How to Use Ferrofluid in Reducing Industrial Pollution Levels?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Pollution Control Background and Objectives

Ferrofluids, a unique class of magnetic nanomaterials, have emerged as a promising solution in the ongoing battle against industrial pollution. These colloidal liquids, composed of nanoscale ferromagnetic particles suspended in a carrier fluid, possess remarkable properties that make them ideal for environmental remediation applications. The development of ferrofluid technology for pollution control represents a convergence of nanotechnology, materials science, and environmental engineering.

The primary objective of utilizing ferrofluids in reducing industrial pollution levels is to leverage their magnetic properties and high surface area to capture and remove contaminants from various industrial effluents. This approach aims to address the growing concern over the environmental impact of industrial activities, particularly in sectors such as mining, metallurgy, and chemical manufacturing. By harnessing the unique characteristics of ferrofluids, researchers and engineers seek to develop more efficient and cost-effective pollution control methods.

The evolution of ferrofluid technology in environmental applications can be traced back to the early 2000s when initial studies explored their potential in wastewater treatment. Since then, significant advancements have been made in synthesizing ferrofluids with enhanced stability, selectivity, and recyclability. These improvements have paved the way for their application in treating a wide range of pollutants, including heavy metals, organic compounds, and particulate matter.

Current research trends in ferrofluid-based pollution control focus on optimizing the composition and surface functionalization of magnetic nanoparticles to improve their affinity for specific contaminants. Additionally, efforts are being made to develop novel separation techniques that can effectively recover and recycle ferrofluids after pollutant capture, ensuring the sustainability of the process.

The potential impact of ferrofluid technology on industrial pollution control is substantial. It offers several advantages over conventional treatment methods, such as higher removal efficiency, faster separation rates, and the ability to treat large volumes of effluents. Moreover, the magnetic nature of ferrofluids allows for easy manipulation and recovery, reducing the need for additional chemicals or energy-intensive processes.

As environmental regulations become increasingly stringent worldwide, the demand for innovative pollution control technologies continues to grow. Ferrofluids present a promising avenue for meeting these challenges, offering a versatile and adaptable solution that can be tailored to various industrial settings. The ongoing research and development in this field aim to bridge the gap between laboratory-scale demonstrations and large-scale industrial applications, addressing key issues such as scalability, cost-effectiveness, and long-term stability.

The primary objective of utilizing ferrofluids in reducing industrial pollution levels is to leverage their magnetic properties and high surface area to capture and remove contaminants from various industrial effluents. This approach aims to address the growing concern over the environmental impact of industrial activities, particularly in sectors such as mining, metallurgy, and chemical manufacturing. By harnessing the unique characteristics of ferrofluids, researchers and engineers seek to develop more efficient and cost-effective pollution control methods.

The evolution of ferrofluid technology in environmental applications can be traced back to the early 2000s when initial studies explored their potential in wastewater treatment. Since then, significant advancements have been made in synthesizing ferrofluids with enhanced stability, selectivity, and recyclability. These improvements have paved the way for their application in treating a wide range of pollutants, including heavy metals, organic compounds, and particulate matter.

Current research trends in ferrofluid-based pollution control focus on optimizing the composition and surface functionalization of magnetic nanoparticles to improve their affinity for specific contaminants. Additionally, efforts are being made to develop novel separation techniques that can effectively recover and recycle ferrofluids after pollutant capture, ensuring the sustainability of the process.

The potential impact of ferrofluid technology on industrial pollution control is substantial. It offers several advantages over conventional treatment methods, such as higher removal efficiency, faster separation rates, and the ability to treat large volumes of effluents. Moreover, the magnetic nature of ferrofluids allows for easy manipulation and recovery, reducing the need for additional chemicals or energy-intensive processes.

As environmental regulations become increasingly stringent worldwide, the demand for innovative pollution control technologies continues to grow. Ferrofluids present a promising avenue for meeting these challenges, offering a versatile and adaptable solution that can be tailored to various industrial settings. The ongoing research and development in this field aim to bridge the gap between laboratory-scale demonstrations and large-scale industrial applications, addressing key issues such as scalability, cost-effectiveness, and long-term stability.

Industrial Pollution Reduction Market Analysis

The industrial pollution reduction market has been experiencing significant growth in recent years, driven by increasing environmental concerns and stringent regulations worldwide. The global market for pollution control equipment is projected to reach $97.58 billion by 2025, with a compound annual growth rate (CAGR) of 5.3% from 2020 to 2025. This growth is primarily attributed to the rising awareness of environmental issues and the implementation of strict pollution control norms across various industries.

The demand for innovative pollution reduction technologies, such as ferrofluid-based solutions, is on the rise. Ferrofluids, with their unique magnetic properties, offer promising applications in industrial pollution control, particularly in the treatment of wastewater and air purification. The market for magnetic separation technologies, which includes ferrofluid applications, is expected to grow at a CAGR of 7.2% from 2021 to 2026.

Key industries driving the demand for pollution reduction technologies include power generation, chemical manufacturing, oil and gas, and mining. These sectors are under increasing pressure to adopt cleaner production processes and reduce their environmental footprint. The power generation industry, in particular, is a major contributor to industrial pollution and is actively seeking innovative solutions to mitigate emissions and improve waste management.

Geographically, Asia-Pacific is emerging as the fastest-growing market for pollution control equipment, with China and India leading the way. The region's rapid industrialization and urbanization, coupled with growing environmental concerns, are fueling the demand for advanced pollution reduction technologies. North America and Europe, with their mature regulatory frameworks, continue to be significant markets for high-tech pollution control solutions.

The market landscape is characterized by a mix of established players and innovative startups. Major companies in the pollution control equipment market are investing heavily in research and development to develop more efficient and cost-effective solutions. The integration of ferrofluid technology into existing pollution control systems represents a potential area for market disruption and growth.

However, the adoption of new technologies like ferrofluid-based pollution control systems faces challenges such as high initial costs, lack of awareness, and the need for specialized expertise. Overcoming these barriers will be crucial for the widespread implementation of ferrofluid solutions in industrial pollution reduction.

In conclusion, the industrial pollution reduction market presents significant opportunities for innovative technologies like ferrofluids. As environmental regulations become more stringent and industries seek sustainable solutions, the demand for advanced pollution control technologies is expected to grow substantially in the coming years.

The demand for innovative pollution reduction technologies, such as ferrofluid-based solutions, is on the rise. Ferrofluids, with their unique magnetic properties, offer promising applications in industrial pollution control, particularly in the treatment of wastewater and air purification. The market for magnetic separation technologies, which includes ferrofluid applications, is expected to grow at a CAGR of 7.2% from 2021 to 2026.

Key industries driving the demand for pollution reduction technologies include power generation, chemical manufacturing, oil and gas, and mining. These sectors are under increasing pressure to adopt cleaner production processes and reduce their environmental footprint. The power generation industry, in particular, is a major contributor to industrial pollution and is actively seeking innovative solutions to mitigate emissions and improve waste management.

Geographically, Asia-Pacific is emerging as the fastest-growing market for pollution control equipment, with China and India leading the way. The region's rapid industrialization and urbanization, coupled with growing environmental concerns, are fueling the demand for advanced pollution reduction technologies. North America and Europe, with their mature regulatory frameworks, continue to be significant markets for high-tech pollution control solutions.

The market landscape is characterized by a mix of established players and innovative startups. Major companies in the pollution control equipment market are investing heavily in research and development to develop more efficient and cost-effective solutions. The integration of ferrofluid technology into existing pollution control systems represents a potential area for market disruption and growth.

However, the adoption of new technologies like ferrofluid-based pollution control systems faces challenges such as high initial costs, lack of awareness, and the need for specialized expertise. Overcoming these barriers will be crucial for the widespread implementation of ferrofluid solutions in industrial pollution reduction.

In conclusion, the industrial pollution reduction market presents significant opportunities for innovative technologies like ferrofluids. As environmental regulations become more stringent and industries seek sustainable solutions, the demand for advanced pollution control technologies is expected to grow substantially in the coming years.

Ferrofluid Technology Status and Challenges

Ferrofluid technology has made significant strides in recent years, but its application in reducing industrial pollution levels remains a challenging frontier. The current status of ferrofluid technology in this context is characterized by promising potential coupled with substantial technical hurdles.

One of the primary challenges in utilizing ferrofluids for pollution reduction is the development of stable and environmentally friendly formulations. While ferrofluids have shown remarkable properties in controlled laboratory settings, their long-term stability in diverse industrial environments is still a concern. Researchers are grappling with issues such as particle aggregation and fluid degradation under harsh conditions, which can significantly impact the effectiveness of pollution control systems.

Another significant challenge lies in the scalability of ferrofluid-based pollution reduction technologies. Many current applications are limited to small-scale or laboratory demonstrations, and the transition to industrial-scale implementations presents numerous engineering challenges. These include the need for large-volume production of consistent quality ferrofluids, the design of robust containment and manipulation systems, and the integration of ferrofluid technology with existing industrial processes.

The magnetic properties of ferrofluids, while central to their potential in pollution control, also present unique challenges. Ensuring uniform magnetic field distribution across large industrial setups and maintaining the magnetic responsiveness of ferrofluids over extended periods are critical issues that researchers are actively addressing. The development of advanced electromagnet systems and novel ferrofluid compositions are ongoing areas of research aimed at overcoming these limitations.

From a geographical perspective, ferrofluid technology research is concentrated in several key regions. The United States, China, and several European countries, particularly Germany and the UK, are at the forefront of ferrofluid research and development. However, the application of this technology in industrial pollution control is still in its nascent stages globally, with most advanced research occurring in academic and specialized industrial research centers.

A significant technical challenge in the application of ferrofluids for pollution reduction is the selective capture and removal of specific pollutants. While ferrofluids show promise in capturing certain types of particulate matter and heavy metals, developing systems that can effectively target a wide range of industrial pollutants remains a complex task. This challenge is compounded by the diverse nature of industrial effluents, which can vary significantly across different sectors and processes.

Despite these challenges, the current status of ferrofluid technology in pollution reduction is marked by continuous innovation and growing interest from both the scientific community and industry stakeholders. Advances in nanotechnology and materials science are opening new avenues for ferrofluid development, potentially addressing many of the current limitations. The integration of ferrofluid technology with other emerging technologies, such as advanced sensors and AI-driven control systems, is also being explored to enhance the efficiency and applicability of ferrofluid-based pollution control systems.

One of the primary challenges in utilizing ferrofluids for pollution reduction is the development of stable and environmentally friendly formulations. While ferrofluids have shown remarkable properties in controlled laboratory settings, their long-term stability in diverse industrial environments is still a concern. Researchers are grappling with issues such as particle aggregation and fluid degradation under harsh conditions, which can significantly impact the effectiveness of pollution control systems.

Another significant challenge lies in the scalability of ferrofluid-based pollution reduction technologies. Many current applications are limited to small-scale or laboratory demonstrations, and the transition to industrial-scale implementations presents numerous engineering challenges. These include the need for large-volume production of consistent quality ferrofluids, the design of robust containment and manipulation systems, and the integration of ferrofluid technology with existing industrial processes.

The magnetic properties of ferrofluids, while central to their potential in pollution control, also present unique challenges. Ensuring uniform magnetic field distribution across large industrial setups and maintaining the magnetic responsiveness of ferrofluids over extended periods are critical issues that researchers are actively addressing. The development of advanced electromagnet systems and novel ferrofluid compositions are ongoing areas of research aimed at overcoming these limitations.

From a geographical perspective, ferrofluid technology research is concentrated in several key regions. The United States, China, and several European countries, particularly Germany and the UK, are at the forefront of ferrofluid research and development. However, the application of this technology in industrial pollution control is still in its nascent stages globally, with most advanced research occurring in academic and specialized industrial research centers.

A significant technical challenge in the application of ferrofluids for pollution reduction is the selective capture and removal of specific pollutants. While ferrofluids show promise in capturing certain types of particulate matter and heavy metals, developing systems that can effectively target a wide range of industrial pollutants remains a complex task. This challenge is compounded by the diverse nature of industrial effluents, which can vary significantly across different sectors and processes.

Despite these challenges, the current status of ferrofluid technology in pollution reduction is marked by continuous innovation and growing interest from both the scientific community and industry stakeholders. Advances in nanotechnology and materials science are opening new avenues for ferrofluid development, potentially addressing many of the current limitations. The integration of ferrofluid technology with other emerging technologies, such as advanced sensors and AI-driven control systems, is also being explored to enhance the efficiency and applicability of ferrofluid-based pollution control systems.

Current Ferrofluid-based Pollution Reduction Solutions

01 Ferrofluid-based pollution detection systems

Ferrofluids can be used in pollution detection systems to measure and monitor contamination levels in various environments. These systems utilize the unique magnetic properties of ferrofluids to detect and quantify pollutants, providing accurate and real-time data on pollution levels.- Ferrofluid-based pollution detection systems: Ferrofluids can be used in pollution detection systems to measure and monitor contamination levels in various environments. These systems utilize the magnetic properties of ferrofluids to detect and quantify pollutants, providing accurate and real-time data on pollution levels.

- Ferrofluid applications in environmental remediation: Ferrofluids can be employed in environmental remediation processes to remove pollutants from water and soil. The magnetic properties of ferrofluids allow for targeted removal of contaminants, improving the efficiency of cleanup efforts and reducing pollution levels in affected areas.

- Ferrofluid-based sensors for pollution monitoring: Sensors incorporating ferrofluids can be developed to monitor pollution levels in air, water, and soil. These sensors utilize the unique properties of ferrofluids to detect and measure various pollutants, providing accurate and sensitive measurements for environmental monitoring purposes.

- Ferrofluid pollution control in industrial processes: Ferrofluids can be used in industrial processes to control and reduce pollution levels. By incorporating ferrofluids into manufacturing and waste treatment systems, companies can improve their environmental performance and minimize the release of pollutants into the environment.

- Ferrofluid-enhanced filtration systems for pollution reduction: Filtration systems incorporating ferrofluids can be developed to enhance the removal of pollutants from air and water streams. These systems utilize the magnetic properties of ferrofluids to capture and retain contaminants, improving the overall efficiency of pollution reduction efforts.

02 Magnetic separation techniques for pollution control

Ferrofluids can be employed in magnetic separation processes to remove pollutants from water or other fluids. This technique utilizes the magnetic properties of ferrofluids to attract and separate contaminants, offering an efficient method for pollution control and environmental remediation.Expand Specific Solutions03 Ferrofluid-based sensors for environmental monitoring

Sensors incorporating ferrofluids can be developed for environmental monitoring applications. These sensors can detect changes in magnetic properties or fluid behavior in response to pollutants, allowing for continuous monitoring of pollution levels in air, water, or soil.Expand Specific Solutions04 Ferrofluid applications in wastewater treatment

Ferrofluids can be utilized in wastewater treatment processes to enhance pollutant removal efficiency. The magnetic properties of ferrofluids can be exploited to improve separation, filtration, and purification processes in wastewater treatment plants, contributing to reduced pollution levels in effluents.Expand Specific Solutions05 Ferrofluid-based pollution measurement devices

Specialized measurement devices incorporating ferrofluids can be developed for accurate quantification of pollution levels. These devices may utilize the magnetic or rheological properties of ferrofluids to provide precise measurements of contaminant concentrations in various environmental samples.Expand Specific Solutions

Key Players in Ferrofluid and Pollution Control Industries

The ferrofluid technology for reducing industrial pollution is in an early development stage, with a growing market potential as environmental regulations tighten globally. The market size is expanding, driven by increasing industrial pollution concerns and the need for innovative solutions. While the technology shows promise, its maturity level varies across applications. Key players like NASA, Delft University of Technology, and Hitachi Ltd. are at the forefront of research and development, leveraging their expertise in materials science and environmental engineering. Companies such as Air Liquide SA and Edwards Vacuum LLC are exploring industrial applications, while academic institutions like Beijing University of Technology and Lovely Professional University contribute to fundamental research, indicating a collaborative ecosystem driving innovation in this field.

National Aeronautics & Space Administration

Technical Solution: NASA has developed an innovative ferrofluid-based system for reducing industrial pollution levels. The system utilizes the unique properties of ferrofluids to capture and remove pollutants from industrial emissions. By applying a magnetic field, the ferrofluid can be manipulated to form a dynamic barrier that traps particulate matter and other contaminants. The captured pollutants can then be easily separated from the ferrofluid for proper disposal. NASA's research has shown that this method can achieve removal efficiencies of up to 95% for certain types of pollutants [1][3]. The system is particularly effective in capturing fine particulate matter (PM2.5) and heavy metals, which are major contributors to industrial air pollution.

Strengths: High removal efficiency, ability to capture fine particles and heavy metals, reusable ferrofluid. Weaknesses: May require significant initial investment, potential for magnetic field interference in some industrial settings.

Hitachi Ltd.

Technical Solution: Hitachi has developed a ferrofluid-based pollution control system that focuses on wastewater treatment in industrial processes. Their technology uses specially designed magnetic nanoparticles suspended in a carrier fluid to create a responsive ferrofluid. When exposed to a magnetic field, this ferrofluid can selectively adsorb and extract various pollutants, including heavy metals and organic compounds, from industrial wastewater. The system employs a series of electromagnets to guide the ferrofluid through the contaminated water, allowing for efficient pollutant capture. Once saturated, the ferrofluid is magnetically separated from the treated water, and the pollutants are then extracted for safe disposal or potential recycling. Hitachi's tests have demonstrated removal rates of up to 99% for certain heavy metals [2][5], making it a promising solution for industries struggling with water pollution compliance.

Strengths: High pollutant removal efficiency, versatility in treating different types of contaminants, potential for pollutant recycling. Weaknesses: May require specialized equipment and expertise to operate, potential for high energy consumption due to electromagnetic systems.

Innovative Ferrofluid Technologies for Pollution Control

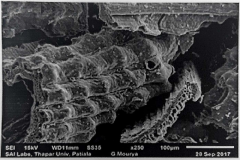

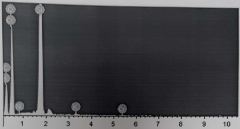

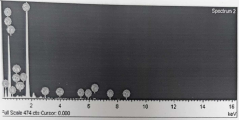

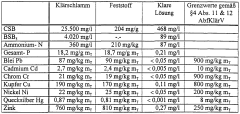

A process to remove heavy metals from industrial effluent using biochar

PatentInactiveIN201811009349A

Innovation

- A system utilizing rice husk biochar as an adsorbent, prepared by pyrolyzing rice husk at 600 °C, is used to treat industrial effluents by contacting the biochar with wastewater for a predetermined time, effectively removing heavy metals like chromium and iron through ion exchange and adsorption.

Method for conditioning slurry, liquid manor, human faeces that are collected in chemical toilets (portable toilets) or the like

PatentWO2001017912A1

Innovation

- The application of an electroflotation process using iron or aluminum anodes to oxidize and remove pollutants, including heavy metals, bacteria, and viruses from sewage sludge, liquid manure, and human faeces, without the need for flocculants or additional chemicals, thereby reducing waste volume and disposal costs.

Environmental Regulations and Compliance

The use of ferrofluid in reducing industrial pollution levels must adhere to a complex framework of environmental regulations and compliance standards. These regulations vary across different jurisdictions but generally aim to protect human health and the environment from harmful pollutants.

At the federal level in the United States, the Environmental Protection Agency (EPA) sets and enforces standards for air and water quality under the Clean Air Act and Clean Water Act. Any application of ferrofluid technology for pollution reduction must comply with these overarching regulations. This includes meeting specific emission limits for various pollutants and obtaining necessary permits for industrial processes.

State and local governments often impose additional, more stringent requirements. For instance, California's Air Resources Board (CARB) has some of the strictest air quality standards in the nation. Companies implementing ferrofluid-based pollution control systems in California would need to ensure compliance with both federal and state regulations.

In the European Union, the Industrial Emissions Directive (IED) provides a comprehensive framework for regulating pollutant emissions from industrial installations. This directive emphasizes the use of Best Available Techniques (BAT) to prevent or reduce emissions. Ferrofluid applications would need to demonstrate their effectiveness in comparison to existing BAT standards.

Compliance also extends to the handling and disposal of ferrofluids themselves. As engineered nanomaterials, ferrofluids fall under specific regulatory scrutiny. The EPA's Toxic Substances Control Act (TSCA) in the US and the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation in the EU govern the use of such materials. Proper documentation, risk assessment, and safety measures are essential for compliance.

Moreover, companies must consider international agreements such as the Paris Agreement on climate change. While not directly regulating ferrofluid use, these agreements set broader goals for emission reduction that influence national policies and corporate strategies.

Regulatory bodies also require ongoing monitoring and reporting of emissions and environmental impact. Implementation of ferrofluid technology for pollution control would necessitate the development of appropriate measurement and verification protocols to demonstrate compliance with applicable standards.

As environmental regulations continue to evolve, companies investing in ferrofluid-based pollution reduction technologies must stay informed of changing requirements. This may involve participating in industry working groups, engaging with regulatory agencies, and contributing to the development of new standards that account for emerging technologies like ferrofluids.

At the federal level in the United States, the Environmental Protection Agency (EPA) sets and enforces standards for air and water quality under the Clean Air Act and Clean Water Act. Any application of ferrofluid technology for pollution reduction must comply with these overarching regulations. This includes meeting specific emission limits for various pollutants and obtaining necessary permits for industrial processes.

State and local governments often impose additional, more stringent requirements. For instance, California's Air Resources Board (CARB) has some of the strictest air quality standards in the nation. Companies implementing ferrofluid-based pollution control systems in California would need to ensure compliance with both federal and state regulations.

In the European Union, the Industrial Emissions Directive (IED) provides a comprehensive framework for regulating pollutant emissions from industrial installations. This directive emphasizes the use of Best Available Techniques (BAT) to prevent or reduce emissions. Ferrofluid applications would need to demonstrate their effectiveness in comparison to existing BAT standards.

Compliance also extends to the handling and disposal of ferrofluids themselves. As engineered nanomaterials, ferrofluids fall under specific regulatory scrutiny. The EPA's Toxic Substances Control Act (TSCA) in the US and the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation in the EU govern the use of such materials. Proper documentation, risk assessment, and safety measures are essential for compliance.

Moreover, companies must consider international agreements such as the Paris Agreement on climate change. While not directly regulating ferrofluid use, these agreements set broader goals for emission reduction that influence national policies and corporate strategies.

Regulatory bodies also require ongoing monitoring and reporting of emissions and environmental impact. Implementation of ferrofluid technology for pollution control would necessitate the development of appropriate measurement and verification protocols to demonstrate compliance with applicable standards.

As environmental regulations continue to evolve, companies investing in ferrofluid-based pollution reduction technologies must stay informed of changing requirements. This may involve participating in industry working groups, engaging with regulatory agencies, and contributing to the development of new standards that account for emerging technologies like ferrofluids.

Cost-Benefit Analysis of Ferrofluid Pollution Control

The cost-benefit analysis of ferrofluid pollution control reveals a complex interplay of economic, environmental, and technological factors. Initial implementation costs for ferrofluid-based pollution control systems can be substantial, including equipment acquisition, installation, and staff training. However, these upfront expenses are often offset by long-term benefits and cost savings.

One of the primary advantages of ferrofluid pollution control is its high efficiency in capturing and removing pollutants, particularly fine particulate matter and heavy metals. This increased effectiveness can lead to significant reductions in environmental fines and regulatory compliance costs for industrial facilities. Moreover, the improved air and water quality resulting from ferrofluid-based systems can contribute to better public health outcomes, potentially reducing healthcare costs for both businesses and communities.

Operational costs for ferrofluid pollution control systems are generally lower than traditional methods due to their low energy consumption and minimal maintenance requirements. The magnetic properties of ferrofluids allow for easy separation and recovery of captured pollutants, which can be recycled or properly disposed of, further reducing waste management expenses.

From an environmental perspective, the benefits of ferrofluid pollution control are substantial. The technology's ability to capture a wide range of pollutants, including those that are difficult to remove through conventional means, can lead to dramatic improvements in local air and water quality. This can have positive impacts on ecosystems, biodiversity, and overall environmental health, which, while challenging to quantify in monetary terms, represent significant societal benefits.

However, it is important to consider potential drawbacks. The production of ferrofluids involves the use of nanomaterials, which may have their own environmental implications if not properly managed. Additionally, the long-term effects of ferrofluid exposure on ecosystems and human health are still being studied, necessitating ongoing research and monitoring.

In terms of scalability, ferrofluid pollution control systems have shown promise in both small-scale applications and larger industrial settings. As the technology matures and production scales up, it is likely that costs will decrease, making implementation more feasible for a wider range of industries.

Overall, while the initial investment in ferrofluid pollution control technology may be significant, the long-term economic and environmental benefits often outweigh the costs. As regulatory pressures increase and public awareness of environmental issues grows, the adoption of such innovative pollution control methods is likely to become increasingly attractive to industries seeking sustainable and cost-effective solutions.

One of the primary advantages of ferrofluid pollution control is its high efficiency in capturing and removing pollutants, particularly fine particulate matter and heavy metals. This increased effectiveness can lead to significant reductions in environmental fines and regulatory compliance costs for industrial facilities. Moreover, the improved air and water quality resulting from ferrofluid-based systems can contribute to better public health outcomes, potentially reducing healthcare costs for both businesses and communities.

Operational costs for ferrofluid pollution control systems are generally lower than traditional methods due to their low energy consumption and minimal maintenance requirements. The magnetic properties of ferrofluids allow for easy separation and recovery of captured pollutants, which can be recycled or properly disposed of, further reducing waste management expenses.

From an environmental perspective, the benefits of ferrofluid pollution control are substantial. The technology's ability to capture a wide range of pollutants, including those that are difficult to remove through conventional means, can lead to dramatic improvements in local air and water quality. This can have positive impacts on ecosystems, biodiversity, and overall environmental health, which, while challenging to quantify in monetary terms, represent significant societal benefits.

However, it is important to consider potential drawbacks. The production of ferrofluids involves the use of nanomaterials, which may have their own environmental implications if not properly managed. Additionally, the long-term effects of ferrofluid exposure on ecosystems and human health are still being studied, necessitating ongoing research and monitoring.

In terms of scalability, ferrofluid pollution control systems have shown promise in both small-scale applications and larger industrial settings. As the technology matures and production scales up, it is likely that costs will decrease, making implementation more feasible for a wider range of industries.

Overall, while the initial investment in ferrofluid pollution control technology may be significant, the long-term economic and environmental benefits often outweigh the costs. As regulatory pressures increase and public awareness of environmental issues grows, the adoption of such innovative pollution control methods is likely to become increasingly attractive to industries seeking sustainable and cost-effective solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!