adhesion between the ferrofluid coating and the underlying surface is critical for durability and longevity. However, the unique composition of ferrofluids, which includes surfactants and carrier fluids, can interfere with traditional bonding mechanisms, necessitating the development of specialized primers or surface treatments.

Environmental factors also pose significant challenges to ferrofluid surface coatings. Exposure to UV radiation, moisture, and temperature fluctuations can degrade the coating's performance over time. The magnetic nanoparticles may oxidize, leading to changes in magnetic properties and potential discoloration. Moreover, the potential leaching of nanoparticles from the coating raises environmental and health concerns, particularly in applications where the coated surfaces come into contact with food, water, or biological systems.

The scalability of ferrofluid coating processes for industrial applications remains a considerable challenge. Current methods for applying ferrofluid coatings are often limited to small-scale or laboratory settings. Developing cost-effective and efficient techniques for large-scale production and application of ferrofluid coatings is essential for their commercial viability. This includes addressing issues related to material handling, uniform magnetic field application during curing, and quality control measures.

Lastly, the long-term performance and reliability of ferrofluid coatings under various operating conditions are not yet fully understood. The dynamic nature of these coatings, which respond to magnetic fields, makes it challenging to predict their behavior over extended periods. This uncertainty can deter potential adopters, especially in industries where long-term stability and predictable performance are critical.

Existing Ferrofluid Coating Techniques

01 Composition and preparation of ferrofluids

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with a surfactant to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with a surfactant to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide a liquid barrier that can be controlled by magnetic fields, offering advantages in terms of low friction, long life, and the ability to operate in vacuum environments. These properties make them valuable in various industrial and mechanical systems.

- Thermal management and cooling systems: Ferrofluids have unique heat transfer properties that make them useful in thermal management applications. They can be used in cooling systems for electronic devices, where their ability to be manipulated by magnetic fields allows for targeted heat removal. This property is particularly valuable in compact or high-performance computing systems.

- Sensor and actuator technologies: The magnetic properties of ferrofluids make them suitable for use in various sensor and actuator technologies. They can be used in accelerometers, tilt sensors, and position sensors, where their movement in response to magnetic fields or physical forces can be detected and measured. This enables the development of precise and responsive control systems.

- Medical and biomedical applications: Ferrofluids have potential applications in medical and biomedical fields. They can be used for targeted drug delivery, magnetic hyperthermia treatment of cancer, and as contrast agents in magnetic resonance imaging (MRI). The ability to control these fluids using external magnetic fields offers new possibilities for non-invasive medical treatments and diagnostics.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide a liquid barrier that can be controlled by magnetic fields, offering advantages in terms of low friction, long life, and the ability to operate in vacuum environments.Expand Specific Solutions03 Thermal management and cooling systems

Ferrofluids are employed in thermal management solutions, particularly for electronic devices. Their unique properties allow for efficient heat transfer and cooling when subjected to magnetic fields, making them valuable in applications such as computer cooling systems and power electronics.Expand Specific Solutions04 Sensor and actuator technologies

Ferrofluids are utilized in various sensor and actuator designs. Their responsiveness to magnetic fields enables applications in accelerometers, tilt sensors, and damping systems. They can also be used in haptic feedback devices and precision positioning systems.Expand Specific Solutions05 Medical and biomedical applications

Ferrofluids have potential applications in the medical field, including targeted drug delivery, magnetic hyperthermia for cancer treatment, and contrast agents for magnetic resonance imaging (MRI). Their ability to be manipulated by external magnetic fields makes them promising for minimally invasive medical procedures.Expand Specific Solutions

Key Players in Ferrofluid Coating Industry

The application of ferrofluid in surface coating techniques is an emerging field in the advanced materials industry. Currently, the market is in its early growth stage, with increasing research and development activities. The global market size for ferrofluid-based coatings is relatively small but expected to grow significantly in the coming years. Technologically, the field is still evolving, with companies like Nihon Parkerizing Co., Ltd. and AI Technology, Inc. leading innovation in surface treatment chemicals and advanced materials for electronic packaging. Universities such as Taiyuan University of Technology and Dalian University of Technology are contributing to research advancements. While the technology shows promise, it is not yet fully mature, with ongoing efforts to improve performance, durability, and cost-effectiveness for widespread industrial applications.

Nihon Parkerizing Co., Ltd.

Technical Solution: Nihon Parkerizing has developed an innovative approach to incorporating ferrofluids in their surface coating techniques, particularly for metal surface treatments. Their method involves using ferrofluids as a component in their phosphate conversion coatings, which enhances the corrosion resistance and paint adhesion properties of treated metals[10]. The company has also explored the use of ferrofluid-enhanced coatings for electromagnetic shielding applications, particularly in automotive and electronics industries[11]. Nihon Parkerizing's ferrofluid coatings have demonstrated improved wear resistance and self-lubricating properties in high-friction applications[12].

Strengths: Enhanced corrosion resistance, improved paint adhesion, and potential for electromagnetic shielding. Weaknesses: Primarily focused on metal surface treatments, may have limited applicability to other substrates.

BASF Coatings GmbH

Technical Solution: BASF Coatings has developed a novel approach to incorporating ferrofluids in surface coating techniques. Their method involves encapsulating ferrofluid particles within polymer microspheres, which are then dispersed in the coating matrix[4]. This encapsulation technique allows for better stability and uniform distribution of the ferrofluid within the coating. BASF has also explored the use of ferrofluids in creating textured surfaces with controllable roughness, which can be adjusted by applying external magnetic fields during the curing process[5]. Additionally, they have investigated the potential of ferrofluid-enhanced coatings for improved thermal management in electronic devices[6].

Strengths: Enhanced stability of ferrofluid in coatings, ability to create tunable surface textures, and potential for thermal management applications. Weaknesses: Complex manufacturing process for encapsulated particles, may limit the magnetic responsiveness of the coating.

Innovative Ferrofluid Coating Patents

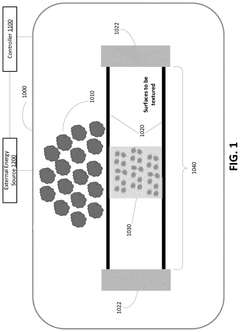

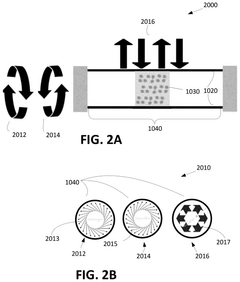

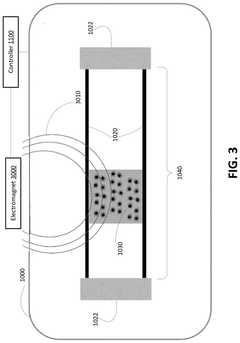

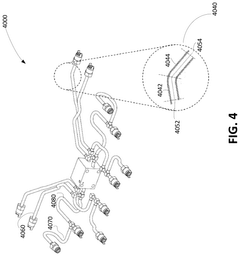

Texturing the interior of the workpiece

PatentPendingUS20240326199A1

Innovation

- A method involving the injection of a ferrofluid material with abrasive particles into the conduit, combined with energy transfer via a vessel powered by a linear or rotary motor, and an electromagnetic field, to uniformly texture the interior surfaces by abrading them, allowing for the restoration of predetermined surface textures and removal of unwanted coatings.

Superhydrophobic coating for metallic surface

PatentPendingIN202411043814A

Innovation

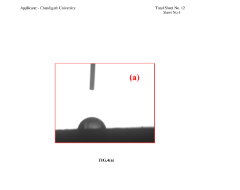

- A superhydrophobic coating composed of perfluorosulfonic acid (PFSA) polymer combined with naturally derived biomaterials from Senna Auriculata leaf extract, applied using a spray coating method and nitrogen gas drying, creating an air layer that inhibits corrosive ion mobility and ice formation on metallic surfaces.

Environmental Impact of Ferrofluid Coatings

The environmental impact of ferrofluid coatings is a critical consideration in their application and development. These innovative coatings, while offering unique properties and potential benefits, also raise concerns about their long-term effects on ecosystems and human health.

One of the primary environmental concerns associated with ferrofluid coatings is the potential release of nanoparticles into the environment. Ferrofluids contain magnetic nanoparticles, typically iron oxide, suspended in a carrier fluid. As these coatings wear or degrade over time, there is a risk of these nanoparticles being released into soil, water systems, or the atmosphere. The behavior and fate of these nanoparticles in various environmental compartments are not yet fully understood, necessitating further research to assess their potential ecological impacts.

The production process of ferrofluid coatings also warrants environmental scrutiny. The synthesis of magnetic nanoparticles and the formulation of ferrofluids often involve chemical processes that may generate hazardous waste or consume significant energy. Manufacturers must address these concerns by implementing cleaner production methods and waste management strategies to minimize the environmental footprint of ferrofluid coating production.

Water pollution is another potential issue associated with ferrofluid coatings. If improperly disposed of or in the event of accidental spills, these materials could contaminate water bodies. The magnetic properties of the nanoparticles might lead to their accumulation in aquatic environments, potentially affecting marine life and ecosystems. Research is needed to understand the bioaccumulation and biomagnification of these particles in food chains.

On the positive side, ferrofluid coatings may offer some environmental benefits. Their unique properties could lead to more durable and efficient surfaces, potentially reducing the need for frequent reapplication or replacement of traditional coatings. This could result in decreased material consumption and waste generation over the long term. Additionally, some applications of ferrofluid coatings, such as in solar panels or water treatment systems, may contribute to environmental protection and resource conservation.

The recyclability and end-of-life management of ferrofluid-coated products are important considerations. Developing effective methods for separating and recovering the magnetic nanoparticles from used coatings could promote circular economy principles and reduce environmental impact. However, the complex nature of these coatings may present challenges in recycling processes.

As the technology advances, ongoing environmental impact assessments and life cycle analyses are crucial. These studies should encompass the entire lifecycle of ferrofluid coatings, from raw material extraction to disposal or recycling. Such comprehensive evaluations will help identify areas for improvement and guide the development of more environmentally friendly ferrofluid coating technologies.

One of the primary environmental concerns associated with ferrofluid coatings is the potential release of nanoparticles into the environment. Ferrofluids contain magnetic nanoparticles, typically iron oxide, suspended in a carrier fluid. As these coatings wear or degrade over time, there is a risk of these nanoparticles being released into soil, water systems, or the atmosphere. The behavior and fate of these nanoparticles in various environmental compartments are not yet fully understood, necessitating further research to assess their potential ecological impacts.

The production process of ferrofluid coatings also warrants environmental scrutiny. The synthesis of magnetic nanoparticles and the formulation of ferrofluids often involve chemical processes that may generate hazardous waste or consume significant energy. Manufacturers must address these concerns by implementing cleaner production methods and waste management strategies to minimize the environmental footprint of ferrofluid coating production.

Water pollution is another potential issue associated with ferrofluid coatings. If improperly disposed of or in the event of accidental spills, these materials could contaminate water bodies. The magnetic properties of the nanoparticles might lead to their accumulation in aquatic environments, potentially affecting marine life and ecosystems. Research is needed to understand the bioaccumulation and biomagnification of these particles in food chains.

On the positive side, ferrofluid coatings may offer some environmental benefits. Their unique properties could lead to more durable and efficient surfaces, potentially reducing the need for frequent reapplication or replacement of traditional coatings. This could result in decreased material consumption and waste generation over the long term. Additionally, some applications of ferrofluid coatings, such as in solar panels or water treatment systems, may contribute to environmental protection and resource conservation.

The recyclability and end-of-life management of ferrofluid-coated products are important considerations. Developing effective methods for separating and recovering the magnetic nanoparticles from used coatings could promote circular economy principles and reduce environmental impact. However, the complex nature of these coatings may present challenges in recycling processes.

As the technology advances, ongoing environmental impact assessments and life cycle analyses are crucial. These studies should encompass the entire lifecycle of ferrofluid coatings, from raw material extraction to disposal or recycling. Such comprehensive evaluations will help identify areas for improvement and guide the development of more environmentally friendly ferrofluid coating technologies.

Ferrofluid Coating Performance Metrics

Ferrofluid coating performance metrics are crucial for evaluating the effectiveness and quality of ferrofluid-based surface coatings. These metrics provide quantitative and qualitative measures to assess the coating's properties, durability, and functionality in various applications.

One of the primary performance metrics for ferrofluid coatings is magnetic responsiveness. This metric measures the coating's ability to react to external magnetic fields, which is essential for applications requiring dynamic surface properties. The magnetic responsiveness is typically quantified by measuring the change in surface morphology or thickness under different magnetic field strengths.

Adhesion strength is another critical metric for ferrofluid coatings. It determines how well the coating adheres to the substrate material, which is vital for long-term durability and resistance to wear and tear. Adhesion strength can be measured through various standardized tests, such as pull-off tests or cross-cut tests, providing numerical values for comparison and quality control.

Corrosion resistance is a key performance metric, especially for ferrofluid coatings used in harsh environments. This metric evaluates the coating's ability to protect the underlying substrate from chemical attack and oxidation. Accelerated corrosion tests, such as salt spray tests or electrochemical impedance spectroscopy, are commonly used to assess this property.

Thermal stability is an important metric for ferrofluid coatings exposed to varying temperatures. This metric measures the coating's ability to maintain its properties and performance across a range of temperatures. Thermal cycling tests and thermogravimetric analysis are often employed to evaluate thermal stability and identify potential degradation mechanisms.

Wear resistance is a crucial metric for ferrofluid coatings subjected to mechanical stress or abrasion. This property is typically assessed through standardized wear tests, such as pin-on-disk or abrasion resistance tests, which provide quantitative data on the coating's ability to withstand mechanical wear over time.

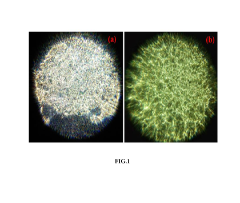

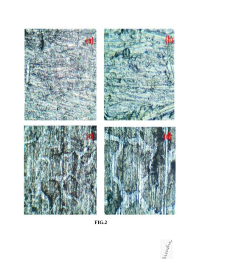

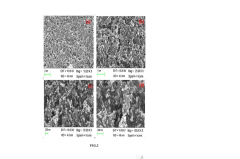

Uniformity and thickness control are essential metrics for ensuring consistent performance across the coated surface. These metrics are typically evaluated using advanced imaging techniques, such as scanning electron microscopy or atomic force microscopy, to analyze the coating's topography and thickness distribution.

Chemical resistance is another important performance metric, particularly for ferrofluid coatings exposed to various chemicals or solvents. This property is assessed through immersion tests or chemical spot tests, evaluating the coating's ability to maintain its integrity and functionality when in contact with different chemical agents.

In addition to these physical and chemical metrics, functional performance metrics specific to the intended application of the ferrofluid coating are often considered. These may include properties such as hydrophobicity, optical transparency, electrical conductivity, or specific magnetic field-induced effects, depending on the desired functionality of the coating.

One of the primary performance metrics for ferrofluid coatings is magnetic responsiveness. This metric measures the coating's ability to react to external magnetic fields, which is essential for applications requiring dynamic surface properties. The magnetic responsiveness is typically quantified by measuring the change in surface morphology or thickness under different magnetic field strengths.

Adhesion strength is another critical metric for ferrofluid coatings. It determines how well the coating adheres to the substrate material, which is vital for long-term durability and resistance to wear and tear. Adhesion strength can be measured through various standardized tests, such as pull-off tests or cross-cut tests, providing numerical values for comparison and quality control.

Corrosion resistance is a key performance metric, especially for ferrofluid coatings used in harsh environments. This metric evaluates the coating's ability to protect the underlying substrate from chemical attack and oxidation. Accelerated corrosion tests, such as salt spray tests or electrochemical impedance spectroscopy, are commonly used to assess this property.

Thermal stability is an important metric for ferrofluid coatings exposed to varying temperatures. This metric measures the coating's ability to maintain its properties and performance across a range of temperatures. Thermal cycling tests and thermogravimetric analysis are often employed to evaluate thermal stability and identify potential degradation mechanisms.

Wear resistance is a crucial metric for ferrofluid coatings subjected to mechanical stress or abrasion. This property is typically assessed through standardized wear tests, such as pin-on-disk or abrasion resistance tests, which provide quantitative data on the coating's ability to withstand mechanical wear over time.

Uniformity and thickness control are essential metrics for ensuring consistent performance across the coated surface. These metrics are typically evaluated using advanced imaging techniques, such as scanning electron microscopy or atomic force microscopy, to analyze the coating's topography and thickness distribution.

Chemical resistance is another important performance metric, particularly for ferrofluid coatings exposed to various chemicals or solvents. This property is assessed through immersion tests or chemical spot tests, evaluating the coating's ability to maintain its integrity and functionality when in contact with different chemical agents.

In addition to these physical and chemical metrics, functional performance metrics specific to the intended application of the ferrofluid coating are often considered. These may include properties such as hydrophobicity, optical transparency, electrical conductivity, or specific magnetic field-induced effects, depending on the desired functionality of the coating.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!