Ferrofluid's Impact on Wearable Technology Performance

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Tech Evolution

Ferrofluids have undergone significant technological evolution since their initial discovery in the 1960s. Originally developed by NASA for rocket fuel applications in zero gravity, these magnetic liquids have found their way into various fields, including wearable technology. The journey of ferrofluids in wearable tech can be traced through several key developmental stages.

In the early 2000s, researchers began exploring the potential of ferrofluids in flexible and wearable devices. The initial focus was on leveraging the unique magnetic properties of ferrofluids to create novel sensing mechanisms. This period saw the emergence of prototype wearable sensors that could detect minute changes in magnetic fields, opening up possibilities for motion tracking and gesture recognition.

The next significant milestone came in the mid-2010s with the integration of ferrofluids into smart fabrics. Scientists developed techniques to encapsulate ferrofluid particles within textile fibers, creating fabrics that could respond to magnetic stimuli. This breakthrough led to the concept of "active clothing" that could change shape or properties based on external magnetic fields, potentially enhancing comfort and functionality in wearable tech.

Around 2018, a major leap forward occurred with the development of ferrofluid-based flexible displays. These displays utilized the dynamic nature of ferrofluids to create shape-shifting interfaces that could adapt to user needs. This innovation paved the way for more intuitive and interactive wearable devices, particularly in the realm of augmented reality and heads-up displays.

In recent years, the focus has shifted towards harnessing ferrofluids for energy harvesting in wearable technology. Researchers have demonstrated the potential of ferrofluid-based triboelectric nanogenerators, which can convert mechanical energy from body movements into electrical energy. This development holds promise for self-powered wearable devices, addressing one of the key challenges in wearable tech – power consumption and battery life.

The latest frontier in ferrofluid technology for wearables involves their application in haptic feedback systems. By manipulating ferrofluids with controlled magnetic fields, researchers are creating tactile interfaces that can simulate a wide range of textures and sensations. This technology is particularly exciting for virtual and augmented reality applications, where realistic tactile feedback can greatly enhance user immersion.

Looking ahead, the evolution of ferrofluid technology in wearables is likely to continue along several paths. These include further miniaturization of ferrofluid-based components, improved integration with other smart materials, and the development of more sophisticated control mechanisms for ferrofluid behavior. As these advancements unfold, we can expect to see increasingly sophisticated and capable wearable devices that leverage the unique properties of ferrofluids to enhance performance, functionality, and user experience.

In the early 2000s, researchers began exploring the potential of ferrofluids in flexible and wearable devices. The initial focus was on leveraging the unique magnetic properties of ferrofluids to create novel sensing mechanisms. This period saw the emergence of prototype wearable sensors that could detect minute changes in magnetic fields, opening up possibilities for motion tracking and gesture recognition.

The next significant milestone came in the mid-2010s with the integration of ferrofluids into smart fabrics. Scientists developed techniques to encapsulate ferrofluid particles within textile fibers, creating fabrics that could respond to magnetic stimuli. This breakthrough led to the concept of "active clothing" that could change shape or properties based on external magnetic fields, potentially enhancing comfort and functionality in wearable tech.

Around 2018, a major leap forward occurred with the development of ferrofluid-based flexible displays. These displays utilized the dynamic nature of ferrofluids to create shape-shifting interfaces that could adapt to user needs. This innovation paved the way for more intuitive and interactive wearable devices, particularly in the realm of augmented reality and heads-up displays.

In recent years, the focus has shifted towards harnessing ferrofluids for energy harvesting in wearable technology. Researchers have demonstrated the potential of ferrofluid-based triboelectric nanogenerators, which can convert mechanical energy from body movements into electrical energy. This development holds promise for self-powered wearable devices, addressing one of the key challenges in wearable tech – power consumption and battery life.

The latest frontier in ferrofluid technology for wearables involves their application in haptic feedback systems. By manipulating ferrofluids with controlled magnetic fields, researchers are creating tactile interfaces that can simulate a wide range of textures and sensations. This technology is particularly exciting for virtual and augmented reality applications, where realistic tactile feedback can greatly enhance user immersion.

Looking ahead, the evolution of ferrofluid technology in wearables is likely to continue along several paths. These include further miniaturization of ferrofluid-based components, improved integration with other smart materials, and the development of more sophisticated control mechanisms for ferrofluid behavior. As these advancements unfold, we can expect to see increasingly sophisticated and capable wearable devices that leverage the unique properties of ferrofluids to enhance performance, functionality, and user experience.

Wearable Market Demand

The wearable technology market has experienced significant growth in recent years, driven by increasing consumer demand for health and fitness tracking devices, smartwatches, and other connected wearables. This trend is expected to continue, with the global wearable technology market projected to reach substantial value in the coming years. The integration of ferrofluids into wearable devices presents an opportunity to enhance performance and expand functionality, potentially addressing existing market needs and creating new demand.

Consumer interest in health and wellness monitoring has been a primary driver of wearable technology adoption. Devices that track vital signs, physical activity, and sleep patterns have gained popularity among health-conscious individuals and those managing chronic conditions. The potential for ferrofluids to improve sensor accuracy and enable new types of measurements could further fuel this segment of the market.

In the fitness and sports sector, wearables have become essential tools for athletes and fitness enthusiasts. The demand for more precise motion tracking, impact measurement, and performance analysis creates an opportunity for ferrofluid-enhanced devices. These could offer improved accuracy in movement detection and provide real-time feedback on form and technique, addressing the needs of both professional athletes and amateur sports participants.

The smartwatch segment, which combines communication features with health and fitness tracking, continues to dominate the wearable market. Consumers are increasingly seeking devices with longer battery life, improved durability, and enhanced functionality. Ferrofluids could potentially contribute to these areas by enabling more efficient power management systems or improving the robustness of internal components.

Enterprise and industrial applications represent a growing segment of the wearable market. There is increasing demand for wearable devices that can enhance worker safety, improve productivity, and facilitate hands-free operations in various industries. Ferrofluid technology could enable the development of more rugged and responsive wearables suitable for challenging work environments.

As the Internet of Things (IoT) ecosystem expands, there is a growing need for wearable devices that can seamlessly integrate with other smart systems. This includes home automation, automotive interfaces, and urban infrastructure. Ferrofluid-based wearables could potentially offer improved connectivity and interaction capabilities, meeting the demand for more integrated and responsive IoT experiences.

The healthcare sector presents significant opportunities for advanced wearable technologies. There is a growing demand for devices that can provide continuous, non-invasive monitoring of various health parameters. Ferrofluid technology could enable the development of more sensitive and versatile medical wearables, addressing the needs of both patients and healthcare providers for more comprehensive and reliable health data collection.

Consumer interest in health and wellness monitoring has been a primary driver of wearable technology adoption. Devices that track vital signs, physical activity, and sleep patterns have gained popularity among health-conscious individuals and those managing chronic conditions. The potential for ferrofluids to improve sensor accuracy and enable new types of measurements could further fuel this segment of the market.

In the fitness and sports sector, wearables have become essential tools for athletes and fitness enthusiasts. The demand for more precise motion tracking, impact measurement, and performance analysis creates an opportunity for ferrofluid-enhanced devices. These could offer improved accuracy in movement detection and provide real-time feedback on form and technique, addressing the needs of both professional athletes and amateur sports participants.

The smartwatch segment, which combines communication features with health and fitness tracking, continues to dominate the wearable market. Consumers are increasingly seeking devices with longer battery life, improved durability, and enhanced functionality. Ferrofluids could potentially contribute to these areas by enabling more efficient power management systems or improving the robustness of internal components.

Enterprise and industrial applications represent a growing segment of the wearable market. There is increasing demand for wearable devices that can enhance worker safety, improve productivity, and facilitate hands-free operations in various industries. Ferrofluid technology could enable the development of more rugged and responsive wearables suitable for challenging work environments.

As the Internet of Things (IoT) ecosystem expands, there is a growing need for wearable devices that can seamlessly integrate with other smart systems. This includes home automation, automotive interfaces, and urban infrastructure. Ferrofluid-based wearables could potentially offer improved connectivity and interaction capabilities, meeting the demand for more integrated and responsive IoT experiences.

The healthcare sector presents significant opportunities for advanced wearable technologies. There is a growing demand for devices that can provide continuous, non-invasive monitoring of various health parameters. Ferrofluid technology could enable the development of more sensitive and versatile medical wearables, addressing the needs of both patients and healthcare providers for more comprehensive and reliable health data collection.

Ferrofluid Challenges

The integration of ferrofluids into wearable technology presents several significant challenges that researchers and engineers must address. One of the primary obstacles is the stability of ferrofluids in dynamic environments. Wearable devices are subject to constant movement, temperature fluctuations, and varying magnetic fields, which can affect the behavior and performance of ferrofluids. Maintaining consistent properties and responsiveness of the ferrofluid under these conditions is crucial for reliable device operation.

Another challenge lies in the biocompatibility and safety of ferrofluids when used in close proximity to the human body. While many ferrofluids are composed of non-toxic materials, long-term exposure and potential skin absorption need to be thoroughly investigated to ensure user safety. This is particularly important for wearables that may be in direct contact with the skin for extended periods.

The miniaturization of ferrofluid-based components poses a significant technical hurdle. Wearable devices demand compact and lightweight designs, which requires the development of micro-scale ferrofluid systems. Achieving precise control and manipulation of ferrofluids at such small scales presents engineering challenges in terms of fluid dynamics and magnetic field generation.

Power consumption is another critical issue. Ferrofluid-based actuators or sensors in wearables often require active magnetic fields, which can be energy-intensive. Developing energy-efficient methods to manipulate ferrofluids without compromising performance is essential for extending battery life and enhancing the practicality of wearable devices.

The integration of ferrofluids with other materials and components in wearable technology is also challenging. Ensuring compatibility with flexible substrates, electronic circuits, and various sensors while maintaining the unique properties of ferrofluids requires innovative material science and engineering solutions.

Manufacturing scalability presents another obstacle. Current production methods for ferrofluid-based components may not be suitable for mass production of wearable devices. Developing cost-effective and scalable manufacturing processes that maintain the quality and performance of ferrofluid elements is crucial for widespread adoption.

Lastly, the long-term reliability and durability of ferrofluid components in wearable devices remain a concern. Factors such as fluid degradation, magnetic particle agglomeration, and seal integrity over time need to be addressed to ensure consistent performance throughout the device's lifespan. Overcoming these challenges will be key to fully leveraging the potential of ferrofluids in enhancing wearable technology performance.

Another challenge lies in the biocompatibility and safety of ferrofluids when used in close proximity to the human body. While many ferrofluids are composed of non-toxic materials, long-term exposure and potential skin absorption need to be thoroughly investigated to ensure user safety. This is particularly important for wearables that may be in direct contact with the skin for extended periods.

The miniaturization of ferrofluid-based components poses a significant technical hurdle. Wearable devices demand compact and lightweight designs, which requires the development of micro-scale ferrofluid systems. Achieving precise control and manipulation of ferrofluids at such small scales presents engineering challenges in terms of fluid dynamics and magnetic field generation.

Power consumption is another critical issue. Ferrofluid-based actuators or sensors in wearables often require active magnetic fields, which can be energy-intensive. Developing energy-efficient methods to manipulate ferrofluids without compromising performance is essential for extending battery life and enhancing the practicality of wearable devices.

The integration of ferrofluids with other materials and components in wearable technology is also challenging. Ensuring compatibility with flexible substrates, electronic circuits, and various sensors while maintaining the unique properties of ferrofluids requires innovative material science and engineering solutions.

Manufacturing scalability presents another obstacle. Current production methods for ferrofluid-based components may not be suitable for mass production of wearable devices. Developing cost-effective and scalable manufacturing processes that maintain the quality and performance of ferrofluid elements is crucial for widespread adoption.

Lastly, the long-term reliability and durability of ferrofluid components in wearable devices remain a concern. Factors such as fluid degradation, magnetic particle agglomeration, and seal integrity over time need to be addressed to ensure consistent performance throughout the device's lifespan. Overcoming these challenges will be key to fully leveraging the potential of ferrofluids in enhancing wearable technology performance.

Current Ferrofluid Apps

01 Magnetic sealing and damping applications

Ferrofluids are utilized in various sealing and damping applications, particularly in mechanical systems. They provide effective sealing in rotating shafts and offer vibration damping properties in various devices. The magnetic properties of ferrofluids allow for precise control and adaptability in these applications, enhancing overall system performance and reliability.- Magnetic sealing and damping applications: Ferrofluids are utilized in various sealing and damping applications, particularly in mechanical systems. They provide effective sealing in rotating shafts and offer vibration damping in various devices. The magnetic properties of ferrofluids allow for precise control and adaptability in these applications, enhancing overall system performance and reliability.

- Thermal management and heat transfer: Ferrofluids exhibit excellent thermal conductivity properties, making them suitable for heat transfer and thermal management applications. They can be used in cooling systems for electronic devices, transformers, and other heat-generating equipment. The magnetic nature of ferrofluids allows for controlled heat dissipation and improved thermal efficiency in various systems.

- Sensor and actuator technologies: Ferrofluids are employed in the development of advanced sensors and actuators. Their unique magnetic properties enable precise control and measurement of various physical parameters. Applications include accelerometers, pressure sensors, and position sensors. Ferrofluid-based actuators offer improved response times and accuracy in various control systems.

- Optical and display applications: Ferrofluids find use in optical systems and display technologies. Their ability to change optical properties under magnetic fields makes them suitable for tunable optical filters, displays, and light modulators. These applications leverage the unique visual characteristics of ferrofluids to create dynamic and responsive optical elements.

- Biomedical and pharmaceutical applications: Ferrofluids show promise in various biomedical and pharmaceutical applications. They can be used for targeted drug delivery, magnetic hyperthermia treatment, and as contrast agents in magnetic resonance imaging (MRI). The ability to manipulate ferrofluids using external magnetic fields offers new possibilities in medical diagnostics and therapies.

02 Thermal management and heat transfer

Ferrofluids exhibit excellent thermal conductivity properties, making them suitable for heat transfer and thermal management applications. They can be used in cooling systems for electronic devices, transformers, and other heat-generating equipment. The magnetic nature of ferrofluids allows for controlled movement and distribution of heat, improving overall thermal efficiency.Expand Specific Solutions03 Sensor and measurement technologies

Ferrofluids are employed in various sensing and measurement applications due to their unique magnetic properties. They can be used in accelerometers, tilt sensors, and fluid level sensors. The responsiveness of ferrofluids to magnetic fields enables precise and reliable measurements in diverse industrial and scientific settings.Expand Specific Solutions04 Optical and display applications

Ferrofluids have found applications in optical systems and display technologies. Their ability to form unique patterns and structures under magnetic fields makes them suitable for creating dynamic displays, light modulators, and optical switches. These properties enable the development of novel visual effects and adaptive optical devices.Expand Specific Solutions05 Biomedical and drug delivery systems

Ferrofluids show promise in biomedical applications, particularly in targeted drug delivery and medical imaging. Their magnetic properties allow for precise control and localization within the body, enabling more effective treatments and diagnostic procedures. Research is ongoing to develop ferrofluid-based systems for cancer therapy and other medical interventions.Expand Specific Solutions

Key Ferrofluid Players

The ferrofluid technology in wearable devices is in an early development stage, with a growing market potential as wearable technology expands. The technology's maturity varies among key players, with academic institutions like Northwestern University, Arizona State University, and MIT leading research efforts. Companies such as Samsung Electronics and Renesas Electronics are exploring practical applications. The competitive landscape is diverse, involving both established tech giants and specialized research institutions, indicating a collaborative approach to advancing ferrofluid integration in wearables. As the technology progresses, we can expect increased commercial interest and potential breakthroughs in enhancing wearable device performance.

Northwestern University

Technical Solution: Northwestern University researchers have developed a groundbreaking approach to using ferrofluids in wearable technology, focusing on biomedical applications. They have created a ferrofluid-based "smart skin" that can detect and respond to magnetic fields, potentially enabling non-invasive health monitoring[6]. The team has also explored using ferrofluids to create self-healing electronic components for wearables, which could significantly improve device longevity and reliability[7]. Furthermore, their work on ferrofluid-enhanced flexible electrodes has shown promise for improving the signal quality in wearable ECG and EEG devices[8].

Strengths: Strong focus on biomedical applications with potential for significant healthcare impact. Innovative approach to self-healing electronics. Weaknesses: May require extensive clinical trials and regulatory approvals before commercialization.

The Regents of the University of California

Technical Solution: The University of California system has been at the forefront of ferrofluid research for wearable technology. Their approach focuses on developing ferrofluid-based microfluidic systems for wearable sensors. These sensors can detect a wide range of biomolecules and environmental pollutants with high sensitivity[9]. The team has also explored using ferrofluids to create reconfigurable antennas for wearable communication devices, potentially improving signal strength and reducing power consumption[10]. Additionally, they have developed ferrofluid-based actuators for haptic feedback in wearables, offering more nuanced and realistic tactile sensations[11].

Strengths: Diverse range of applications from biosensing to communications. Strong potential for improving both functionality and user experience in wearables. Weaknesses: Integration of microfluidic systems into compact wearable form factors may present manufacturing challenges.

Ferrofluid Innovations

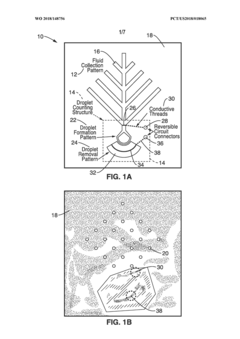

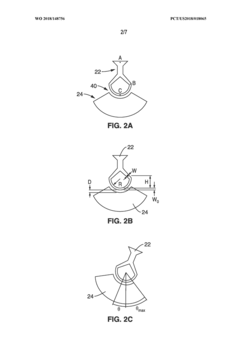

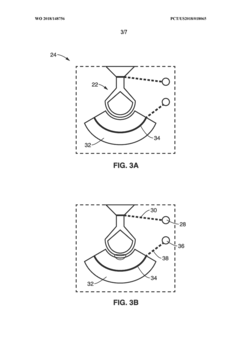

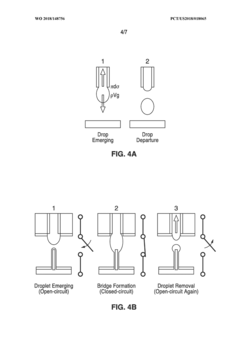

Apparatus and methods for digital droplet flowmetry

PatentWO2018148756A1

Innovation

- A wearable digital droplet flowmetry platform using conventional fabric materials and laser micromachining, which employs interfacial microfluidics to discretize continuous flow into droplets, allowing for real-time, continuous measurement of perspiration rates with high precision through a digital microfluidic flowmeter that utilizes interfacial bursting events and impedance detection.

Systems and methods for wireless, real-time monitoring parameters of sweat and applications of same

PatentWO2022011118A1

Innovation

- A wireless, miniaturized system using a thermal sensing module with a Bluetooth Low Energy (BLE) system-on-a-chip (SoC) for non-contact measurement of sweat rate, combining a thermal actuator and precision thermistors with a BLE SoC for wireless data transfer, and integrating with advanced microfluidic systems for colorimetric detection of pH and biomarker concentrations.

Ferrofluid Safety Regs

As the integration of ferrofluids into wearable technology continues to advance, it is crucial to address the safety regulations surrounding their use. Ferrofluids, being a unique class of magnetic nanomaterials, require specific safety considerations to ensure the well-being of users and the environment.

The primary safety concern with ferrofluids in wearable technology is the potential for nanoparticle exposure. Regulatory bodies, such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA), have established guidelines for the use of nanomaterials in consumer products. These regulations typically focus on particle size, composition, and potential for release or absorption through the skin.

For wearable devices incorporating ferrofluids, manufacturers must adhere to strict quality control measures to prevent leakage or degradation of the fluid over time. This includes robust encapsulation techniques and the use of biocompatible materials for any components that may come into direct contact with the skin.

Environmental safety is another critical aspect of ferrofluid regulations. The disposal and recycling of wearable devices containing ferrofluids must comply with electronic waste (e-waste) management protocols. Additionally, manufacturers are required to provide clear instructions for proper disposal to prevent environmental contamination.

Electromagnetic compatibility (EMC) regulations also play a significant role in ferrofluid-based wearables. As these devices often utilize magnetic fields for actuation or sensing, they must meet EMC standards to ensure they do not interfere with other electronic devices or medical implants.

Occupational safety standards for workers involved in the production and handling of ferrofluids in wearable technology manufacturing are equally important. These standards typically include guidelines for personal protective equipment, ventilation requirements, and safe handling procedures to minimize exposure risks.

As the field of wearable technology evolves, regulatory frameworks are continuously updated to address new challenges. For instance, the long-term effects of prolonged exposure to ferrofluids in close proximity to the human body are still being studied. This ongoing research may lead to the development of more specific safety regulations tailored to ferrofluid-based wearables in the future.

Compliance with these safety regulations is not only a legal requirement but also a crucial factor in gaining consumer trust and market acceptance. Manufacturers must demonstrate thorough safety testing and risk assessment processes to obtain necessary certifications and approvals before bringing ferrofluid-enhanced wearable products to market.

The primary safety concern with ferrofluids in wearable technology is the potential for nanoparticle exposure. Regulatory bodies, such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA), have established guidelines for the use of nanomaterials in consumer products. These regulations typically focus on particle size, composition, and potential for release or absorption through the skin.

For wearable devices incorporating ferrofluids, manufacturers must adhere to strict quality control measures to prevent leakage or degradation of the fluid over time. This includes robust encapsulation techniques and the use of biocompatible materials for any components that may come into direct contact with the skin.

Environmental safety is another critical aspect of ferrofluid regulations. The disposal and recycling of wearable devices containing ferrofluids must comply with electronic waste (e-waste) management protocols. Additionally, manufacturers are required to provide clear instructions for proper disposal to prevent environmental contamination.

Electromagnetic compatibility (EMC) regulations also play a significant role in ferrofluid-based wearables. As these devices often utilize magnetic fields for actuation or sensing, they must meet EMC standards to ensure they do not interfere with other electronic devices or medical implants.

Occupational safety standards for workers involved in the production and handling of ferrofluids in wearable technology manufacturing are equally important. These standards typically include guidelines for personal protective equipment, ventilation requirements, and safe handling procedures to minimize exposure risks.

As the field of wearable technology evolves, regulatory frameworks are continuously updated to address new challenges. For instance, the long-term effects of prolonged exposure to ferrofluids in close proximity to the human body are still being studied. This ongoing research may lead to the development of more specific safety regulations tailored to ferrofluid-based wearables in the future.

Compliance with these safety regulations is not only a legal requirement but also a crucial factor in gaining consumer trust and market acceptance. Manufacturers must demonstrate thorough safety testing and risk assessment processes to obtain necessary certifications and approvals before bringing ferrofluid-enhanced wearable products to market.

Ferrofluid Sustainability

The sustainability of ferrofluids in wearable technology is a critical consideration as the industry moves towards more environmentally conscious practices. Ferrofluids, composed of nanoscale ferromagnetic particles suspended in a carrier fluid, present both opportunities and challenges in terms of sustainability.

One of the primary sustainability concerns with ferrofluids is the potential environmental impact of nanoparticles. As wearable devices incorporating ferrofluids reach the end of their lifecycle, proper disposal and recycling methods must be developed to prevent these nanoparticles from entering ecosystems. Research is ongoing to assess the long-term effects of ferromagnetic nanoparticles on the environment and to develop containment strategies.

The production of ferrofluids also raises sustainability questions. The synthesis of nanoparticles often involves energy-intensive processes and the use of potentially harmful chemicals. Efforts are being made to develop greener synthesis methods, such as using plant-based reducing agents or employing microwave-assisted techniques, which can significantly reduce energy consumption and the use of toxic substances.

On the positive side, the unique properties of ferrofluids can contribute to the overall sustainability of wearable technology. Their ability to enhance energy harvesting in devices could lead to more efficient power management systems, potentially reducing the need for frequent battery replacements and extending device lifespans. This aligns with the principles of circular economy and sustainable product design.

The recyclability of ferrofluid-containing components is another area of focus. Researchers are exploring methods to separate and recover the magnetic nanoparticles from used devices, which could allow for the reuse of these materials in new products. This approach not only reduces waste but also decreases the demand for raw materials in ferrofluid production.

As wearable technology evolves, there is a growing emphasis on using biocompatible and biodegradable materials in ferrofluid formulations. This includes the development of carrier fluids derived from renewable resources and the exploration of naturally occurring magnetic nanoparticles. Such innovations could significantly improve the end-of-life management of ferrofluid-enhanced wearables.

The integration of ferrofluids into wearable technology also presents opportunities for more durable and adaptable devices. By leveraging the self-healing and shape-shifting properties of ferrofluids, manufacturers can potentially create products with longer lifespans and reduced need for replacement, thereby minimizing electronic waste.

One of the primary sustainability concerns with ferrofluids is the potential environmental impact of nanoparticles. As wearable devices incorporating ferrofluids reach the end of their lifecycle, proper disposal and recycling methods must be developed to prevent these nanoparticles from entering ecosystems. Research is ongoing to assess the long-term effects of ferromagnetic nanoparticles on the environment and to develop containment strategies.

The production of ferrofluids also raises sustainability questions. The synthesis of nanoparticles often involves energy-intensive processes and the use of potentially harmful chemicals. Efforts are being made to develop greener synthesis methods, such as using plant-based reducing agents or employing microwave-assisted techniques, which can significantly reduce energy consumption and the use of toxic substances.

On the positive side, the unique properties of ferrofluids can contribute to the overall sustainability of wearable technology. Their ability to enhance energy harvesting in devices could lead to more efficient power management systems, potentially reducing the need for frequent battery replacements and extending device lifespans. This aligns with the principles of circular economy and sustainable product design.

The recyclability of ferrofluid-containing components is another area of focus. Researchers are exploring methods to separate and recover the magnetic nanoparticles from used devices, which could allow for the reuse of these materials in new products. This approach not only reduces waste but also decreases the demand for raw materials in ferrofluid production.

As wearable technology evolves, there is a growing emphasis on using biocompatible and biodegradable materials in ferrofluid formulations. This includes the development of carrier fluids derived from renewable resources and the exploration of naturally occurring magnetic nanoparticles. Such innovations could significantly improve the end-of-life management of ferrofluid-enhanced wearables.

The integration of ferrofluids into wearable technology also presents opportunities for more durable and adaptable devices. By leveraging the self-healing and shape-shifting properties of ferrofluids, manufacturers can potentially create products with longer lifespans and reduced need for replacement, thereby minimizing electronic waste.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!