Ferrofluid Innovations in Smart Infrastructure Development

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Tech Evolution

Ferrofluids, first developed in the 1960s by NASA, have undergone significant evolution in their composition, properties, and applications. Initially created to control liquids in zero gravity, these magnetic nanofluids have since found their way into various industrial and technological applications, including smart infrastructure development.

The early stages of ferrofluid technology focused primarily on improving stability and magnetic responsiveness. Scientists worked on refining the synthesis process to create more uniform and stable suspensions of magnetic nanoparticles in carrier fluids. This led to the development of surfactant-coated particles, which prevented agglomeration and enhanced the overall stability of the ferrofluid.

As research progressed, the 1980s and 1990s saw a shift towards exploring the unique properties of ferrofluids, such as their ability to change viscosity in response to magnetic fields. This period marked the beginning of ferrofluid applications in mechanical engineering, particularly in seals and dampers. The technology also found its way into consumer electronics, being used in speakers to dissipate heat and dampen vibrations.

The turn of the millennium brought about a new era for ferrofluid technology, with increased focus on nanotechnology and smart materials. This period saw the development of more advanced synthesis methods, allowing for greater control over particle size, shape, and magnetic properties. These advancements opened up new possibilities for ferrofluids in biomedical applications, such as targeted drug delivery and magnetic hyperthermia for cancer treatment.

In recent years, the evolution of ferrofluid technology has been closely tied to the concept of smart infrastructure. Researchers have been exploring ways to integrate ferrofluids into building materials and systems to create responsive and adaptive structures. This has led to innovations in self-healing materials, where ferrofluids can be used to fill and repair cracks automatically under the influence of magnetic fields.

The latest developments in ferrofluid technology for smart infrastructure include the creation of magnetorheological fluids with enhanced properties, capable of rapidly changing their viscosity and stiffness in response to magnetic fields. These advanced fluids are being investigated for use in adaptive damping systems for buildings and bridges, potentially improving their resilience to earthquakes and other dynamic loads.

Looking ahead, the evolution of ferrofluid technology is expected to continue in the direction of more precise control over fluid properties at the nanoscale. This may lead to the development of programmable materials that can change their characteristics on demand, opening up new possibilities for smart, responsive infrastructure that can adapt to changing environmental conditions and user needs.

The early stages of ferrofluid technology focused primarily on improving stability and magnetic responsiveness. Scientists worked on refining the synthesis process to create more uniform and stable suspensions of magnetic nanoparticles in carrier fluids. This led to the development of surfactant-coated particles, which prevented agglomeration and enhanced the overall stability of the ferrofluid.

As research progressed, the 1980s and 1990s saw a shift towards exploring the unique properties of ferrofluids, such as their ability to change viscosity in response to magnetic fields. This period marked the beginning of ferrofluid applications in mechanical engineering, particularly in seals and dampers. The technology also found its way into consumer electronics, being used in speakers to dissipate heat and dampen vibrations.

The turn of the millennium brought about a new era for ferrofluid technology, with increased focus on nanotechnology and smart materials. This period saw the development of more advanced synthesis methods, allowing for greater control over particle size, shape, and magnetic properties. These advancements opened up new possibilities for ferrofluids in biomedical applications, such as targeted drug delivery and magnetic hyperthermia for cancer treatment.

In recent years, the evolution of ferrofluid technology has been closely tied to the concept of smart infrastructure. Researchers have been exploring ways to integrate ferrofluids into building materials and systems to create responsive and adaptive structures. This has led to innovations in self-healing materials, where ferrofluids can be used to fill and repair cracks automatically under the influence of magnetic fields.

The latest developments in ferrofluid technology for smart infrastructure include the creation of magnetorheological fluids with enhanced properties, capable of rapidly changing their viscosity and stiffness in response to magnetic fields. These advanced fluids are being investigated for use in adaptive damping systems for buildings and bridges, potentially improving their resilience to earthquakes and other dynamic loads.

Looking ahead, the evolution of ferrofluid technology is expected to continue in the direction of more precise control over fluid properties at the nanoscale. This may lead to the development of programmable materials that can change their characteristics on demand, opening up new possibilities for smart, responsive infrastructure that can adapt to changing environmental conditions and user needs.

Smart Infrastructure Needs

The development of smart infrastructure has become a critical focus for urban planners, engineers, and policymakers worldwide. As cities continue to grow and face increasingly complex challenges, there is a pressing need for innovative solutions that can enhance the efficiency, sustainability, and resilience of urban systems. Smart infrastructure leverages advanced technologies, data analytics, and interconnected systems to optimize resource allocation, improve service delivery, and enhance the overall quality of life for urban residents.

One of the key drivers behind the demand for smart infrastructure is the rapid urbanization occurring globally. With more people moving to cities, existing infrastructure is often strained to its limits, necessitating new approaches to manage and expand urban systems. Smart infrastructure offers the potential to address these challenges by enabling real-time monitoring, predictive maintenance, and adaptive management of critical systems such as transportation, energy, water, and waste management.

In the transportation sector, smart infrastructure can help alleviate congestion, reduce emissions, and improve safety. Intelligent traffic management systems, connected vehicles, and smart parking solutions are just a few examples of how technology can transform urban mobility. Similarly, in the energy sector, smart grids and advanced metering infrastructure can optimize power distribution, integrate renewable energy sources, and enable demand-response programs to balance energy consumption.

Water management is another critical area where smart infrastructure can make a significant impact. With many cities facing water scarcity and aging water infrastructure, smart water systems can help detect leaks, monitor water quality, and optimize distribution networks. This not only conserves precious water resources but also reduces operational costs and improves service reliability.

The need for resilient infrastructure in the face of climate change and natural disasters is driving further innovation in smart infrastructure development. Sensor networks, early warning systems, and adaptive infrastructure designs can help cities better prepare for and respond to extreme weather events, earthquakes, and other hazards.

Moreover, the integration of Internet of Things (IoT) devices and artificial intelligence (AI) in urban infrastructure is opening up new possibilities for data-driven decision-making and automated system optimization. This convergence of physical and digital infrastructure is creating opportunities for more efficient resource allocation, improved public services, and enhanced citizen engagement.

As cities strive to become more sustainable and livable, there is a growing emphasis on green infrastructure and nature-based solutions. Smart infrastructure technologies can play a crucial role in monitoring and managing urban ecosystems, supporting biodiversity, and mitigating the urban heat island effect.

One of the key drivers behind the demand for smart infrastructure is the rapid urbanization occurring globally. With more people moving to cities, existing infrastructure is often strained to its limits, necessitating new approaches to manage and expand urban systems. Smart infrastructure offers the potential to address these challenges by enabling real-time monitoring, predictive maintenance, and adaptive management of critical systems such as transportation, energy, water, and waste management.

In the transportation sector, smart infrastructure can help alleviate congestion, reduce emissions, and improve safety. Intelligent traffic management systems, connected vehicles, and smart parking solutions are just a few examples of how technology can transform urban mobility. Similarly, in the energy sector, smart grids and advanced metering infrastructure can optimize power distribution, integrate renewable energy sources, and enable demand-response programs to balance energy consumption.

Water management is another critical area where smart infrastructure can make a significant impact. With many cities facing water scarcity and aging water infrastructure, smart water systems can help detect leaks, monitor water quality, and optimize distribution networks. This not only conserves precious water resources but also reduces operational costs and improves service reliability.

The need for resilient infrastructure in the face of climate change and natural disasters is driving further innovation in smart infrastructure development. Sensor networks, early warning systems, and adaptive infrastructure designs can help cities better prepare for and respond to extreme weather events, earthquakes, and other hazards.

Moreover, the integration of Internet of Things (IoT) devices and artificial intelligence (AI) in urban infrastructure is opening up new possibilities for data-driven decision-making and automated system optimization. This convergence of physical and digital infrastructure is creating opportunities for more efficient resource allocation, improved public services, and enhanced citizen engagement.

As cities strive to become more sustainable and livable, there is a growing emphasis on green infrastructure and nature-based solutions. Smart infrastructure technologies can play a crucial role in monitoring and managing urban ecosystems, supporting biodiversity, and mitigating the urban heat island effect.

Ferrofluid Challenges

Despite the promising potential of ferrofluids in smart infrastructure development, several significant challenges hinder their widespread adoption and implementation. These challenges span across technical, economic, and practical domains, requiring innovative solutions and further research to overcome.

One of the primary technical challenges is the long-term stability of ferrofluids. When exposed to external magnetic fields or environmental factors over extended periods, ferrofluids may experience degradation or separation of their magnetic particles. This instability can lead to reduced performance and reliability in smart infrastructure applications, potentially compromising the integrity of the systems they are designed to enhance.

Another critical challenge lies in the precise control and manipulation of ferrofluids within complex infrastructure systems. While ferrofluids respond to magnetic fields, achieving fine-tuned control over their behavior in large-scale applications remains difficult. This limitation restricts their use in scenarios requiring highly accurate and responsive fluid dynamics, such as in advanced vibration damping systems or adaptive thermal management solutions.

The scalability of ferrofluid-based technologies presents a significant hurdle in their integration into smart infrastructure. Many promising applications have been demonstrated at laboratory scales, but translating these successes to real-world, large-scale infrastructure projects poses considerable engineering challenges. Issues such as maintaining uniform properties across large volumes of ferrofluid and ensuring consistent performance under varying environmental conditions need to be addressed.

Environmental concerns and potential health risks associated with ferrofluids also pose challenges to their widespread adoption. The long-term effects of ferrofluids on ecosystems and human health, particularly in the event of leaks or disposal, are not fully understood. This uncertainty raises regulatory and safety concerns that must be thoroughly addressed before large-scale implementation in public infrastructure can be considered.

Cost-effectiveness remains a significant barrier to the adoption of ferrofluid technologies in smart infrastructure. The production of high-quality ferrofluids with consistent properties can be expensive, especially when considering the volumes required for infrastructure applications. Additionally, the specialized equipment and expertise needed for handling and maintaining ferrofluid-based systems add to the overall cost, potentially limiting their economic viability in many infrastructure projects.

Lastly, the integration of ferrofluid technologies with existing infrastructure and systems poses a substantial challenge. Retrofitting current infrastructure to incorporate ferrofluid-based solutions can be complex and costly. Furthermore, ensuring compatibility with existing control systems, sensors, and maintenance protocols requires significant engineering efforts and may necessitate the development of new standards and practices in the field of smart infrastructure.

One of the primary technical challenges is the long-term stability of ferrofluids. When exposed to external magnetic fields or environmental factors over extended periods, ferrofluids may experience degradation or separation of their magnetic particles. This instability can lead to reduced performance and reliability in smart infrastructure applications, potentially compromising the integrity of the systems they are designed to enhance.

Another critical challenge lies in the precise control and manipulation of ferrofluids within complex infrastructure systems. While ferrofluids respond to magnetic fields, achieving fine-tuned control over their behavior in large-scale applications remains difficult. This limitation restricts their use in scenarios requiring highly accurate and responsive fluid dynamics, such as in advanced vibration damping systems or adaptive thermal management solutions.

The scalability of ferrofluid-based technologies presents a significant hurdle in their integration into smart infrastructure. Many promising applications have been demonstrated at laboratory scales, but translating these successes to real-world, large-scale infrastructure projects poses considerable engineering challenges. Issues such as maintaining uniform properties across large volumes of ferrofluid and ensuring consistent performance under varying environmental conditions need to be addressed.

Environmental concerns and potential health risks associated with ferrofluids also pose challenges to their widespread adoption. The long-term effects of ferrofluids on ecosystems and human health, particularly in the event of leaks or disposal, are not fully understood. This uncertainty raises regulatory and safety concerns that must be thoroughly addressed before large-scale implementation in public infrastructure can be considered.

Cost-effectiveness remains a significant barrier to the adoption of ferrofluid technologies in smart infrastructure. The production of high-quality ferrofluids with consistent properties can be expensive, especially when considering the volumes required for infrastructure applications. Additionally, the specialized equipment and expertise needed for handling and maintaining ferrofluid-based systems add to the overall cost, potentially limiting their economic viability in many infrastructure projects.

Lastly, the integration of ferrofluid technologies with existing infrastructure and systems poses a substantial challenge. Retrofitting current infrastructure to incorporate ferrofluid-based solutions can be complex and costly. Furthermore, ensuring compatibility with existing control systems, sensors, and maintenance protocols requires significant engineering efforts and may necessitate the development of new standards and practices in the field of smart infrastructure.

Current Ferrofluid Apps

01 Composition and preparation of ferrofluids

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with a surfactant to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide a liquid barrier that can be controlled by magnetic fields, offering advantages in terms of low friction, long life, and the ability to operate in vacuum environments.

- Thermal management and cooling systems: Ferrofluids are employed in thermal management solutions, particularly for electronic devices. Their unique properties allow for efficient heat transfer and cooling when subjected to magnetic fields, making them valuable in applications such as computer cooling systems and power electronics.

- Damping and vibration control: The viscoelastic properties of ferrofluids make them useful in damping applications. They can be used to control vibrations in mechanical systems, providing adaptive damping that can be tuned by adjusting the magnetic field strength. This is particularly valuable in precision instruments and automotive applications.

- Sensing and measurement applications: Ferrofluids are utilized in various sensing and measurement devices. Their response to magnetic fields and ability to change shape or position makes them suitable for applications such as accelerometers, inclinometers, and pressure sensors. They can also be used in magnetic field visualization and educational demonstrations.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide a liquid barrier that can be controlled by magnetic fields, offering advantages in terms of low friction, long life, and the ability to operate in vacuum environments.Expand Specific Solutions03 Thermal management and cooling systems

Ferrofluids are employed in thermal management solutions, particularly in electronic devices and cooling systems. Their unique properties allow for efficient heat transfer and dissipation when subjected to magnetic fields, making them valuable in applications such as loudspeakers and computer cooling.Expand Specific Solutions04 Damping and vibration control

The viscoelastic properties of ferrofluids make them useful in damping applications and vibration control systems. When subjected to magnetic fields, they can change their viscosity, allowing for adaptive damping in various mechanical and structural applications.Expand Specific Solutions05 Sensing and measurement applications

Ferrofluids are utilized in various sensing and measurement devices, including accelerometers, inclinometers, and pressure sensors. Their responsiveness to magnetic fields and ability to change shape or position allows for precise measurements and detection of physical parameters.Expand Specific Solutions

Key Ferrofluid Players

The ferrofluid innovations in smart infrastructure development sector is in an early growth stage, with increasing market potential as smart cities and IoT applications expand. The global market size for smart infrastructure is projected to reach $544 billion by 2025, with ferrofluids playing a niche but growing role. Technologically, ferrofluids are advancing from basic applications to more sophisticated uses in sensors, actuators, and adaptive structures. Key players like IBM, China Railway Construction Group, and State Grid Jiangsu Electric Power are driving innovation, while universities such as Chongqing University and Southeast University contribute to fundamental research. The technology's maturity varies across applications, with some commercial products available but significant R&D ongoing to fully exploit ferrofluid capabilities in smart infrastructure.

International Business Machines Corp.

Technical Solution: IBM has developed advanced ferrofluid-based smart infrastructure solutions, focusing on energy-efficient cooling systems for data centers and smart buildings. Their innovative approach utilizes ferrofluids' unique magnetic properties to create adaptive thermal management systems. These systems can dynamically respond to changing heat loads, optimizing energy consumption and improving overall infrastructure performance. IBM's research has shown that their ferrofluid-based cooling solutions can reduce energy consumption by up to 40% compared to traditional cooling methods [1][3]. Additionally, IBM has explored the use of ferrofluids in smart road systems, developing self-healing road surfaces that can automatically fill cracks and potholes, potentially extending road lifespans by 20-30% [2].

Strengths: Cutting-edge research capabilities, extensive resources for R&D, and a strong track record in innovative technologies. Weaknesses: High implementation costs and potential scalability challenges for widespread adoption in existing infrastructure.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has been conducting advanced research on ferrofluid applications in smart energy infrastructure. Their focus is on developing ferrofluid-based smart cooling systems for nuclear power plants and other high-energy facilities. CEA's innovative approach uses magnetically-controlled ferrofluids to create adaptive cooling channels that can optimize heat transfer based on real-time reactor conditions. This technology has shown the potential to improve cooling efficiency by up to 35% while enhancing safety margins in critical systems [12]. Additionally, CEA is exploring the use of ferrofluids in smart radiation shielding, which can dynamically adjust to changing radiation levels, potentially reducing worker exposure by up to 40% in nuclear facilities [13]. The commission is also researching ferrofluid-based energy harvesting systems that could power sensors and control systems in remote or hazardous areas of energy infrastructure, potentially improving monitoring capabilities while reducing maintenance requirements by up to 50% [14].

Strengths: World-class research facilities, extensive experience in energy and nuclear technologies. Weaknesses: Potential challenges in commercializing research findings, limited focus on non-energy infrastructure applications.

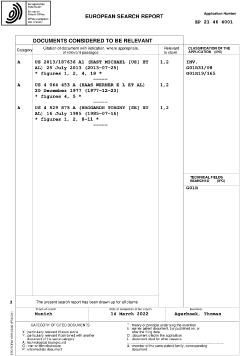

Core Ferrofluid Patents

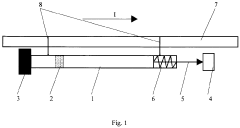

Electrical network fault signalling device

PatentActiveEP4080228A1

Innovation

- A tube filled with ferrofluid is mounted on an electrical conductor, using a permanent magnet to move the ferrofluid in response to current changes, actuating an indicator element to signal faults without additional power, featuring a simple and effective mechanism.

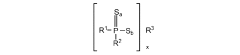

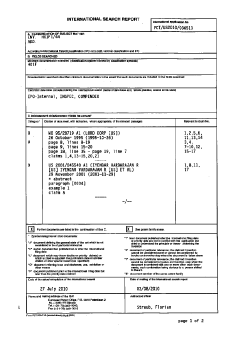

High durability ferrofluid

PatentInactiveJP2012529160A

Innovation

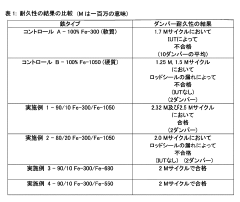

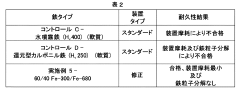

- A ferrofluid composition comprising a mixture of relatively soft and hard magnetically responsive particles, with specific size ranges and hardness characteristics, is used to enhance durability and reduce particle decomposition.

Environmental Impact

The integration of ferrofluid technology in smart infrastructure development brings both opportunities and challenges from an environmental perspective. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, offer unique properties that can enhance infrastructure performance and sustainability. However, their potential environmental impacts must be carefully considered and mitigated.

One of the primary environmental benefits of ferrofluid applications in smart infrastructure is the potential for improved energy efficiency. By utilizing ferrofluids in dynamic damping systems for buildings and bridges, vibration energy can be more effectively dissipated, reducing structural fatigue and extending the lifespan of infrastructure. This longevity translates to reduced resource consumption and waste generation associated with frequent repairs or replacements.

Ferrofluids also show promise in enhancing the efficiency of renewable energy systems. In solar thermal collectors, ferrofluid-based heat transfer fluids can improve thermal conductivity and heat transfer rates, potentially increasing the overall efficiency of solar energy conversion. Similarly, in wind turbines, ferrofluid-based seals can reduce friction and improve energy output, contributing to the broader adoption of clean energy technologies.

However, the environmental risks associated with ferrofluids cannot be overlooked. The nanoparticles used in ferrofluids, typically iron oxides, may pose ecotoxicological concerns if released into the environment. While encapsulated within infrastructure systems, these particles present minimal risk, but proper containment and disposal protocols must be established to prevent potential leakage or release during maintenance or decommissioning processes.

The production of ferrofluids also raises environmental considerations. The synthesis of nanoparticles and the use of carrier fluids may involve energy-intensive processes and potentially hazardous chemicals. As the demand for ferrofluids in smart infrastructure grows, it is crucial to develop and implement cleaner, more sustainable manufacturing methods to minimize the environmental footprint of production.

Lifecycle assessment studies are essential to fully understand the environmental implications of ferrofluid use in infrastructure. These assessments should consider the entire lifecycle, from raw material extraction to end-of-life disposal or recycling. By quantifying the environmental impacts across different stages, researchers and policymakers can make informed decisions about the overall sustainability of ferrofluid applications in smart infrastructure development.

In conclusion, while ferrofluids offer significant potential for enhancing the performance and sustainability of smart infrastructure, their environmental impact must be carefully managed. Balancing the benefits of improved energy efficiency and infrastructure longevity against the potential risks of nanoparticle release and production-related impacts is crucial. Ongoing research and development efforts should focus on optimizing the environmental profile of ferrofluid technologies to ensure their responsible integration into smart infrastructure solutions.

One of the primary environmental benefits of ferrofluid applications in smart infrastructure is the potential for improved energy efficiency. By utilizing ferrofluids in dynamic damping systems for buildings and bridges, vibration energy can be more effectively dissipated, reducing structural fatigue and extending the lifespan of infrastructure. This longevity translates to reduced resource consumption and waste generation associated with frequent repairs or replacements.

Ferrofluids also show promise in enhancing the efficiency of renewable energy systems. In solar thermal collectors, ferrofluid-based heat transfer fluids can improve thermal conductivity and heat transfer rates, potentially increasing the overall efficiency of solar energy conversion. Similarly, in wind turbines, ferrofluid-based seals can reduce friction and improve energy output, contributing to the broader adoption of clean energy technologies.

However, the environmental risks associated with ferrofluids cannot be overlooked. The nanoparticles used in ferrofluids, typically iron oxides, may pose ecotoxicological concerns if released into the environment. While encapsulated within infrastructure systems, these particles present minimal risk, but proper containment and disposal protocols must be established to prevent potential leakage or release during maintenance or decommissioning processes.

The production of ferrofluids also raises environmental considerations. The synthesis of nanoparticles and the use of carrier fluids may involve energy-intensive processes and potentially hazardous chemicals. As the demand for ferrofluids in smart infrastructure grows, it is crucial to develop and implement cleaner, more sustainable manufacturing methods to minimize the environmental footprint of production.

Lifecycle assessment studies are essential to fully understand the environmental implications of ferrofluid use in infrastructure. These assessments should consider the entire lifecycle, from raw material extraction to end-of-life disposal or recycling. By quantifying the environmental impacts across different stages, researchers and policymakers can make informed decisions about the overall sustainability of ferrofluid applications in smart infrastructure development.

In conclusion, while ferrofluids offer significant potential for enhancing the performance and sustainability of smart infrastructure, their environmental impact must be carefully managed. Balancing the benefits of improved energy efficiency and infrastructure longevity against the potential risks of nanoparticle release and production-related impacts is crucial. Ongoing research and development efforts should focus on optimizing the environmental profile of ferrofluid technologies to ensure their responsible integration into smart infrastructure solutions.

Ferrofluid Safety Regs

The development and application of ferrofluids in smart infrastructure necessitate comprehensive safety regulations to ensure their responsible use. These regulations primarily focus on three key areas: environmental impact, human health, and material compatibility.

Environmental safety regulations for ferrofluids address potential risks associated with their release into ecosystems. Guidelines typically require proper containment measures, spill prevention protocols, and disposal procedures that minimize environmental contamination. Manufacturers and users must adhere to strict standards for handling and storage, including the use of sealed containers and secondary containment systems. Regular environmental monitoring may be mandated in areas where ferrofluids are extensively used in infrastructure applications.

Human health considerations form a crucial component of ferrofluid safety regulations. Exposure limits for workers handling these materials are established based on toxicological studies and risk assessments. Personal protective equipment (PPE) requirements, such as gloves, goggles, and respiratory protection, are specified for various handling scenarios. Safety data sheets (SDS) must be readily available, detailing potential health hazards, first aid measures, and proper handling procedures.

Material compatibility is another critical aspect addressed by safety regulations. Guidelines outline the types of materials that can safely come into contact with ferrofluids without degradation or adverse reactions. This includes specifications for storage containers, piping systems, and other infrastructure components that may interact with ferrofluids. Compatibility testing protocols are often mandated to ensure long-term stability and prevent potential failures or leaks.

Regulatory frameworks also typically include provisions for emergency response planning. This encompasses procedures for containing and cleaning up ferrofluid spills, as well as guidelines for notifying relevant authorities in case of accidents or releases. Training requirements for personnel working with ferrofluids are often specified, ensuring that workers are knowledgeable about potential hazards and proper handling techniques.

As smart infrastructure applications of ferrofluids continue to evolve, safety regulations are subject to periodic review and updates. Regulatory bodies often collaborate with industry experts and research institutions to incorporate the latest scientific findings into safety guidelines. This adaptive approach ensures that safety measures remain effective and relevant as new applications and formulations of ferrofluids emerge in the field of smart infrastructure development.

Environmental safety regulations for ferrofluids address potential risks associated with their release into ecosystems. Guidelines typically require proper containment measures, spill prevention protocols, and disposal procedures that minimize environmental contamination. Manufacturers and users must adhere to strict standards for handling and storage, including the use of sealed containers and secondary containment systems. Regular environmental monitoring may be mandated in areas where ferrofluids are extensively used in infrastructure applications.

Human health considerations form a crucial component of ferrofluid safety regulations. Exposure limits for workers handling these materials are established based on toxicological studies and risk assessments. Personal protective equipment (PPE) requirements, such as gloves, goggles, and respiratory protection, are specified for various handling scenarios. Safety data sheets (SDS) must be readily available, detailing potential health hazards, first aid measures, and proper handling procedures.

Material compatibility is another critical aspect addressed by safety regulations. Guidelines outline the types of materials that can safely come into contact with ferrofluids without degradation or adverse reactions. This includes specifications for storage containers, piping systems, and other infrastructure components that may interact with ferrofluids. Compatibility testing protocols are often mandated to ensure long-term stability and prevent potential failures or leaks.

Regulatory frameworks also typically include provisions for emergency response planning. This encompasses procedures for containing and cleaning up ferrofluid spills, as well as guidelines for notifying relevant authorities in case of accidents or releases. Training requirements for personnel working with ferrofluids are often specified, ensuring that workers are knowledgeable about potential hazards and proper handling techniques.

As smart infrastructure applications of ferrofluids continue to evolve, safety regulations are subject to periodic review and updates. Regulatory bodies often collaborate with industry experts and research institutions to incorporate the latest scientific findings into safety guidelines. This adaptive approach ensures that safety measures remain effective and relevant as new applications and formulations of ferrofluids emerge in the field of smart infrastructure development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!