PHEV torque vectoring in enhancing handling performance

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHEV Torque Vectoring Background and Objectives

Plug-in Hybrid Electric Vehicles (PHEVs) have emerged as a significant technological advancement in the automotive industry, bridging the gap between conventional internal combustion engine vehicles and fully electric vehicles. As environmental concerns and energy efficiency demands continue to rise, PHEVs offer a promising solution by combining the benefits of both electric and conventional powertrains.

Torque vectoring, a technology initially developed for high-performance vehicles, has gained traction in recent years as a means to enhance vehicle handling and stability. This technology allows for the precise distribution of torque between wheels, improving cornering performance and overall vehicle dynamics. The integration of torque vectoring in PHEVs presents a unique opportunity to leverage the advantages of both electric and conventional powertrains to achieve superior handling characteristics.

The evolution of PHEV torque vectoring technology can be traced back to the early 2010s when automotive manufacturers began exploring ways to improve the driving experience of hybrid vehicles. Initially, the focus was on optimizing energy efficiency and reducing emissions. However, as consumer expectations for performance and handling increased, engineers turned their attention to enhancing the dynamic capabilities of PHEVs.

The primary objective of implementing torque vectoring in PHEVs is to overcome the inherent challenges associated with the additional weight of battery packs and electric motors. By precisely controlling the distribution of torque to individual wheels, PHEV torque vectoring systems aim to mitigate understeer and oversteer tendencies, improve cornering stability, and enhance overall vehicle agility.

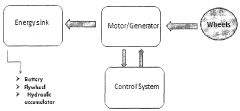

Furthermore, PHEV torque vectoring technology seeks to capitalize on the unique characteristics of electric motors, such as their instant torque delivery and precise control capabilities. This allows for more responsive and accurate torque distribution compared to traditional mechanical differential-based systems. The integration of torque vectoring with regenerative braking systems in PHEVs also presents opportunities for improved energy recovery and enhanced deceleration performance.

As the automotive industry continues to push towards electrification, the development of PHEV torque vectoring technology is expected to play a crucial role in bridging the performance gap between conventional and fully electric vehicles. The ultimate goal is to create PHEVs that not only offer improved fuel efficiency and reduced emissions but also deliver a driving experience that matches or surpasses that of traditional high-performance vehicles.

Torque vectoring, a technology initially developed for high-performance vehicles, has gained traction in recent years as a means to enhance vehicle handling and stability. This technology allows for the precise distribution of torque between wheels, improving cornering performance and overall vehicle dynamics. The integration of torque vectoring in PHEVs presents a unique opportunity to leverage the advantages of both electric and conventional powertrains to achieve superior handling characteristics.

The evolution of PHEV torque vectoring technology can be traced back to the early 2010s when automotive manufacturers began exploring ways to improve the driving experience of hybrid vehicles. Initially, the focus was on optimizing energy efficiency and reducing emissions. However, as consumer expectations for performance and handling increased, engineers turned their attention to enhancing the dynamic capabilities of PHEVs.

The primary objective of implementing torque vectoring in PHEVs is to overcome the inherent challenges associated with the additional weight of battery packs and electric motors. By precisely controlling the distribution of torque to individual wheels, PHEV torque vectoring systems aim to mitigate understeer and oversteer tendencies, improve cornering stability, and enhance overall vehicle agility.

Furthermore, PHEV torque vectoring technology seeks to capitalize on the unique characteristics of electric motors, such as their instant torque delivery and precise control capabilities. This allows for more responsive and accurate torque distribution compared to traditional mechanical differential-based systems. The integration of torque vectoring with regenerative braking systems in PHEVs also presents opportunities for improved energy recovery and enhanced deceleration performance.

As the automotive industry continues to push towards electrification, the development of PHEV torque vectoring technology is expected to play a crucial role in bridging the performance gap between conventional and fully electric vehicles. The ultimate goal is to create PHEVs that not only offer improved fuel efficiency and reduced emissions but also deliver a driving experience that matches or surpasses that of traditional high-performance vehicles.

Market Analysis for Enhanced PHEV Handling

The market for enhanced PHEV handling through torque vectoring technology is experiencing significant growth, driven by increasing consumer demand for improved vehicle performance and safety. As hybrid electric vehicles gain popularity, manufacturers are focusing on enhancing their driving dynamics to compete with traditional internal combustion engine vehicles. Torque vectoring systems, which can precisely control the distribution of power to individual wheels, offer a compelling solution to improve handling characteristics in PHEVs.

Market research indicates that the global torque vectoring market is expected to grow substantially in the coming years, with a particular emphasis on electric and hybrid vehicle applications. This growth is attributed to the rising adoption of advanced driver assistance systems (ADAS) and the increasing focus on vehicle stability and cornering performance. The PHEV segment, in particular, is poised to benefit from torque vectoring technology as it combines the advantages of both electric and conventional powertrains.

Consumer preferences are shifting towards vehicles that offer superior handling and driving dynamics, especially in premium and performance-oriented market segments. PHEV models equipped with torque vectoring systems are positioned to meet this demand by providing enhanced cornering abilities, improved traction, and overall better vehicle control. This technology not only appeals to driving enthusiasts but also contributes to increased safety and stability in various driving conditions.

The market potential for torque vectoring in PHEVs extends beyond personal vehicles to include commercial and fleet applications. As businesses and organizations seek to reduce their carbon footprint while maintaining operational efficiency, PHEVs with advanced handling capabilities present an attractive option. The improved maneuverability and stability offered by torque vectoring systems can be particularly beneficial in urban environments and challenging road conditions.

Geographically, mature automotive markets such as North America, Europe, and parts of Asia are expected to lead the adoption of torque vectoring technology in PHEVs. These regions have a strong presence of premium automotive brands and tech-savvy consumers who are more likely to appreciate and invest in advanced vehicle technologies. However, emerging markets are also showing increasing interest in PHEVs with enhanced handling capabilities as environmental concerns and technological advancements drive changes in consumer preferences globally.

The competitive landscape in this market segment is intensifying, with both established automotive manufacturers and new entrants vying for market share. This competition is likely to drive innovation and potentially lead to more affordable torque vectoring solutions for PHEVs in the future. As the technology matures and production scales up, it is anticipated that torque vectoring systems will become more widely available across different vehicle segments, further expanding the market potential.

Market research indicates that the global torque vectoring market is expected to grow substantially in the coming years, with a particular emphasis on electric and hybrid vehicle applications. This growth is attributed to the rising adoption of advanced driver assistance systems (ADAS) and the increasing focus on vehicle stability and cornering performance. The PHEV segment, in particular, is poised to benefit from torque vectoring technology as it combines the advantages of both electric and conventional powertrains.

Consumer preferences are shifting towards vehicles that offer superior handling and driving dynamics, especially in premium and performance-oriented market segments. PHEV models equipped with torque vectoring systems are positioned to meet this demand by providing enhanced cornering abilities, improved traction, and overall better vehicle control. This technology not only appeals to driving enthusiasts but also contributes to increased safety and stability in various driving conditions.

The market potential for torque vectoring in PHEVs extends beyond personal vehicles to include commercial and fleet applications. As businesses and organizations seek to reduce their carbon footprint while maintaining operational efficiency, PHEVs with advanced handling capabilities present an attractive option. The improved maneuverability and stability offered by torque vectoring systems can be particularly beneficial in urban environments and challenging road conditions.

Geographically, mature automotive markets such as North America, Europe, and parts of Asia are expected to lead the adoption of torque vectoring technology in PHEVs. These regions have a strong presence of premium automotive brands and tech-savvy consumers who are more likely to appreciate and invest in advanced vehicle technologies. However, emerging markets are also showing increasing interest in PHEVs with enhanced handling capabilities as environmental concerns and technological advancements drive changes in consumer preferences globally.

The competitive landscape in this market segment is intensifying, with both established automotive manufacturers and new entrants vying for market share. This competition is likely to drive innovation and potentially lead to more affordable torque vectoring solutions for PHEVs in the future. As the technology matures and production scales up, it is anticipated that torque vectoring systems will become more widely available across different vehicle segments, further expanding the market potential.

Current Challenges in PHEV Torque Vectoring

Despite the promising potential of torque vectoring in Plug-in Hybrid Electric Vehicles (PHEVs), several significant challenges persist in its implementation and optimization. These challenges span across technical, economic, and practical domains, hindering the widespread adoption and effectiveness of this technology.

One of the primary technical challenges is the complexity of integrating torque vectoring systems with existing PHEV powertrains. The dual nature of PHEVs, combining both electric and internal combustion engines, creates a more intricate powertrain architecture compared to conventional vehicles or pure electric vehicles. This complexity makes it difficult to seamlessly incorporate torque vectoring mechanisms without compromising the overall efficiency and performance of the vehicle.

Another significant hurdle is the development of sophisticated control algorithms capable of managing torque distribution in real-time. These algorithms must account for various factors such as vehicle speed, steering angle, road conditions, and driver inputs, while also considering the unique characteristics of PHEVs, including battery state of charge and power management between electric and combustion engines. The need for high-speed processing and precise actuation further complicates the implementation of these control systems.

Weight and packaging constraints pose additional challenges for PHEV torque vectoring systems. The inclusion of electric motors, batteries, and associated components already adds considerable weight to PHEVs. Incorporating additional hardware for torque vectoring, such as electronic differentials or individual wheel motors, can further increase vehicle weight and complexity, potentially offsetting some of the handling benefits gained from torque vectoring.

Energy management is another critical challenge in PHEV torque vectoring. The system must balance the power demands of torque vectoring with the overall energy efficiency goals of the vehicle. This balancing act becomes particularly crucial in PHEVs, where maintaining optimal battery charge levels and maximizing electric-only driving range are key priorities.

Cost considerations also present a significant barrier to widespread adoption. The additional components and advanced control systems required for effective torque vectoring can substantially increase the production costs of PHEVs, which are already more expensive than conventional vehicles. This cost increase may limit the market appeal of torque vectoring technology, especially in more affordable vehicle segments.

Durability and reliability of torque vectoring systems in PHEVs remain concerns, particularly given the added stress on components due to the frequent transitions between electric and combustion power sources. Ensuring long-term performance and reliability under various driving conditions and usage patterns presents an ongoing challenge for manufacturers.

Lastly, the regulatory landscape and safety considerations add another layer of complexity. Ensuring that torque vectoring systems comply with existing vehicle safety standards and regulations, while also addressing potential new safety concerns specific to this technology, requires extensive testing and validation processes.

One of the primary technical challenges is the complexity of integrating torque vectoring systems with existing PHEV powertrains. The dual nature of PHEVs, combining both electric and internal combustion engines, creates a more intricate powertrain architecture compared to conventional vehicles or pure electric vehicles. This complexity makes it difficult to seamlessly incorporate torque vectoring mechanisms without compromising the overall efficiency and performance of the vehicle.

Another significant hurdle is the development of sophisticated control algorithms capable of managing torque distribution in real-time. These algorithms must account for various factors such as vehicle speed, steering angle, road conditions, and driver inputs, while also considering the unique characteristics of PHEVs, including battery state of charge and power management between electric and combustion engines. The need for high-speed processing and precise actuation further complicates the implementation of these control systems.

Weight and packaging constraints pose additional challenges for PHEV torque vectoring systems. The inclusion of electric motors, batteries, and associated components already adds considerable weight to PHEVs. Incorporating additional hardware for torque vectoring, such as electronic differentials or individual wheel motors, can further increase vehicle weight and complexity, potentially offsetting some of the handling benefits gained from torque vectoring.

Energy management is another critical challenge in PHEV torque vectoring. The system must balance the power demands of torque vectoring with the overall energy efficiency goals of the vehicle. This balancing act becomes particularly crucial in PHEVs, where maintaining optimal battery charge levels and maximizing electric-only driving range are key priorities.

Cost considerations also present a significant barrier to widespread adoption. The additional components and advanced control systems required for effective torque vectoring can substantially increase the production costs of PHEVs, which are already more expensive than conventional vehicles. This cost increase may limit the market appeal of torque vectoring technology, especially in more affordable vehicle segments.

Durability and reliability of torque vectoring systems in PHEVs remain concerns, particularly given the added stress on components due to the frequent transitions between electric and combustion power sources. Ensuring long-term performance and reliability under various driving conditions and usage patterns presents an ongoing challenge for manufacturers.

Lastly, the regulatory landscape and safety considerations add another layer of complexity. Ensuring that torque vectoring systems comply with existing vehicle safety standards and regulations, while also addressing potential new safety concerns specific to this technology, requires extensive testing and validation processes.

Existing PHEV Torque Vectoring Solutions

01 Torque vectoring for improved vehicle handling

Torque vectoring systems distribute power between wheels or axles to enhance vehicle handling and stability. This technology allows for precise control of torque distribution, improving cornering performance and overall vehicle dynamics. By selectively applying torque to specific wheels, the system can reduce understeer or oversteer, resulting in better maneuverability and driver control.- Torque vectoring for improved vehicle handling: Torque vectoring systems distribute power between wheels or axles to enhance vehicle handling and stability. This technology allows for precise control of torque distribution, improving cornering performance, traction, and overall vehicle dynamics. By selectively applying torque to specific wheels, the system can reduce understeer or oversteer, resulting in more responsive and predictable handling characteristics.

- Electronic control systems for torque vectoring: Advanced electronic control systems are employed to manage torque vectoring in real-time. These systems use sensors to monitor vehicle dynamics, road conditions, and driver inputs. The collected data is processed by sophisticated algorithms to determine optimal torque distribution. This enables quick and precise adjustments to improve handling performance across various driving scenarios, from everyday commuting to high-performance driving.

- Integration with other vehicle systems: Torque vectoring systems are often integrated with other vehicle technologies such as stability control, traction control, and all-wheel drive systems. This integration allows for a holistic approach to vehicle dynamics management, enhancing overall performance and safety. The combined systems work in harmony to provide optimal handling characteristics in various driving conditions, from dry roads to challenging low-friction surfaces.

- Adaptive torque vectoring for different driving modes: Modern torque vectoring systems can adapt to different driving modes and conditions. This adaptability allows the system to optimize handling performance based on the selected driving mode (e.g., comfort, sport, off-road) or automatically adjust to changing road conditions. The system can alter its behavior to prioritize stability, performance, or efficiency, providing a versatile solution for diverse driving scenarios.

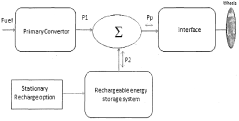

- Torque vectoring in electric and hybrid vehicles: Electric and hybrid vehicles utilize torque vectoring to enhance handling performance and efficiency. In these vehicles, electric motors can provide instant and precise torque control to individual wheels, offering advantages over traditional mechanical systems. This allows for more responsive handling, improved energy recuperation during braking, and optimized power distribution for enhanced efficiency and performance in electric and hybrid powertrains.

02 Electronic control systems for torque vectoring

Advanced electronic control systems are employed to manage torque vectoring in real-time. These systems use sensors to monitor vehicle dynamics, road conditions, and driver inputs. The collected data is processed to determine optimal torque distribution, allowing for quick adjustments to enhance handling performance. Such systems can integrate with other vehicle control modules for comprehensive vehicle dynamics management.Expand Specific Solutions03 Torque vectoring in electric and hybrid vehicles

Electric and hybrid vehicles utilize torque vectoring to improve handling and efficiency. In these vehicles, individual electric motors can control the torque applied to each wheel independently. This allows for more precise and responsive torque distribution, enhancing cornering abilities and overall vehicle performance. The system can also contribute to energy recuperation during deceleration.Expand Specific Solutions04 Integration of torque vectoring with other vehicle systems

Torque vectoring systems are often integrated with other vehicle control systems such as stability control, traction control, and all-wheel drive. This integration allows for a holistic approach to vehicle dynamics management. By coordinating with these systems, torque vectoring can provide enhanced stability, traction, and handling performance across various driving conditions and scenarios.Expand Specific Solutions05 Adaptive torque vectoring based on driving conditions

Advanced torque vectoring systems can adapt to different driving conditions and driver preferences. These systems use artificial intelligence and machine learning algorithms to analyze driving patterns, road conditions, and environmental factors. Based on this analysis, the system can adjust torque distribution strategies to optimize handling performance for specific scenarios, such as sporty driving on a track or navigating slippery roads.Expand Specific Solutions

Key Players in PHEV Torque Vectoring Industry

The PHEV torque vectoring market for enhancing handling performance is in a growth phase, with increasing adoption across the automotive industry. The market size is expanding as more manufacturers integrate this technology into their hybrid vehicles. Technologically, it's reaching maturity, with key players like Hyundai Motor Co., Kia Corp., and Ford Global Technologies LLC leading innovation. Toyota Motor Corp. and BorgWarner Sweden AB are also significant contributors, leveraging their extensive automotive expertise. The competition is intensifying as companies like Great Wall Motor Co. and AUDI AG enter the market, driving further advancements in torque vectoring systems for PHEVs.

Ford Global Technologies LLC

Technical Solution: Ford's PHEV torque vectoring system focuses on enhancing handling performance through a combination of mechanical and electronic solutions. Their system employs a twin-clutch rear drive unit that can distribute torque between the rear wheels[2]. This is complemented by an advanced control algorithm that takes into account vehicle speed, steering angle, and other parameters to optimize torque distribution. Ford's system also integrates regenerative braking to recover energy during cornering, improving overall efficiency. The company has patented a predictive torque vectoring system that uses GPS and map data to anticipate upcoming turns and adjust torque distribution accordingly[4].

Strengths: Combination of mechanical and electronic solutions, energy recovery, predictive capabilities. Weaknesses: Reliance on accurate GPS data, potential for system complexity.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced PHEV torque vectoring system for enhancing handling performance. Their system utilizes electric motors on each rear wheel, allowing for precise control of torque distribution. This enables dynamic torque vectoring, which can actively adjust the torque sent to each wheel based on driving conditions[1]. The system integrates with the vehicle's stability control and can predict driver intentions, adjusting torque distribution preemptively. Toyota's approach also incorporates a sophisticated power management system that balances performance with energy efficiency, ensuring optimal use of the battery charge[3].

Strengths: Precise control, integration with vehicle systems, predictive capabilities. Weaknesses: Complexity, potential high cost, additional weight from multiple motors.

Core Innovations in PHEV Torque Vectoring

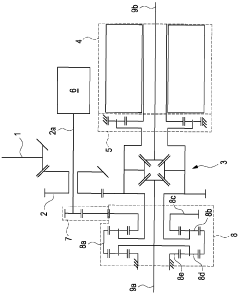

Hybrid rear axle drive, this comprehensive powertrain for a PHEV and electronic torque distribution method

PatentActiveDE102021132321A1

Innovation

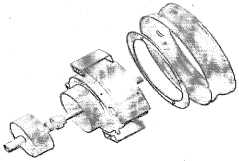

- A hybridized rear axle drive (H-HAG) with an electric torque vectoring system (eTV) that integrates a permanently connected traction electric motor and an eTV drive module, utilizing a modular structure with a countershaft and two-row planetary gear to enhance torque distribution and stability, allowing for agile and stabilizing interventions in driving dynamics.

I-moped: intelligent moped vehicles moves using hybrid technology

PatentInactiveIN201821029069A

Innovation

- A hybrid electric moped using a two-stroke internal combustion engine and a hub motor, integrated with a regenerative braking system and wind power generation, where the vehicle automatically switches to a petrol fuel source when the battery is low, optimizing energy and fuel consumption through a multi-mode approach.

Environmental Impact of PHEV Torque Vectoring

The environmental impact of PHEV torque vectoring in enhancing handling performance is a multifaceted issue that warrants careful consideration. This advanced technology, while primarily aimed at improving vehicle dynamics, also has significant implications for energy efficiency and emissions reduction.

Torque vectoring in PHEVs allows for precise control of power distribution to individual wheels, optimizing traction and stability. This enhanced handling capability can lead to more efficient driving patterns, potentially reducing overall energy consumption. By minimizing wheel slip and maximizing grip, torque vectoring systems can help maintain optimal vehicle speed and reduce unnecessary acceleration and braking, which are often sources of energy waste.

Furthermore, the improved handling characteristics enabled by torque vectoring can contribute to safer driving conditions. This increased safety may indirectly benefit the environment by reducing the likelihood of accidents, which can result in traffic congestion and increased emissions from idling vehicles.

However, the environmental benefits of PHEV torque vectoring must be weighed against the potential drawbacks. The additional components required for torque vectoring systems, such as electronic control units and actuators, may increase the overall weight of the vehicle. This added weight could partially offset the efficiency gains achieved through improved handling, especially in urban driving scenarios with frequent stops and starts.

The manufacturing process of these advanced torque vectoring systems also needs to be considered from an environmental perspective. The production of specialized components may require energy-intensive processes and rare materials, potentially increasing the carbon footprint of vehicle production.

On the positive side, the integration of torque vectoring in PHEVs can enhance the overall appeal of hybrid vehicles, potentially accelerating their adoption. As PHEVs become more attractive to consumers due to improved performance and handling, this could lead to a faster transition away from conventional internal combustion engine vehicles, resulting in a net positive environmental impact.

In terms of long-term sustainability, the durability and lifespan of torque vectoring systems in PHEVs are crucial factors. If these systems prove to be robust and long-lasting, they could contribute to extended vehicle lifespans, reducing the environmental impact associated with frequent vehicle replacements and manufacturing.

Torque vectoring in PHEVs allows for precise control of power distribution to individual wheels, optimizing traction and stability. This enhanced handling capability can lead to more efficient driving patterns, potentially reducing overall energy consumption. By minimizing wheel slip and maximizing grip, torque vectoring systems can help maintain optimal vehicle speed and reduce unnecessary acceleration and braking, which are often sources of energy waste.

Furthermore, the improved handling characteristics enabled by torque vectoring can contribute to safer driving conditions. This increased safety may indirectly benefit the environment by reducing the likelihood of accidents, which can result in traffic congestion and increased emissions from idling vehicles.

However, the environmental benefits of PHEV torque vectoring must be weighed against the potential drawbacks. The additional components required for torque vectoring systems, such as electronic control units and actuators, may increase the overall weight of the vehicle. This added weight could partially offset the efficiency gains achieved through improved handling, especially in urban driving scenarios with frequent stops and starts.

The manufacturing process of these advanced torque vectoring systems also needs to be considered from an environmental perspective. The production of specialized components may require energy-intensive processes and rare materials, potentially increasing the carbon footprint of vehicle production.

On the positive side, the integration of torque vectoring in PHEVs can enhance the overall appeal of hybrid vehicles, potentially accelerating their adoption. As PHEVs become more attractive to consumers due to improved performance and handling, this could lead to a faster transition away from conventional internal combustion engine vehicles, resulting in a net positive environmental impact.

In terms of long-term sustainability, the durability and lifespan of torque vectoring systems in PHEVs are crucial factors. If these systems prove to be robust and long-lasting, they could contribute to extended vehicle lifespans, reducing the environmental impact associated with frequent vehicle replacements and manufacturing.

Safety Considerations in PHEV Torque Vectoring

Safety considerations play a crucial role in the implementation of torque vectoring systems for Plug-in Hybrid Electric Vehicles (PHEVs). As these advanced control systems aim to enhance handling performance, they must also prioritize the safety of vehicle occupants and other road users. One primary concern is the potential for sudden changes in vehicle dynamics during torque vectoring operations, which could lead to unexpected vehicle behavior and loss of control, especially in adverse weather conditions or during emergency maneuvers.

To address these safety challenges, manufacturers implement robust fail-safe mechanisms and redundant control systems. These systems continuously monitor the vehicle's state, including wheel speeds, yaw rate, and lateral acceleration, to ensure that torque vectoring interventions remain within safe operational limits. Additionally, advanced stability control systems are integrated with torque vectoring functionality to provide a comprehensive safety net, intervening when necessary to maintain vehicle stability.

Another critical safety aspect is the management of high-voltage electrical systems in PHEVs. The torque vectoring system must be designed to operate safely in conjunction with the vehicle's hybrid powertrain, ensuring proper isolation of high-voltage components and protection against electrical faults. This includes implementing sophisticated battery management systems and thermal management strategies to prevent overheating or electrical hazards during high-performance driving scenarios.

Driver awareness and interface design also contribute significantly to the safety of PHEV torque vectoring systems. Clear and intuitive feedback mechanisms are essential to inform drivers of system status and interventions, allowing them to anticipate and adapt to changes in vehicle behavior. This may include visual displays, haptic feedback through the steering wheel, or subtle auditory cues.

Furthermore, the integration of torque vectoring with other advanced driver assistance systems (ADAS) requires careful consideration. Ensuring seamless cooperation between torque vectoring, adaptive cruise control, lane-keeping assist, and autonomous emergency braking systems is crucial for maintaining consistent and predictable vehicle behavior across various driving scenarios.

Lastly, rigorous testing and validation processes are imperative to ensure the safety and reliability of PHEV torque vectoring systems. This includes extensive simulations, closed-course testing, and real-world trials under a wide range of driving conditions and scenarios. Manufacturers must also consider the long-term durability and reliability of these systems, implementing robust diagnostics and maintenance protocols to maintain safety performance throughout the vehicle's lifecycle.

To address these safety challenges, manufacturers implement robust fail-safe mechanisms and redundant control systems. These systems continuously monitor the vehicle's state, including wheel speeds, yaw rate, and lateral acceleration, to ensure that torque vectoring interventions remain within safe operational limits. Additionally, advanced stability control systems are integrated with torque vectoring functionality to provide a comprehensive safety net, intervening when necessary to maintain vehicle stability.

Another critical safety aspect is the management of high-voltage electrical systems in PHEVs. The torque vectoring system must be designed to operate safely in conjunction with the vehicle's hybrid powertrain, ensuring proper isolation of high-voltage components and protection against electrical faults. This includes implementing sophisticated battery management systems and thermal management strategies to prevent overheating or electrical hazards during high-performance driving scenarios.

Driver awareness and interface design also contribute significantly to the safety of PHEV torque vectoring systems. Clear and intuitive feedback mechanisms are essential to inform drivers of system status and interventions, allowing them to anticipate and adapt to changes in vehicle behavior. This may include visual displays, haptic feedback through the steering wheel, or subtle auditory cues.

Furthermore, the integration of torque vectoring with other advanced driver assistance systems (ADAS) requires careful consideration. Ensuring seamless cooperation between torque vectoring, adaptive cruise control, lane-keeping assist, and autonomous emergency braking systems is crucial for maintaining consistent and predictable vehicle behavior across various driving scenarios.

Lastly, rigorous testing and validation processes are imperative to ensure the safety and reliability of PHEV torque vectoring systems. This includes extensive simulations, closed-course testing, and real-world trials under a wide range of driving conditions and scenarios. Manufacturers must also consider the long-term durability and reliability of these systems, implementing robust diagnostics and maintenance protocols to maintain safety performance throughout the vehicle's lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!