Ferrofluid's Impact on Reducing Marine Vessel Emissions

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Technology Evolution and Objectives

Ferrofluid technology has evolved significantly since its inception in the 1960s, with a growing focus on its potential applications in reducing marine vessel emissions. The development of ferrofluids, colloidal suspensions of magnetic nanoparticles in a carrier fluid, has been driven by advancements in nanotechnology and materials science. Initially conceived for space applications, ferrofluids have found their way into various industrial and environmental sectors, including maritime transportation.

The evolution of ferrofluid technology in the context of marine vessel emissions reduction can be traced through several key stages. Early research focused on understanding the fundamental properties of ferrofluids, such as their response to magnetic fields and their stability in different environments. As environmental concerns grew, scientists began exploring the potential of ferrofluids for pollution control and emission reduction in various industries, including shipping.

In recent years, there has been a significant shift towards developing ferrofluid-based solutions specifically tailored for marine applications. This includes the creation of more stable and environmentally friendly ferrofluids that can withstand the harsh conditions of marine environments. Researchers have also made progress in optimizing the magnetic properties of ferrofluids to enhance their effectiveness in capturing and removing pollutants from exhaust gases.

The primary objective of ferrofluid technology in reducing marine vessel emissions is to develop innovative and efficient systems that can effectively capture and neutralize harmful pollutants before they are released into the atmosphere. This includes targeting key pollutants such as sulfur oxides (SOx), nitrogen oxides (NOx), and particulate matter. By leveraging the unique properties of ferrofluids, researchers aim to create more compact, energy-efficient, and cost-effective emission control systems compared to traditional methods.

Another important goal is to integrate ferrofluid-based emission reduction technologies seamlessly into existing marine propulsion systems. This involves addressing challenges related to scalability, durability, and compatibility with various engine types and fuel compositions. Additionally, there is a focus on developing intelligent control systems that can optimize the performance of ferrofluid-based emission reduction devices in real-time, adapting to changing operational conditions and environmental regulations.

Looking ahead, the objectives of ferrofluid technology in marine emission reduction extend beyond immediate pollution control. Researchers are exploring the potential of ferrofluids in enhancing overall engine efficiency, which could lead to reduced fuel consumption and, consequently, lower emissions. There is also growing interest in developing closed-loop systems that not only capture pollutants but also facilitate their conversion into less harmful substances or even useful byproducts.

The evolution of ferrofluid technology in the context of marine vessel emissions reduction can be traced through several key stages. Early research focused on understanding the fundamental properties of ferrofluids, such as their response to magnetic fields and their stability in different environments. As environmental concerns grew, scientists began exploring the potential of ferrofluids for pollution control and emission reduction in various industries, including shipping.

In recent years, there has been a significant shift towards developing ferrofluid-based solutions specifically tailored for marine applications. This includes the creation of more stable and environmentally friendly ferrofluids that can withstand the harsh conditions of marine environments. Researchers have also made progress in optimizing the magnetic properties of ferrofluids to enhance their effectiveness in capturing and removing pollutants from exhaust gases.

The primary objective of ferrofluid technology in reducing marine vessel emissions is to develop innovative and efficient systems that can effectively capture and neutralize harmful pollutants before they are released into the atmosphere. This includes targeting key pollutants such as sulfur oxides (SOx), nitrogen oxides (NOx), and particulate matter. By leveraging the unique properties of ferrofluids, researchers aim to create more compact, energy-efficient, and cost-effective emission control systems compared to traditional methods.

Another important goal is to integrate ferrofluid-based emission reduction technologies seamlessly into existing marine propulsion systems. This involves addressing challenges related to scalability, durability, and compatibility with various engine types and fuel compositions. Additionally, there is a focus on developing intelligent control systems that can optimize the performance of ferrofluid-based emission reduction devices in real-time, adapting to changing operational conditions and environmental regulations.

Looking ahead, the objectives of ferrofluid technology in marine emission reduction extend beyond immediate pollution control. Researchers are exploring the potential of ferrofluids in enhancing overall engine efficiency, which could lead to reduced fuel consumption and, consequently, lower emissions. There is also growing interest in developing closed-loop systems that not only capture pollutants but also facilitate their conversion into less harmful substances or even useful byproducts.

Marine Emission Reduction Market Analysis

The marine emission reduction market has experienced significant growth in recent years, driven by increasingly stringent environmental regulations and a growing awareness of the shipping industry's impact on climate change. The International Maritime Organization (IMO) has set ambitious targets to reduce greenhouse gas emissions from ships by at least 50% by 2050 compared to 2008 levels. This regulatory pressure has created a substantial market opportunity for innovative technologies like ferrofluids that can contribute to emission reduction.

The global market for marine emission control systems is projected to reach $14.5 billion by 2025, growing at a CAGR of 8.3% from 2020 to 2025. This growth is primarily attributed to the increasing adoption of scrubbers, selective catalytic reduction (SCR) systems, and other emission reduction technologies. However, the market is constantly evolving, with new solutions like ferrofluids emerging as potential game-changers in the industry.

Ferrofluids, with their unique magnetic properties, have the potential to address several key challenges in marine emission reduction. Their ability to enhance heat transfer and improve combustion efficiency could lead to significant reductions in fuel consumption and, consequently, emissions. This aligns well with the industry's focus on energy efficiency and clean propulsion technologies.

The demand for emission reduction solutions in the maritime sector is not uniform across all vessel types and regions. Large container ships and tankers, which are responsible for a significant portion of global shipping emissions, represent a particularly lucrative market segment. Geographically, regions with strict emission control areas (ECAs) such as Europe and North America are likely to be early adopters of advanced emission reduction technologies, including ferrofluid-based solutions.

Despite the promising outlook, the marine emission reduction market faces several challenges. The high initial investment costs associated with retrofitting existing vessels with new technologies can be a significant barrier to adoption. Additionally, the long lifespan of ships means that the transition to cleaner technologies is likely to be gradual. However, these challenges also present opportunities for innovative, cost-effective solutions like ferrofluids that can be integrated into existing systems with minimal disruption.

As the industry continues to evolve, there is a growing trend towards holistic approaches to emission reduction that combine multiple technologies and strategies. Ferrofluids could play a crucial role in this integrated approach, complementing other emission reduction technologies and contributing to the overall efficiency of marine propulsion systems. This trend towards comprehensive solutions is likely to shape the future direction of the marine emission reduction market, creating new opportunities for cross-technology collaborations and innovations.

The global market for marine emission control systems is projected to reach $14.5 billion by 2025, growing at a CAGR of 8.3% from 2020 to 2025. This growth is primarily attributed to the increasing adoption of scrubbers, selective catalytic reduction (SCR) systems, and other emission reduction technologies. However, the market is constantly evolving, with new solutions like ferrofluids emerging as potential game-changers in the industry.

Ferrofluids, with their unique magnetic properties, have the potential to address several key challenges in marine emission reduction. Their ability to enhance heat transfer and improve combustion efficiency could lead to significant reductions in fuel consumption and, consequently, emissions. This aligns well with the industry's focus on energy efficiency and clean propulsion technologies.

The demand for emission reduction solutions in the maritime sector is not uniform across all vessel types and regions. Large container ships and tankers, which are responsible for a significant portion of global shipping emissions, represent a particularly lucrative market segment. Geographically, regions with strict emission control areas (ECAs) such as Europe and North America are likely to be early adopters of advanced emission reduction technologies, including ferrofluid-based solutions.

Despite the promising outlook, the marine emission reduction market faces several challenges. The high initial investment costs associated with retrofitting existing vessels with new technologies can be a significant barrier to adoption. Additionally, the long lifespan of ships means that the transition to cleaner technologies is likely to be gradual. However, these challenges also present opportunities for innovative, cost-effective solutions like ferrofluids that can be integrated into existing systems with minimal disruption.

As the industry continues to evolve, there is a growing trend towards holistic approaches to emission reduction that combine multiple technologies and strategies. Ferrofluids could play a crucial role in this integrated approach, complementing other emission reduction technologies and contributing to the overall efficiency of marine propulsion systems. This trend towards comprehensive solutions is likely to shape the future direction of the marine emission reduction market, creating new opportunities for cross-technology collaborations and innovations.

Ferrofluid Application Challenges in Marine Industry

The application of ferrofluids in the marine industry faces several significant challenges that hinder its widespread adoption for reducing vessel emissions. One of the primary obstacles is the stability of ferrofluids in harsh marine environments. Saltwater, extreme temperatures, and constant motion can degrade the magnetic properties of ferrofluids over time, reducing their effectiveness in emission control systems.

Another challenge lies in the integration of ferrofluid-based technologies with existing marine propulsion and exhaust systems. Retrofitting vessels with ferrofluid components requires substantial modifications to ship designs and may not be economically viable for older vessels. Additionally, the potential for ferrofluid contamination in marine ecosystems raises environmental concerns, necessitating robust containment and disposal protocols.

The scalability of ferrofluid applications presents a further hurdle. While laboratory tests and small-scale demonstrations have shown promising results, translating these successes to large commercial vessels remains problematic. The volume of ferrofluid required for effective emission reduction in ocean-going ships is substantial, raising questions about production capacity and cost-effectiveness.

Regulatory compliance and standardization pose additional challenges. The marine industry operates under strict international regulations, and new technologies must undergo rigorous testing and certification processes. The lack of established standards for ferrofluid applications in marine emission control systems complicates their approval and adoption.

Maintenance and operational considerations also present obstacles. Ferrofluids require specialized handling and storage, and crew members need extensive training to manage these systems effectively. The potential for magnetic interference with navigational equipment and other onboard systems must be carefully addressed to ensure vessel safety.

Lastly, the long-term durability and performance of ferrofluid-based emission reduction systems in real-world marine conditions remain uncertain. Extended sea trials and comprehensive data collection are necessary to validate the technology's reliability and effectiveness over the typical lifespan of a marine vessel. These factors collectively contribute to the hesitancy of shipowners and operators to invest in ferrofluid technologies, despite their potential benefits in reducing marine vessel emissions.

Another challenge lies in the integration of ferrofluid-based technologies with existing marine propulsion and exhaust systems. Retrofitting vessels with ferrofluid components requires substantial modifications to ship designs and may not be economically viable for older vessels. Additionally, the potential for ferrofluid contamination in marine ecosystems raises environmental concerns, necessitating robust containment and disposal protocols.

The scalability of ferrofluid applications presents a further hurdle. While laboratory tests and small-scale demonstrations have shown promising results, translating these successes to large commercial vessels remains problematic. The volume of ferrofluid required for effective emission reduction in ocean-going ships is substantial, raising questions about production capacity and cost-effectiveness.

Regulatory compliance and standardization pose additional challenges. The marine industry operates under strict international regulations, and new technologies must undergo rigorous testing and certification processes. The lack of established standards for ferrofluid applications in marine emission control systems complicates their approval and adoption.

Maintenance and operational considerations also present obstacles. Ferrofluids require specialized handling and storage, and crew members need extensive training to manage these systems effectively. The potential for magnetic interference with navigational equipment and other onboard systems must be carefully addressed to ensure vessel safety.

Lastly, the long-term durability and performance of ferrofluid-based emission reduction systems in real-world marine conditions remain uncertain. Extended sea trials and comprehensive data collection are necessary to validate the technology's reliability and effectiveness over the typical lifespan of a marine vessel. These factors collectively contribute to the hesitancy of shipowners and operators to invest in ferrofluid technologies, despite their potential benefits in reducing marine vessel emissions.

Current Ferrofluid Solutions for Emission Reduction

01 Ferrofluid sealing applications

Ferrofluids are used in various sealing applications to prevent the emission of gases, liquids, or particles. These seals are particularly useful in rotating shaft assemblies, where they can provide a hermetic seal while allowing for low-friction movement. The magnetic properties of ferrofluids enable them to maintain a stable seal under various conditions, making them ideal for use in industrial machinery, computer hard drives, and other precision equipment.- Ferrofluid sealing applications: Ferrofluids are used in various sealing applications to prevent the emission of gases, liquids, or particles. These magnetic fluids create a barrier that can be controlled and manipulated using magnetic fields, providing effective sealing in rotating shafts, bearings, and other mechanical systems. The unique properties of ferrofluids allow for dynamic sealing that can adapt to different operating conditions.

- Ferrofluid-based emission control in vehicles: Ferrofluids are utilized in automotive applications to control emissions and improve engine performance. These magnetic fluids can be incorporated into exhaust systems, fuel injection systems, or other engine components to trap and filter harmful emissions. The magnetic properties of ferrofluids allow for efficient capture and removal of particulate matter and other pollutants from exhaust gases.

- Ferrofluid cooling systems: Ferrofluids are employed in cooling systems to enhance heat transfer and manage thermal emissions. These magnetic fluids can be used in heat sinks, radiators, or other cooling devices to improve thermal conductivity and dissipate heat more efficiently. The ability to control ferrofluids using magnetic fields allows for adaptive cooling solutions in various applications, including electronics and industrial processes.

- Ferrofluid-based sensors and detectors: Ferrofluids are utilized in sensors and detectors to measure and monitor various types of emissions. These magnetic fluids can be incorporated into devices that detect gas leaks, particulate matter, or other environmental pollutants. The unique properties of ferrofluids allow for highly sensitive and responsive sensing capabilities in a wide range of applications, including industrial safety and environmental monitoring.

- Ferrofluid-based electromagnetic shielding: Ferrofluids are used in electromagnetic shielding applications to reduce electromagnetic emissions and interference. These magnetic fluids can be incorporated into coatings, enclosures, or other shielding materials to absorb and attenuate electromagnetic radiation. The ability to manipulate ferrofluids using magnetic fields allows for adaptive shielding solutions that can respond to changing electromagnetic environments.

02 Ferrofluid-based emission control in vehicles

Ferrofluids are employed in automotive applications to control emissions and improve engine performance. These magnetic fluids can be used in exhaust systems to trap particulate matter and reduce harmful emissions. Additionally, ferrofluids can be incorporated into engine components to enhance heat transfer and lubrication, potentially leading to more efficient combustion and reduced emissions.Expand Specific Solutions03 Ferrofluid cooling systems

Ferrofluids are utilized in cooling systems to manage heat dissipation and reduce thermal emissions. These systems take advantage of the magnetic properties of ferrofluids to circulate coolant more efficiently, particularly in electronic devices and power systems. By improving heat transfer and thermal management, ferrofluid-based cooling systems can help reduce energy consumption and associated emissions.Expand Specific Solutions04 Ferrofluid-based sensors and detectors

Ferrofluids are employed in various sensing and detection applications, including the monitoring of emissions and environmental pollutants. These sensors utilize the unique properties of ferrofluids to detect changes in magnetic fields, pressure, or chemical composition. Such devices can be used in industrial settings, environmental monitoring stations, and research facilities to measure and control emissions more accurately.Expand Specific Solutions05 Ferrofluid-based waste treatment

Ferrofluids are used in waste treatment processes to remove contaminants and reduce emissions from industrial effluents. These magnetic fluids can be employed to separate and extract pollutants from wastewater or other waste streams. By enhancing the efficiency of waste treatment processes, ferrofluid-based systems can help minimize the release of harmful substances into the environment and improve overall emission control.Expand Specific Solutions

Key Players in Ferrofluid and Marine Technology

The ferrofluid technology for reducing marine vessel emissions is in an early development stage, with a growing market potential as environmental regulations tighten. The global market for green shipping solutions is expanding, driven by increasing awareness of maritime pollution. While the technology shows promise, it is still emerging and requires further research and development. Key players like Teledyne Scientific & Imaging LLC, Yale University, and TotalEnergies OneTech SAS are actively involved in advancing ferrofluid applications for marine emissions reduction. However, the technology's maturity level varies among companies, with some focusing on fundamental research while others are progressing towards practical implementations.

TotalEnergies OneTech SAS

Technical Solution: TotalEnergies OneTech SAS has developed a ferrofluid-based emission reduction system for marine vessels. Their approach involves using ferrofluids as a magnetizable catalyst support in exhaust gas treatment. The system employs a magnetically stabilized fluidized bed reactor containing ferrofluid-coated catalytic particles. This design enhances the contact between exhaust gases and the catalyst, significantly improving the removal of nitrogen oxides (NOx) and volatile organic compounds (VOCs)[2]. The magnetic properties of the ferrofluid allow for precise control of the catalyst distribution and residence time within the reactor. TotalEnergies has also explored combining this technology with membrane separation techniques to further reduce emissions of greenhouse gases like CO2[4].

Strengths: High catalytic efficiency, precise control over reaction conditions, potential for multi-pollutant removal. Weaknesses: May require specialized handling and disposal procedures for used ferrofluids, potential for catalyst deactivation in harsh marine environments.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory has developed an innovative approach using ferrofluids to reduce marine vessel emissions. Their technology involves a ferrofluid-based scrubber system that efficiently captures and neutralizes exhaust pollutants. The system utilizes the magnetic properties of ferrofluids to create a dynamic, high-surface-area interface for gas-liquid interactions. This allows for enhanced absorption of sulfur oxides (SOx) and particulate matter from ship exhaust[1]. The ferrofluid scrubber can be integrated into existing marine propulsion systems, offering a retrofit solution for older vessels. Additionally, the NRL has explored using ferrofluids in advanced heat transfer applications for more efficient engine cooling, indirectly contributing to reduced emissions through improved overall engine performance[3].

Strengths: Highly efficient pollutant capture, adaptable to existing vessels, dual functionality in emissions reduction and heat transfer. Weaknesses: Potential complexity in system maintenance, need for careful magnetic field management to prevent ferrofluid loss.

Innovative Ferrofluid Patents for Marine Applications

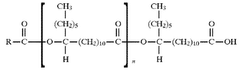

Cooling composition for powertrain of electric vehicles

PatentWO2025061695A1

Innovation

- A ferrofluid comprising a liquid carrier, ferromagnetic particles, and a dispersant is used for direct contact cooling of powertrain elements in electric vehicles, enhancing heat extraction through the application of a magnetic field.

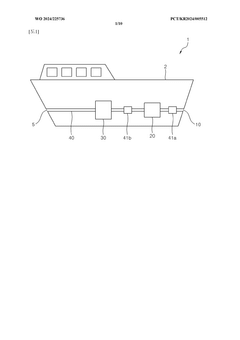

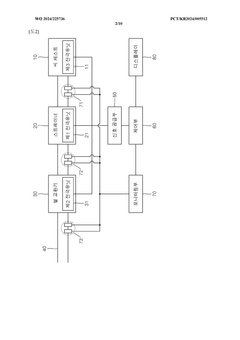

System for preventing contamination of ship

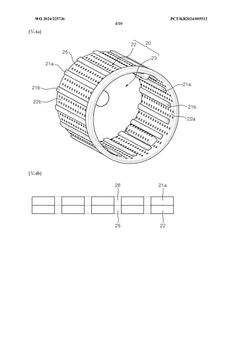

PatentWO2024225736A1

Innovation

- A ship pollution prevention system utilizing special microcurrent electromagnetic waves generated by mixing AC and DC signals, applied through electrode units installed in the sea chest, strainer, and heat exchanger, along with resistance measurement and monitoring units to control the driving signal for biofilm removal and contamination monitoring.

Environmental Regulations in Maritime Industry

The maritime industry has been facing increasing pressure to reduce its environmental impact, particularly in terms of emissions. Over the past few decades, a series of international regulations have been implemented to address this issue. The International Maritime Organization (IMO) has been at the forefront of these efforts, introducing several key measures to curb emissions from marine vessels.

One of the most significant regulations is the International Convention for the Prevention of Pollution from Ships (MARPOL), specifically Annex VI, which sets limits on sulfur oxide and nitrogen oxide emissions from ship exhausts. The global sulfur cap, which came into effect in 2020, requires ships to use fuel with a sulfur content of no more than 0.5% or employ equivalent emission reduction technologies.

In addition to sulfur regulations, the IMO has also established Energy Efficiency Design Index (EEDI) standards for new ships and the Ship Energy Efficiency Management Plan (SEEMP) for all vessels. These measures aim to improve the overall energy efficiency of the global fleet and reduce greenhouse gas emissions.

The European Union has implemented its own set of regulations, including the Monitoring, Reporting, and Verification (MRV) system, which requires large ships calling at EU ports to report their CO2 emissions. Similarly, the United States has established Emission Control Areas (ECAs) along its coasts, where stricter emission standards apply.

Looking ahead, the IMO has set ambitious targets for reducing greenhouse gas emissions from international shipping. The initial strategy aims to reduce total annual GHG emissions by at least 50% by 2050 compared to 2008 levels. This has spurred research and development into alternative fuels and propulsion technologies, including the potential use of ferrofluids in emission reduction systems.

As these regulations continue to evolve and become more stringent, the maritime industry is exploring innovative solutions to meet compliance requirements while maintaining operational efficiency. The development of technologies like ferrofluid-based emission reduction systems could play a crucial role in helping the industry adapt to this changing regulatory landscape and achieve its environmental goals.

One of the most significant regulations is the International Convention for the Prevention of Pollution from Ships (MARPOL), specifically Annex VI, which sets limits on sulfur oxide and nitrogen oxide emissions from ship exhausts. The global sulfur cap, which came into effect in 2020, requires ships to use fuel with a sulfur content of no more than 0.5% or employ equivalent emission reduction technologies.

In addition to sulfur regulations, the IMO has also established Energy Efficiency Design Index (EEDI) standards for new ships and the Ship Energy Efficiency Management Plan (SEEMP) for all vessels. These measures aim to improve the overall energy efficiency of the global fleet and reduce greenhouse gas emissions.

The European Union has implemented its own set of regulations, including the Monitoring, Reporting, and Verification (MRV) system, which requires large ships calling at EU ports to report their CO2 emissions. Similarly, the United States has established Emission Control Areas (ECAs) along its coasts, where stricter emission standards apply.

Looking ahead, the IMO has set ambitious targets for reducing greenhouse gas emissions from international shipping. The initial strategy aims to reduce total annual GHG emissions by at least 50% by 2050 compared to 2008 levels. This has spurred research and development into alternative fuels and propulsion technologies, including the potential use of ferrofluids in emission reduction systems.

As these regulations continue to evolve and become more stringent, the maritime industry is exploring innovative solutions to meet compliance requirements while maintaining operational efficiency. The development of technologies like ferrofluid-based emission reduction systems could play a crucial role in helping the industry adapt to this changing regulatory landscape and achieve its environmental goals.

Economic Feasibility of Ferrofluid-based Solutions

The economic feasibility of ferrofluid-based solutions for reducing marine vessel emissions is a critical factor in determining their potential for widespread adoption in the maritime industry. Initial cost-benefit analyses suggest that while the implementation of ferrofluid technology may require significant upfront investments, the long-term economic benefits could be substantial.

The primary economic advantage of ferrofluid-based solutions lies in their potential to significantly reduce fuel consumption. By improving the hydrodynamic efficiency of vessels, these solutions can lead to considerable savings in fuel costs, which constitute a major portion of operational expenses for shipping companies. Preliminary studies indicate that fuel savings of up to 10-15% could be achievable, translating to millions of dollars in annual savings for large shipping fleets.

Furthermore, the reduction in emissions resulting from decreased fuel consumption aligns with increasingly stringent environmental regulations. This alignment could potentially save shipping companies from hefty fines and penalties associated with non-compliance, thereby offering additional economic benefits. The technology could also position adopting companies favorably in an increasingly environmentally conscious market, potentially leading to competitive advantages and increased market share.

However, the economic viability of ferrofluid-based solutions is not without challenges. The initial costs of retrofitting existing vessels or incorporating the technology into new builds are substantial. These costs include not only the ferrofluid materials themselves but also the necessary modifications to vessel hulls and propulsion systems. Additionally, there may be ongoing maintenance costs and potential downtime for system upkeep, which need to be factored into the overall economic assessment.

The scalability of ferrofluid production for large-scale maritime application is another crucial economic consideration. Current production methods may not be cost-effective for the volumes required by the global shipping industry. Significant investments in research and development will likely be necessary to optimize production processes and reduce costs to make the technology economically viable on a large scale.

Regulatory factors also play a role in the economic feasibility. While stricter emission standards could drive adoption, the lack of established regulations specifically addressing ferrofluid technology in maritime applications could create uncertainty and potentially slow down implementation. This regulatory landscape will significantly influence the economic calculations of potential adopters.

In conclusion, while ferrofluid-based solutions show promise in terms of long-term economic benefits through fuel savings and environmental compliance, the high initial costs and uncertainties surrounding large-scale implementation present significant challenges. The ultimate economic feasibility will depend on technological advancements, regulatory developments, and the ability to achieve economies of scale in production and implementation.

The primary economic advantage of ferrofluid-based solutions lies in their potential to significantly reduce fuel consumption. By improving the hydrodynamic efficiency of vessels, these solutions can lead to considerable savings in fuel costs, which constitute a major portion of operational expenses for shipping companies. Preliminary studies indicate that fuel savings of up to 10-15% could be achievable, translating to millions of dollars in annual savings for large shipping fleets.

Furthermore, the reduction in emissions resulting from decreased fuel consumption aligns with increasingly stringent environmental regulations. This alignment could potentially save shipping companies from hefty fines and penalties associated with non-compliance, thereby offering additional economic benefits. The technology could also position adopting companies favorably in an increasingly environmentally conscious market, potentially leading to competitive advantages and increased market share.

However, the economic viability of ferrofluid-based solutions is not without challenges. The initial costs of retrofitting existing vessels or incorporating the technology into new builds are substantial. These costs include not only the ferrofluid materials themselves but also the necessary modifications to vessel hulls and propulsion systems. Additionally, there may be ongoing maintenance costs and potential downtime for system upkeep, which need to be factored into the overall economic assessment.

The scalability of ferrofluid production for large-scale maritime application is another crucial economic consideration. Current production methods may not be cost-effective for the volumes required by the global shipping industry. Significant investments in research and development will likely be necessary to optimize production processes and reduce costs to make the technology economically viable on a large scale.

Regulatory factors also play a role in the economic feasibility. While stricter emission standards could drive adoption, the lack of established regulations specifically addressing ferrofluid technology in maritime applications could create uncertainty and potentially slow down implementation. This regulatory landscape will significantly influence the economic calculations of potential adopters.

In conclusion, while ferrofluid-based solutions show promise in terms of long-term economic benefits through fuel savings and environmental compliance, the high initial costs and uncertainties surrounding large-scale implementation present significant challenges. The ultimate economic feasibility will depend on technological advancements, regulatory developments, and the ability to achieve economies of scale in production and implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!