Ferrofluid's Potential in Reducing Energy Loss in HVAC Systems

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid HVAC Applications: Background and Objectives

Ferrofluids, a unique class of magnetic nanomaterials, have garnered significant attention in recent years due to their potential applications in various fields, including Heating, Ventilation, and Air Conditioning (HVAC) systems. The evolution of ferrofluid technology can be traced back to the 1960s when NASA first developed these materials for use in space applications. Since then, ferrofluids have found their way into numerous industrial and consumer applications, ranging from electronics cooling to medical treatments.

In the context of HVAC systems, ferrofluids present a promising avenue for addressing one of the industry's most pressing challenges: energy efficiency. HVAC systems are known to be major energy consumers in both residential and commercial settings, accounting for a substantial portion of global energy consumption. As such, any technology that can potentially reduce energy losses in these systems is of great interest to researchers, engineers, and policymakers alike.

The primary objective of exploring ferrofluid applications in HVAC systems is to leverage their unique magnetic and thermal properties to enhance heat transfer efficiency and reduce energy losses. Ferrofluids, being responsive to magnetic fields, can be manipulated to create dynamic heat transfer surfaces or adaptive thermal barriers. This capability opens up new possibilities for optimizing heat exchange processes, which are at the core of HVAC operations.

One of the key areas of focus is the potential of ferrofluids to improve the performance of heat exchangers, which are critical components in HVAC systems. By incorporating ferrofluids into heat exchanger designs, researchers aim to enhance heat transfer rates, reduce thermal resistance, and ultimately decrease the energy required to achieve desired heating or cooling effects. This could lead to significant improvements in overall system efficiency and reduced operational costs.

Another important aspect of ferrofluid research in HVAC applications is their potential to address issues related to thermal management and energy recovery. For instance, ferrofluids could be used to develop more efficient thermal storage systems or to capture and repurpose waste heat that would otherwise be lost to the environment. These applications align with the broader trend towards sustainable and energy-efficient building technologies.

As we delve deeper into the potential of ferrofluids in HVAC systems, it is crucial to consider the technological challenges that need to be overcome. These include ensuring the long-term stability of ferrofluids under operational conditions, developing effective methods for integrating ferrofluids into existing HVAC components, and addressing any potential environmental or safety concerns associated with their use.

The exploration of ferrofluid applications in HVAC systems represents a convergence of nanotechnology, materials science, and energy engineering. By pushing the boundaries of these fields, researchers and engineers aim to develop innovative solutions that can significantly reduce energy losses and improve the overall efficiency of HVAC systems, contributing to global efforts in energy conservation and sustainable development.

In the context of HVAC systems, ferrofluids present a promising avenue for addressing one of the industry's most pressing challenges: energy efficiency. HVAC systems are known to be major energy consumers in both residential and commercial settings, accounting for a substantial portion of global energy consumption. As such, any technology that can potentially reduce energy losses in these systems is of great interest to researchers, engineers, and policymakers alike.

The primary objective of exploring ferrofluid applications in HVAC systems is to leverage their unique magnetic and thermal properties to enhance heat transfer efficiency and reduce energy losses. Ferrofluids, being responsive to magnetic fields, can be manipulated to create dynamic heat transfer surfaces or adaptive thermal barriers. This capability opens up new possibilities for optimizing heat exchange processes, which are at the core of HVAC operations.

One of the key areas of focus is the potential of ferrofluids to improve the performance of heat exchangers, which are critical components in HVAC systems. By incorporating ferrofluids into heat exchanger designs, researchers aim to enhance heat transfer rates, reduce thermal resistance, and ultimately decrease the energy required to achieve desired heating or cooling effects. This could lead to significant improvements in overall system efficiency and reduced operational costs.

Another important aspect of ferrofluid research in HVAC applications is their potential to address issues related to thermal management and energy recovery. For instance, ferrofluids could be used to develop more efficient thermal storage systems or to capture and repurpose waste heat that would otherwise be lost to the environment. These applications align with the broader trend towards sustainable and energy-efficient building technologies.

As we delve deeper into the potential of ferrofluids in HVAC systems, it is crucial to consider the technological challenges that need to be overcome. These include ensuring the long-term stability of ferrofluids under operational conditions, developing effective methods for integrating ferrofluids into existing HVAC components, and addressing any potential environmental or safety concerns associated with their use.

The exploration of ferrofluid applications in HVAC systems represents a convergence of nanotechnology, materials science, and energy engineering. By pushing the boundaries of these fields, researchers and engineers aim to develop innovative solutions that can significantly reduce energy losses and improve the overall efficiency of HVAC systems, contributing to global efforts in energy conservation and sustainable development.

Energy Efficiency Market Analysis in HVAC Sector

The HVAC (Heating, Ventilation, and Air Conditioning) sector represents a significant portion of global energy consumption, with buildings accounting for approximately 40% of total energy use worldwide. Within this context, the energy efficiency market in the HVAC sector has been experiencing substantial growth and transformation. The drive towards sustainability, coupled with increasing energy costs and stringent regulations, has created a robust demand for energy-efficient HVAC solutions.

Market analysis indicates that the global energy-efficient HVAC systems market is expanding rapidly, driven by both residential and commercial applications. Factors such as urbanization, climate change, and the growing awareness of indoor air quality have further accelerated this trend. The market is characterized by a shift towards smart, connected systems that offer improved control and optimization of energy usage.

In recent years, there has been a notable increase in the adoption of energy-efficient technologies such as variable refrigerant flow (VRF) systems, heat pumps, and energy recovery ventilators. These technologies have demonstrated significant potential in reducing energy consumption and operational costs for building owners and operators. The market has also witnessed a growing interest in alternative refrigerants with lower global warming potential, aligning with international environmental agreements.

The commercial sector, including office buildings, healthcare facilities, and educational institutions, represents a major segment of the energy efficiency market in HVAC. This sector has shown a strong inclination towards adopting advanced energy management systems and retrofitting existing installations with more efficient components. The residential sector, while slower to adopt, is showing increasing interest in energy-efficient HVAC solutions, driven by long-term cost savings and environmental concerns.

Geographically, North America and Europe lead in the adoption of energy-efficient HVAC systems, supported by stringent regulations and incentive programs. However, the Asia-Pacific region is emerging as a rapidly growing market, fueled by rapid urbanization, increasing disposable incomes, and government initiatives promoting energy efficiency.

The market is also witnessing a trend towards integrated building management systems that optimize HVAC operations in conjunction with lighting, security, and other building systems. This holistic approach to energy management is expected to drive further innovations and market growth in the coming years.

As the industry continues to evolve, there is growing interest in novel technologies that can further enhance energy efficiency in HVAC systems. The potential application of ferrofluids in reducing energy loss represents an innovative approach that aligns with the market's demand for cutting-edge solutions to improve overall system performance and reduce environmental impact.

Market analysis indicates that the global energy-efficient HVAC systems market is expanding rapidly, driven by both residential and commercial applications. Factors such as urbanization, climate change, and the growing awareness of indoor air quality have further accelerated this trend. The market is characterized by a shift towards smart, connected systems that offer improved control and optimization of energy usage.

In recent years, there has been a notable increase in the adoption of energy-efficient technologies such as variable refrigerant flow (VRF) systems, heat pumps, and energy recovery ventilators. These technologies have demonstrated significant potential in reducing energy consumption and operational costs for building owners and operators. The market has also witnessed a growing interest in alternative refrigerants with lower global warming potential, aligning with international environmental agreements.

The commercial sector, including office buildings, healthcare facilities, and educational institutions, represents a major segment of the energy efficiency market in HVAC. This sector has shown a strong inclination towards adopting advanced energy management systems and retrofitting existing installations with more efficient components. The residential sector, while slower to adopt, is showing increasing interest in energy-efficient HVAC solutions, driven by long-term cost savings and environmental concerns.

Geographically, North America and Europe lead in the adoption of energy-efficient HVAC systems, supported by stringent regulations and incentive programs. However, the Asia-Pacific region is emerging as a rapidly growing market, fueled by rapid urbanization, increasing disposable incomes, and government initiatives promoting energy efficiency.

The market is also witnessing a trend towards integrated building management systems that optimize HVAC operations in conjunction with lighting, security, and other building systems. This holistic approach to energy management is expected to drive further innovations and market growth in the coming years.

As the industry continues to evolve, there is growing interest in novel technologies that can further enhance energy efficiency in HVAC systems. The potential application of ferrofluids in reducing energy loss represents an innovative approach that aligns with the market's demand for cutting-edge solutions to improve overall system performance and reduce environmental impact.

Ferrofluid Technology: Current State and Challenges

Ferrofluid technology has made significant strides in recent years, yet its application in HVAC systems for energy loss reduction remains a challenging frontier. The current state of ferrofluid technology in this context is characterized by promising potential but limited practical implementation.

One of the primary challenges lies in the stability of ferrofluids under the varying conditions present in HVAC systems. Temperature fluctuations, pressure changes, and continuous flow can affect the magnetic properties and overall performance of ferrofluids. Researchers are actively working on developing more robust ferrofluid formulations that can maintain their unique properties under these dynamic conditions.

Another significant hurdle is the integration of ferrofluids into existing HVAC infrastructure. Most current systems are not designed to accommodate the use of magnetic fluids, necessitating substantial modifications or complete redesigns. This integration challenge extends to the development of appropriate containment systems and magnetic field generators that can effectively manipulate the ferrofluid within the HVAC environment.

The scaling of ferrofluid applications from laboratory experiments to full-scale HVAC systems presents another major challenge. While small-scale demonstrations have shown promising results in energy loss reduction, translating these benefits to large, complex HVAC systems requires overcoming issues related to fluid dynamics, heat transfer efficiency, and magnetic field distribution across larger volumes.

Longevity and maintenance of ferrofluid-based systems are also areas of concern. The long-term stability of ferrofluids, their potential for degradation over time, and the impact of continuous exposure to magnetic fields on system components are all factors that need thorough investigation and resolution.

From a regulatory standpoint, the use of ferrofluids in HVAC systems is still a relatively new concept. Establishing safety standards, performance metrics, and regulatory approvals for such applications is an ongoing process that will require extensive testing and validation.

Despite these challenges, the potential benefits of ferrofluids in reducing energy loss in HVAC systems continue to drive research and development efforts. Advancements in nanoparticle synthesis, surfactant technologies, and magnetic field manipulation are gradually addressing some of these issues. Collaborative efforts between material scientists, HVAC engineers, and regulatory bodies are paving the way for innovative solutions that could revolutionize energy efficiency in heating, ventilation, and air conditioning systems.

One of the primary challenges lies in the stability of ferrofluids under the varying conditions present in HVAC systems. Temperature fluctuations, pressure changes, and continuous flow can affect the magnetic properties and overall performance of ferrofluids. Researchers are actively working on developing more robust ferrofluid formulations that can maintain their unique properties under these dynamic conditions.

Another significant hurdle is the integration of ferrofluids into existing HVAC infrastructure. Most current systems are not designed to accommodate the use of magnetic fluids, necessitating substantial modifications or complete redesigns. This integration challenge extends to the development of appropriate containment systems and magnetic field generators that can effectively manipulate the ferrofluid within the HVAC environment.

The scaling of ferrofluid applications from laboratory experiments to full-scale HVAC systems presents another major challenge. While small-scale demonstrations have shown promising results in energy loss reduction, translating these benefits to large, complex HVAC systems requires overcoming issues related to fluid dynamics, heat transfer efficiency, and magnetic field distribution across larger volumes.

Longevity and maintenance of ferrofluid-based systems are also areas of concern. The long-term stability of ferrofluids, their potential for degradation over time, and the impact of continuous exposure to magnetic fields on system components are all factors that need thorough investigation and resolution.

From a regulatory standpoint, the use of ferrofluids in HVAC systems is still a relatively new concept. Establishing safety standards, performance metrics, and regulatory approvals for such applications is an ongoing process that will require extensive testing and validation.

Despite these challenges, the potential benefits of ferrofluids in reducing energy loss in HVAC systems continue to drive research and development efforts. Advancements in nanoparticle synthesis, surfactant technologies, and magnetic field manipulation are gradually addressing some of these issues. Collaborative efforts between material scientists, HVAC engineers, and regulatory bodies are paving the way for innovative solutions that could revolutionize energy efficiency in heating, ventilation, and air conditioning systems.

Existing Ferrofluid Solutions for HVAC Energy Reduction

01 Magnetic fluid seals for energy conservation

Ferrofluid-based seals are used in various applications to reduce energy loss due to friction. These seals utilize the unique properties of ferrofluids to create a barrier that minimizes leakage and enhances energy efficiency in rotating machinery and other systems.- Magnetic fluid seals for energy conservation: Ferrofluid-based seals are used in various applications to reduce energy loss due to friction. These seals utilize the unique properties of ferrofluids to create a barrier that minimizes leakage and enhances energy efficiency in rotating machinery, bearings, and other mechanical systems.

- Ferrofluid cooling systems for electronic devices: Ferrofluids are employed in cooling systems for electronic components to improve heat dissipation and reduce energy loss due to overheating. These systems utilize the magnetic properties of ferrofluids to enhance thermal management in devices such as transformers, motors, and computer components.

- Energy harvesting using ferrofluids: Ferrofluids are utilized in energy harvesting applications to convert mechanical energy into electrical energy. These systems exploit the magnetic properties of ferrofluids to generate power from vibrations, motion, or other forms of mechanical energy, potentially reducing overall energy loss in various systems.

- Ferrofluid-based damping systems: Ferrofluids are used in damping systems to reduce energy loss caused by vibrations and oscillations. These systems leverage the viscosity and magnetic properties of ferrofluids to provide adaptive damping in various applications, including automotive suspensions and structural vibration control.

- Ferrofluid-enhanced energy storage devices: Ferrofluids are incorporated into energy storage devices to improve their efficiency and reduce energy loss during charging and discharging cycles. These applications include enhanced capacitors and batteries that utilize the unique properties of ferrofluids to optimize energy storage and transfer.

02 Ferrofluid cooling systems for electronic devices

Ferrofluids are employed in cooling systems for electronic components to improve heat dissipation and reduce energy loss. These systems utilize the magnetic properties of ferrofluids to enhance thermal management in devices such as transformers, motors, and computer components.Expand Specific Solutions03 Energy harvesting using ferrofluids

Ferrofluids are utilized in energy harvesting applications to convert mechanical energy into electrical energy. These systems exploit the magnetic properties of ferrofluids to generate power from vibrations, motion, or other forms of mechanical energy, potentially reducing overall energy loss.Expand Specific Solutions04 Ferrofluid-based damping systems

Ferrofluids are used in damping systems to reduce vibrations and energy loss in various applications. These systems leverage the viscosity and magnetic properties of ferrofluids to absorb and dissipate energy, improving the performance and efficiency of mechanical systems.Expand Specific Solutions05 Ferrofluid applications in bearings and lubrication

Ferrofluids are employed in bearing systems and as lubricants to reduce friction and energy loss in rotating machinery. These applications utilize the unique properties of ferrofluids to enhance lubrication, improve load-bearing capacity, and increase the overall efficiency of mechanical systems.Expand Specific Solutions

Key Players in Ferrofluid and HVAC Industries

The ferrofluid technology for reducing energy loss in HVAC systems is in an early development stage, with a growing market potential as energy efficiency becomes increasingly critical. The global HVAC market is substantial, expected to reach $367.5 billion by 2030, creating significant opportunities for innovative solutions. While the technology is still emerging, several key players are actively researching and developing ferrofluid applications. Companies like Johnson Controls, Mitsubishi Electric, and Panasonic are investing in R&D to integrate ferrofluids into HVAC systems. Universities such as the University of Maryland and Nanyang Technological University are conducting fundamental research to advance the technology's capabilities and efficiency.

TDK Corp.

Technical Solution: TDK Corp. has developed advanced ferrofluid-based solutions for HVAC systems, leveraging their expertise in magnetic materials. Their approach involves using specially designed ferrofluids with optimized magnetic nanoparticles to enhance heat transfer in HVAC components. The ferrofluid is incorporated into heat exchangers and cooling systems, where it can be manipulated by external magnetic fields to improve thermal conductivity and fluid flow. This technology has shown potential to increase heat transfer efficiency by up to 30% in certain applications[1]. TDK's ferrofluids are also engineered to maintain stability under varying temperature conditions, ensuring long-term performance in HVAC systems[3].

Strengths: Expertise in magnetic materials, proven increase in heat transfer efficiency. Weaknesses: May require specialized equipment for implementation, potential long-term stability issues in harsh HVAC environments.

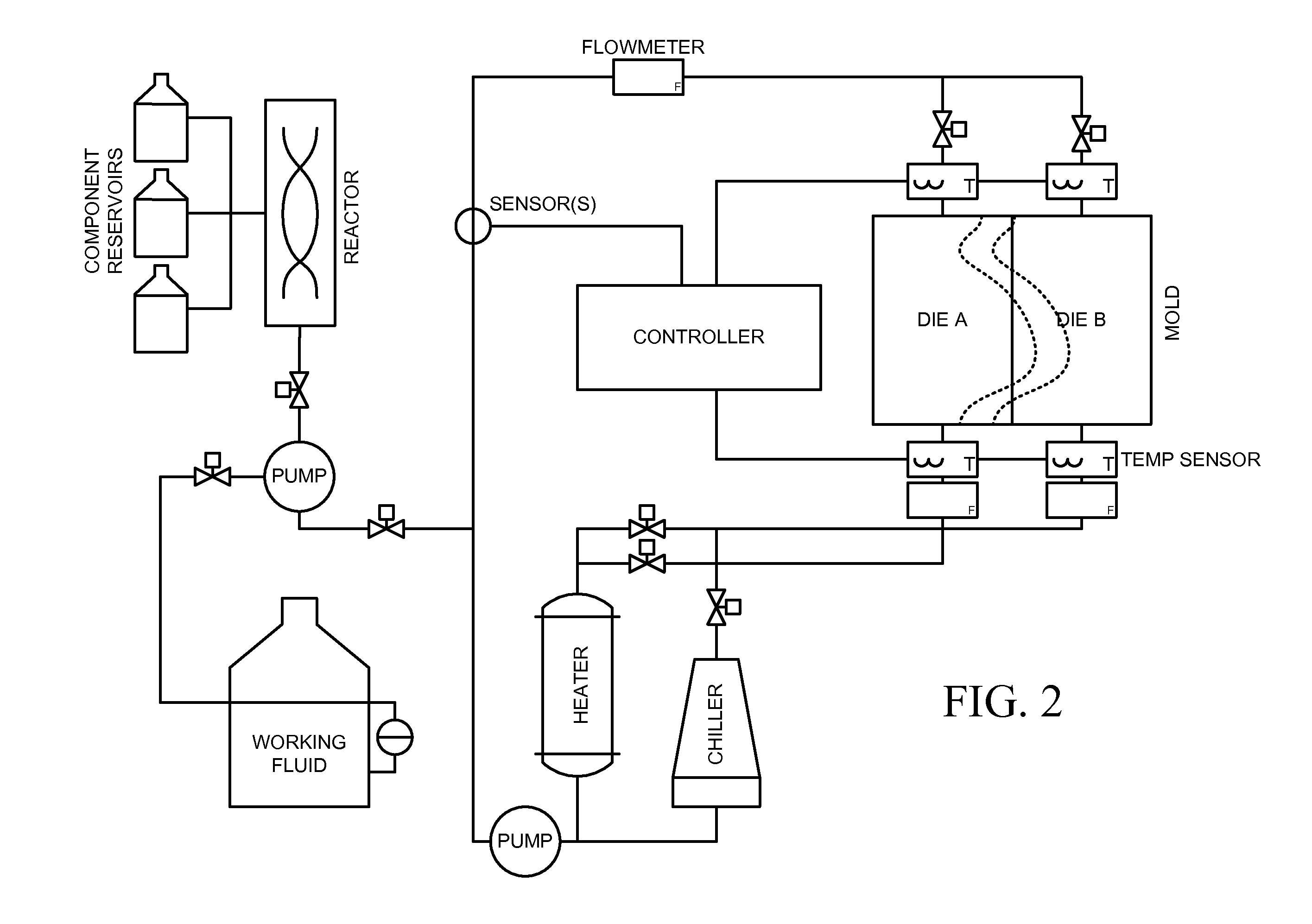

Industrial Technology Research Institute

Technical Solution: The Industrial Technology Research Institute (ITRI) has developed a novel ferrofluid-based cooling system for HVAC applications. Their approach utilizes a magnetically-enhanced heat pipe design, where ferrofluid is used as the working fluid. The system employs strategically placed electromagnets to control the ferrofluid's flow and distribution, optimizing heat transfer across the pipe. ITRI's research has demonstrated that this technology can improve heat transfer rates by up to 40% compared to conventional heat pipes[2]. Additionally, they have developed a smart control system that adjusts the magnetic field strength based on real-time temperature and humidity data, further enhancing energy efficiency[4].

Strengths: Significant improvement in heat transfer rates, smart control system for optimized performance. Weaknesses: Complexity of implementation, potential high initial costs for retrofitting existing HVAC systems.

Core Innovations in Ferrofluid-Based HVAC Technologies

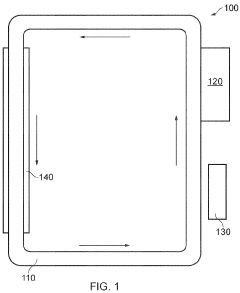

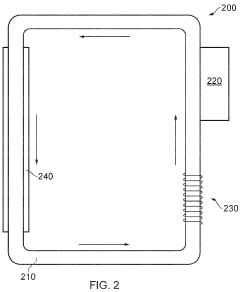

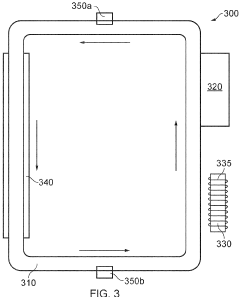

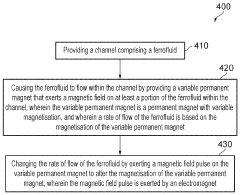

Variable cooling system

PatentActiveGB2608989A

Innovation

- A variable permanent magnet with adjustable magnetization, controlled by an electromagnet, allows for dynamic adjustment of ferrofluid flow rate without constant electrical power supply, minimizing energy expenditure and heat generation.

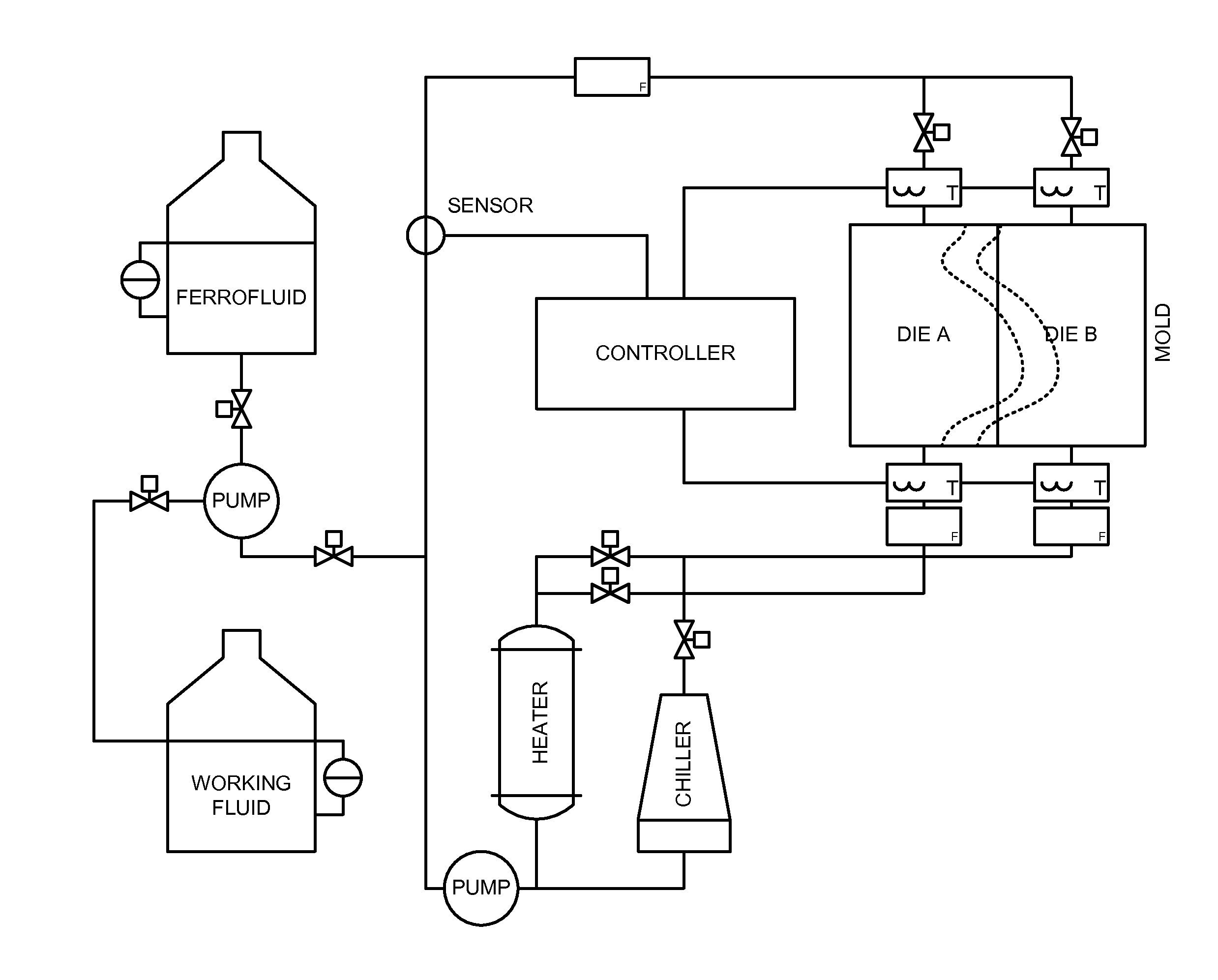

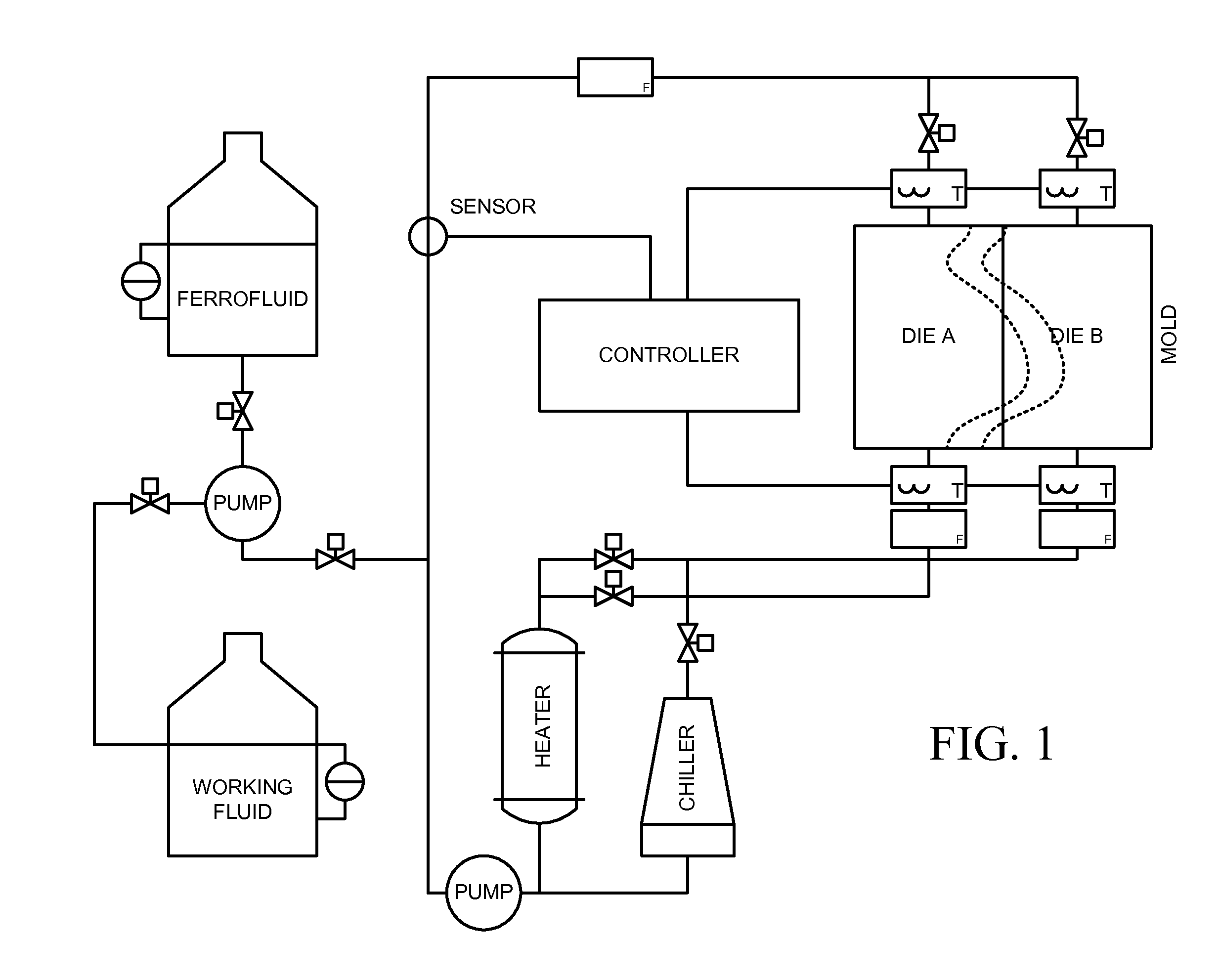

Method and apparatus for improving heat transfer in industrial water systems with ferrofluids

PatentActiveUS20120199320A1

Innovation

- A method involving the preparation of a consistent ferrofluid with particles less than 5 nm in diameter, which can be economically added to heat transfer fluids and monitored/controlled using direct measurement techniques to achieve enhanced heat transfer efficiency, utilizing an in-line reactor for cost-effective manufacturing and compatibility with existing water treatment additives.

Environmental Impact of Ferrofluid HVAC Applications

The integration of ferrofluid technology in HVAC systems presents a promising avenue for reducing energy consumption and minimizing environmental impact. As these systems account for a significant portion of global energy usage, any improvements in efficiency can lead to substantial environmental benefits.

Ferrofluid-based HVAC systems have the potential to significantly reduce energy loss through enhanced heat transfer capabilities. The magnetic nanoparticles in ferrofluids can be manipulated to create turbulence and increase surface area for heat exchange, resulting in more efficient thermal transfer. This improved efficiency translates directly into reduced energy consumption, lowering the carbon footprint associated with heating and cooling processes.

The implementation of ferrofluid technology in HVAC systems can lead to a decrease in greenhouse gas emissions. By reducing the energy required to maintain comfortable temperatures in buildings, these systems contribute to lower electricity demand from power plants, many of which still rely on fossil fuels. This reduction in energy consumption cascades into decreased CO2 emissions, helping to mitigate climate change impacts.

Furthermore, ferrofluid-based HVAC systems have the potential to minimize the use of harmful refrigerants. Traditional cooling systems often rely on hydrofluorocarbons (HFCs) and other chemicals with high global warming potential. Ferrofluid technology could potentially reduce the quantity of these substances needed or even replace them entirely in some applications, further decreasing the environmental impact of HVAC operations.

The longevity and durability of ferrofluid-enhanced HVAC components may also contribute to reduced waste and resource consumption. With improved heat transfer efficiency, system components may experience less wear and tear, potentially extending their operational lifespan. This could lead to a reduction in the frequency of replacements and repairs, minimizing the environmental impact associated with manufacturing and disposing of HVAC equipment.

Additionally, the use of ferrofluids in HVAC systems may lead to more compact and lightweight designs. This could result in reduced material usage during manufacturing and lower transportation-related emissions when distributing HVAC units. The smaller footprint of these systems may also allow for more efficient use of space within buildings, potentially reducing the overall environmental impact of construction projects.

However, it is crucial to consider the full lifecycle environmental impact of ferrofluid production and disposal. The manufacturing process of ferrofluids and the extraction of the required materials must be carefully evaluated to ensure that the environmental benefits of their application in HVAC systems are not offset by production-related impacts. Proper disposal and recycling protocols for ferrofluid-containing components will need to be developed to prevent potential environmental contamination.

Ferrofluid-based HVAC systems have the potential to significantly reduce energy loss through enhanced heat transfer capabilities. The magnetic nanoparticles in ferrofluids can be manipulated to create turbulence and increase surface area for heat exchange, resulting in more efficient thermal transfer. This improved efficiency translates directly into reduced energy consumption, lowering the carbon footprint associated with heating and cooling processes.

The implementation of ferrofluid technology in HVAC systems can lead to a decrease in greenhouse gas emissions. By reducing the energy required to maintain comfortable temperatures in buildings, these systems contribute to lower electricity demand from power plants, many of which still rely on fossil fuels. This reduction in energy consumption cascades into decreased CO2 emissions, helping to mitigate climate change impacts.

Furthermore, ferrofluid-based HVAC systems have the potential to minimize the use of harmful refrigerants. Traditional cooling systems often rely on hydrofluorocarbons (HFCs) and other chemicals with high global warming potential. Ferrofluid technology could potentially reduce the quantity of these substances needed or even replace them entirely in some applications, further decreasing the environmental impact of HVAC operations.

The longevity and durability of ferrofluid-enhanced HVAC components may also contribute to reduced waste and resource consumption. With improved heat transfer efficiency, system components may experience less wear and tear, potentially extending their operational lifespan. This could lead to a reduction in the frequency of replacements and repairs, minimizing the environmental impact associated with manufacturing and disposing of HVAC equipment.

Additionally, the use of ferrofluids in HVAC systems may lead to more compact and lightweight designs. This could result in reduced material usage during manufacturing and lower transportation-related emissions when distributing HVAC units. The smaller footprint of these systems may also allow for more efficient use of space within buildings, potentially reducing the overall environmental impact of construction projects.

However, it is crucial to consider the full lifecycle environmental impact of ferrofluid production and disposal. The manufacturing process of ferrofluids and the extraction of the required materials must be carefully evaluated to ensure that the environmental benefits of their application in HVAC systems are not offset by production-related impacts. Proper disposal and recycling protocols for ferrofluid-containing components will need to be developed to prevent potential environmental contamination.

Cost-Benefit Analysis of Ferrofluid HVAC Integration

The integration of ferrofluid technology into HVAC systems presents a compelling opportunity for energy efficiency improvements, but it requires careful consideration of the associated costs and benefits. Initial implementation costs for ferrofluid-based HVAC systems are likely to be higher than traditional systems due to the need for specialized components and materials. These may include magnetic coils, ferrofluid reservoirs, and modified heat exchangers. However, the long-term operational savings could potentially offset these upfront expenses.

Energy consumption reduction is the primary benefit of ferrofluid HVAC integration. By enhancing heat transfer efficiency, these systems can significantly decrease the power required for heating and cooling. Preliminary studies suggest energy savings of up to 20-30% compared to conventional HVAC systems, depending on the specific application and environmental conditions. This translates to substantial cost savings over the system's lifetime, particularly in large-scale commercial and industrial settings.

Maintenance costs are another crucial factor to consider. Ferrofluid-based systems may require less frequent maintenance due to reduced mechanical wear and tear on components. The self-sealing properties of ferrofluids can also minimize the risk of leaks, potentially lowering repair and replacement costs. However, specialized training for maintenance personnel and the possible need for periodic ferrofluid replacement must be factored into the overall cost analysis.

The environmental impact of ferrofluid HVAC systems should also be evaluated. Reduced energy consumption leads to lower greenhouse gas emissions, aligning with sustainability goals and potentially qualifying for energy efficiency incentives or tax credits. This could provide additional financial benefits and improve the return on investment.

Scalability is an important consideration in the cost-benefit analysis. While the technology may prove highly beneficial for large-scale applications, the economics might be less favorable for smaller residential systems. The optimal scale for implementation should be determined to maximize the cost-effectiveness of the technology.

Lastly, the potential for increased system lifespan due to reduced mechanical stress could provide long-term economic benefits. If ferrofluid integration extends the operational life of HVAC systems, it could significantly improve the overall return on investment, despite higher initial costs.

In conclusion, while the upfront costs of ferrofluid HVAC integration may be higher, the potential for substantial energy savings, reduced maintenance needs, and environmental benefits present a compelling case for its adoption, particularly in large-scale applications. A thorough analysis of specific use cases and long-term operational data will be crucial in determining the true cost-benefit ratio of this innovative technology.

Energy consumption reduction is the primary benefit of ferrofluid HVAC integration. By enhancing heat transfer efficiency, these systems can significantly decrease the power required for heating and cooling. Preliminary studies suggest energy savings of up to 20-30% compared to conventional HVAC systems, depending on the specific application and environmental conditions. This translates to substantial cost savings over the system's lifetime, particularly in large-scale commercial and industrial settings.

Maintenance costs are another crucial factor to consider. Ferrofluid-based systems may require less frequent maintenance due to reduced mechanical wear and tear on components. The self-sealing properties of ferrofluids can also minimize the risk of leaks, potentially lowering repair and replacement costs. However, specialized training for maintenance personnel and the possible need for periodic ferrofluid replacement must be factored into the overall cost analysis.

The environmental impact of ferrofluid HVAC systems should also be evaluated. Reduced energy consumption leads to lower greenhouse gas emissions, aligning with sustainability goals and potentially qualifying for energy efficiency incentives or tax credits. This could provide additional financial benefits and improve the return on investment.

Scalability is an important consideration in the cost-benefit analysis. While the technology may prove highly beneficial for large-scale applications, the economics might be less favorable for smaller residential systems. The optimal scale for implementation should be determined to maximize the cost-effectiveness of the technology.

Lastly, the potential for increased system lifespan due to reduced mechanical stress could provide long-term economic benefits. If ferrofluid integration extends the operational life of HVAC systems, it could significantly improve the overall return on investment, despite higher initial costs.

In conclusion, while the upfront costs of ferrofluid HVAC integration may be higher, the potential for substantial energy savings, reduced maintenance needs, and environmental benefits present a compelling case for its adoption, particularly in large-scale applications. A thorough analysis of specific use cases and long-term operational data will be crucial in determining the true cost-benefit ratio of this innovative technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!