How to Harness Ferrofluid in Magnetic Field Manipulation Techniques?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Technology Evolution and Objectives

Ferrofluid technology has undergone significant evolution since its inception in the 1960s. Initially developed by NASA for rocket fuel manipulation in zero gravity, ferrofluids have found diverse applications across various industries. The technology's progression has been marked by advancements in material science, nanotechnology, and magnetic field manipulation techniques.

The early stages of ferrofluid development focused on improving stability and magnetic responsiveness. Researchers worked on optimizing particle size, surfactant coatings, and carrier fluid compositions to enhance the colloidal stability and magnetic properties of ferrofluids. This led to the creation of more robust and versatile ferrofluid formulations capable of withstanding a wider range of environmental conditions.

As the technology matured, the focus shifted towards expanding its application domains. The unique properties of ferrofluids, such as their ability to change shape and viscosity in response to magnetic fields, opened up new possibilities in fields like mechanical engineering, biomedical sciences, and electronics. This expansion drove further research into tailoring ferrofluid properties for specific applications, resulting in a diverse range of specialized formulations.

Recent advancements in ferrofluid technology have been closely tied to developments in nanotechnology and advanced manufacturing techniques. The ability to precisely control the size, shape, and composition of magnetic nanoparticles has led to ferrofluids with enhanced magnetic responsiveness and stability. Additionally, progress in microfluidics and 3D printing has enabled the integration of ferrofluids into complex systems and devices, further expanding their potential applications.

The current objectives in ferrofluid research and development are multifaceted. One primary goal is to improve the precision and control of magnetic field manipulation techniques using ferrofluids. This includes developing more sophisticated methods for shaping and directing ferrofluids in three-dimensional space, which could revolutionize areas such as soft robotics and adaptive optics.

Another key objective is to enhance the biocompatibility and functionality of ferrofluids for medical applications. Researchers are working on creating ferrofluids that can be safely used in the human body for targeted drug delivery, magnetic hyperthermia treatments, and as contrast agents in medical imaging.

Furthermore, there is a growing interest in developing "smart" ferrofluids that can respond to multiple stimuli beyond magnetic fields, such as temperature, pH, or light. These multi-responsive ferrofluids could enable the creation of highly adaptive and responsive systems for various applications in sensing, actuation, and energy harvesting.

The early stages of ferrofluid development focused on improving stability and magnetic responsiveness. Researchers worked on optimizing particle size, surfactant coatings, and carrier fluid compositions to enhance the colloidal stability and magnetic properties of ferrofluids. This led to the creation of more robust and versatile ferrofluid formulations capable of withstanding a wider range of environmental conditions.

As the technology matured, the focus shifted towards expanding its application domains. The unique properties of ferrofluids, such as their ability to change shape and viscosity in response to magnetic fields, opened up new possibilities in fields like mechanical engineering, biomedical sciences, and electronics. This expansion drove further research into tailoring ferrofluid properties for specific applications, resulting in a diverse range of specialized formulations.

Recent advancements in ferrofluid technology have been closely tied to developments in nanotechnology and advanced manufacturing techniques. The ability to precisely control the size, shape, and composition of magnetic nanoparticles has led to ferrofluids with enhanced magnetic responsiveness and stability. Additionally, progress in microfluidics and 3D printing has enabled the integration of ferrofluids into complex systems and devices, further expanding their potential applications.

The current objectives in ferrofluid research and development are multifaceted. One primary goal is to improve the precision and control of magnetic field manipulation techniques using ferrofluids. This includes developing more sophisticated methods for shaping and directing ferrofluids in three-dimensional space, which could revolutionize areas such as soft robotics and adaptive optics.

Another key objective is to enhance the biocompatibility and functionality of ferrofluids for medical applications. Researchers are working on creating ferrofluids that can be safely used in the human body for targeted drug delivery, magnetic hyperthermia treatments, and as contrast agents in medical imaging.

Furthermore, there is a growing interest in developing "smart" ferrofluids that can respond to multiple stimuli beyond magnetic fields, such as temperature, pH, or light. These multi-responsive ferrofluids could enable the creation of highly adaptive and responsive systems for various applications in sensing, actuation, and energy harvesting.

Market Applications of Ferrofluid Manipulation

Ferrofluid manipulation techniques have found diverse applications across various industries, driving market growth and innovation. In the medical field, ferrofluids are being explored for targeted drug delivery systems, where magnetic fields can guide nanoparticles containing medications to specific areas of the body. This approach shows promise in cancer treatment, potentially reducing side effects and improving therapeutic efficacy. Additionally, ferrofluids are being utilized in magnetic resonance imaging (MRI) as contrast agents, enhancing image quality and diagnostic accuracy.

In the electronics industry, ferrofluid-based cooling systems are gaining traction for thermal management in high-performance computing and data centers. These systems offer improved heat dissipation capabilities compared to traditional cooling methods, potentially leading to more efficient and compact electronic devices. Ferrofluids are also being incorporated into speaker systems to dampen vibrations and enhance audio quality, particularly in high-end audio equipment.

The automotive sector is exploring ferrofluid applications in adaptive suspension systems and shock absorbers. By manipulating the viscosity of ferrofluids through magnetic fields, these systems can provide real-time adjustments to vehicle handling and ride comfort. This technology has the potential to revolutionize automotive suspension design, offering improved performance and safety.

In the energy sector, ferrofluids are being investigated for use in renewable energy systems. For instance, in wind turbines, ferrofluid-based seals can enhance efficiency and reduce maintenance requirements. Solar thermal power plants are also exploring ferrofluid heat transfer systems to improve energy conversion and storage capabilities.

The aerospace industry is leveraging ferrofluid manipulation techniques for attitude control in small satellites and spacecraft. By using ferrofluids in place of traditional mechanical systems, these solutions offer reduced weight, lower power consumption, and improved reliability in space applications.

In manufacturing, ferrofluids are finding applications in precision polishing and machining processes. The ability to control ferrofluid behavior through magnetic fields allows for highly accurate material removal and surface finishing, particularly in the production of optical components and semiconductor devices.

As research in ferrofluid manipulation techniques continues to advance, new market applications are likely to emerge. The unique properties of ferrofluids, combined with the ability to control them through magnetic fields, offer significant potential for innovation across multiple industries. However, challenges such as long-term stability, cost-effectiveness, and scalability need to be addressed to fully realize the market potential of these technologies.

In the electronics industry, ferrofluid-based cooling systems are gaining traction for thermal management in high-performance computing and data centers. These systems offer improved heat dissipation capabilities compared to traditional cooling methods, potentially leading to more efficient and compact electronic devices. Ferrofluids are also being incorporated into speaker systems to dampen vibrations and enhance audio quality, particularly in high-end audio equipment.

The automotive sector is exploring ferrofluid applications in adaptive suspension systems and shock absorbers. By manipulating the viscosity of ferrofluids through magnetic fields, these systems can provide real-time adjustments to vehicle handling and ride comfort. This technology has the potential to revolutionize automotive suspension design, offering improved performance and safety.

In the energy sector, ferrofluids are being investigated for use in renewable energy systems. For instance, in wind turbines, ferrofluid-based seals can enhance efficiency and reduce maintenance requirements. Solar thermal power plants are also exploring ferrofluid heat transfer systems to improve energy conversion and storage capabilities.

The aerospace industry is leveraging ferrofluid manipulation techniques for attitude control in small satellites and spacecraft. By using ferrofluids in place of traditional mechanical systems, these solutions offer reduced weight, lower power consumption, and improved reliability in space applications.

In manufacturing, ferrofluids are finding applications in precision polishing and machining processes. The ability to control ferrofluid behavior through magnetic fields allows for highly accurate material removal and surface finishing, particularly in the production of optical components and semiconductor devices.

As research in ferrofluid manipulation techniques continues to advance, new market applications are likely to emerge. The unique properties of ferrofluids, combined with the ability to control them through magnetic fields, offer significant potential for innovation across multiple industries. However, challenges such as long-term stability, cost-effectiveness, and scalability need to be addressed to fully realize the market potential of these technologies.

Current Challenges in Ferrofluid Control

Despite the significant advancements in ferrofluid technology, several challenges persist in achieving precise control and manipulation of these magnetic liquids. One of the primary obstacles is the complex rheological behavior of ferrofluids under varying magnetic field strengths. The non-Newtonian characteristics of ferrofluids make it difficult to predict and model their flow patterns accurately, especially in dynamic field environments.

Another critical challenge lies in the long-term stability of ferrofluids. Over time, the magnetic nanoparticles tend to agglomerate, leading to sedimentation and a reduction in the fluid's magnetic responsiveness. This degradation affects the performance and reliability of ferrofluid-based systems, particularly in applications requiring sustained operation.

The precise control of ferrofluid interfaces remains a significant hurdle. While magnetic fields can shape the fluid's surface, achieving fine-tuned, stable configurations for extended periods is challenging. This limitation impacts applications in adaptive optics, microfluidics, and shape-morphing technologies, where precise and sustained control of fluid interfaces is crucial.

Thermal management presents another obstacle in ferrofluid control. The application of magnetic fields can induce localized heating within the fluid, altering its viscosity and magnetic properties. This thermal effect complicates the maintenance of consistent fluid behavior across different operating conditions and can lead to performance degradation in heat-sensitive applications.

The scalability of ferrofluid control techniques poses a significant challenge for industrial applications. While small-scale demonstrations have shown promising results, scaling up these control methods to larger volumes or more complex geometries often introduces unforeseen complications, such as field inhomogeneities and fluid instabilities.

Lastly, the integration of ferrofluid control systems with other technologies presents interdisciplinary challenges. Combining magnetic field manipulation with other control mechanisms, such as electric fields or mechanical actuation, requires sophisticated multiphysics modeling and control algorithms. This integration is essential for developing advanced applications but remains a complex undertaking due to the interplay of various physical phenomena.

Addressing these challenges requires a multifaceted approach, combining advances in materials science, fluid dynamics, and control systems engineering. Overcoming these hurdles will be crucial for unlocking the full potential of ferrofluids in diverse applications, from adaptive mechanical systems to next-generation biomedical devices.

Another critical challenge lies in the long-term stability of ferrofluids. Over time, the magnetic nanoparticles tend to agglomerate, leading to sedimentation and a reduction in the fluid's magnetic responsiveness. This degradation affects the performance and reliability of ferrofluid-based systems, particularly in applications requiring sustained operation.

The precise control of ferrofluid interfaces remains a significant hurdle. While magnetic fields can shape the fluid's surface, achieving fine-tuned, stable configurations for extended periods is challenging. This limitation impacts applications in adaptive optics, microfluidics, and shape-morphing technologies, where precise and sustained control of fluid interfaces is crucial.

Thermal management presents another obstacle in ferrofluid control. The application of magnetic fields can induce localized heating within the fluid, altering its viscosity and magnetic properties. This thermal effect complicates the maintenance of consistent fluid behavior across different operating conditions and can lead to performance degradation in heat-sensitive applications.

The scalability of ferrofluid control techniques poses a significant challenge for industrial applications. While small-scale demonstrations have shown promising results, scaling up these control methods to larger volumes or more complex geometries often introduces unforeseen complications, such as field inhomogeneities and fluid instabilities.

Lastly, the integration of ferrofluid control systems with other technologies presents interdisciplinary challenges. Combining magnetic field manipulation with other control mechanisms, such as electric fields or mechanical actuation, requires sophisticated multiphysics modeling and control algorithms. This integration is essential for developing advanced applications but remains a complex undertaking due to the interplay of various physical phenomena.

Addressing these challenges requires a multifaceted approach, combining advances in materials science, fluid dynamics, and control systems engineering. Overcoming these hurdles will be crucial for unlocking the full potential of ferrofluids in diverse applications, from adaptive mechanical systems to next-generation biomedical devices.

Existing Ferrofluid Control Methods

01 Magnetic field manipulation for fluid control

Ferrofluids can be controlled and manipulated using magnetic fields. This technique is applied in various applications such as sealing, damping, and heat transfer. The magnetic field can be used to change the shape, position, and properties of the ferrofluid, allowing for precise control in different devices and systems.- Magnetic field manipulation for fluid control: Ferrofluids can be controlled and manipulated using magnetic fields. This technique is applied in various applications such as sealing, damping, and heat transfer. The magnetic field can be used to change the shape, position, and properties of the ferrofluid, allowing for precise control in different devices and systems.

- Ferrofluid-based sensors and actuators: Ferrofluids are utilized in the development of sensors and actuators that respond to magnetic fields. These devices can detect changes in magnetic fields or convert magnetic energy into mechanical motion. Applications include pressure sensors, accelerometers, and microfluidic devices.

- Magnetic field-induced assembly and patterning: Magnetic fields can be used to assemble and pattern ferrofluid particles into specific structures or configurations. This technique is useful in creating dynamic patterns, self-assembling structures, and responsive surfaces for various applications in optics, electronics, and materials science.

- Ferrofluid-based heat transfer and cooling systems: Magnetic field manipulation of ferrofluids is employed in heat transfer and cooling applications. The ability to control the flow and distribution of ferrofluids using magnetic fields allows for the development of efficient heat management systems in electronics and other thermal applications.

- Magnetic field-controlled ferrofluid seals and bearings: Ferrofluids are used in creating dynamic seals and bearings that can be controlled by magnetic fields. These systems provide low-friction, adjustable sealing and bearing solutions for various industrial and mechanical applications, offering improved performance and longevity.

02 Ferrofluid-based sensors and actuators

Ferrofluids are utilized in the development of sensors and actuators that respond to magnetic fields. These devices can detect changes in magnetic fields or convert magnetic energy into mechanical motion. Applications include pressure sensors, accelerometers, and microfluidic devices.Expand Specific Solutions03 Magnetic field-induced assembly and patterning

Magnetic fields can be used to assemble and pattern ferrofluid particles into specific structures or configurations. This technique is useful in creating dynamic structures, self-assembling systems, and adaptive materials that can change their properties in response to external magnetic stimuli.Expand Specific Solutions04 Ferrofluid-based heat transfer and cooling systems

Magnetic field manipulation of ferrofluids is employed in heat transfer and cooling applications. The ability to control the flow and distribution of ferrofluids using magnetic fields allows for the development of efficient cooling systems in electronics and other heat-generating devices.Expand Specific Solutions05 Magnetic field-controlled ferrofluid seals and bearings

Ferrofluids are used in the creation of dynamic seals and bearings that can be controlled by magnetic fields. These systems provide low-friction, adjustable sealing and bearing solutions for various industrial and mechanical applications, offering improved performance and longevity.Expand Specific Solutions

Key Players in Ferrofluid Industry

The ferrofluid magnetic field manipulation techniques market is in an early growth stage, with increasing research and commercial applications emerging. The global market size is estimated to be relatively small but growing rapidly, driven by advancements in nanotechnology and magnetism. While the technology shows promise, it is still maturing in terms of large-scale industrial applications. Key players like Hitachi, Philips, and MIT are leading research efforts, with companies such as Western Digital exploring potential uses in data storage. Emerging startups and research institutions are also contributing to innovation in this field, indicating a competitive and dynamic landscape.

Hitachi Ltd.

Technical Solution: Hitachi has developed ferrofluid-based sealing technology for use in hard disk drives and other rotating machinery. Their approach involves creating a magnetic fluid seal that prevents contamination while allowing for smooth rotation[4]. They've also explored using ferrofluids in damping systems for precision equipment, leveraging the fluid's ability to change viscosity in response to magnetic fields[5]. Hitachi's research extends to using ferrofluids in cooling systems for electronics, where magnetic fields can be used to direct heat transfer more efficiently[6].

Strengths: Practical applications in existing technology sectors. Weaknesses: May be limited to specific industrial applications rather than broader scientific research.

Koninklijke Philips NV

Technical Solution: Philips has focused on medical applications of ferrofluids, particularly in magnetic particle imaging (MPI) for diagnostic purposes. They've developed techniques to manipulate ferrofluid nanoparticles using precisely controlled magnetic fields to create high-resolution images of blood flow and organ function[7]. Philips has also explored using ferrofluids in targeted drug delivery systems, where magnetic fields can guide medication-laden ferrofluid particles to specific areas in the body[8]. Additionally, they've investigated ferrofluid-based contrast agents for MRI, enhancing image quality through magnetic field interactions[9].

Strengths: Strong focus on medical applications with potential for significant impact on healthcare. Weaknesses: Regulatory hurdles may slow down implementation in clinical settings.

Innovative Ferrofluid Manipulation Techniques

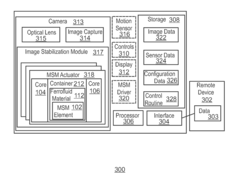

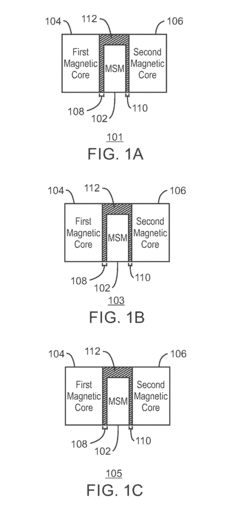

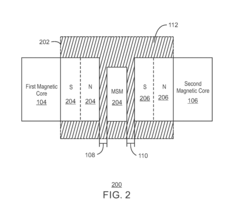

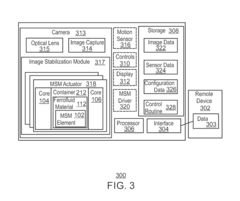

Ferrofluid material interface for magnetic shape-memory element configuration

PatentActiveUS20160381294A1

Innovation

- Incorporating a ferrofluid material at the interface between the MSM element and the magnetic core to increase magnetic permeability, allowing for more efficient magnetic flux transmission and reducing magnetic resistance, thereby enhancing the performance of MSM actuators in optical image stabilization systems.

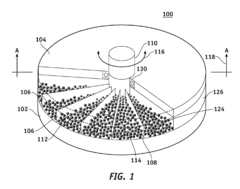

Ferrofluid motor

PatentActiveEP2849322A3

Innovation

- A ferrofluid electric motor that utilizes a rotating electromagnetic field to induce a flow in a ferrofluid, which then rotates a turbine and transfers rotational inertia to an output shaft, with the ferrofluid being the only moving part, thereby minimizing energy loss and enhancing efficiency.

Environmental Impact of Ferrofluids

The environmental impact of ferrofluids in magnetic field manipulation techniques is a critical consideration as these materials gain prominence in various applications. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, possess unique properties that make them valuable for technological advancements. However, their potential effects on ecosystems and human health warrant careful examination.

One primary environmental concern is the potential release of ferrofluids into natural systems. While ferrofluids are typically contained within closed systems, accidental spills or improper disposal could lead to contamination of soil and water bodies. The nanoparticles in ferrofluids may persist in the environment for extended periods, potentially accumulating in organisms and moving through food chains. This bioaccumulation could have unforeseen consequences on ecosystem dynamics and biodiversity.

The magnetic properties of ferrofluids raise questions about their interaction with Earth's magnetic field and potential disruption of natural magnetic cues used by various organisms for navigation and other vital functions. Migratory birds, sea turtles, and certain fish species rely on geomagnetic cues for orientation. The introduction of ferrofluids into their habitats could potentially interfere with these natural processes, affecting migration patterns and breeding behaviors.

Furthermore, the production and disposal of ferrofluids may contribute to environmental pollution. The synthesis of magnetic nanoparticles often involves chemical processes that generate waste products. Proper handling and disposal of these materials are essential to minimize their environmental footprint. Additionally, the energy-intensive nature of nanoparticle production raises concerns about carbon emissions and overall sustainability.

On the other hand, ferrofluids also offer potential environmental benefits when applied in certain technologies. For instance, their use in enhanced oil recovery techniques could improve the efficiency of extraction processes, potentially reducing the environmental impact of traditional oil drilling methods. Similarly, ferrofluid-based seals and dampers in industrial machinery can lead to improved energy efficiency and reduced wear, thereby extending equipment lifespan and minimizing waste.

The long-term effects of ferrofluids on human health are still not fully understood. While direct exposure is limited in most applications, the potential for nanoparticles to enter the body through inhalation or skin contact during manufacturing or maintenance processes requires further investigation. Occupational safety measures and proper handling protocols are crucial to mitigate potential health risks associated with ferrofluid exposure.

As research in this field progresses, it is imperative to conduct comprehensive life cycle assessments of ferrofluid-based technologies. These assessments should consider the environmental impact from production to disposal, including energy consumption, resource depletion, and potential for recycling or reuse. By understanding the full environmental implications, researchers and industry professionals can work towards developing more sustainable and eco-friendly ferrofluid applications.

One primary environmental concern is the potential release of ferrofluids into natural systems. While ferrofluids are typically contained within closed systems, accidental spills or improper disposal could lead to contamination of soil and water bodies. The nanoparticles in ferrofluids may persist in the environment for extended periods, potentially accumulating in organisms and moving through food chains. This bioaccumulation could have unforeseen consequences on ecosystem dynamics and biodiversity.

The magnetic properties of ferrofluids raise questions about their interaction with Earth's magnetic field and potential disruption of natural magnetic cues used by various organisms for navigation and other vital functions. Migratory birds, sea turtles, and certain fish species rely on geomagnetic cues for orientation. The introduction of ferrofluids into their habitats could potentially interfere with these natural processes, affecting migration patterns and breeding behaviors.

Furthermore, the production and disposal of ferrofluids may contribute to environmental pollution. The synthesis of magnetic nanoparticles often involves chemical processes that generate waste products. Proper handling and disposal of these materials are essential to minimize their environmental footprint. Additionally, the energy-intensive nature of nanoparticle production raises concerns about carbon emissions and overall sustainability.

On the other hand, ferrofluids also offer potential environmental benefits when applied in certain technologies. For instance, their use in enhanced oil recovery techniques could improve the efficiency of extraction processes, potentially reducing the environmental impact of traditional oil drilling methods. Similarly, ferrofluid-based seals and dampers in industrial machinery can lead to improved energy efficiency and reduced wear, thereby extending equipment lifespan and minimizing waste.

The long-term effects of ferrofluids on human health are still not fully understood. While direct exposure is limited in most applications, the potential for nanoparticles to enter the body through inhalation or skin contact during manufacturing or maintenance processes requires further investigation. Occupational safety measures and proper handling protocols are crucial to mitigate potential health risks associated with ferrofluid exposure.

As research in this field progresses, it is imperative to conduct comprehensive life cycle assessments of ferrofluid-based technologies. These assessments should consider the environmental impact from production to disposal, including energy consumption, resource depletion, and potential for recycling or reuse. By understanding the full environmental implications, researchers and industry professionals can work towards developing more sustainable and eco-friendly ferrofluid applications.

Safety Protocols in Ferrofluid Handling

Ferrofluid handling requires strict adherence to safety protocols due to its unique properties and potential hazards. When working with ferrofluids in magnetic field manipulation techniques, it is crucial to implement comprehensive safety measures to protect personnel, equipment, and the environment.

Personal protective equipment (PPE) is essential when handling ferrofluids. This includes wearing chemical-resistant gloves, safety goggles, and lab coats to prevent skin contact and eye exposure. In cases where aerosolization is possible, respiratory protection may also be necessary. All PPE should be properly maintained and regularly inspected for damage or wear.

Proper storage and containment of ferrofluids are vital to prevent spills and contamination. Ferrofluids should be stored in sealed, non-magnetic containers in a cool, dry place away from strong magnetic fields. Secondary containment measures, such as spill trays or cabinets, should be used to mitigate the risk of accidental releases.

Workspace design plays a crucial role in ferrofluid safety. Dedicated areas for ferrofluid handling should be established, equipped with non-porous, easily cleanable surfaces. These areas should be well-ventilated and free from strong magnetic sources that could interfere with experiments or cause unexpected fluid behavior.

Spill response procedures must be clearly defined and communicated to all personnel working with ferrofluids. This includes having appropriate spill kits readily available, containing materials such as absorbent pads, non-magnetic tools for cleanup, and proper disposal containers. Regular training on spill response techniques should be conducted to ensure quick and effective action in case of accidents.

Disposal of ferrofluids requires special consideration. They should never be poured down drains or disposed of in regular waste streams. Instead, ferrofluids should be treated as hazardous waste and disposed of according to local regulations, typically through specialized waste management services.

When conducting experiments or manipulations involving ferrofluids and magnetic fields, additional precautions are necessary. This includes using non-magnetic tools and equipment to prevent unexpected interactions, implementing shielding measures to contain magnetic fields, and establishing safe distances from sensitive electronic equipment or medical devices that could be affected by strong magnetic fields.

Regular safety audits and risk assessments should be performed to identify potential hazards and improve safety protocols. This includes reviewing handling procedures, updating safety documentation, and incorporating lessons learned from any incidents or near-misses.

Lastly, proper training and education of all personnel involved in ferrofluid handling are paramount. This should cover not only the specific safety protocols but also the fundamental properties of ferrofluids, their behavior in magnetic fields, and the potential risks associated with their use. Ongoing education and refresher courses help maintain a high level of safety awareness and competence among researchers and technicians working with these unique materials.

Personal protective equipment (PPE) is essential when handling ferrofluids. This includes wearing chemical-resistant gloves, safety goggles, and lab coats to prevent skin contact and eye exposure. In cases where aerosolization is possible, respiratory protection may also be necessary. All PPE should be properly maintained and regularly inspected for damage or wear.

Proper storage and containment of ferrofluids are vital to prevent spills and contamination. Ferrofluids should be stored in sealed, non-magnetic containers in a cool, dry place away from strong magnetic fields. Secondary containment measures, such as spill trays or cabinets, should be used to mitigate the risk of accidental releases.

Workspace design plays a crucial role in ferrofluid safety. Dedicated areas for ferrofluid handling should be established, equipped with non-porous, easily cleanable surfaces. These areas should be well-ventilated and free from strong magnetic sources that could interfere with experiments or cause unexpected fluid behavior.

Spill response procedures must be clearly defined and communicated to all personnel working with ferrofluids. This includes having appropriate spill kits readily available, containing materials such as absorbent pads, non-magnetic tools for cleanup, and proper disposal containers. Regular training on spill response techniques should be conducted to ensure quick and effective action in case of accidents.

Disposal of ferrofluids requires special consideration. They should never be poured down drains or disposed of in regular waste streams. Instead, ferrofluids should be treated as hazardous waste and disposed of according to local regulations, typically through specialized waste management services.

When conducting experiments or manipulations involving ferrofluids and magnetic fields, additional precautions are necessary. This includes using non-magnetic tools and equipment to prevent unexpected interactions, implementing shielding measures to contain magnetic fields, and establishing safe distances from sensitive electronic equipment or medical devices that could be affected by strong magnetic fields.

Regular safety audits and risk assessments should be performed to identify potential hazards and improve safety protocols. This includes reviewing handling procedures, updating safety documentation, and incorporating lessons learned from any incidents or near-misses.

Lastly, proper training and education of all personnel involved in ferrofluid handling are paramount. This should cover not only the specific safety protocols but also the fundamental properties of ferrofluids, their behavior in magnetic fields, and the potential risks associated with their use. Ongoing education and refresher courses help maintain a high level of safety awareness and competence among researchers and technicians working with these unique materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!