Key Milestones in Ferrofluid Research for Material Science

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Evolution

Ferrofluids, first developed in the 1960s by NASA, have undergone significant evolution in material science research. The initial breakthrough came with Steve Papell's invention at NASA, aimed at creating a magnetic liquid for fuel control in zero gravity. This marked the beginning of ferrofluid technology, opening up a new field of study in magnetism and fluid dynamics.

In the 1970s, researchers focused on understanding the fundamental properties of ferrofluids. Key milestones included the development of stable ferrofluid compositions and the exploration of their unique magnetic and rheological behaviors. Scientists like Ronald Rosensweig made significant contributions to the theoretical understanding of ferrofluid physics during this period.

The 1980s saw a shift towards practical applications of ferrofluids. Researchers began exploring their potential in various fields, including mechanical engineering, electronics, and biomedicine. Notable achievements included the use of ferrofluids in sealing and damping applications, as well as early experiments in targeted drug delivery.

The 1990s brought advancements in ferrofluid synthesis techniques. Researchers developed methods to produce ferrofluids with more uniform particle sizes and improved stability. This decade also saw the emergence of biocompatible ferrofluids, paving the way for medical applications.

The turn of the millennium marked a new era in ferrofluid research. Nanotechnology advancements enabled the production of ferrofluids with precisely controlled nanoparticle sizes and distributions. This led to enhanced magnetic properties and opened up new possibilities in fields like microfluidics and nanomedicine.

In the 2010s, ferrofluid research expanded into novel areas such as energy harvesting and smart materials. Scientists explored the use of ferrofluids in magnetocaloric refrigeration and developed responsive materials that could change properties under magnetic fields. The integration of ferrofluids with other advanced materials, like graphene and polymers, also became a significant research focus.

Recent years have seen a surge in biomedical applications of ferrofluids. Researchers have made substantial progress in using ferrofluids for magnetic hyperthermia in cancer treatment, MRI contrast enhancement, and targeted drug delivery systems. The development of biocompatible and biodegradable ferrofluids has been crucial in advancing these medical applications.

Looking towards the future, ferrofluid research is poised to make further breakthroughs in areas such as soft robotics, adaptive optics, and environmental remediation. The ongoing miniaturization of ferrofluid-based devices and the exploration of quantum effects in nanoscale ferrofluids represent exciting frontiers in this evolving field of material science.

In the 1970s, researchers focused on understanding the fundamental properties of ferrofluids. Key milestones included the development of stable ferrofluid compositions and the exploration of their unique magnetic and rheological behaviors. Scientists like Ronald Rosensweig made significant contributions to the theoretical understanding of ferrofluid physics during this period.

The 1980s saw a shift towards practical applications of ferrofluids. Researchers began exploring their potential in various fields, including mechanical engineering, electronics, and biomedicine. Notable achievements included the use of ferrofluids in sealing and damping applications, as well as early experiments in targeted drug delivery.

The 1990s brought advancements in ferrofluid synthesis techniques. Researchers developed methods to produce ferrofluids with more uniform particle sizes and improved stability. This decade also saw the emergence of biocompatible ferrofluids, paving the way for medical applications.

The turn of the millennium marked a new era in ferrofluid research. Nanotechnology advancements enabled the production of ferrofluids with precisely controlled nanoparticle sizes and distributions. This led to enhanced magnetic properties and opened up new possibilities in fields like microfluidics and nanomedicine.

In the 2010s, ferrofluid research expanded into novel areas such as energy harvesting and smart materials. Scientists explored the use of ferrofluids in magnetocaloric refrigeration and developed responsive materials that could change properties under magnetic fields. The integration of ferrofluids with other advanced materials, like graphene and polymers, also became a significant research focus.

Recent years have seen a surge in biomedical applications of ferrofluids. Researchers have made substantial progress in using ferrofluids for magnetic hyperthermia in cancer treatment, MRI contrast enhancement, and targeted drug delivery systems. The development of biocompatible and biodegradable ferrofluids has been crucial in advancing these medical applications.

Looking towards the future, ferrofluid research is poised to make further breakthroughs in areas such as soft robotics, adaptive optics, and environmental remediation. The ongoing miniaturization of ferrofluid-based devices and the exploration of quantum effects in nanoscale ferrofluids represent exciting frontiers in this evolving field of material science.

Market Applications

Ferrofluids have found diverse applications across various industries, leveraging their unique properties as magnetic liquids. In the biomedical field, ferrofluids have shown promise in targeted drug delivery systems, where they can be guided to specific locations in the body using external magnetic fields. This approach has the potential to enhance the efficacy of cancer treatments while minimizing side effects on healthy tissues. Additionally, ferrofluids are being explored for use in magnetic hyperthermia, a technique that employs localized heating to destroy cancer cells.

The electronics industry has also embraced ferrofluid technology, particularly in the development of advanced cooling systems for high-performance computing devices. By utilizing the thermal conductivity and magnetic properties of ferrofluids, engineers have created more efficient heat dissipation mechanisms for processors and other electronic components. This application has become increasingly important as the demand for more powerful and compact electronic devices continues to grow.

In the automotive sector, ferrofluids have found applications in adaptive suspension systems and shock absorbers. These smart fluids can rapidly change their viscosity in response to magnetic fields, allowing for real-time adjustments to vehicle handling and ride comfort. This technology has the potential to significantly improve vehicle performance and safety across a wide range of driving conditions.

The energy sector has also recognized the potential of ferrofluids, particularly in the field of renewable energy. Researchers are exploring the use of ferrofluids in solar thermal collectors to enhance heat transfer efficiency. Additionally, ferrofluids are being investigated for their potential in improving the efficiency of wind turbines by reducing friction in bearings and other moving parts.

In the manufacturing industry, ferrofluids have found applications in precision polishing and sealing. Their ability to conform to complex shapes while maintaining a strong magnetic hold has made them valuable in creating high-quality seals for rotating shafts in various machinery. This application has led to improved performance and longevity in a wide range of industrial equipment.

The aerospace industry has also begun to explore the potential of ferrofluids, particularly in the development of advanced propulsion systems and attitude control mechanisms for satellites. The unique properties of ferrofluids offer new possibilities for designing more efficient and reliable space technologies, potentially revolutionizing satellite operations and space exploration efforts.

The electronics industry has also embraced ferrofluid technology, particularly in the development of advanced cooling systems for high-performance computing devices. By utilizing the thermal conductivity and magnetic properties of ferrofluids, engineers have created more efficient heat dissipation mechanisms for processors and other electronic components. This application has become increasingly important as the demand for more powerful and compact electronic devices continues to grow.

In the automotive sector, ferrofluids have found applications in adaptive suspension systems and shock absorbers. These smart fluids can rapidly change their viscosity in response to magnetic fields, allowing for real-time adjustments to vehicle handling and ride comfort. This technology has the potential to significantly improve vehicle performance and safety across a wide range of driving conditions.

The energy sector has also recognized the potential of ferrofluids, particularly in the field of renewable energy. Researchers are exploring the use of ferrofluids in solar thermal collectors to enhance heat transfer efficiency. Additionally, ferrofluids are being investigated for their potential in improving the efficiency of wind turbines by reducing friction in bearings and other moving parts.

In the manufacturing industry, ferrofluids have found applications in precision polishing and sealing. Their ability to conform to complex shapes while maintaining a strong magnetic hold has made them valuable in creating high-quality seals for rotating shafts in various machinery. This application has led to improved performance and longevity in a wide range of industrial equipment.

The aerospace industry has also begun to explore the potential of ferrofluids, particularly in the development of advanced propulsion systems and attitude control mechanisms for satellites. The unique properties of ferrofluids offer new possibilities for designing more efficient and reliable space technologies, potentially revolutionizing satellite operations and space exploration efforts.

Technical Challenges

Ferrofluid research in material science has made significant strides over the years, but it still faces several technical challenges that hinder its widespread application and further development. One of the primary obstacles is the long-term stability of ferrofluids. These colloidal suspensions tend to aggregate over time, leading to sedimentation and loss of their unique properties. Researchers are grappling with finding effective ways to maintain the uniform dispersion of magnetic nanoparticles in the carrier fluid for extended periods without compromising the fluid's magnetic responsiveness.

Another critical challenge lies in the precise control of ferrofluid properties. While ferrofluids exhibit remarkable responsiveness to external magnetic fields, achieving fine-tuned control over their behavior remains difficult. This includes accurately manipulating their viscosity, magnetic susceptibility, and thermal conductivity in response to varying field strengths and frequencies. The ability to dynamically adjust these properties is crucial for advanced applications in areas such as adaptive optics and microfluidics.

The biocompatibility of ferrofluids presents a significant hurdle, particularly for biomedical applications. Many ferrofluids contain materials that may be toxic or trigger immune responses when introduced into biological systems. Developing ferrofluids that are both functionally effective and safe for in vivo use is an ongoing challenge. This involves not only selecting appropriate materials for the magnetic nanoparticles and carrier fluids but also designing surface coatings that prevent particle agglomeration and reduce potential toxicity.

Scaling up the production of high-quality ferrofluids for industrial applications remains a technical challenge. Current synthesis methods often struggle to maintain consistency in nanoparticle size, shape, and magnetic properties when scaled to larger volumes. This inconsistency can lead to variations in ferrofluid performance, making it difficult to standardize their use in commercial products. Additionally, the cost-effective production of ferrofluids with specific, tailored properties for different applications is an area that requires further research and development.

The environmental impact and recyclability of ferrofluids are emerging concerns. As the use of ferrofluids in various industries grows, there is an increasing need to address their potential environmental effects and develop sustainable practices for their disposal or recycling. This includes finding ways to separate and recover magnetic nanoparticles from used ferrofluids without causing environmental contamination.

Lastly, the integration of ferrofluids with other advanced materials and technologies poses unique challenges. For instance, combining ferrofluids with smart polymers or incorporating them into nanocomposite structures requires overcoming issues related to material compatibility, interfacial interactions, and maintaining the distinct properties of each component. Addressing these integration challenges is crucial for realizing the full potential of ferrofluids in next-generation materials and devices.

Another critical challenge lies in the precise control of ferrofluid properties. While ferrofluids exhibit remarkable responsiveness to external magnetic fields, achieving fine-tuned control over their behavior remains difficult. This includes accurately manipulating their viscosity, magnetic susceptibility, and thermal conductivity in response to varying field strengths and frequencies. The ability to dynamically adjust these properties is crucial for advanced applications in areas such as adaptive optics and microfluidics.

The biocompatibility of ferrofluids presents a significant hurdle, particularly for biomedical applications. Many ferrofluids contain materials that may be toxic or trigger immune responses when introduced into biological systems. Developing ferrofluids that are both functionally effective and safe for in vivo use is an ongoing challenge. This involves not only selecting appropriate materials for the magnetic nanoparticles and carrier fluids but also designing surface coatings that prevent particle agglomeration and reduce potential toxicity.

Scaling up the production of high-quality ferrofluids for industrial applications remains a technical challenge. Current synthesis methods often struggle to maintain consistency in nanoparticle size, shape, and magnetic properties when scaled to larger volumes. This inconsistency can lead to variations in ferrofluid performance, making it difficult to standardize their use in commercial products. Additionally, the cost-effective production of ferrofluids with specific, tailored properties for different applications is an area that requires further research and development.

The environmental impact and recyclability of ferrofluids are emerging concerns. As the use of ferrofluids in various industries grows, there is an increasing need to address their potential environmental effects and develop sustainable practices for their disposal or recycling. This includes finding ways to separate and recover magnetic nanoparticles from used ferrofluids without causing environmental contamination.

Lastly, the integration of ferrofluids with other advanced materials and technologies poses unique challenges. For instance, combining ferrofluids with smart polymers or incorporating them into nanocomposite structures requires overcoming issues related to material compatibility, interfacial interactions, and maintaining the distinct properties of each component. Addressing these integration challenges is crucial for realizing the full potential of ferrofluids in next-generation materials and devices.

Current Solutions

01 Composition and preparation of ferrofluids

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide a liquid barrier that can be controlled by magnetic fields, offering advantages in terms of low friction, long life, and the ability to operate in vacuum environments.

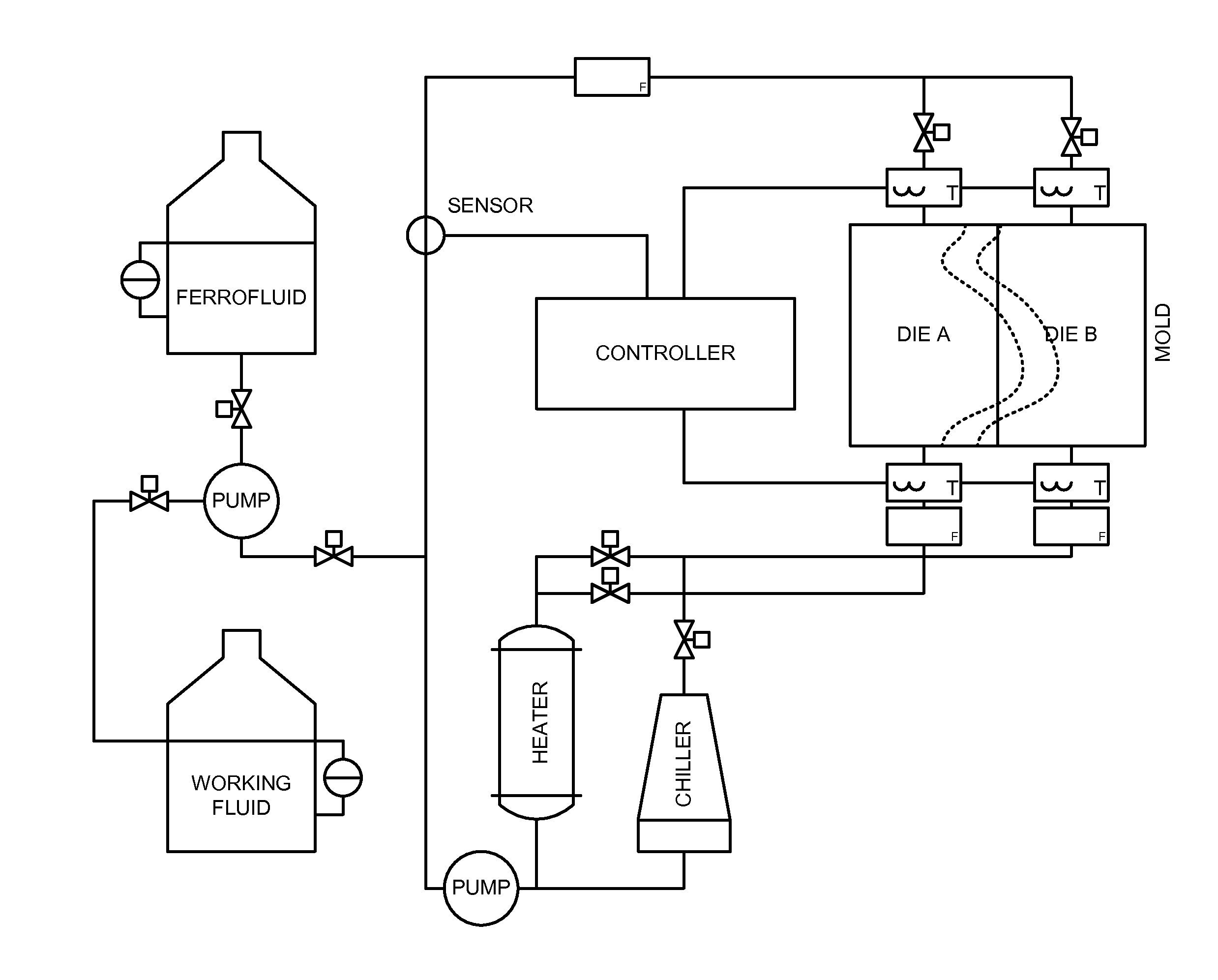

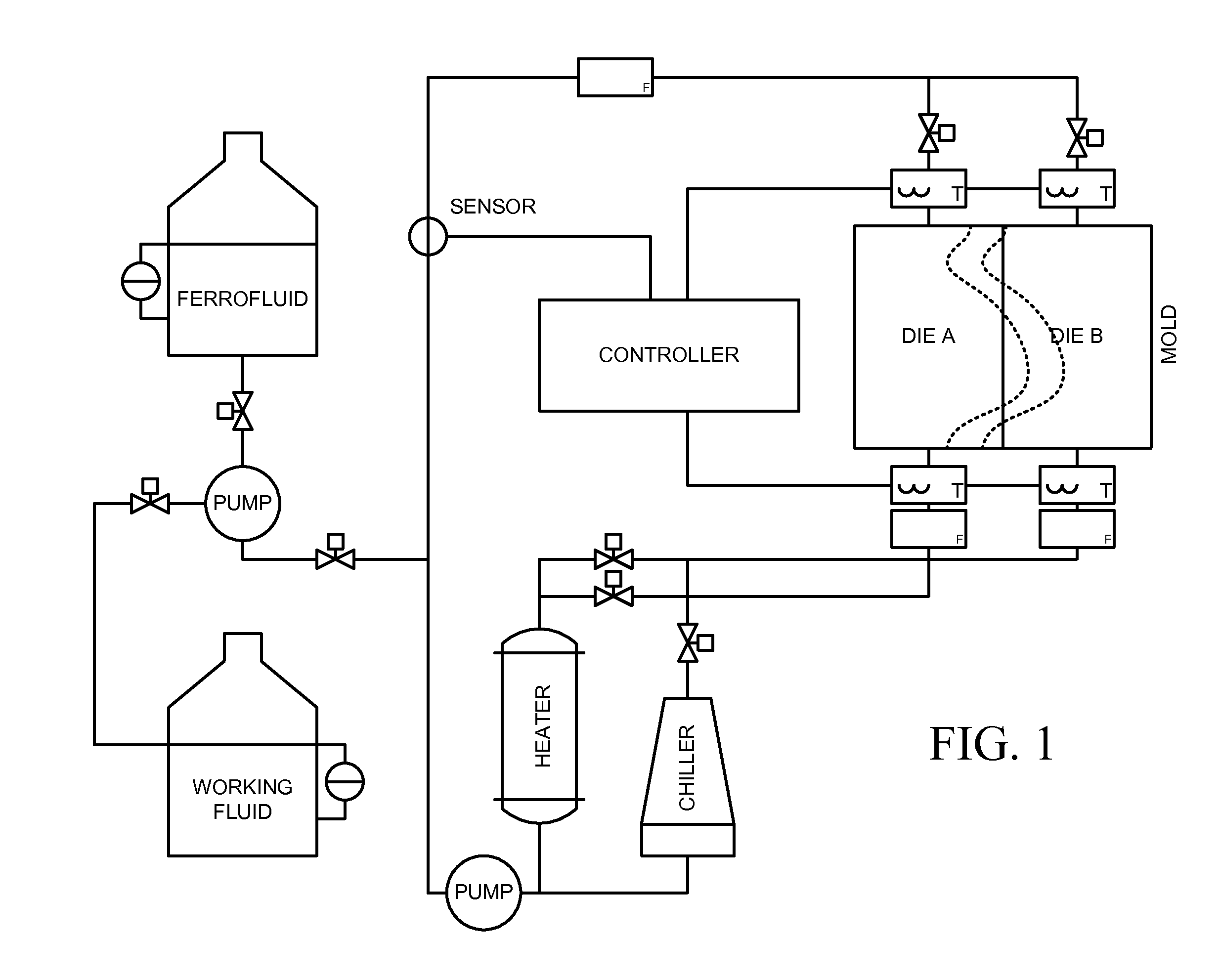

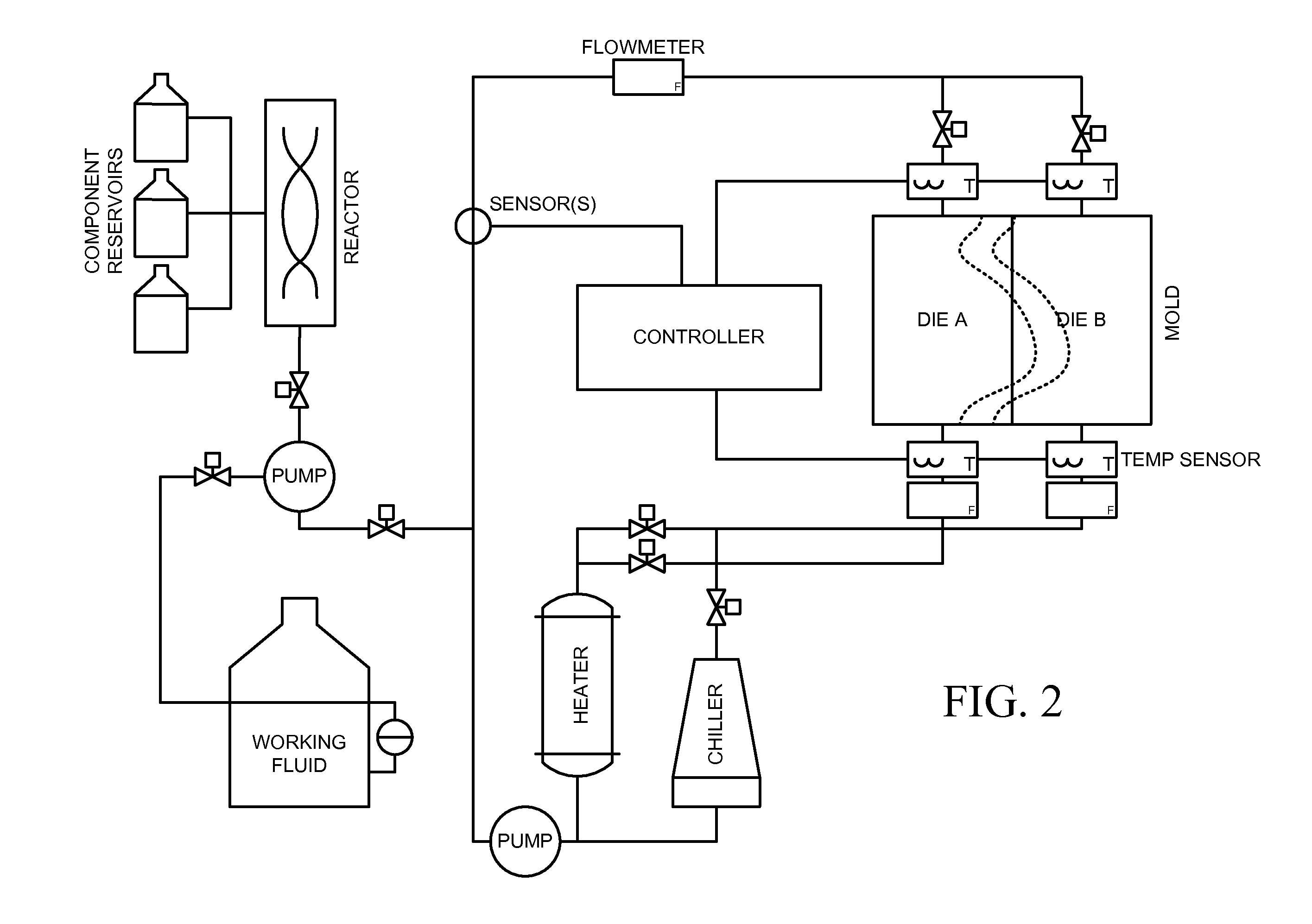

- Thermal management and cooling systems: Ferrofluids are employed in thermal management solutions, particularly in electronic cooling systems. Their unique properties allow for efficient heat transfer and the ability to be directed by magnetic fields, making them useful in applications such as CPU cooling and heat dissipation in various devices.

- Sensor and actuator technologies: Ferrofluids are utilized in various sensor and actuator technologies. Their responsiveness to magnetic fields and ability to change shape or position makes them suitable for applications in accelerometers, position sensors, and haptic feedback devices. They can also be used in adaptive optics and tunable lenses.

- Medical and biomedical applications: Ferrofluids have potential applications in the medical and biomedical fields. They can be used for targeted drug delivery, magnetic hyperthermia treatment of cancer, and as contrast agents in magnetic resonance imaging (MRI). Research is ongoing to develop biocompatible ferrofluids for various therapeutic and diagnostic purposes.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals and bearings. They provide low-friction, contamination-free sealing in various industrial and technological settings, such as hard disk drives and vacuum systems.Expand Specific Solutions03 Thermal management and cooling systems

Ferrofluids are employed in thermal management solutions, particularly in electronic cooling systems. Their unique properties allow for efficient heat transfer and dissipation when subjected to magnetic fields, making them valuable in cooling applications for various devices and equipment.Expand Specific Solutions04 Sensor and actuator technologies

Ferrofluids are utilized in various sensor and actuator technologies, including accelerometers, inertial sensors, and haptic feedback devices. Their responsiveness to magnetic fields and ability to change properties under different conditions make them suitable for these applications.Expand Specific Solutions05 Medical and biomedical applications

Ferrofluids have potential applications in medical and biomedical fields, including targeted drug delivery, magnetic hyperthermia for cancer treatment, and contrast agents for magnetic resonance imaging (MRI). Their magnetic properties and biocompatibility make them promising for various therapeutic and diagnostic purposes.Expand Specific Solutions

Industry Leaders

The research on ferrofluids in material science is currently in a growth phase, with increasing market potential and technological advancements. The global ferrofluid market is expanding, driven by applications in electronics, medical devices, and mechanical engineering. While the technology is maturing, there is still room for innovation and improvement. Key players in this field include academic institutions like Tianjin University of Technology, Delft University of Technology, and Cornell University, as well as industrial entities such as TDK Corp. and Siemens Medical Solutions. These organizations are contributing to the development of novel ferrofluid applications and enhancing their properties for various industrial uses.

TDK Corp.

Technical Solution: TDK Corporation has been at the forefront of ferrofluid research and development for industrial applications. They have made significant advancements in the production of high-quality ferrofluids for use in various electronic components and devices. TDK's research has focused on improving the thermal and magnetic properties of ferrofluids, particularly for use in loudspeakers and hard disk drive seals[5]. They have developed proprietary manufacturing processes that ensure consistent particle size distribution and magnetic saturation[6]. TDK has also explored the use of ferrofluids in cooling systems for high-power electronics, leveraging their unique thermomagnetic convection properties[7]. Their research extends to the development of ferrofluid-based sensors and actuators for precision control applications[8].

Strengths: Strong industrial focus with practical applications. Established manufacturing processes for high-quality ferrofluids. Weaknesses: May have limited research in emerging applications outside their core business areas.

The Regents of the University of California

Technical Solution: The University of California has made significant contributions to ferrofluid research in material science. They have developed novel ferrofluid compositions with enhanced magnetic properties and stability[1]. Their research focuses on improving the synthesis methods of ferrofluids, including the use of surfactants to prevent particle agglomeration and enhance colloidal stability[2]. They have also explored the application of ferrofluids in various fields, such as biomedical applications, where they have developed magnetic nanoparticles for targeted drug delivery and hyperthermia treatment[3]. Additionally, the university has conducted extensive research on the rheological properties of ferrofluids, studying their behavior under different magnetic field strengths and frequencies[4].

Strengths: Comprehensive research covering synthesis, characterization, and applications. Strong focus on biomedical applications. Weaknesses: May face challenges in scaling up production for industrial applications.

Key Innovations

Development of water based ferrofluid for efficient heat transfer

PatentUndeterminedIN202021015289A

Innovation

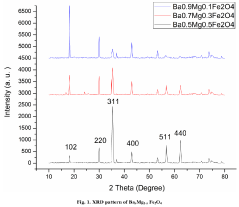

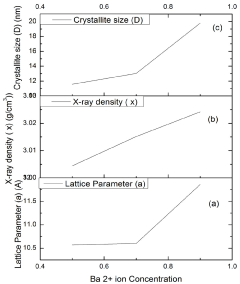

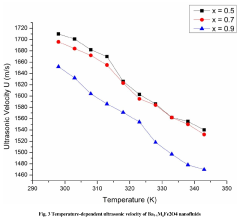

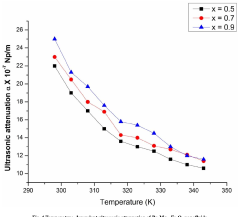

- The synthesis of Ba substituted Mg ferrite nanoparticles and their incorporation into water-based ferrofluids using ultrasonication to enhance thermal conductivity, ensuring stable single-phase formation and optimized thermoacoustical properties.

Method and apparatus for improving heat transfer in industrial water systems with ferrofluids

PatentActiveUS20120199320A1

Innovation

- A method involving the preparation of a consistent ferrofluid with particles less than 5 nm in diameter, which can be economically added to heat transfer fluids and monitored/controlled using direct measurement techniques to achieve enhanced heat transfer efficiency, utilizing an in-line reactor for cost-effective manufacturing and compatibility with existing water treatment additives.

Regulatory Framework

The regulatory framework surrounding ferrofluid research and applications has evolved significantly over the years, reflecting the growing understanding of these unique materials and their potential impacts. Initially, ferrofluids were primarily governed by general chemical and material safety regulations. However, as their applications expanded into various fields, more specific guidelines emerged.

In the United States, the Environmental Protection Agency (EPA) and the Food and Drug Administration (FDA) play crucial roles in regulating ferrofluids. The EPA oversees the environmental impact and potential risks associated with the production and disposal of ferrofluids, particularly concerning their nanoparticle components. The FDA, on the other hand, is involved in regulating ferrofluid applications in medical devices and potential biomedical uses.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which affects ferrofluid research and production. Under REACH, manufacturers must register and provide safety data for nanomaterials, including those used in ferrofluids. This has led to more rigorous testing and documentation requirements for ferrofluid researchers and producers in Europe.

In the realm of workplace safety, organizations like the Occupational Safety and Health Administration (OSHA) in the U.S. have developed guidelines for handling nanomaterials, which apply to ferrofluid research and manufacturing environments. These guidelines address potential exposure risks and recommend appropriate safety measures.

As ferrofluids find applications in consumer products, regulatory bodies have also focused on product safety and labeling requirements. For instance, the use of ferrofluids in electronic devices has led to considerations under electronic waste (e-waste) regulations in various countries.

The international scientific community has also contributed to the regulatory landscape through organizations like the International Organization for Standardization (ISO). The ISO has developed standards for nanotechnology, including methods for characterizing nanoparticles, which are relevant to ferrofluid research and quality control.

Looking ahead, the regulatory framework for ferrofluids is likely to continue evolving. As new applications emerge, particularly in fields like biomedicine and environmental remediation, regulators will need to adapt existing frameworks or develop new ones to address specific safety and ethical concerns. This ongoing development of regulations will play a crucial role in shaping the future of ferrofluid research and applications in material science.

In the United States, the Environmental Protection Agency (EPA) and the Food and Drug Administration (FDA) play crucial roles in regulating ferrofluids. The EPA oversees the environmental impact and potential risks associated with the production and disposal of ferrofluids, particularly concerning their nanoparticle components. The FDA, on the other hand, is involved in regulating ferrofluid applications in medical devices and potential biomedical uses.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which affects ferrofluid research and production. Under REACH, manufacturers must register and provide safety data for nanomaterials, including those used in ferrofluids. This has led to more rigorous testing and documentation requirements for ferrofluid researchers and producers in Europe.

In the realm of workplace safety, organizations like the Occupational Safety and Health Administration (OSHA) in the U.S. have developed guidelines for handling nanomaterials, which apply to ferrofluid research and manufacturing environments. These guidelines address potential exposure risks and recommend appropriate safety measures.

As ferrofluids find applications in consumer products, regulatory bodies have also focused on product safety and labeling requirements. For instance, the use of ferrofluids in electronic devices has led to considerations under electronic waste (e-waste) regulations in various countries.

The international scientific community has also contributed to the regulatory landscape through organizations like the International Organization for Standardization (ISO). The ISO has developed standards for nanotechnology, including methods for characterizing nanoparticles, which are relevant to ferrofluid research and quality control.

Looking ahead, the regulatory framework for ferrofluids is likely to continue evolving. As new applications emerge, particularly in fields like biomedicine and environmental remediation, regulators will need to adapt existing frameworks or develop new ones to address specific safety and ethical concerns. This ongoing development of regulations will play a crucial role in shaping the future of ferrofluid research and applications in material science.

Environmental Impact

Ferrofluids, as innovative materials in material science, have garnered significant attention due to their unique properties and potential applications. However, their environmental impact has become an increasingly important consideration in research and development. The production and use of ferrofluids can have both positive and negative effects on the environment, necessitating a comprehensive assessment of their ecological footprint.

One of the primary environmental concerns associated with ferrofluids is the potential release of nanoparticles into ecosystems. These magnetic nanoparticles, typically composed of iron oxides, may pose risks to aquatic and terrestrial organisms if not properly contained or disposed of. Studies have shown that nanoparticles can accumulate in living tissues, potentially disrupting biological processes and food chains. Consequently, researchers have focused on developing more environmentally friendly ferrofluid formulations and improved containment strategies to mitigate these risks.

On the other hand, ferrofluids have demonstrated potential for environmental remediation applications. Their magnetic properties make them valuable tools for removing contaminants from water and soil. For instance, ferrofluids can be used to extract heavy metals and oil spills from water bodies, offering a more efficient and less invasive alternative to traditional cleanup methods. This application highlights the dual nature of ferrofluids' environmental impact, showcasing their potential to both pose risks and provide solutions to environmental challenges.

The production process of ferrofluids also warrants consideration from an environmental perspective. The synthesis of magnetic nanoparticles often involves energy-intensive processes and the use of potentially harmful chemicals. As research in this field progresses, there has been a growing emphasis on developing greener synthesis methods that reduce energy consumption and utilize more environmentally benign reagents. These efforts aim to minimize the ecological footprint of ferrofluid production while maintaining or enhancing their desirable properties.

Lifecycle assessment studies have become crucial in evaluating the overall environmental impact of ferrofluids. These assessments consider factors such as raw material extraction, production processes, use phase, and end-of-life disposal. By analyzing the entire lifecycle, researchers can identify areas for improvement and develop strategies to enhance the sustainability of ferrofluid technologies. This holistic approach has led to innovations in recycling and reuse techniques for ferrofluids, further reducing their environmental impact.

As the field of ferrofluid research continues to evolve, the focus on environmental considerations has become increasingly prominent. Researchers are now exploring biodegradable surfactants and carrier fluids to create more eco-friendly ferrofluid formulations. Additionally, the development of ferrofluids with enhanced stability and longevity aims to reduce the frequency of replacement and disposal, thereby minimizing waste generation. These advancements represent key milestones in aligning ferrofluid technology with principles of environmental sustainability and responsible material science.

One of the primary environmental concerns associated with ferrofluids is the potential release of nanoparticles into ecosystems. These magnetic nanoparticles, typically composed of iron oxides, may pose risks to aquatic and terrestrial organisms if not properly contained or disposed of. Studies have shown that nanoparticles can accumulate in living tissues, potentially disrupting biological processes and food chains. Consequently, researchers have focused on developing more environmentally friendly ferrofluid formulations and improved containment strategies to mitigate these risks.

On the other hand, ferrofluids have demonstrated potential for environmental remediation applications. Their magnetic properties make them valuable tools for removing contaminants from water and soil. For instance, ferrofluids can be used to extract heavy metals and oil spills from water bodies, offering a more efficient and less invasive alternative to traditional cleanup methods. This application highlights the dual nature of ferrofluids' environmental impact, showcasing their potential to both pose risks and provide solutions to environmental challenges.

The production process of ferrofluids also warrants consideration from an environmental perspective. The synthesis of magnetic nanoparticles often involves energy-intensive processes and the use of potentially harmful chemicals. As research in this field progresses, there has been a growing emphasis on developing greener synthesis methods that reduce energy consumption and utilize more environmentally benign reagents. These efforts aim to minimize the ecological footprint of ferrofluid production while maintaining or enhancing their desirable properties.

Lifecycle assessment studies have become crucial in evaluating the overall environmental impact of ferrofluids. These assessments consider factors such as raw material extraction, production processes, use phase, and end-of-life disposal. By analyzing the entire lifecycle, researchers can identify areas for improvement and develop strategies to enhance the sustainability of ferrofluid technologies. This holistic approach has led to innovations in recycling and reuse techniques for ferrofluids, further reducing their environmental impact.

As the field of ferrofluid research continues to evolve, the focus on environmental considerations has become increasingly prominent. Researchers are now exploring biodegradable surfactants and carrier fluids to create more eco-friendly ferrofluid formulations. Additionally, the development of ferrofluids with enhanced stability and longevity aims to reduce the frequency of replacement and disposal, thereby minimizing waste generation. These advancements represent key milestones in aligning ferrofluid technology with principles of environmental sustainability and responsible material science.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!