How circular economy principles guide PHEV design

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHEV Circular Design Evolution

The evolution of PHEV (Plug-in Hybrid Electric Vehicle) circular design has been shaped by the growing emphasis on sustainability and resource efficiency in the automotive industry. This progression can be traced through several key stages, each marked by significant technological advancements and shifts in design philosophy.

In the early 2000s, the initial focus was on developing hybrid powertrains that could reduce fuel consumption and emissions. These early PHEVs primarily aimed to combine the benefits of electric and combustion engines without significant consideration for end-of-life recycling or material recovery.

As circular economy principles gained traction in the mid-2010s, PHEV designers began incorporating more recyclable materials into vehicle components. This phase saw the introduction of bio-based plastics, recycled metals, and easily separable parts to facilitate future recycling processes.

The next stage, emerging around 2018-2020, emphasized modular design approaches. This strategy allowed for easier component replacement and upgrades, extending the vehicle's lifespan and reducing waste. Manufacturers started designing PHEVs with standardized battery packs and powertrain components that could be easily swapped or refurbished.

Recent years have witnessed a shift towards "design for disassembly" principles in PHEV development. This approach prioritizes the use of reversible joining techniques, such as mechanical fasteners instead of adhesives, enabling more efficient end-of-life vehicle dismantling and material recovery.

The latest evolution in PHEV circular design focuses on the concept of "material passports." This involves detailed tracking of materials used in vehicle production, facilitating more effective recycling and reuse strategies. Advanced digital technologies, such as blockchain, are being employed to maintain accurate records of material composition and lifecycle.

Looking forward, the next phase of PHEV circular design is likely to integrate advanced AI and IoT technologies. These will enable predictive maintenance, optimize vehicle performance, and further extend the lifespan of components. Additionally, there is a growing trend towards the development of "closed-loop" supply chains, where manufacturers take responsibility for the entire lifecycle of their vehicles, from production to recycling.

This evolution reflects a fundamental shift in how PHEVs are conceptualized – from products designed for a single lifecycle to complex systems designed for multiple use cycles and eventual full material recovery. As circular economy principles continue to guide PHEV design, we can expect further innovations that push the boundaries of sustainability in automotive engineering.

In the early 2000s, the initial focus was on developing hybrid powertrains that could reduce fuel consumption and emissions. These early PHEVs primarily aimed to combine the benefits of electric and combustion engines without significant consideration for end-of-life recycling or material recovery.

As circular economy principles gained traction in the mid-2010s, PHEV designers began incorporating more recyclable materials into vehicle components. This phase saw the introduction of bio-based plastics, recycled metals, and easily separable parts to facilitate future recycling processes.

The next stage, emerging around 2018-2020, emphasized modular design approaches. This strategy allowed for easier component replacement and upgrades, extending the vehicle's lifespan and reducing waste. Manufacturers started designing PHEVs with standardized battery packs and powertrain components that could be easily swapped or refurbished.

Recent years have witnessed a shift towards "design for disassembly" principles in PHEV development. This approach prioritizes the use of reversible joining techniques, such as mechanical fasteners instead of adhesives, enabling more efficient end-of-life vehicle dismantling and material recovery.

The latest evolution in PHEV circular design focuses on the concept of "material passports." This involves detailed tracking of materials used in vehicle production, facilitating more effective recycling and reuse strategies. Advanced digital technologies, such as blockchain, are being employed to maintain accurate records of material composition and lifecycle.

Looking forward, the next phase of PHEV circular design is likely to integrate advanced AI and IoT technologies. These will enable predictive maintenance, optimize vehicle performance, and further extend the lifespan of components. Additionally, there is a growing trend towards the development of "closed-loop" supply chains, where manufacturers take responsibility for the entire lifecycle of their vehicles, from production to recycling.

This evolution reflects a fundamental shift in how PHEVs are conceptualized – from products designed for a single lifecycle to complex systems designed for multiple use cycles and eventual full material recovery. As circular economy principles continue to guide PHEV design, we can expect further innovations that push the boundaries of sustainability in automotive engineering.

Circular Economy Market Drivers

The circular economy has emerged as a powerful market driver for the design and development of Plug-in Hybrid Electric Vehicles (PHEVs). This paradigm shift is primarily fueled by increasing environmental concerns, resource scarcity, and the growing demand for sustainable transportation solutions. Governments worldwide are implementing stringent regulations and policies to reduce carbon emissions and promote sustainable practices, creating a favorable market environment for circular economy-driven PHEV designs.

Consumer awareness and preferences are also playing a crucial role in shaping the market for circular economy-based PHEVs. As environmental consciousness grows, consumers are increasingly seeking products that align with sustainable values. This shift in consumer behavior is driving automakers to adopt circular economy principles in their PHEV designs, focusing on recyclability, reusability, and longevity of components.

The rising costs of raw materials and the volatility of supply chains have further accelerated the adoption of circular economy principles in PHEV design. Manufacturers are exploring innovative ways to reduce their reliance on virgin materials and minimize waste generation. This approach not only helps in cost reduction but also enhances the overall sustainability of the production process.

The growing emphasis on extended producer responsibility (EPR) is another significant market driver. Governments and regulatory bodies are increasingly holding manufacturers accountable for the entire lifecycle of their products, including end-of-life management. This has prompted PHEV manufacturers to incorporate circular economy principles from the design phase to ensure easier disassembly, recycling, and refurbishment of vehicles.

The emergence of new business models centered around the sharing economy and product-as-a-service concepts is also influencing PHEV design. These models prioritize longevity, modularity, and upgradability, aligning perfectly with circular economy principles. As a result, PHEV manufacturers are focusing on designing vehicles that can be easily maintained, upgraded, and repurposed throughout their lifecycle.

Technological advancements in recycling and material recovery processes are further propelling the adoption of circular economy principles in PHEV design. Innovations in battery recycling technologies, for instance, are making it more economically viable to recover and reuse critical materials from end-of-life vehicles. This not only reduces the environmental impact but also creates new revenue streams for manufacturers.

The increasing focus on lifecycle assessment (LCA) and environmental product declarations (EPDs) is driving transparency in the automotive industry. This trend is pushing PHEV manufacturers to adopt circular economy principles to improve their environmental performance and gain a competitive edge in the market.

Consumer awareness and preferences are also playing a crucial role in shaping the market for circular economy-based PHEVs. As environmental consciousness grows, consumers are increasingly seeking products that align with sustainable values. This shift in consumer behavior is driving automakers to adopt circular economy principles in their PHEV designs, focusing on recyclability, reusability, and longevity of components.

The rising costs of raw materials and the volatility of supply chains have further accelerated the adoption of circular economy principles in PHEV design. Manufacturers are exploring innovative ways to reduce their reliance on virgin materials and minimize waste generation. This approach not only helps in cost reduction but also enhances the overall sustainability of the production process.

The growing emphasis on extended producer responsibility (EPR) is another significant market driver. Governments and regulatory bodies are increasingly holding manufacturers accountable for the entire lifecycle of their products, including end-of-life management. This has prompted PHEV manufacturers to incorporate circular economy principles from the design phase to ensure easier disassembly, recycling, and refurbishment of vehicles.

The emergence of new business models centered around the sharing economy and product-as-a-service concepts is also influencing PHEV design. These models prioritize longevity, modularity, and upgradability, aligning perfectly with circular economy principles. As a result, PHEV manufacturers are focusing on designing vehicles that can be easily maintained, upgraded, and repurposed throughout their lifecycle.

Technological advancements in recycling and material recovery processes are further propelling the adoption of circular economy principles in PHEV design. Innovations in battery recycling technologies, for instance, are making it more economically viable to recover and reuse critical materials from end-of-life vehicles. This not only reduces the environmental impact but also creates new revenue streams for manufacturers.

The increasing focus on lifecycle assessment (LCA) and environmental product declarations (EPDs) is driving transparency in the automotive industry. This trend is pushing PHEV manufacturers to adopt circular economy principles to improve their environmental performance and gain a competitive edge in the market.

PHEV Circularity Challenges

Plug-in Hybrid Electric Vehicles (PHEVs) face several significant challenges in achieving circularity, which is essential for sustainable design and production. One of the primary obstacles is the complexity of PHEV components, particularly the battery systems. These batteries contain a mix of materials, including rare earth elements and toxic substances, making recycling and reuse difficult and potentially hazardous.

The integration of electrical and mechanical systems in PHEVs also presents a challenge for disassembly and component recovery. The intricate interconnections between various parts often require specialized tools and expertise for proper dismantling, which can hinder efficient recycling processes. This complexity also increases the risk of damaging components during disassembly, potentially reducing their reusability.

Another significant challenge is the rapid pace of technological advancement in the automotive industry. As PHEV technology evolves, older models may become obsolete more quickly, leading to shorter product lifecycles. This accelerated obsolescence can result in increased waste generation and reduced opportunities for reuse or refurbishment of components.

The lack of standardization across different PHEV models and manufacturers further complicates circularity efforts. Variations in design, materials, and components make it challenging to develop universal recycling and remanufacturing processes. This diversity also impacts the potential for interchangeability of parts between different PHEV models, limiting opportunities for component reuse.

Additionally, the global supply chain for PHEV components presents logistical challenges for implementing circular economy principles. The dispersed nature of production and end-of-life management makes it difficult to establish efficient reverse logistics systems for collecting, sorting, and processing used components. This geographical spread can lead to increased transportation costs and environmental impacts, potentially offsetting some of the sustainability benefits of PHEVs.

The economic viability of circular practices for PHEVs is another significant challenge. The costs associated with disassembly, refurbishment, and recycling of complex components can be high, potentially outweighing the economic benefits of material recovery. This economic barrier can discourage manufacturers and recyclers from investing in circular economy initiatives for PHEVs.

Lastly, regulatory frameworks and consumer awareness play crucial roles in addressing PHEV circularity challenges. The lack of comprehensive policies and incentives for circular design and end-of-life management of PHEVs can hinder progress in this area. Similarly, limited consumer understanding of the importance of circularity in PHEV design may result in reduced demand for more sustainable and recyclable vehicle options.

The integration of electrical and mechanical systems in PHEVs also presents a challenge for disassembly and component recovery. The intricate interconnections between various parts often require specialized tools and expertise for proper dismantling, which can hinder efficient recycling processes. This complexity also increases the risk of damaging components during disassembly, potentially reducing their reusability.

Another significant challenge is the rapid pace of technological advancement in the automotive industry. As PHEV technology evolves, older models may become obsolete more quickly, leading to shorter product lifecycles. This accelerated obsolescence can result in increased waste generation and reduced opportunities for reuse or refurbishment of components.

The lack of standardization across different PHEV models and manufacturers further complicates circularity efforts. Variations in design, materials, and components make it challenging to develop universal recycling and remanufacturing processes. This diversity also impacts the potential for interchangeability of parts between different PHEV models, limiting opportunities for component reuse.

Additionally, the global supply chain for PHEV components presents logistical challenges for implementing circular economy principles. The dispersed nature of production and end-of-life management makes it difficult to establish efficient reverse logistics systems for collecting, sorting, and processing used components. This geographical spread can lead to increased transportation costs and environmental impacts, potentially offsetting some of the sustainability benefits of PHEVs.

The economic viability of circular practices for PHEVs is another significant challenge. The costs associated with disassembly, refurbishment, and recycling of complex components can be high, potentially outweighing the economic benefits of material recovery. This economic barrier can discourage manufacturers and recyclers from investing in circular economy initiatives for PHEVs.

Lastly, regulatory frameworks and consumer awareness play crucial roles in addressing PHEV circularity challenges. The lack of comprehensive policies and incentives for circular design and end-of-life management of PHEVs can hinder progress in this area. Similarly, limited consumer understanding of the importance of circularity in PHEV design may result in reduced demand for more sustainable and recyclable vehicle options.

Current Circular PHEV Solutions

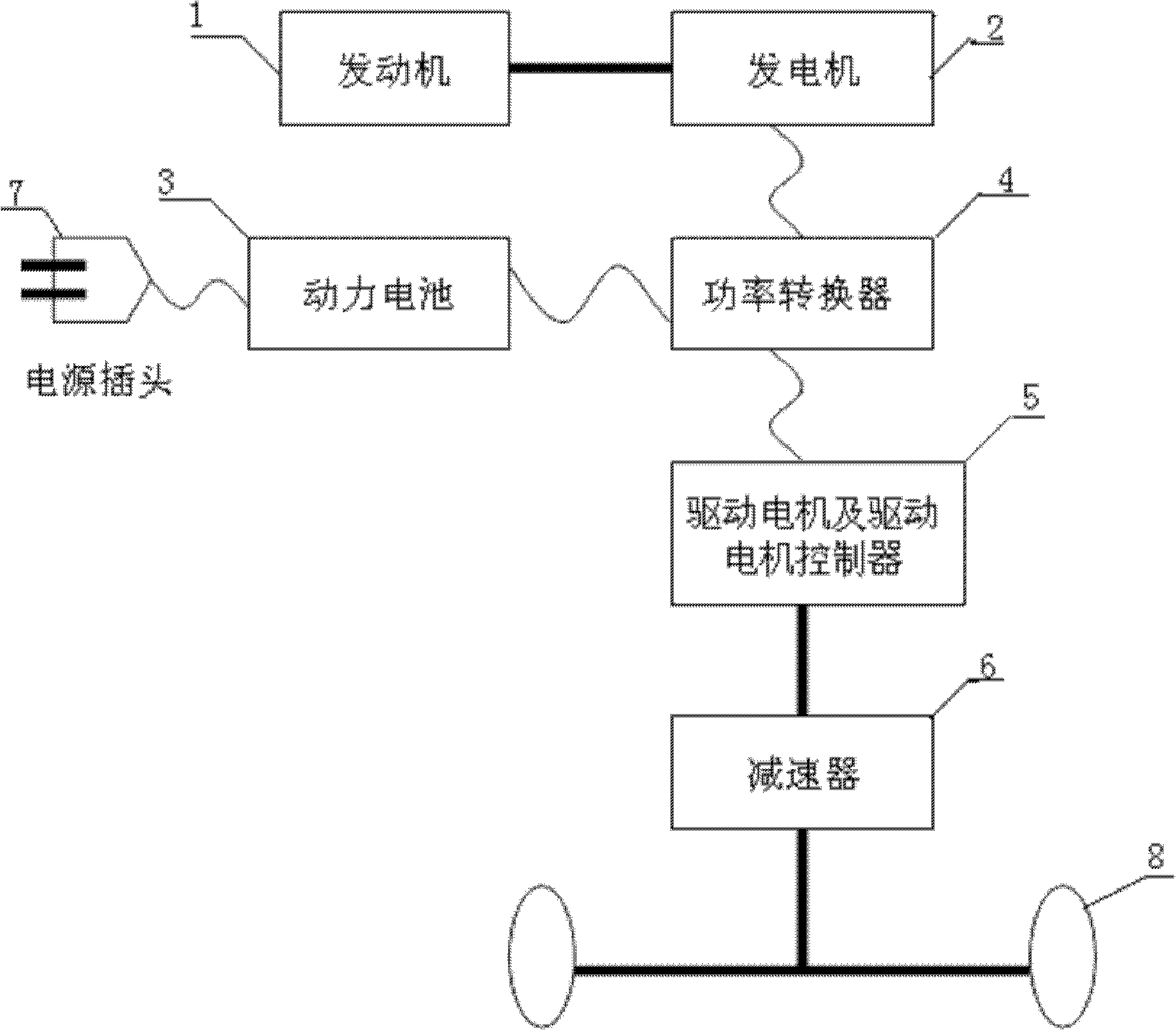

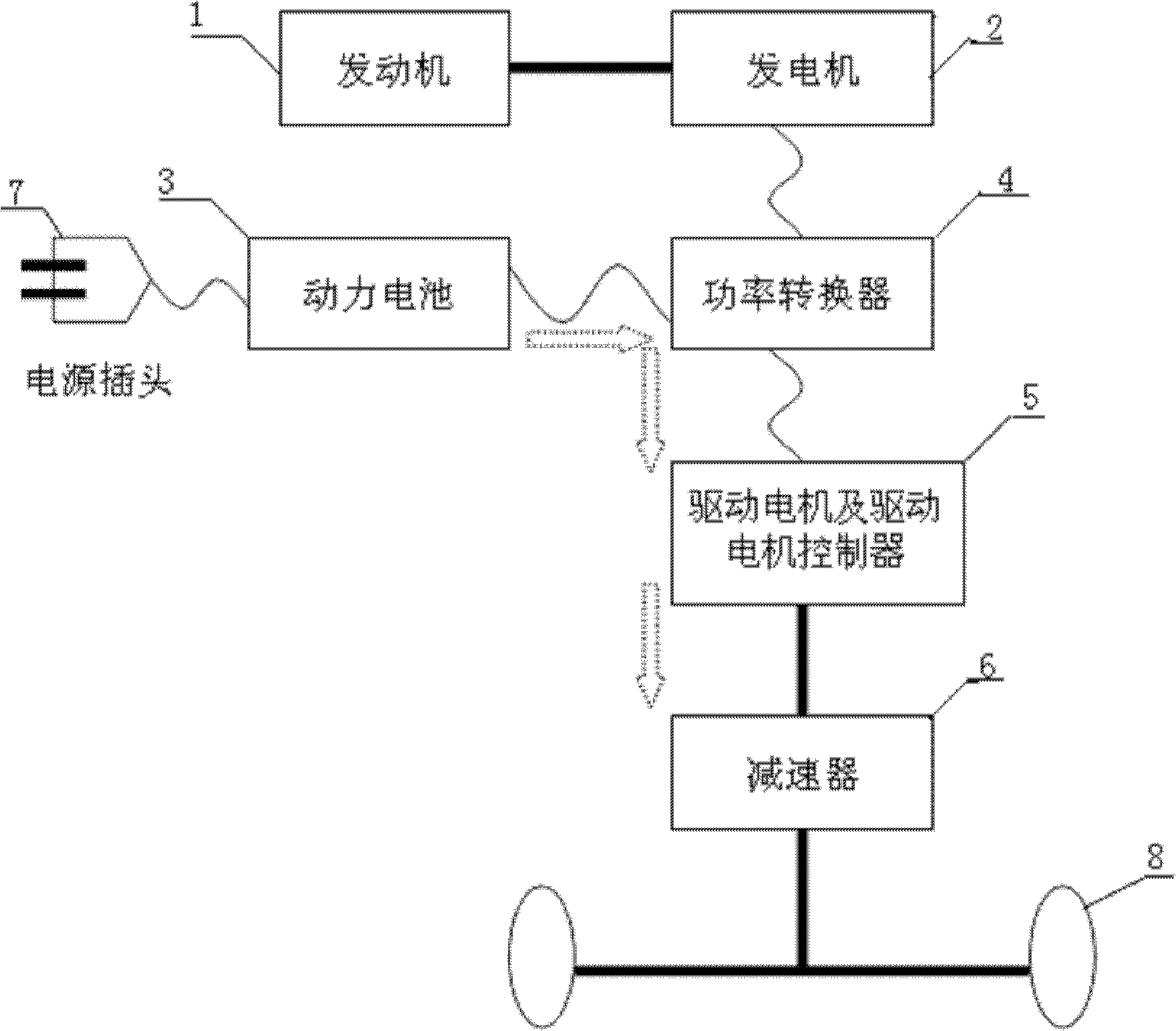

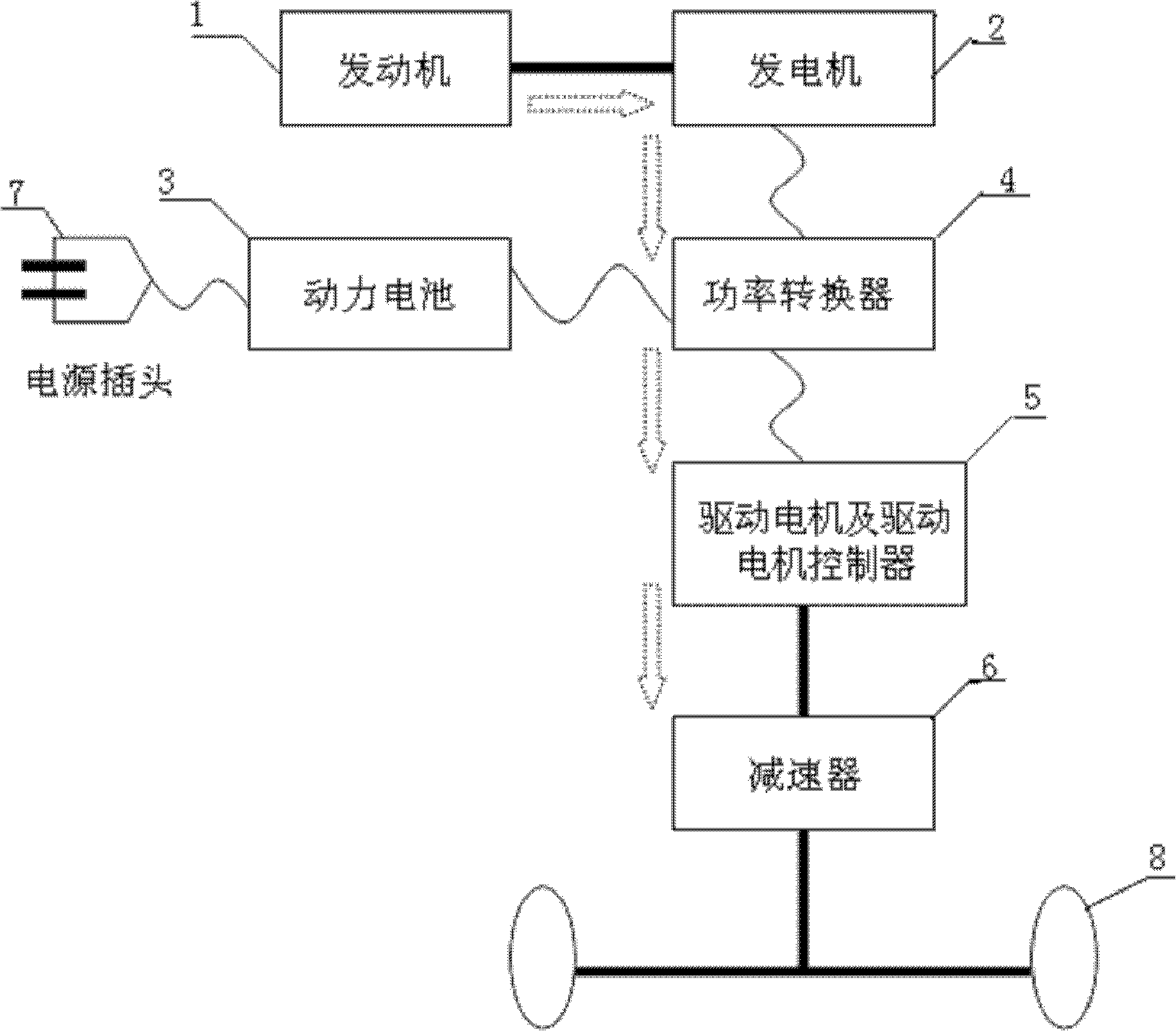

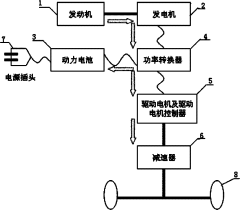

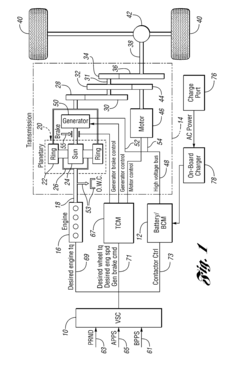

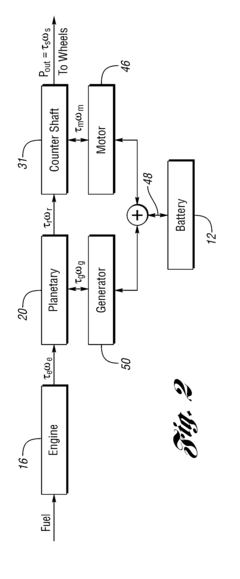

01 Power management systems for PHEVs

Advanced power management systems are crucial for optimizing the performance of plug-in hybrid electric vehicles. These systems control the distribution of power between the electric motor and internal combustion engine, manage battery charging, and improve overall energy efficiency. They often incorporate intelligent algorithms to predict energy needs and adjust power output accordingly.- Power management systems for PHEVs: Advanced power management systems are crucial for optimizing the performance of plug-in hybrid electric vehicles. These systems control the distribution of power between the electric motor and internal combustion engine, manage battery charging, and improve overall energy efficiency. They often incorporate intelligent algorithms to predict driving conditions and adjust power usage accordingly.

- Charging infrastructure and methods for PHEVs: Developing efficient charging infrastructure is essential for the widespread adoption of PHEVs. This includes the design of charging stations, integration with smart grids, and implementation of fast-charging technologies. Advanced charging methods, such as wireless charging and vehicle-to-grid systems, are also being explored to enhance convenience and grid stability.

- Drivetrain and transmission systems for PHEVs: Innovative drivetrain and transmission systems are being developed to optimize the integration of electric motors and internal combustion engines in PHEVs. These systems aim to improve power transfer efficiency, reduce energy losses, and enhance overall vehicle performance. Advanced designs may include multi-speed transmissions or continuously variable transmissions specifically tailored for hybrid powertrains.

- Battery technology and management for PHEVs: Advancements in battery technology are crucial for improving the electric range and overall performance of PHEVs. This includes the development of high-capacity, fast-charging batteries with improved energy density and longevity. Sophisticated battery management systems are also being designed to optimize battery life, monitor state of charge, and ensure safe operation under various conditions.

- Control strategies for hybrid powertrain optimization: Developing advanced control strategies is essential for optimizing the performance of PHEV powertrains. These strategies focus on efficiently managing the interplay between the electric motor and internal combustion engine, adapting to various driving conditions, and maximizing fuel economy. Machine learning and artificial intelligence techniques are being explored to enhance these control systems and improve overall vehicle efficiency.

02 Charging infrastructure and methods for PHEVs

Developing efficient charging infrastructure is essential for the widespread adoption of PHEVs. This includes the design of charging stations, integration with smart grids, and implementation of fast-charging technologies. Advanced charging methods, such as wireless charging and vehicle-to-grid systems, are also being explored to enhance convenience and grid stability.Expand Specific Solutions03 Drivetrain and transmission systems for PHEVs

Innovative drivetrain and transmission systems are being developed to optimize the integration of electric motors and internal combustion engines in PHEVs. These systems aim to improve power delivery, reduce energy losses, and enhance overall vehicle performance. Advanced designs may include multi-speed transmissions, integrated motor-generators, and sophisticated control units.Expand Specific Solutions04 Battery technology and management for PHEVs

Advancements in battery technology are crucial for improving the electric range and overall performance of PHEVs. This includes the development of high-capacity batteries, improved thermal management systems, and sophisticated battery management systems. Research is also focused on extending battery life, reducing charging times, and enhancing safety features.Expand Specific Solutions05 Control strategies and algorithms for PHEVs

Sophisticated control strategies and algorithms are being developed to optimize the operation of PHEVs. These include predictive energy management systems, adaptive control algorithms, and machine learning-based approaches. The goal is to maximize fuel efficiency, reduce emissions, and enhance the overall driving experience by intelligently managing the interplay between electric and combustion power sources.Expand Specific Solutions

Circular PHEV Industry Leaders

The circular economy principles in PHEV design are gaining traction in the automotive industry, which is currently in a transitional phase. The market for PHEVs is expanding, driven by increasing environmental concerns and regulatory pressures. However, the technology is still evolving, with varying levels of maturity across different manufacturers. Companies like Ford, Volvo, and Geely are at the forefront, investing heavily in circular design principles for their PHEV models. Other players such as Chery, Dongfeng, and BMW are also making significant strides in this area. The competitive landscape is dynamic, with both established automakers and new entrants vying for market share in this growing segment.

Ford Motor Co.

Technical Solution: Ford has implemented circular economy principles in their PHEV design through their "Closed Loop" recycling system. This system focuses on recycling and reusing materials from end-of-life vehicles, particularly aluminum and plastics. For their PHEVs, Ford has developed a process to recover and reprocess up to 95% of high-strength aluminum from scrap material during manufacturing[1]. They've also introduced recycled ocean plastics in their vehicle interiors, including the Ford Escape PHEV[2]. Ford's circular approach extends to battery lifecycle management, partnering with Redwood Materials to create a closed-loop battery recycling program, aiming to recover critical battery materials for reuse in new batteries[3].

Strengths: Significant reduction in raw material usage and environmental impact. Weaknesses: Initial implementation costs and complexity in establishing recycling infrastructure.

Volvo Lastvagnar AB

Technical Solution: Volvo Trucks has embraced circular economy principles in their PHEV design, focusing on sustainability and resource efficiency. They've implemented a "Design for Remanufacturing" approach, where components are designed from the outset to be easily disassembled, refurbished, and reused[4]. For their PHEV models, Volvo has developed modular battery packs that can be easily replaced and recycled. They've also introduced a battery leasing program, ensuring proper management and recycling of batteries throughout their lifecycle[5]. Additionally, Volvo uses recycled plastics in their PHEVs, with a goal to have at least 25% recycled plastics in every new truck by 2025[6].

Strengths: Extends product lifespan, reduces waste, and improves resource efficiency. Weaknesses: Potential higher initial costs and need for specialized remanufacturing facilities.

Key Circular PHEV Innovations

Cost based method for optimizing external PHEV (Plug-in Hybrid Electric Vehicle) power assembly and application thereof

PatentInactiveCN102180169A

Innovation

- By establishing a cost-based optimization method, determine the variables to be optimized and construct a cost objective function equation, and use quadratic programming or matrix partitioning optimization algorithms to optimize the maximum output power of the engine, the maximum output power of the drive motor, the output power of the power battery and the capacity of the power battery pack. , to achieve the lowest cost powertrain design.

Method for increasing fuel economy of plug-in hybrid electric vehicles

PatentInactiveUS9580062B2

Innovation

- Implementing a control strategy that prioritizes electric energy use in the charge-depleting mode and operates the engine below peak efficiency to supply only the power difference when battery power is insufficient, switching to charge-sustaining mode to maximize fuel economy by depleting the battery to a minimum state of charge before engine use.

Circular PHEV Policy Landscape

The circular economy principles are increasingly shaping the policy landscape for Plug-in Hybrid Electric Vehicles (PHEVs). Governments worldwide are recognizing the potential of circular economy strategies to address environmental challenges and resource scarcity in the automotive sector.

At the European Union level, the Circular Economy Action Plan, adopted in 2020, explicitly targets the automotive industry. It emphasizes the need for extended producer responsibility, improved recyclability of vehicle components, and increased use of recycled materials in PHEV production. The EU's End-of-Life Vehicles Directive has been updated to reflect these circular economy principles, setting higher targets for recovery and recycling rates.

In the United States, several states have introduced legislation promoting circular economy practices in the automotive sector. California, for instance, has implemented the Advanced Clean Cars II regulation, which not only sets stringent emission standards but also includes provisions for battery recycling and second-life applications for PHEV batteries.

China, as a major player in the electric vehicle market, has also embraced circular economy principles in its PHEV policies. The country's New Energy Vehicle Industry Development Plan (2021-2035) emphasizes the importance of establishing a comprehensive recycling system for batteries and other key components.

At the local level, cities are implementing policies to support circular economy practices in PHEV design and use. Amsterdam, for example, has launched a circular economy strategy that includes initiatives to promote car-sharing schemes and extend the lifespan of electric vehicles through improved maintenance and repair services.

The policy landscape is also evolving to address specific aspects of PHEV design. Battery regulations are becoming more stringent, with a focus on recyclability, traceability, and responsible sourcing of materials. The EU's proposed Battery Regulation, expected to come into force in 2023, sets ambitious targets for the recovery of materials from used batteries and mandates the use of recycled content in new batteries.

Furthermore, policies are emerging to support the development of circular business models in the PHEV sector. These include incentives for vehicle-to-grid technologies, which enable PHEVs to serve as energy storage units, and support for remanufacturing and refurbishment initiatives that extend vehicle lifespans.

As the circular economy concept gains traction, policymakers are increasingly recognizing the need for a holistic approach that considers the entire lifecycle of PHEVs. This is leading to more integrated policies that address design, production, use, and end-of-life stages simultaneously, creating a more conducive environment for circular PHEV design and implementation.

At the European Union level, the Circular Economy Action Plan, adopted in 2020, explicitly targets the automotive industry. It emphasizes the need for extended producer responsibility, improved recyclability of vehicle components, and increased use of recycled materials in PHEV production. The EU's End-of-Life Vehicles Directive has been updated to reflect these circular economy principles, setting higher targets for recovery and recycling rates.

In the United States, several states have introduced legislation promoting circular economy practices in the automotive sector. California, for instance, has implemented the Advanced Clean Cars II regulation, which not only sets stringent emission standards but also includes provisions for battery recycling and second-life applications for PHEV batteries.

China, as a major player in the electric vehicle market, has also embraced circular economy principles in its PHEV policies. The country's New Energy Vehicle Industry Development Plan (2021-2035) emphasizes the importance of establishing a comprehensive recycling system for batteries and other key components.

At the local level, cities are implementing policies to support circular economy practices in PHEV design and use. Amsterdam, for example, has launched a circular economy strategy that includes initiatives to promote car-sharing schemes and extend the lifespan of electric vehicles through improved maintenance and repair services.

The policy landscape is also evolving to address specific aspects of PHEV design. Battery regulations are becoming more stringent, with a focus on recyclability, traceability, and responsible sourcing of materials. The EU's proposed Battery Regulation, expected to come into force in 2023, sets ambitious targets for the recovery of materials from used batteries and mandates the use of recycled content in new batteries.

Furthermore, policies are emerging to support the development of circular business models in the PHEV sector. These include incentives for vehicle-to-grid technologies, which enable PHEVs to serve as energy storage units, and support for remanufacturing and refurbishment initiatives that extend vehicle lifespans.

As the circular economy concept gains traction, policymakers are increasingly recognizing the need for a holistic approach that considers the entire lifecycle of PHEVs. This is leading to more integrated policies that address design, production, use, and end-of-life stages simultaneously, creating a more conducive environment for circular PHEV design and implementation.

Lifecycle Assessment Methods

Lifecycle Assessment (LCA) methods play a crucial role in guiding the design of Plug-in Hybrid Electric Vehicles (PHEVs) according to circular economy principles. These methods provide a comprehensive framework for evaluating the environmental impacts of PHEVs throughout their entire lifecycle, from raw material extraction to end-of-life disposal.

One of the primary LCA methods used in PHEV design is the cradle-to-grave approach. This method considers all stages of a vehicle's life, including material production, manufacturing, use phase, and end-of-life treatment. By analyzing each stage, designers can identify hotspots of environmental impact and prioritize areas for improvement in line with circular economy principles.

Another important LCA method is the cradle-to-cradle approach, which aligns closely with circular economy concepts. This method focuses on designing PHEVs with components and materials that can be easily disassembled, reused, or recycled at the end of the vehicle's life. It encourages the use of renewable materials and the creation of closed-loop systems for resource recovery.

The ISO 14040 and 14044 standards provide a standardized framework for conducting LCAs in PHEV design. These standards ensure consistency and comparability in assessing environmental impacts across different vehicle designs and manufacturers. They outline key steps such as goal and scope definition, inventory analysis, impact assessment, and interpretation of results.

Input-Output LCA is another method that can be applied to PHEV design. This approach uses economic data to estimate environmental impacts associated with the production and consumption of goods and services throughout the supply chain. It helps designers understand the broader implications of their material and component choices on the overall environmental footprint of PHEVs.

Process-based LCA is a detailed method that examines specific processes within the PHEV lifecycle. This approach allows designers to focus on particular aspects of the vehicle, such as battery production or powertrain efficiency, and optimize them for circular economy principles. It provides granular insights that can lead to targeted improvements in resource efficiency and waste reduction.

Hybrid LCA methods combine elements of process-based and input-output approaches to provide a more comprehensive assessment. These methods are particularly useful for complex systems like PHEVs, where both detailed process information and broader economic data are relevant to understanding the full environmental impact.

By employing these various LCA methods, PHEV designers can make informed decisions that align with circular economy principles. They can identify opportunities for material substitution, design for disassembly, and optimize energy efficiency throughout the vehicle's lifecycle. This holistic approach ensures that PHEVs not only perform well during their use phase but also contribute to a more sustainable and circular automotive industry.

One of the primary LCA methods used in PHEV design is the cradle-to-grave approach. This method considers all stages of a vehicle's life, including material production, manufacturing, use phase, and end-of-life treatment. By analyzing each stage, designers can identify hotspots of environmental impact and prioritize areas for improvement in line with circular economy principles.

Another important LCA method is the cradle-to-cradle approach, which aligns closely with circular economy concepts. This method focuses on designing PHEVs with components and materials that can be easily disassembled, reused, or recycled at the end of the vehicle's life. It encourages the use of renewable materials and the creation of closed-loop systems for resource recovery.

The ISO 14040 and 14044 standards provide a standardized framework for conducting LCAs in PHEV design. These standards ensure consistency and comparability in assessing environmental impacts across different vehicle designs and manufacturers. They outline key steps such as goal and scope definition, inventory analysis, impact assessment, and interpretation of results.

Input-Output LCA is another method that can be applied to PHEV design. This approach uses economic data to estimate environmental impacts associated with the production and consumption of goods and services throughout the supply chain. It helps designers understand the broader implications of their material and component choices on the overall environmental footprint of PHEVs.

Process-based LCA is a detailed method that examines specific processes within the PHEV lifecycle. This approach allows designers to focus on particular aspects of the vehicle, such as battery production or powertrain efficiency, and optimize them for circular economy principles. It provides granular insights that can lead to targeted improvements in resource efficiency and waste reduction.

Hybrid LCA methods combine elements of process-based and input-output approaches to provide a more comprehensive assessment. These methods are particularly useful for complex systems like PHEVs, where both detailed process information and broader economic data are relevant to understanding the full environmental impact.

By employing these various LCA methods, PHEV designers can make informed decisions that align with circular economy principles. They can identify opportunities for material substitution, design for disassembly, and optimize energy efficiency throughout the vehicle's lifecycle. This holistic approach ensures that PHEVs not only perform well during their use phase but also contribute to a more sustainable and circular automotive industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!