Exploring Ferrofluid's Potential in Novel Sensor Development

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Sensor Tech Evolution and Objectives

Ferrofluids, discovered in the 1960s by NASA, have evolved from a space-age curiosity to a versatile material with significant potential in sensor technology. These colloidal suspensions of magnetic nanoparticles in a carrier fluid exhibit unique properties that respond to magnetic fields, making them ideal candidates for novel sensor applications.

The evolution of ferrofluid technology has been marked by significant milestones. Initially developed for controlling fuel in zero gravity, ferrofluids have found applications in various fields, including electronics, mechanical engineering, and biomedical sciences. The progression from basic magnetic fluid dynamics to sophisticated sensor designs has been driven by advancements in nanotechnology and materials science.

In the context of sensor development, ferrofluids have shown remarkable versatility. Their ability to change shape, viscosity, and other physical properties in response to magnetic fields has opened up new avenues for sensing applications. Early ferrofluid sensors were primarily used for simple position and tilt detection. However, recent research has expanded their potential to include pressure sensors, accelerometers, and even biosensors.

The objectives of exploring ferrofluids in novel sensor development are multifaceted. Primarily, researchers aim to leverage the unique properties of ferrofluids to create sensors with enhanced sensitivity, reliability, and adaptability. One key goal is to develop sensors that can operate in extreme environments where traditional sensors fail. This includes high-temperature settings, corrosive atmospheres, and areas with intense electromagnetic interference.

Another objective is to miniaturize sensor technology. Ferrofluids' ability to be manipulated at the nanoscale offers promising prospects for developing ultra-compact sensors for applications in microelectronics and nanotechnology. Additionally, there is a growing interest in creating multi-functional sensors that can simultaneously measure multiple parameters, such as pressure, temperature, and magnetic field strength.

Researchers are also exploring the potential of ferrofluids in creating self-healing and self-calibrating sensors. The fluid nature of these materials presents opportunities for developing sensors that can adapt to changing conditions and maintain accuracy over extended periods without manual intervention.

In the biomedical field, a key objective is to develop non-invasive diagnostic tools using ferrofluid-based sensors. This includes research into magnetic nanoparticle-based biosensors for detecting specific biomolecules or pathogens with high sensitivity and specificity.

As we look to the future, the evolution of ferrofluid sensor technology is expected to continue at a rapid pace. Objectives include improving the stability and longevity of ferrofluid-based sensors, enhancing their response time and accuracy, and expanding their application range. The integration of ferrofluid sensors with emerging technologies like artificial intelligence and the Internet of Things is also a key focus area, aiming to create smart, interconnected sensing systems capable of real-time data analysis and decision-making.

The evolution of ferrofluid technology has been marked by significant milestones. Initially developed for controlling fuel in zero gravity, ferrofluids have found applications in various fields, including electronics, mechanical engineering, and biomedical sciences. The progression from basic magnetic fluid dynamics to sophisticated sensor designs has been driven by advancements in nanotechnology and materials science.

In the context of sensor development, ferrofluids have shown remarkable versatility. Their ability to change shape, viscosity, and other physical properties in response to magnetic fields has opened up new avenues for sensing applications. Early ferrofluid sensors were primarily used for simple position and tilt detection. However, recent research has expanded their potential to include pressure sensors, accelerometers, and even biosensors.

The objectives of exploring ferrofluids in novel sensor development are multifaceted. Primarily, researchers aim to leverage the unique properties of ferrofluids to create sensors with enhanced sensitivity, reliability, and adaptability. One key goal is to develop sensors that can operate in extreme environments where traditional sensors fail. This includes high-temperature settings, corrosive atmospheres, and areas with intense electromagnetic interference.

Another objective is to miniaturize sensor technology. Ferrofluids' ability to be manipulated at the nanoscale offers promising prospects for developing ultra-compact sensors for applications in microelectronics and nanotechnology. Additionally, there is a growing interest in creating multi-functional sensors that can simultaneously measure multiple parameters, such as pressure, temperature, and magnetic field strength.

Researchers are also exploring the potential of ferrofluids in creating self-healing and self-calibrating sensors. The fluid nature of these materials presents opportunities for developing sensors that can adapt to changing conditions and maintain accuracy over extended periods without manual intervention.

In the biomedical field, a key objective is to develop non-invasive diagnostic tools using ferrofluid-based sensors. This includes research into magnetic nanoparticle-based biosensors for detecting specific biomolecules or pathogens with high sensitivity and specificity.

As we look to the future, the evolution of ferrofluid sensor technology is expected to continue at a rapid pace. Objectives include improving the stability and longevity of ferrofluid-based sensors, enhancing their response time and accuracy, and expanding their application range. The integration of ferrofluid sensors with emerging technologies like artificial intelligence and the Internet of Things is also a key focus area, aiming to create smart, interconnected sensing systems capable of real-time data analysis and decision-making.

Market Demand for Ferrofluid-based Sensors

The market demand for ferrofluid-based sensors is experiencing significant growth, driven by advancements in nanotechnology and the increasing need for high-precision sensing devices across various industries. Ferrofluids, which are colloidal liquids containing magnetic nanoparticles, offer unique properties that make them particularly suitable for sensor applications.

In the automotive sector, ferrofluid-based sensors are gaining traction for their potential in improving vehicle safety systems. These sensors can provide more accurate and responsive measurements for applications such as anti-lock braking systems, traction control, and adaptive suspension systems. The automotive industry's shift towards electric and autonomous vehicles is further fueling the demand for advanced sensing technologies, including those based on ferrofluids.

The aerospace industry is another key market for ferrofluid sensors. These sensors can be used in flight control systems, providing precise measurements of aircraft orientation and movement. The ability of ferrofluid sensors to operate in extreme conditions, such as high altitudes and varying temperatures, makes them particularly valuable in this sector.

In the medical field, ferrofluid-based sensors are showing promise in diagnostic and monitoring devices. Their high sensitivity and ability to detect minute changes in magnetic fields make them suitable for applications such as magnetic resonance imaging (MRI) enhancements and biosensors for detecting specific molecules or pathogens.

The industrial automation sector is also driving demand for ferrofluid sensors. These sensors can be used in various applications, including position sensing, flow measurement, and vibration detection. The increasing adoption of Industry 4.0 technologies and the Internet of Things (IoT) is expected to further boost the demand for advanced sensing solutions, including those based on ferrofluids.

Environmental monitoring is another area where ferrofluid sensors are gaining attention. Their ability to detect small changes in magnetic fields can be leveraged for applications such as water quality monitoring, pollution detection, and geological surveys.

The consumer electronics market is also showing interest in ferrofluid-based sensors. These sensors could potentially be used in smartphones, wearables, and other devices for applications such as motion sensing, gesture recognition, and haptic feedback systems.

While the market for ferrofluid-based sensors is still in its early stages, it is expected to grow significantly in the coming years. The unique properties of ferrofluids, combined with ongoing research and development efforts, are likely to open up new applications and market opportunities. However, challenges such as cost-effectiveness and scalability of production will need to be addressed to fully realize the market potential of these innovative sensors.

In the automotive sector, ferrofluid-based sensors are gaining traction for their potential in improving vehicle safety systems. These sensors can provide more accurate and responsive measurements for applications such as anti-lock braking systems, traction control, and adaptive suspension systems. The automotive industry's shift towards electric and autonomous vehicles is further fueling the demand for advanced sensing technologies, including those based on ferrofluids.

The aerospace industry is another key market for ferrofluid sensors. These sensors can be used in flight control systems, providing precise measurements of aircraft orientation and movement. The ability of ferrofluid sensors to operate in extreme conditions, such as high altitudes and varying temperatures, makes them particularly valuable in this sector.

In the medical field, ferrofluid-based sensors are showing promise in diagnostic and monitoring devices. Their high sensitivity and ability to detect minute changes in magnetic fields make them suitable for applications such as magnetic resonance imaging (MRI) enhancements and biosensors for detecting specific molecules or pathogens.

The industrial automation sector is also driving demand for ferrofluid sensors. These sensors can be used in various applications, including position sensing, flow measurement, and vibration detection. The increasing adoption of Industry 4.0 technologies and the Internet of Things (IoT) is expected to further boost the demand for advanced sensing solutions, including those based on ferrofluids.

Environmental monitoring is another area where ferrofluid sensors are gaining attention. Their ability to detect small changes in magnetic fields can be leveraged for applications such as water quality monitoring, pollution detection, and geological surveys.

The consumer electronics market is also showing interest in ferrofluid-based sensors. These sensors could potentially be used in smartphones, wearables, and other devices for applications such as motion sensing, gesture recognition, and haptic feedback systems.

While the market for ferrofluid-based sensors is still in its early stages, it is expected to grow significantly in the coming years. The unique properties of ferrofluids, combined with ongoing research and development efforts, are likely to open up new applications and market opportunities. However, challenges such as cost-effectiveness and scalability of production will need to be addressed to fully realize the market potential of these innovative sensors.

Current Challenges in Ferrofluid Sensor Development

Despite the promising potential of ferrofluid-based sensors, several significant challenges currently hinder their widespread adoption and development. One of the primary obstacles is the long-term stability of ferrofluids. These colloidal suspensions tend to aggregate over time, leading to changes in their magnetic properties and overall performance. This instability can result in inconsistent sensor readings and reduced reliability, particularly in applications requiring prolonged use or exposure to varying environmental conditions.

Another critical challenge lies in the precise control and manipulation of ferrofluids within sensor devices. The complex interplay between magnetic fields, surface tension, and fluid dynamics makes it difficult to achieve consistent and repeatable sensor responses. This issue is particularly pronounced in miniaturized sensor designs, where even small variations in ferrofluid behavior can significantly impact sensor accuracy and sensitivity.

The temperature sensitivity of ferrofluids presents an additional hurdle in sensor development. Ferrofluid properties, including viscosity and magnetic susceptibility, can change dramatically with temperature fluctuations. This temperature dependence complicates the design of sensors intended for use across a wide range of environmental conditions, necessitating complex compensation mechanisms or limiting their applicability in certain scenarios.

Biocompatibility and environmental concerns also pose challenges, especially for sensors intended for medical or environmental monitoring applications. While some ferrofluids have shown promise in biomedical contexts, ensuring long-term safety and preventing potential toxicity remain areas of ongoing research and development.

Furthermore, the manufacturing and integration of ferrofluid-based sensors into existing systems present significant engineering challenges. Achieving consistent quality in ferrofluid production, preventing contamination, and developing effective sealing mechanisms to contain the fluid within sensor devices are all critical issues that need to be addressed for large-scale production and deployment.

Lastly, the cost-effectiveness of ferrofluid sensors compared to existing sensor technologies remains a concern. While ferrofluids offer unique capabilities, the materials and manufacturing processes involved can be expensive, potentially limiting their adoption in cost-sensitive applications. Overcoming these economic barriers while maintaining the performance advantages of ferrofluid sensors is crucial for their commercial viability and widespread implementation.

Another critical challenge lies in the precise control and manipulation of ferrofluids within sensor devices. The complex interplay between magnetic fields, surface tension, and fluid dynamics makes it difficult to achieve consistent and repeatable sensor responses. This issue is particularly pronounced in miniaturized sensor designs, where even small variations in ferrofluid behavior can significantly impact sensor accuracy and sensitivity.

The temperature sensitivity of ferrofluids presents an additional hurdle in sensor development. Ferrofluid properties, including viscosity and magnetic susceptibility, can change dramatically with temperature fluctuations. This temperature dependence complicates the design of sensors intended for use across a wide range of environmental conditions, necessitating complex compensation mechanisms or limiting their applicability in certain scenarios.

Biocompatibility and environmental concerns also pose challenges, especially for sensors intended for medical or environmental monitoring applications. While some ferrofluids have shown promise in biomedical contexts, ensuring long-term safety and preventing potential toxicity remain areas of ongoing research and development.

Furthermore, the manufacturing and integration of ferrofluid-based sensors into existing systems present significant engineering challenges. Achieving consistent quality in ferrofluid production, preventing contamination, and developing effective sealing mechanisms to contain the fluid within sensor devices are all critical issues that need to be addressed for large-scale production and deployment.

Lastly, the cost-effectiveness of ferrofluid sensors compared to existing sensor technologies remains a concern. While ferrofluids offer unique capabilities, the materials and manufacturing processes involved can be expensive, potentially limiting their adoption in cost-sensitive applications. Overcoming these economic barriers while maintaining the performance advantages of ferrofluid sensors is crucial for their commercial viability and widespread implementation.

Existing Ferrofluid Sensor Solutions

01 Composition and preparation of ferrofluids

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with a surfactant to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication systems, particularly in rotating shaft seals. They provide effective sealing against pressure differentials and contaminants while reducing friction. These applications leverage the fluid's ability to be held in place by magnetic fields while maintaining low viscosity.

- Thermal management and heat transfer: Ferrofluids exhibit enhanced heat transfer properties due to their magnetic nature. They are used in cooling systems for electronic devices and in thermal management applications. The fluid's movement can be controlled by external magnetic fields, allowing for directed heat dissipation and improved thermal conductivity.

- Damping and vibration control: The unique properties of ferrofluids make them excellent for damping and vibration control applications. They can be used in shock absorbers, inertial dampers, and acoustic devices. The fluid's response to magnetic fields allows for adaptive damping characteristics and improved system performance.

- Sensing and measurement applications: Ferrofluids are employed in various sensing and measurement devices. They are used in accelerometers, inclinometers, and pressure sensors. The fluid's response to magnetic fields and gravity enables precise measurements and detection of motion or orientation changes.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide a liquid barrier that can be controlled by magnetic fields, offering advantages in terms of low friction, long life, and the ability to operate in vacuum environments.Expand Specific Solutions03 Magnetic field-responsive devices

Ferrofluids are utilized in various devices that respond to magnetic fields. These include actuators, sensors, and dampers. The unique properties of ferrofluids allow for precise control and manipulation of fluid behavior in response to external magnetic fields, enabling novel applications in areas such as robotics and vibration control.Expand Specific Solutions04 Heat transfer and cooling applications

Ferrofluids have found applications in heat transfer and cooling systems. Their ability to be manipulated by magnetic fields allows for enhanced heat transfer in targeted areas. This property is particularly useful in electronic cooling applications, where precise thermal management is crucial.Expand Specific Solutions05 Measurement and analysis techniques

Various techniques have been developed for measuring and analyzing the properties of ferrofluids. These include methods for determining particle size distribution, magnetic susceptibility, and rheological properties. Advanced imaging and spectroscopic techniques are also employed to characterize the behavior of ferrofluids under different conditions.Expand Specific Solutions

Key Players in Ferrofluid Sensor Industry

The ferrofluid sensor development market is in an early growth stage, characterized by increasing research activities and emerging commercial applications. While the market size remains relatively small, it shows significant potential for expansion due to the unique properties of ferrofluids. The technology's maturity varies across different applications, with some areas more advanced than others. Key players in this field include Honeywell International Technologies Ltd., known for their expertise in sensor technologies, and academic institutions like Chongqing University and Northwestern University, which are driving fundamental research. The University of California and MultiDimension Technology Co., Ltd. are also making notable contributions, indicating a blend of academic and industrial efforts in advancing ferrofluid-based sensor technologies.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed a novel ferrofluid-based sensor technology for precise measurement of angular position and velocity. The sensor utilizes the unique magnetic properties of ferrofluids to create a highly sensitive and accurate measurement system. The ferrofluid is contained within a sealed chamber and responds to changes in magnetic field caused by the rotation of a nearby permanent magnet. This movement is then detected by Hall effect sensors, allowing for non-contact measurement of rotational parameters[1][3]. The technology offers improved reliability and durability compared to traditional mechanical sensors, as there are no moving parts in direct contact. Honeywell's ferrofluid sensors have found applications in aerospace, automotive, and industrial control systems, providing high-resolution angular measurements in harsh environments[2].

Strengths: High accuracy, non-contact measurement, durability in harsh environments. Weaknesses: Potential temperature sensitivity, need for careful magnetic shielding.

The Regents of the University of California

Technical Solution: The University of California has pioneered a ferrofluid-based wearable sensor for continuous health monitoring. This innovative approach uses a thin layer of ferrofluid encapsulated in a flexible polymer matrix. When subjected to mechanical deformation, the ferrofluid's magnetic properties change, which is detected by integrated magnetic sensors. The system can measure various physiological parameters such as pulse, respiration rate, and muscle movements[4]. The sensor's flexibility allows it to conform to the body's contours, providing accurate measurements without impeding movement. Additionally, the research team has developed signal processing algorithms to filter out noise and extract meaningful health data from the sensor readings[5]. This technology shows promise for applications in personalized medicine, sports performance monitoring, and early disease detection.

Strengths: Non-invasive, continuous monitoring, adaptable to various body locations. Weaknesses: Potential for magnetic interference, need for frequent calibration.

Core Innovations in Ferrofluid Sensor Tech

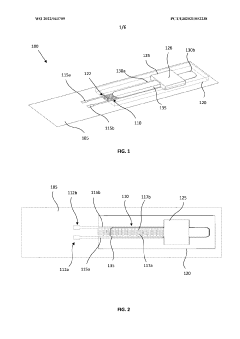

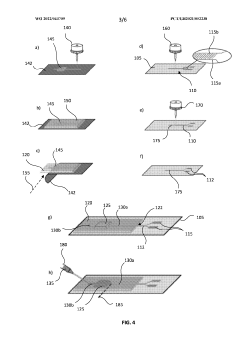

Tubular multifunction sensor in fluids method for production and use thereof

PatentWO2009100988A2

Innovation

- A method for manufacturing tubular multifunction sensors using ferromagnetic micro/nano-tubes with controlled dimensions and magnetic content, which can be precisely positioned and used as single portable sensors in liquids, avoiding contamination by applying an external magnetic field to measure rotational dynamics.

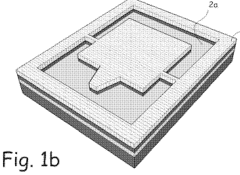

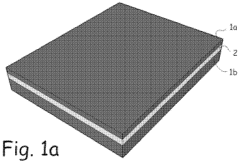

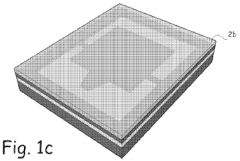

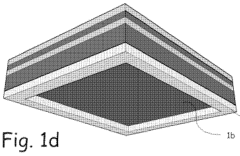

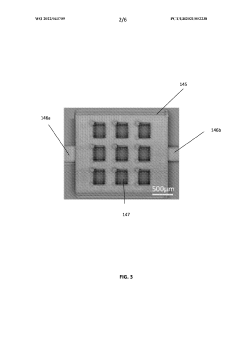

A microfluidic sensor

PatentWO2022043709A1

Innovation

- A microfluidic sensor with a deformable capacitive element and dielectric sensing liquid, where the reservoir portion deforms to displace the liquid along a channel, changing capacitance without altering electrode distance, and an insulative coating to protect electrodes, allowing for sensitive and robust force measurement across a wide range.

Environmental Impact of Ferrofluid Sensors

The development and deployment of ferrofluid-based sensors raise important environmental considerations that must be carefully evaluated. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, have unique properties that make them attractive for sensor applications. However, their potential environmental impact requires thorough assessment.

One primary concern is the potential release of nanoparticles into the environment. While ferrofluids are typically contained within sealed sensor systems, there is a risk of leakage or improper disposal. The small size of these particles allows them to easily disperse in air, water, and soil, potentially affecting ecosystems and organisms. Studies have shown that some nanoparticles can accumulate in living tissues, leading to potential toxicity issues in plants and animals.

The production process of ferrofluids also warrants attention from an environmental perspective. The synthesis of magnetic nanoparticles often involves chemical processes that may generate hazardous waste. Ensuring proper handling and disposal of these byproducts is crucial to minimize environmental contamination. Additionally, the energy-intensive nature of nanoparticle production contributes to the overall carbon footprint of ferrofluid sensor manufacturing.

On the positive side, ferrofluid sensors have the potential to contribute to environmental monitoring and protection. Their high sensitivity and versatility make them suitable for detecting pollutants, monitoring water quality, and measuring environmental parameters with greater accuracy. This could lead to more effective environmental management strategies and early warning systems for ecological threats.

The lifecycle of ferrofluid sensors is another important consideration. As these devices become more widespread, proper recycling and disposal methods must be developed to prevent the accumulation of electronic waste containing nanomaterials. This requires the establishment of specialized recycling facilities and protocols to safely handle and recover materials from decommissioned sensors.

Regulatory frameworks and safety guidelines for the use of ferrofluids in sensors are still evolving. As research progresses, it is essential to establish comprehensive standards for the production, use, and disposal of ferrofluid-based devices. This includes developing protocols for risk assessment, safety testing, and environmental impact studies specific to nanomaterial-containing sensors.

In conclusion, while ferrofluid sensors offer promising capabilities for various applications, their environmental impact must be carefully managed. Balancing the potential benefits with responsible development and deployment practices is crucial for ensuring the sustainable integration of this technology into our environmental monitoring and sensing systems.

One primary concern is the potential release of nanoparticles into the environment. While ferrofluids are typically contained within sealed sensor systems, there is a risk of leakage or improper disposal. The small size of these particles allows them to easily disperse in air, water, and soil, potentially affecting ecosystems and organisms. Studies have shown that some nanoparticles can accumulate in living tissues, leading to potential toxicity issues in plants and animals.

The production process of ferrofluids also warrants attention from an environmental perspective. The synthesis of magnetic nanoparticles often involves chemical processes that may generate hazardous waste. Ensuring proper handling and disposal of these byproducts is crucial to minimize environmental contamination. Additionally, the energy-intensive nature of nanoparticle production contributes to the overall carbon footprint of ferrofluid sensor manufacturing.

On the positive side, ferrofluid sensors have the potential to contribute to environmental monitoring and protection. Their high sensitivity and versatility make them suitable for detecting pollutants, monitoring water quality, and measuring environmental parameters with greater accuracy. This could lead to more effective environmental management strategies and early warning systems for ecological threats.

The lifecycle of ferrofluid sensors is another important consideration. As these devices become more widespread, proper recycling and disposal methods must be developed to prevent the accumulation of electronic waste containing nanomaterials. This requires the establishment of specialized recycling facilities and protocols to safely handle and recover materials from decommissioned sensors.

Regulatory frameworks and safety guidelines for the use of ferrofluids in sensors are still evolving. As research progresses, it is essential to establish comprehensive standards for the production, use, and disposal of ferrofluid-based devices. This includes developing protocols for risk assessment, safety testing, and environmental impact studies specific to nanomaterial-containing sensors.

In conclusion, while ferrofluid sensors offer promising capabilities for various applications, their environmental impact must be carefully managed. Balancing the potential benefits with responsible development and deployment practices is crucial for ensuring the sustainable integration of this technology into our environmental monitoring and sensing systems.

Ferrofluid Sensor Standardization

The standardization of ferrofluid sensors is a critical step in advancing their development and widespread adoption. As the field of ferrofluid-based sensing technologies continues to expand, establishing uniform guidelines and protocols becomes increasingly important. These standards will ensure consistency in sensor performance, reliability, and compatibility across different applications and industries.

One of the primary areas requiring standardization is the composition and quality of ferrofluids used in sensor applications. Defining specific ranges for particle size, concentration, and magnetic properties will help manufacturers produce sensors with predictable and reproducible characteristics. This standardization will also facilitate easier comparison and evaluation of different sensor designs.

Measurement protocols and calibration procedures form another crucial aspect of ferrofluid sensor standardization. Establishing standardized methods for assessing sensor sensitivity, response time, and accuracy will enable more meaningful comparisons between different sensor types and brands. These protocols should account for various environmental factors that may influence sensor performance, such as temperature, humidity, and external magnetic fields.

Standardization efforts should also address the interface and output formats of ferrofluid sensors. Defining common communication protocols and data formats will enhance interoperability and integration with existing systems and equipment. This standardization will be particularly beneficial in industries where multiple sensors need to work together seamlessly, such as in industrial automation or environmental monitoring.

Safety considerations are another vital component of ferrofluid sensor standardization. Establishing guidelines for the safe handling, storage, and disposal of ferrofluids used in sensors will help mitigate potential environmental and health risks. These standards should also address the long-term stability and degradation of ferrofluids to ensure consistent sensor performance over time.

As the application areas for ferrofluid sensors continue to diversify, industry-specific standards may also need to be developed. For instance, sensors used in medical applications may require additional certifications and quality control measures compared to those used in industrial settings. Collaborations between academic institutions, industry leaders, and regulatory bodies will be essential in developing comprehensive and widely accepted standards for ferrofluid sensors.

One of the primary areas requiring standardization is the composition and quality of ferrofluids used in sensor applications. Defining specific ranges for particle size, concentration, and magnetic properties will help manufacturers produce sensors with predictable and reproducible characteristics. This standardization will also facilitate easier comparison and evaluation of different sensor designs.

Measurement protocols and calibration procedures form another crucial aspect of ferrofluid sensor standardization. Establishing standardized methods for assessing sensor sensitivity, response time, and accuracy will enable more meaningful comparisons between different sensor types and brands. These protocols should account for various environmental factors that may influence sensor performance, such as temperature, humidity, and external magnetic fields.

Standardization efforts should also address the interface and output formats of ferrofluid sensors. Defining common communication protocols and data formats will enhance interoperability and integration with existing systems and equipment. This standardization will be particularly beneficial in industries where multiple sensors need to work together seamlessly, such as in industrial automation or environmental monitoring.

Safety considerations are another vital component of ferrofluid sensor standardization. Establishing guidelines for the safe handling, storage, and disposal of ferrofluids used in sensors will help mitigate potential environmental and health risks. These standards should also address the long-term stability and degradation of ferrofluids to ensure consistent sensor performance over time.

As the application areas for ferrofluid sensors continue to diversify, industry-specific standards may also need to be developed. For instance, sensors used in medical applications may require additional certifications and quality control measures compared to those used in industrial settings. Collaborations between academic institutions, industry leaders, and regulatory bodies will be essential in developing comprehensive and widely accepted standards for ferrofluid sensors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!