The Role of Ferrofluid in Optimizing Battery Performance

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Battery Tech Evolution

The evolution of ferrofluid technology in battery optimization has been marked by significant milestones and breakthroughs. Initially developed in the 1960s by NASA, ferrofluids have found their way into various applications, including battery technology, over the past few decades.

In the early stages, researchers primarily focused on understanding the fundamental properties of ferrofluids and their potential applications in energy storage. The 1980s saw the first attempts to incorporate ferrofluids into battery designs, mainly as a means to improve thermal management.

The 1990s brought about a shift towards exploring the magnetic properties of ferrofluids for enhancing battery performance. Scientists began investigating how the unique behavior of ferrofluids under magnetic fields could be leveraged to improve electrolyte distribution and ion transport within batteries.

The turn of the millennium marked a significant leap forward, with researchers developing novel electrode materials incorporating ferrofluid nanoparticles. These advancements led to improved conductivity and increased surface area for electrochemical reactions, resulting in enhanced battery capacity and charge/discharge rates.

In the 2010s, the focus shifted towards optimizing the composition and properties of ferrofluids specifically for battery applications. This period saw the development of tailored ferrofluid formulations designed to address specific challenges in battery performance, such as dendrite formation in lithium-ion batteries.

Recent years have witnessed a surge in research on ferrofluid-based smart electrolytes. These advanced materials can dynamically respond to external stimuli, such as magnetic fields or temperature changes, allowing for real-time optimization of battery performance and safety features.

The latest developments in ferrofluid battery technology include the exploration of hybrid systems that combine ferrofluids with other advanced materials, such as graphene or carbon nanotubes. These innovative approaches aim to synergistically enhance multiple aspects of battery performance, including energy density, power output, and cycle life.

Looking ahead, the evolution of ferrofluid technology in battery optimization is expected to continue at a rapid pace. Emerging trends suggest a focus on developing environmentally friendly ferrofluid formulations and exploring their potential in next-generation battery chemistries, such as solid-state and metal-air batteries.

In the early stages, researchers primarily focused on understanding the fundamental properties of ferrofluids and their potential applications in energy storage. The 1980s saw the first attempts to incorporate ferrofluids into battery designs, mainly as a means to improve thermal management.

The 1990s brought about a shift towards exploring the magnetic properties of ferrofluids for enhancing battery performance. Scientists began investigating how the unique behavior of ferrofluids under magnetic fields could be leveraged to improve electrolyte distribution and ion transport within batteries.

The turn of the millennium marked a significant leap forward, with researchers developing novel electrode materials incorporating ferrofluid nanoparticles. These advancements led to improved conductivity and increased surface area for electrochemical reactions, resulting in enhanced battery capacity and charge/discharge rates.

In the 2010s, the focus shifted towards optimizing the composition and properties of ferrofluids specifically for battery applications. This period saw the development of tailored ferrofluid formulations designed to address specific challenges in battery performance, such as dendrite formation in lithium-ion batteries.

Recent years have witnessed a surge in research on ferrofluid-based smart electrolytes. These advanced materials can dynamically respond to external stimuli, such as magnetic fields or temperature changes, allowing for real-time optimization of battery performance and safety features.

The latest developments in ferrofluid battery technology include the exploration of hybrid systems that combine ferrofluids with other advanced materials, such as graphene or carbon nanotubes. These innovative approaches aim to synergistically enhance multiple aspects of battery performance, including energy density, power output, and cycle life.

Looking ahead, the evolution of ferrofluid technology in battery optimization is expected to continue at a rapid pace. Emerging trends suggest a focus on developing environmentally friendly ferrofluid formulations and exploring their potential in next-generation battery chemistries, such as solid-state and metal-air batteries.

Market Demand Analysis

The market demand for ferrofluid technology in battery optimization is experiencing significant growth, driven by the increasing need for more efficient and high-performance energy storage solutions. As the global shift towards renewable energy and electric vehicles accelerates, the demand for advanced battery technologies has surged. Ferrofluids, with their unique magnetic properties, have emerged as a promising solution to address several key challenges in battery performance.

In the electric vehicle (EV) sector, there is a strong push for batteries that can deliver higher energy density, faster charging times, and longer lifespans. Ferrofluid technology has shown potential in improving thermal management within batteries, which is crucial for maintaining optimal performance and extending battery life. This aligns with the automotive industry's goals of increasing EV range and reducing charging times, making ferrofluid-enhanced batteries an attractive prospect for manufacturers.

The renewable energy storage market is another area where ferrofluid-optimized batteries are gaining traction. As wind and solar power generation becomes more widespread, the need for efficient and reliable energy storage systems grows. Ferrofluid technology can potentially enhance the stability and performance of large-scale battery systems used in grid storage applications, addressing the intermittency issues associated with renewable energy sources.

Consumer electronics represent another significant market for ferrofluid-enhanced batteries. With the ever-increasing power demands of smartphones, laptops, and wearable devices, there is a constant need for batteries that can deliver more power in smaller form factors. Ferrofluid technology's potential to improve energy density and thermal management aligns well with these requirements, potentially leading to longer-lasting and more compact devices.

The industrial sector also shows promise for ferrofluid-optimized batteries. In applications such as uninterruptible power supplies (UPS) and backup power systems, where reliability and longevity are critical, the improved thermal management and potential performance enhancements offered by ferrofluid technology are highly valued.

Market analysts project substantial growth in the ferrofluid market, with battery applications expected to be a key driver. The increasing focus on sustainability and energy efficiency across various industries is likely to further boost demand for ferrofluid-enhanced battery solutions. As research and development in this field progress, we can anticipate a wider adoption of ferrofluid technology in battery systems across multiple sectors.

However, it's important to note that the market is still in its early stages, and widespread commercial adoption will depend on factors such as cost-effectiveness, scalability, and proven long-term performance benefits. As these challenges are addressed, the market potential for ferrofluid-optimized batteries is expected to expand significantly, offering opportunities for both established battery manufacturers and innovative startups in the energy storage sector.

In the electric vehicle (EV) sector, there is a strong push for batteries that can deliver higher energy density, faster charging times, and longer lifespans. Ferrofluid technology has shown potential in improving thermal management within batteries, which is crucial for maintaining optimal performance and extending battery life. This aligns with the automotive industry's goals of increasing EV range and reducing charging times, making ferrofluid-enhanced batteries an attractive prospect for manufacturers.

The renewable energy storage market is another area where ferrofluid-optimized batteries are gaining traction. As wind and solar power generation becomes more widespread, the need for efficient and reliable energy storage systems grows. Ferrofluid technology can potentially enhance the stability and performance of large-scale battery systems used in grid storage applications, addressing the intermittency issues associated with renewable energy sources.

Consumer electronics represent another significant market for ferrofluid-enhanced batteries. With the ever-increasing power demands of smartphones, laptops, and wearable devices, there is a constant need for batteries that can deliver more power in smaller form factors. Ferrofluid technology's potential to improve energy density and thermal management aligns well with these requirements, potentially leading to longer-lasting and more compact devices.

The industrial sector also shows promise for ferrofluid-optimized batteries. In applications such as uninterruptible power supplies (UPS) and backup power systems, where reliability and longevity are critical, the improved thermal management and potential performance enhancements offered by ferrofluid technology are highly valued.

Market analysts project substantial growth in the ferrofluid market, with battery applications expected to be a key driver. The increasing focus on sustainability and energy efficiency across various industries is likely to further boost demand for ferrofluid-enhanced battery solutions. As research and development in this field progress, we can anticipate a wider adoption of ferrofluid technology in battery systems across multiple sectors.

However, it's important to note that the market is still in its early stages, and widespread commercial adoption will depend on factors such as cost-effectiveness, scalability, and proven long-term performance benefits. As these challenges are addressed, the market potential for ferrofluid-optimized batteries is expected to expand significantly, offering opportunities for both established battery manufacturers and innovative startups in the energy storage sector.

Current Challenges

The integration of ferrofluid technology into battery systems presents several significant challenges that researchers and engineers must address. One of the primary obstacles is achieving uniform dispersion of ferrofluid nanoparticles within the battery's electrolyte. Uneven distribution can lead to inconsistent performance and potential hotspots, compromising the battery's efficiency and safety.

Another critical challenge lies in maintaining the long-term stability of ferrofluid within the battery environment. The harsh chemical conditions and repeated charge-discharge cycles can potentially degrade the magnetic nanoparticles, reducing their effectiveness over time. This degradation may lead to a decrease in the battery's thermal management capabilities and overall performance.

The compatibility of ferrofluid with existing battery chemistries and components poses a substantial hurdle. Researchers must ensure that the introduction of ferrofluid does not negatively impact the electrochemical reactions or the structural integrity of the battery. This includes preventing unwanted interactions between the ferrofluid and the electrodes, separators, or other battery materials.

Scaling up ferrofluid-enhanced battery technology from laboratory prototypes to commercial production presents its own set of challenges. The manufacturing processes must be adapted to incorporate ferrofluid efficiently and consistently, while maintaining cost-effectiveness. This may require significant modifications to existing battery production lines and quality control measures.

The optimization of ferrofluid properties for specific battery applications is another area of ongoing research. Different battery chemistries and form factors may require tailored ferrofluid formulations to maximize their benefits. Finding the right balance between magnetic properties, viscosity, and thermal conductivity for each application is a complex task that demands extensive experimentation and modeling.

Regulatory and safety concerns also pose challenges to the widespread adoption of ferrofluid in battery systems. Rigorous testing and certification processes will be necessary to ensure that ferrofluid-enhanced batteries meet or exceed current safety standards. This includes evaluating the long-term environmental impact and developing appropriate recycling and disposal methods for these advanced battery systems.

Lastly, the cost-benefit analysis of incorporating ferrofluid technology into batteries remains a significant consideration. While the potential performance improvements are promising, the additional costs associated with ferrofluid production and integration must be justified by tangible benefits in battery life, efficiency, and safety. Striking the right balance between enhanced performance and economic viability will be crucial for the commercial success of this technology.

Another critical challenge lies in maintaining the long-term stability of ferrofluid within the battery environment. The harsh chemical conditions and repeated charge-discharge cycles can potentially degrade the magnetic nanoparticles, reducing their effectiveness over time. This degradation may lead to a decrease in the battery's thermal management capabilities and overall performance.

The compatibility of ferrofluid with existing battery chemistries and components poses a substantial hurdle. Researchers must ensure that the introduction of ferrofluid does not negatively impact the electrochemical reactions or the structural integrity of the battery. This includes preventing unwanted interactions between the ferrofluid and the electrodes, separators, or other battery materials.

Scaling up ferrofluid-enhanced battery technology from laboratory prototypes to commercial production presents its own set of challenges. The manufacturing processes must be adapted to incorporate ferrofluid efficiently and consistently, while maintaining cost-effectiveness. This may require significant modifications to existing battery production lines and quality control measures.

The optimization of ferrofluid properties for specific battery applications is another area of ongoing research. Different battery chemistries and form factors may require tailored ferrofluid formulations to maximize their benefits. Finding the right balance between magnetic properties, viscosity, and thermal conductivity for each application is a complex task that demands extensive experimentation and modeling.

Regulatory and safety concerns also pose challenges to the widespread adoption of ferrofluid in battery systems. Rigorous testing and certification processes will be necessary to ensure that ferrofluid-enhanced batteries meet or exceed current safety standards. This includes evaluating the long-term environmental impact and developing appropriate recycling and disposal methods for these advanced battery systems.

Lastly, the cost-benefit analysis of incorporating ferrofluid technology into batteries remains a significant consideration. While the potential performance improvements are promising, the additional costs associated with ferrofluid production and integration must be justified by tangible benefits in battery life, efficiency, and safety. Striking the right balance between enhanced performance and economic viability will be crucial for the commercial success of this technology.

Existing Ferrofluid Solutions

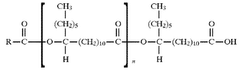

01 Ferrofluid composition for improved battery performance

Ferrofluids with specific compositions can enhance battery performance. These compositions may include magnetic nanoparticles suspended in a carrier fluid, which can improve energy density, conductivity, and overall efficiency of batteries. The unique properties of ferrofluids allow for better heat dissipation and improved electrode-electrolyte interactions.- Ferrofluid composition for improved battery performance: Ferrofluids with specific compositions can enhance battery performance. These compositions may include magnetic nanoparticles suspended in a carrier fluid, which can improve energy density, conductivity, and overall efficiency of the battery. The unique properties of ferrofluids allow for better heat dissipation and improved electrical contact within the battery system.

- Magnetic field control in ferrofluid-based batteries: Utilizing magnetic fields to control the behavior of ferrofluids in batteries can lead to improved performance. This approach allows for dynamic adjustment of fluid properties, enhancing charge distribution, reducing internal resistance, and potentially increasing the battery's lifespan. Magnetic field control can also be used to manage thermal properties and prevent electrode degradation.

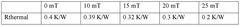

- Ferrofluid-based cooling systems for batteries: Incorporating ferrofluids into battery cooling systems can significantly improve thermal management. The magnetic properties of ferrofluids allow for enhanced heat transfer and more efficient cooling of battery components. This can lead to improved battery performance, increased safety, and extended battery life by preventing overheating and maintaining optimal operating temperatures.

- Ferrofluid electrodes for advanced battery designs: Developing electrodes using ferrofluids can lead to novel battery designs with improved performance characteristics. These electrodes can offer benefits such as increased surface area, enhanced conductivity, and better charge distribution. The unique properties of ferrofluid electrodes may also contribute to faster charging times and higher energy densities in battery systems.

- Ferrofluid-based sealing and insulation in battery systems: Utilizing ferrofluids for sealing and insulation purposes in battery systems can improve overall performance and reliability. Ferrofluid seals can prevent electrolyte leakage, enhance thermal insulation, and provide better protection against environmental factors. This application of ferrofluids can lead to increased battery longevity and improved safety in various operating conditions.

02 Magnetic field manipulation for battery optimization

Applying controlled magnetic fields to ferrofluid-based batteries can optimize their performance. This technique allows for dynamic adjustment of fluid properties, enhancing charge distribution, reducing internal resistance, and potentially increasing the battery's lifespan. Magnetic field manipulation can also be used to control heat distribution within the battery.Expand Specific Solutions03 Ferrofluid-based cooling systems for batteries

Integrating ferrofluid-based cooling systems into battery designs can significantly improve thermal management. These systems utilize the magnetic properties of ferrofluids to efficiently dissipate heat, preventing overheating and extending battery life. The cooling effect can be precisely controlled through magnetic field adjustments, allowing for adaptive thermal regulation.Expand Specific Solutions04 Ferrofluid electrodes for enhanced battery capacity

Incorporating ferrofluids into battery electrodes can lead to increased capacity and improved charge-discharge cycles. The magnetic nanoparticles in ferrofluids can enhance the surface area of electrodes, facilitating better ion exchange and electron transfer. This approach may result in faster charging times and higher energy storage capabilities.Expand Specific Solutions05 Ferrofluid-based sealing and vibration damping in batteries

Utilizing ferrofluids for sealing and vibration damping in battery assemblies can improve overall performance and durability. Ferrofluid seals can prevent electrolyte leakage and contamination, while their vibration damping properties can protect battery components from mechanical stress. This application can lead to more robust and longer-lasting battery designs.Expand Specific Solutions

Key Industry Players

The ferrofluid battery optimization market is in an early growth stage, with increasing interest from both automotive and energy storage sectors. The market size is projected to expand significantly as the technology matures and finds wider applications. Currently, the technology is at a moderate level of maturity, with ongoing research and development efforts. Key players like Toyota Motor Corp., China Overseas Energy Storage Technology, and LG Energy Solution are investing in ferrofluid-based battery innovations. Academic institutions such as MIT and Rutgers University are also contributing to advancements in this field. As the technology progresses, we can expect increased competition and potential breakthroughs from both established companies and emerging startups in the coming years.

Apple, Inc.

Technical Solution: Apple has been investigating the use of ferrofluid in battery technology to improve the performance and longevity of their mobile devices. Their approach involves incorporating ferrofluid as a dynamic heat sink within the battery structure. The ferrofluid is designed to circulate through microchannels embedded in the battery casing, allowing for efficient heat dissipation[2]. Apple's system utilizes miniaturized electromagnets to control the ferrofluid flow, directing it to hotspots as needed. This targeted cooling approach helps maintain optimal operating temperatures across the entire battery, reducing thermal stress and extending battery life. Furthermore, Apple is exploring the integration of ferrofluid-based sensors to provide real-time temperature monitoring and predictive maintenance capabilities for their devices[4].

Strengths: Compact design suitable for mobile devices, targeted cooling capabilities, potential for integrated diagnostics. Weaknesses: Increased manufacturing complexity, potential for leakage in long-term use.

Massachusetts Institute of Technology

Technical Solution: MIT has developed a novel approach using ferrofluid to enhance battery performance. Their research focuses on using ferrofluid as a heat transfer medium in battery thermal management systems. The ferrofluid, composed of magnetic nanoparticles suspended in a carrier fluid, can be precisely controlled by external magnetic fields to optimize heat distribution within the battery pack[1]. This allows for more efficient cooling and temperature regulation, which is crucial for maintaining battery longevity and performance. MIT's system can adapt to varying thermal loads in real-time, adjusting the ferrofluid flow to areas that require more cooling[3]. Additionally, they have explored the use of ferrofluid in energy harvesting applications within batteries, potentially converting waste heat into usable energy[5].

Strengths: Precise thermal management, adaptability to varying loads, potential for energy harvesting. Weaknesses: Complexity of implementation, potential for magnetic interference with battery components.

Core Ferrofluid Innovations

Cooling composition for powertrain of electric vehicles

PatentWO2025061695A1

Innovation

- A ferrofluid comprising a liquid carrier, ferromagnetic particles, and a dispersant is used for direct contact cooling of powertrain elements in electric vehicles, enhancing heat extraction through the application of a magnetic field.

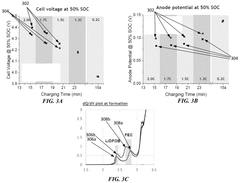

Non-aqueous electrolyte and secondary battery comprising the same

PatentPendingUS20250167301A1

Innovation

- The use of an electrolyte fluid comprising specific compounds such as tris(2,2,2-trifluoroethyl) borate (TFEB) and tris(2,2-difluoroethyl) borate (DFEB) enhances the battery cell's performance by reducing anode overpotential and stabilizing the cathode interface, thereby improving fast charging capabilities and longevity.

Environmental Impact

The integration of ferrofluid technology in battery systems presents both opportunities and challenges from an environmental perspective. While ferrofluids offer potential improvements in battery performance and efficiency, their production and disposal require careful consideration to minimize ecological impact.

Ferrofluids typically consist of nanoscale magnetic particles suspended in a carrier fluid. The production of these nanoparticles often involves energy-intensive processes and the use of potentially hazardous chemicals. However, advancements in green synthesis methods are gradually reducing the environmental footprint of ferrofluid manufacturing. These eco-friendly approaches include the use of plant extracts and biodegradable surfactants, which can significantly decrease the reliance on harmful solvents and reduce energy consumption during production.

The application of ferrofluids in batteries may contribute to extended battery life and improved energy density. This could lead to a reduction in the overall number of batteries produced and discarded, potentially mitigating the environmental burden associated with battery waste. Additionally, the enhanced thermal management capabilities of ferrofluid-based systems may reduce the risk of thermal runaway and battery fires, which can release toxic substances into the environment.

However, the long-term environmental effects of ferrofluids in battery systems remain a subject of ongoing research. The potential leakage or disposal of ferrofluid-containing batteries raises concerns about the release of nanoparticles into ecosystems. These particles may accumulate in soil and water systems, with unknown consequences for flora and fauna. To address this, researchers are exploring biodegradable ferrofluids and developing robust containment strategies to prevent environmental contamination.

The recycling of ferrofluid-enhanced batteries presents another environmental challenge. Current battery recycling processes may not be adequately equipped to handle the unique properties of ferrofluids, potentially leading to inefficient resource recovery or increased processing waste. Developing specialized recycling techniques for these advanced battery systems is crucial to ensure the sustainable management of resources and minimize environmental impact.

As the technology progresses, life cycle assessments (LCAs) will play a vital role in quantifying the environmental impact of ferrofluid-enhanced batteries. These assessments will help identify areas for improvement in the production, use, and end-of-life stages of these batteries, guiding the development of more sustainable practices throughout the product lifecycle.

In conclusion, while ferrofluids show promise in optimizing battery performance, their environmental impact must be carefully managed. Balancing the potential benefits with ecological considerations will be essential for the responsible development and implementation of this technology in the battery industry.

Ferrofluids typically consist of nanoscale magnetic particles suspended in a carrier fluid. The production of these nanoparticles often involves energy-intensive processes and the use of potentially hazardous chemicals. However, advancements in green synthesis methods are gradually reducing the environmental footprint of ferrofluid manufacturing. These eco-friendly approaches include the use of plant extracts and biodegradable surfactants, which can significantly decrease the reliance on harmful solvents and reduce energy consumption during production.

The application of ferrofluids in batteries may contribute to extended battery life and improved energy density. This could lead to a reduction in the overall number of batteries produced and discarded, potentially mitigating the environmental burden associated with battery waste. Additionally, the enhanced thermal management capabilities of ferrofluid-based systems may reduce the risk of thermal runaway and battery fires, which can release toxic substances into the environment.

However, the long-term environmental effects of ferrofluids in battery systems remain a subject of ongoing research. The potential leakage or disposal of ferrofluid-containing batteries raises concerns about the release of nanoparticles into ecosystems. These particles may accumulate in soil and water systems, with unknown consequences for flora and fauna. To address this, researchers are exploring biodegradable ferrofluids and developing robust containment strategies to prevent environmental contamination.

The recycling of ferrofluid-enhanced batteries presents another environmental challenge. Current battery recycling processes may not be adequately equipped to handle the unique properties of ferrofluids, potentially leading to inefficient resource recovery or increased processing waste. Developing specialized recycling techniques for these advanced battery systems is crucial to ensure the sustainable management of resources and minimize environmental impact.

As the technology progresses, life cycle assessments (LCAs) will play a vital role in quantifying the environmental impact of ferrofluid-enhanced batteries. These assessments will help identify areas for improvement in the production, use, and end-of-life stages of these batteries, guiding the development of more sustainable practices throughout the product lifecycle.

In conclusion, while ferrofluids show promise in optimizing battery performance, their environmental impact must be carefully managed. Balancing the potential benefits with ecological considerations will be essential for the responsible development and implementation of this technology in the battery industry.

Safety Considerations

The integration of ferrofluid in battery systems introduces several safety considerations that must be carefully addressed. Ferrofluids, being magnetic nanoparticle suspensions, possess unique properties that can potentially impact battery safety. One primary concern is the potential for ferrofluid leakage or migration within the battery structure. If not properly contained, ferrofluid could compromise the integrity of battery components, leading to short circuits or other electrical failures.

The magnetic properties of ferrofluids also raise questions about their long-term stability within battery environments. Exposure to strong electromagnetic fields, which are inherent in battery operations, could potentially alter the ferrofluid's behavior or composition over time. This necessitates thorough testing to ensure the ferrofluid remains stable and functional throughout the battery's lifecycle.

Another critical safety aspect is the chemical compatibility between ferrofluids and other battery materials. The nanoparticles in ferrofluids, typically iron oxides, must not react adversely with electrolytes, electrodes, or separator materials. Any unforeseen chemical interactions could lead to degradation of battery components or the generation of harmful byproducts, potentially compromising both performance and safety.

The thermal management implications of incorporating ferrofluids also warrant careful consideration. While ferrofluids may enhance heat dissipation, their behavior under extreme temperature conditions, such as those encountered in battery thermal runaway scenarios, must be thoroughly evaluated. It is crucial to ensure that ferrofluids do not exacerbate thermal issues or introduce new failure modes under high-stress conditions.

Environmental and health considerations are equally important. The production, handling, and disposal of ferrofluid-enhanced batteries must be assessed for potential environmental impacts and health risks. Nanoparticles, if released, could pose inhalation or absorption hazards, necessitating stringent safety protocols throughout the battery's lifecycle.

Regulatory compliance is another key aspect of safety considerations. As a novel technology in battery applications, ferrofluid integration may require new or modified safety standards and certifications. Manufacturers must work closely with regulatory bodies to ensure that ferrofluid-enhanced batteries meet all applicable safety requirements and undergo appropriate testing protocols.

Lastly, the scalability of safety measures from laboratory to commercial production must be carefully planned. Safety protocols that are effective in small-scale experiments may need significant adaptation for large-scale manufacturing and deployment. This includes developing robust quality control measures to ensure consistent safety performance across mass-produced batteries incorporating ferrofluid technology.

The magnetic properties of ferrofluids also raise questions about their long-term stability within battery environments. Exposure to strong electromagnetic fields, which are inherent in battery operations, could potentially alter the ferrofluid's behavior or composition over time. This necessitates thorough testing to ensure the ferrofluid remains stable and functional throughout the battery's lifecycle.

Another critical safety aspect is the chemical compatibility between ferrofluids and other battery materials. The nanoparticles in ferrofluids, typically iron oxides, must not react adversely with electrolytes, electrodes, or separator materials. Any unforeseen chemical interactions could lead to degradation of battery components or the generation of harmful byproducts, potentially compromising both performance and safety.

The thermal management implications of incorporating ferrofluids also warrant careful consideration. While ferrofluids may enhance heat dissipation, their behavior under extreme temperature conditions, such as those encountered in battery thermal runaway scenarios, must be thoroughly evaluated. It is crucial to ensure that ferrofluids do not exacerbate thermal issues or introduce new failure modes under high-stress conditions.

Environmental and health considerations are equally important. The production, handling, and disposal of ferrofluid-enhanced batteries must be assessed for potential environmental impacts and health risks. Nanoparticles, if released, could pose inhalation or absorption hazards, necessitating stringent safety protocols throughout the battery's lifecycle.

Regulatory compliance is another key aspect of safety considerations. As a novel technology in battery applications, ferrofluid integration may require new or modified safety standards and certifications. Manufacturers must work closely with regulatory bodies to ensure that ferrofluid-enhanced batteries meet all applicable safety requirements and undergo appropriate testing protocols.

Lastly, the scalability of safety measures from laboratory to commercial production must be carefully planned. Safety protocols that are effective in small-scale experiments may need significant adaptation for large-scale manufacturing and deployment. This includes developing robust quality control measures to ensure consistent safety performance across mass-produced batteries incorporating ferrofluid technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!