Ferrofluid's Role in Boosting Artificial Intelligence Processing Speeds

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid AI Acceleration: Background and Objectives

Ferrofluids, a unique class of magnetic nanomaterials, have recently emerged as a promising candidate for revolutionizing artificial intelligence processing speeds. These colloidal liquids, composed of nanoscale ferromagnetic particles suspended in a carrier fluid, exhibit remarkable properties that align with the growing demands of AI computational efficiency.

The field of artificial intelligence has experienced exponential growth over the past decade, with increasingly complex algorithms and models requiring ever-greater processing power. Traditional silicon-based computing architectures are approaching their physical limits, necessitating innovative solutions to overcome these barriers. This convergence of AI's computational needs and the limitations of current hardware has sparked interest in alternative computing paradigms, including those leveraging novel materials like ferrofluids.

Ferrofluids' unique characteristics, such as their ability to change shape and properties in response to magnetic fields, offer intriguing possibilities for enhancing AI processing capabilities. Their potential applications range from improved heat dissipation in AI chips to novel computing architectures that exploit the fluid's magnetic properties for information processing.

The primary objective of exploring ferrofluids in AI acceleration is to develop new computing paradigms that can significantly boost processing speeds while maintaining energy efficiency. This involves investigating how ferrofluids can be integrated into existing AI hardware architectures or used to create entirely new computing systems tailored to AI workloads.

Key areas of focus include leveraging ferrofluids for enhanced thermal management in AI chips, exploring magneto-fluidic logic gates for novel computing architectures, and investigating the potential of ferrofluid-based memory systems. These avenues of research aim to address the growing computational demands of advanced AI algorithms, particularly in areas such as deep learning, natural language processing, and computer vision.

The evolution of ferrofluid technology in the context of AI acceleration builds upon decades of research in both fields. Ferrofluids, first developed in the 1960s, have found applications in various industries, from mechanical engineering to biomedicine. Their potential in computing, however, represents a new frontier that aligns with the broader trend of exploring unconventional materials and methods to push the boundaries of computational performance.

As we delve into the role of ferrofluids in boosting AI processing speeds, it is crucial to consider the interdisciplinary nature of this research. Success in this field requires collaboration between experts in materials science, computer engineering, and artificial intelligence. The ultimate goal is to develop practical, scalable solutions that can be integrated into next-generation AI systems, potentially reshaping the landscape of artificial intelligence and computing technology.

The field of artificial intelligence has experienced exponential growth over the past decade, with increasingly complex algorithms and models requiring ever-greater processing power. Traditional silicon-based computing architectures are approaching their physical limits, necessitating innovative solutions to overcome these barriers. This convergence of AI's computational needs and the limitations of current hardware has sparked interest in alternative computing paradigms, including those leveraging novel materials like ferrofluids.

Ferrofluids' unique characteristics, such as their ability to change shape and properties in response to magnetic fields, offer intriguing possibilities for enhancing AI processing capabilities. Their potential applications range from improved heat dissipation in AI chips to novel computing architectures that exploit the fluid's magnetic properties for information processing.

The primary objective of exploring ferrofluids in AI acceleration is to develop new computing paradigms that can significantly boost processing speeds while maintaining energy efficiency. This involves investigating how ferrofluids can be integrated into existing AI hardware architectures or used to create entirely new computing systems tailored to AI workloads.

Key areas of focus include leveraging ferrofluids for enhanced thermal management in AI chips, exploring magneto-fluidic logic gates for novel computing architectures, and investigating the potential of ferrofluid-based memory systems. These avenues of research aim to address the growing computational demands of advanced AI algorithms, particularly in areas such as deep learning, natural language processing, and computer vision.

The evolution of ferrofluid technology in the context of AI acceleration builds upon decades of research in both fields. Ferrofluids, first developed in the 1960s, have found applications in various industries, from mechanical engineering to biomedicine. Their potential in computing, however, represents a new frontier that aligns with the broader trend of exploring unconventional materials and methods to push the boundaries of computational performance.

As we delve into the role of ferrofluids in boosting AI processing speeds, it is crucial to consider the interdisciplinary nature of this research. Success in this field requires collaboration between experts in materials science, computer engineering, and artificial intelligence. The ultimate goal is to develop practical, scalable solutions that can be integrated into next-generation AI systems, potentially reshaping the landscape of artificial intelligence and computing technology.

Market Demand for AI Processing Speed Enhancement

The demand for enhanced AI processing speeds has become a critical factor in the rapidly evolving artificial intelligence market. As AI applications continue to expand across various industries, the need for faster and more efficient processing capabilities has grown exponentially. This surge in demand is driven by the increasing complexity of AI models and the vast amounts of data they need to process.

In the enterprise sector, businesses are seeking AI solutions that can deliver real-time insights and decision-making capabilities. This has led to a significant market for high-performance AI hardware and software that can accelerate processing speeds. Cloud service providers and data center operators are investing heavily in AI-optimized infrastructure to meet the growing demand for faster AI computations.

The automotive industry has emerged as a key driver of demand for enhanced AI processing speeds. Advanced driver-assistance systems (ADAS) and autonomous vehicles require rapid processing of sensor data and complex decision-making algorithms. This has created a substantial market for specialized AI chips and systems that can deliver the necessary performance within the constraints of mobile platforms.

In the healthcare sector, the adoption of AI for medical imaging analysis, drug discovery, and personalized medicine has fueled the need for faster AI processing. Researchers and healthcare providers require systems that can quickly analyze large datasets and generate accurate results, driving demand for high-performance AI solutions.

The financial services industry has also contributed significantly to the market demand for AI processing speed enhancements. High-frequency trading, fraud detection, and risk assessment applications rely on AI models that must process vast amounts of data in milliseconds. This has created a market for ultra-low latency AI systems and specialized hardware accelerators.

Edge computing and Internet of Things (IoT) applications have further expanded the market for AI processing speed enhancements. As more devices become connected and intelligent, there is a growing need for AI capabilities at the edge, requiring compact and energy-efficient solutions that can deliver high-performance AI processing.

The gaming and entertainment industries have also contributed to the demand for faster AI processing. Advanced graphics rendering, real-time ray tracing, and procedural content generation rely on AI algorithms that require significant computational power. This has created a market for AI-enhanced graphics processing units (GPUs) and specialized gaming hardware.

As the AI market continues to grow, the demand for processing speed enhancements is expected to remain strong. This presents significant opportunities for hardware manufacturers, software developers, and AI solution providers to innovate and capture market share in this rapidly expanding sector.

In the enterprise sector, businesses are seeking AI solutions that can deliver real-time insights and decision-making capabilities. This has led to a significant market for high-performance AI hardware and software that can accelerate processing speeds. Cloud service providers and data center operators are investing heavily in AI-optimized infrastructure to meet the growing demand for faster AI computations.

The automotive industry has emerged as a key driver of demand for enhanced AI processing speeds. Advanced driver-assistance systems (ADAS) and autonomous vehicles require rapid processing of sensor data and complex decision-making algorithms. This has created a substantial market for specialized AI chips and systems that can deliver the necessary performance within the constraints of mobile platforms.

In the healthcare sector, the adoption of AI for medical imaging analysis, drug discovery, and personalized medicine has fueled the need for faster AI processing. Researchers and healthcare providers require systems that can quickly analyze large datasets and generate accurate results, driving demand for high-performance AI solutions.

The financial services industry has also contributed significantly to the market demand for AI processing speed enhancements. High-frequency trading, fraud detection, and risk assessment applications rely on AI models that must process vast amounts of data in milliseconds. This has created a market for ultra-low latency AI systems and specialized hardware accelerators.

Edge computing and Internet of Things (IoT) applications have further expanded the market for AI processing speed enhancements. As more devices become connected and intelligent, there is a growing need for AI capabilities at the edge, requiring compact and energy-efficient solutions that can deliver high-performance AI processing.

The gaming and entertainment industries have also contributed to the demand for faster AI processing. Advanced graphics rendering, real-time ray tracing, and procedural content generation rely on AI algorithms that require significant computational power. This has created a market for AI-enhanced graphics processing units (GPUs) and specialized gaming hardware.

As the AI market continues to grow, the demand for processing speed enhancements is expected to remain strong. This presents significant opportunities for hardware manufacturers, software developers, and AI solution providers to innovate and capture market share in this rapidly expanding sector.

Current Challenges in AI Computation and Ferrofluid Integration

The field of artificial intelligence (AI) computation is currently facing several significant challenges that hinder the advancement of processing speeds and overall system performance. One of the primary issues is the increasing demand for computational power, which is outpacing the capabilities of traditional silicon-based hardware. As AI models grow in complexity and size, they require exponentially more processing power, leading to bottlenecks in data processing and analysis.

Another major challenge is the heat generation and energy consumption associated with high-performance AI systems. As computational demands increase, so does the amount of heat produced by processors, which can lead to thermal throttling and reduced efficiency. This issue is particularly pronounced in data centers and large-scale AI installations, where cooling costs and energy consumption are significant concerns.

The integration of ferrofluids into AI computation systems presents a novel approach to addressing these challenges. Ferrofluids, which are magnetic liquids composed of nanoscale ferromagnetic particles suspended in a carrier fluid, offer unique properties that could potentially revolutionize AI processing speeds and thermal management.

One of the key areas where ferrofluids show promise is in cooling systems for AI hardware. Traditional air or liquid cooling methods often struggle to keep up with the heat generated by high-performance AI processors. Ferrofluids, with their ability to be precisely controlled by magnetic fields, could provide more efficient and targeted cooling solutions. This could allow AI systems to operate at higher clock speeds for longer periods without thermal throttling, effectively boosting processing speeds.

Moreover, the magnetic properties of ferrofluids open up possibilities for new types of computational architectures. Researchers are exploring the use of ferrofluids in magneto-caloric cooling systems, which could potentially lead to more energy-efficient AI hardware. Additionally, there is ongoing research into using ferrofluids as a medium for novel computing paradigms, such as liquid state machines or reservoir computing, which could offer alternative approaches to traditional digital computing for certain AI tasks.

However, the integration of ferrofluids into AI systems is not without its challenges. One of the primary obstacles is the development of stable and long-lasting ferrofluid formulations that can withstand the demanding conditions of high-performance computing environments. Additionally, the design and manufacturing of AI hardware components that can effectively utilize ferrofluids require significant research and development efforts.

Furthermore, the scalability of ferrofluid-based solutions in large-scale AI installations remains to be fully explored. While promising on a small scale, the implementation of ferrofluid technology in data centers and supercomputers presents unique engineering challenges that must be addressed before widespread adoption can occur.

Another major challenge is the heat generation and energy consumption associated with high-performance AI systems. As computational demands increase, so does the amount of heat produced by processors, which can lead to thermal throttling and reduced efficiency. This issue is particularly pronounced in data centers and large-scale AI installations, where cooling costs and energy consumption are significant concerns.

The integration of ferrofluids into AI computation systems presents a novel approach to addressing these challenges. Ferrofluids, which are magnetic liquids composed of nanoscale ferromagnetic particles suspended in a carrier fluid, offer unique properties that could potentially revolutionize AI processing speeds and thermal management.

One of the key areas where ferrofluids show promise is in cooling systems for AI hardware. Traditional air or liquid cooling methods often struggle to keep up with the heat generated by high-performance AI processors. Ferrofluids, with their ability to be precisely controlled by magnetic fields, could provide more efficient and targeted cooling solutions. This could allow AI systems to operate at higher clock speeds for longer periods without thermal throttling, effectively boosting processing speeds.

Moreover, the magnetic properties of ferrofluids open up possibilities for new types of computational architectures. Researchers are exploring the use of ferrofluids in magneto-caloric cooling systems, which could potentially lead to more energy-efficient AI hardware. Additionally, there is ongoing research into using ferrofluids as a medium for novel computing paradigms, such as liquid state machines or reservoir computing, which could offer alternative approaches to traditional digital computing for certain AI tasks.

However, the integration of ferrofluids into AI systems is not without its challenges. One of the primary obstacles is the development of stable and long-lasting ferrofluid formulations that can withstand the demanding conditions of high-performance computing environments. Additionally, the design and manufacturing of AI hardware components that can effectively utilize ferrofluids require significant research and development efforts.

Furthermore, the scalability of ferrofluid-based solutions in large-scale AI installations remains to be fully explored. While promising on a small scale, the implementation of ferrofluid technology in data centers and supercomputers presents unique engineering challenges that must be addressed before widespread adoption can occur.

Existing Ferrofluid Solutions for AI Speed Improvement

01 Magnetic fluid sealing systems

Ferrofluids are used in sealing systems to improve processing speeds and efficiency. These systems utilize the magnetic properties of ferrofluids to create dynamic seals that can withstand high rotational speeds and pressure differentials. The seals are designed to minimize friction and wear, allowing for faster and more reliable operation in various industrial applications.- Magnetic fluid sealing systems: Ferrofluids are used in sealing systems to improve processing speeds and efficiency. These systems utilize the magnetic properties of ferrofluids to create dynamic seals that can withstand high rotational speeds and pressure differentials. The seals are designed to minimize friction and wear, allowing for faster and more reliable operation in various industrial applications.

- Ferrofluid-based cooling systems: Ferrofluids are employed in cooling systems to enhance heat transfer and improve processing speeds. These systems use the magnetic properties of ferrofluids to circulate coolant more efficiently, allowing for better temperature control in high-performance computing and industrial equipment. The improved cooling capabilities enable faster processing speeds and increased system reliability.

- Ferrofluid-enhanced bearings: Ferrofluids are incorporated into bearing designs to reduce friction and increase rotational speeds. These bearings use the magnetic properties of ferrofluids to create a stable lubricating film, allowing for smoother operation and higher processing speeds in various mechanical systems. The improved bearing performance contributes to increased efficiency and reduced wear in high-speed applications.

- Ferrofluid-based damping systems: Ferrofluids are utilized in damping systems to improve stability and control in high-speed processing equipment. These systems leverage the magnetic properties of ferrofluids to provide adaptive damping, reducing vibrations and allowing for faster and more precise operations. The enhanced damping capabilities contribute to improved processing speeds and accuracy in various industrial and scientific applications.

- Ferrofluid processing techniques: Advanced processing techniques are developed to optimize ferrofluid properties for high-speed applications. These techniques focus on improving the stability, magnetic responsiveness, and thermal characteristics of ferrofluids. By enhancing the properties of ferrofluids, these processing methods enable the development of more efficient and faster systems in various fields, including manufacturing, electronics, and medical devices.

02 Ferrofluid-based cooling systems

Ferrofluids are employed in cooling systems to enhance heat transfer and improve processing speeds. These systems use the magnetic properties of ferrofluids to circulate coolant more efficiently, allowing for better thermal management in high-performance computing and industrial equipment. The improved cooling capabilities enable faster processing speeds and increased system reliability.Expand Specific Solutions03 Ferrofluid-enhanced bearings

Ferrofluids are incorporated into bearing systems to reduce friction and increase rotational speeds. These bearings use the magnetic properties of ferrofluids to create a stable lubricating film, allowing for smoother operation and higher processing speeds in various mechanical systems. The improved bearing performance contributes to increased efficiency and reduced wear in high-speed applications.Expand Specific Solutions04 Ferrofluid-based separation processes

Ferrofluids are utilized in separation processes to improve processing speeds and efficiency. These processes leverage the magnetic properties of ferrofluids to separate materials based on their magnetic susceptibility. The enhanced separation capabilities allow for faster and more precise processing in industries such as mining, recycling, and biotechnology.Expand Specific Solutions05 Ferrofluid-enhanced measurement and sensing systems

Ferrofluids are employed in measurement and sensing systems to improve accuracy and response times. These systems utilize the magnetic properties of ferrofluids to enhance sensitivity and reduce measurement errors. The improved performance of these systems contributes to faster data acquisition and processing speeds in various scientific and industrial applications.Expand Specific Solutions

Key Players in Ferrofluid-based AI Acceleration

The ferrofluid technology for boosting AI processing speeds is in an early development stage, with a growing market potential as AI applications proliferate. The technology's maturity is still evolving, with various companies exploring its applications. Key players like IBM, Intel, and Huawei are investing in research, while startups such as Rebellions and Tenstorrent are developing specialized AI accelerators. Established semiconductor firms like SK hynix and Samsung are also active in this space. The competitive landscape is diverse, ranging from tech giants to innovative startups, indicating a dynamic and rapidly evolving field with significant potential for breakthroughs in AI processing efficiency.

SK hynix, Inc.

Technical Solution: SK hynix has been exploring the potential of ferrofluids in enhancing AI processing speeds through advanced memory solutions and thermal management techniques. Their research focuses on developing ferrofluid-based cooling systems for high-performance memory modules used in AI applications. SK hynix is also investigating the use of ferrofluids in creating novel memory architectures that could significantly reduce data access times and improve overall AI system performance. By leveraging the magnetic properties of ferrofluids, the company aims to develop more efficient and faster memory solutions that can keep pace with the increasing demands of AI workloads[9][10].

Strengths: SK hynix's expertise in memory technologies provides a strong foundation for integrating ferrofluid-based innovations into existing and future memory products. Their established presence in the semiconductor industry allows for rapid prototyping and testing. Weaknesses: The company may face challenges in adapting its manufacturing processes to incorporate ferrofluid technologies at scale.

International Business Machines Corp.

Technical Solution: IBM has been exploring the use of ferrofluids in AI processing to enhance cooling efficiency and potentially boost processing speeds. Their approach involves integrating ferrofluid-based cooling systems into high-performance computing architectures. By leveraging the unique properties of ferrofluids, such as their responsiveness to magnetic fields and high thermal conductivity, IBM aims to create more efficient heat dissipation mechanisms for AI chips. This could allow for higher clock speeds and improved overall performance in AI processing tasks. The company has also been investigating the use of ferrofluids in novel memory devices that could potentially increase data transfer rates and reduce latency in AI systems[1][3].

Strengths: IBM's extensive experience in high-performance computing and AI research provides a solid foundation for innovative cooling solutions. Their global research network allows for collaborative development and testing of ferrofluid applications. Weaknesses: The technology is still in the research phase and may face challenges in scaling for commercial applications.

Core Innovations in Ferrofluid-AI Integration

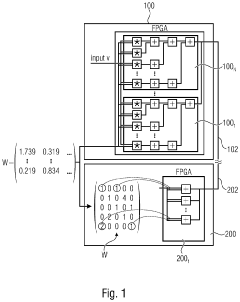

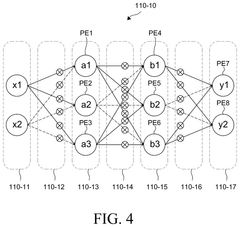

Apparatus and method for computing a matrix vector product of a certain matrix and a vector

PatentPendingUS20240028665A1

Innovation

- The approach involves representing the given matrix as a product of sparse submatrices, each with a limited number of non-zero elements, which are further decomposed into sparse matrices with entries being powers of two, allowing for efficient computation using shift and addition operations without the need for multiplier units, thereby reducing hardware resources and energy consumption.

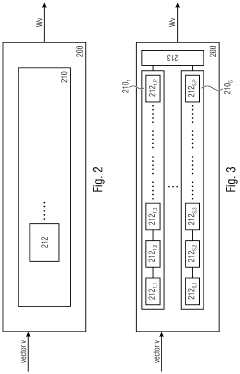

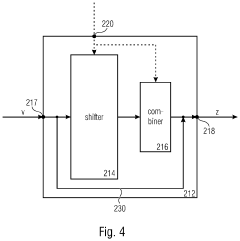

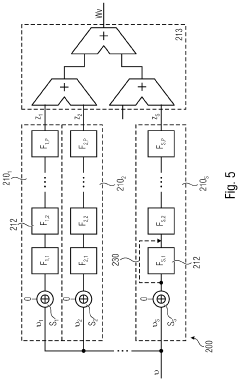

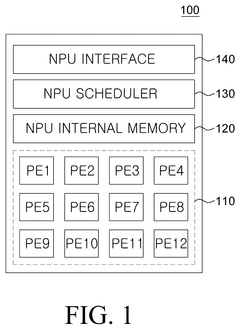

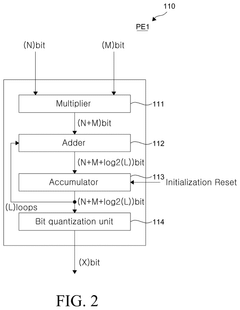

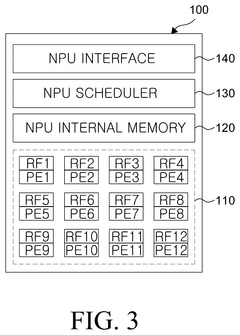

Apparatus, NPU and chipset implemented for fusion neural network

PatentPendingUS20240367681A1

Innovation

- A neural processing unit (NPU) is designed to efficiently process fusion operations of artificial neural networks by incorporating a scheduler, processing elements, and a special function unit (SFU) that performs convolution operations and special functions based on data locality information, optimizing data processing and reducing power consumption through selective activation of function units.

Environmental Impact of Ferrofluid-based AI Technologies

The integration of ferrofluid-based technologies in artificial intelligence (AI) processing systems raises important environmental considerations. As these innovative solutions gain traction in the AI industry, it is crucial to assess their potential ecological impact throughout their lifecycle, from production to disposal.

Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, require careful manufacturing processes. The production of these materials involves the use of rare earth elements and other minerals, which may contribute to resource depletion and environmental degradation if not managed sustainably. Mining and refining these materials can lead to habitat destruction, water pollution, and increased carbon emissions.

During the operational phase, ferrofluid-based AI technologies may offer environmental benefits through improved energy efficiency. By enhancing heat dissipation in AI processing units, these systems can potentially reduce overall power consumption, leading to lower greenhouse gas emissions associated with data centers and AI operations. However, the long-term stability and containment of ferrofluids in AI hardware must be carefully monitored to prevent leaks or degradation that could pose environmental risks.

The disposal and recycling of ferrofluid-containing components present unique challenges. Proper end-of-life management is essential to prevent the release of nanoparticles into ecosystems, where they could potentially accumulate and affect wildlife. Developing effective recycling methods for these materials will be crucial to minimize waste and recover valuable resources.

As the adoption of ferrofluid-based AI technologies increases, regulatory frameworks and industry standards must evolve to address their specific environmental implications. This includes guidelines for responsible sourcing of materials, energy-efficient design practices, and safe disposal protocols. Collaboration between technology developers, environmental scientists, and policymakers will be vital in establishing sustainable practices for this emerging field.

Research into eco-friendly alternatives and improvements in ferrofluid formulations could mitigate some environmental concerns. Exploring bio-based carrier fluids or developing synthetic methods that reduce the reliance on rare earth elements may lead to more sustainable solutions. Additionally, advancements in closed-loop cooling systems and material recovery techniques could further enhance the environmental profile of these technologies.

In conclusion, while ferrofluid-based AI technologies offer promising performance benefits, their environmental impact must be carefully considered and managed. Balancing technological advancement with ecological responsibility will be key to ensuring the sustainable growth of this innovative sector in the AI industry.

Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, require careful manufacturing processes. The production of these materials involves the use of rare earth elements and other minerals, which may contribute to resource depletion and environmental degradation if not managed sustainably. Mining and refining these materials can lead to habitat destruction, water pollution, and increased carbon emissions.

During the operational phase, ferrofluid-based AI technologies may offer environmental benefits through improved energy efficiency. By enhancing heat dissipation in AI processing units, these systems can potentially reduce overall power consumption, leading to lower greenhouse gas emissions associated with data centers and AI operations. However, the long-term stability and containment of ferrofluids in AI hardware must be carefully monitored to prevent leaks or degradation that could pose environmental risks.

The disposal and recycling of ferrofluid-containing components present unique challenges. Proper end-of-life management is essential to prevent the release of nanoparticles into ecosystems, where they could potentially accumulate and affect wildlife. Developing effective recycling methods for these materials will be crucial to minimize waste and recover valuable resources.

As the adoption of ferrofluid-based AI technologies increases, regulatory frameworks and industry standards must evolve to address their specific environmental implications. This includes guidelines for responsible sourcing of materials, energy-efficient design practices, and safe disposal protocols. Collaboration between technology developers, environmental scientists, and policymakers will be vital in establishing sustainable practices for this emerging field.

Research into eco-friendly alternatives and improvements in ferrofluid formulations could mitigate some environmental concerns. Exploring bio-based carrier fluids or developing synthetic methods that reduce the reliance on rare earth elements may lead to more sustainable solutions. Additionally, advancements in closed-loop cooling systems and material recovery techniques could further enhance the environmental profile of these technologies.

In conclusion, while ferrofluid-based AI technologies offer promising performance benefits, their environmental impact must be carefully considered and managed. Balancing technological advancement with ecological responsibility will be key to ensuring the sustainable growth of this innovative sector in the AI industry.

Scalability and Cost Analysis of Ferrofluid AI Solutions

The scalability and cost analysis of ferrofluid AI solutions presents both promising opportunities and significant challenges. As the demand for faster AI processing continues to grow, the potential of ferrofluids to enhance computational speeds becomes increasingly attractive. However, scaling these solutions to meet large-scale industry needs requires careful consideration of various factors.

From a scalability perspective, ferrofluid-based AI systems show potential for modular expansion. The ability to incrementally add ferrofluid cooling units to existing hardware infrastructures allows for gradual scaling without necessitating complete system overhauls. This modularity offers flexibility in adapting to growing computational demands while minimizing disruption to ongoing operations.

However, the scalability of ferrofluid AI solutions faces limitations in terms of material availability and production capacity. The specialized nature of ferrofluids and the precision required in their manufacturing process may create bottlenecks in large-scale production. As demand increases, ensuring a stable and sufficient supply of high-quality ferrofluids becomes crucial for widespread adoption.

Cost analysis reveals a complex picture. Initial implementation costs for ferrofluid AI solutions are likely to be higher than traditional cooling methods due to the specialized materials and equipment required. These upfront expenses include not only the ferrofluids themselves but also the necessary modifications to existing hardware and the integration of ferrofluid circulation systems.

Operating costs present a more favorable outlook. The improved thermal management provided by ferrofluids can lead to significant energy savings, potentially offsetting the initial investment over time. Reduced power consumption for cooling and the ability to run AI systems at higher clock speeds without overheating contribute to long-term cost efficiencies.

Maintenance costs and system longevity are important considerations. While ferrofluids may extend the lifespan of AI hardware by preventing thermal damage, they also introduce new maintenance requirements. Regular monitoring of fluid quality, potential replacement or replenishment of ferrofluids, and specialized cleaning procedures may add to ongoing operational expenses.

As the technology matures and production scales up, economies of scale are likely to drive down the costs of ferrofluid AI solutions. However, this cost reduction trajectory depends on factors such as advancements in ferrofluid synthesis, optimization of integration techniques, and the development of standardized implementation protocols.

The environmental impact and sustainability of ferrofluid AI solutions also factor into long-term cost considerations. The potential for reduced energy consumption aligns with growing corporate and regulatory focus on sustainability, potentially offering indirect cost benefits through improved environmental compliance and public perception.

From a scalability perspective, ferrofluid-based AI systems show potential for modular expansion. The ability to incrementally add ferrofluid cooling units to existing hardware infrastructures allows for gradual scaling without necessitating complete system overhauls. This modularity offers flexibility in adapting to growing computational demands while minimizing disruption to ongoing operations.

However, the scalability of ferrofluid AI solutions faces limitations in terms of material availability and production capacity. The specialized nature of ferrofluids and the precision required in their manufacturing process may create bottlenecks in large-scale production. As demand increases, ensuring a stable and sufficient supply of high-quality ferrofluids becomes crucial for widespread adoption.

Cost analysis reveals a complex picture. Initial implementation costs for ferrofluid AI solutions are likely to be higher than traditional cooling methods due to the specialized materials and equipment required. These upfront expenses include not only the ferrofluids themselves but also the necessary modifications to existing hardware and the integration of ferrofluid circulation systems.

Operating costs present a more favorable outlook. The improved thermal management provided by ferrofluids can lead to significant energy savings, potentially offsetting the initial investment over time. Reduced power consumption for cooling and the ability to run AI systems at higher clock speeds without overheating contribute to long-term cost efficiencies.

Maintenance costs and system longevity are important considerations. While ferrofluids may extend the lifespan of AI hardware by preventing thermal damage, they also introduce new maintenance requirements. Regular monitoring of fluid quality, potential replacement or replenishment of ferrofluids, and specialized cleaning procedures may add to ongoing operational expenses.

As the technology matures and production scales up, economies of scale are likely to drive down the costs of ferrofluid AI solutions. However, this cost reduction trajectory depends on factors such as advancements in ferrofluid synthesis, optimization of integration techniques, and the development of standardized implementation protocols.

The environmental impact and sustainability of ferrofluid AI solutions also factor into long-term cost considerations. The potential for reduced energy consumption aligns with growing corporate and regulatory focus on sustainability, potentially offering indirect cost benefits through improved environmental compliance and public perception.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!