How 3D printing revolutionizes PHEV manufacturing

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

3D Printing in PHEV Evolution

The evolution of 3D printing in PHEV (Plug-in Hybrid Electric Vehicle) manufacturing represents a significant technological leap in the automotive industry. This innovative approach has transformed traditional manufacturing processes, offering unprecedented flexibility and efficiency in production.

The journey of 3D printing in PHEV manufacturing began with rapid prototyping, allowing designers and engineers to quickly iterate and test new components. As the technology matured, its application expanded to include the production of complex, lightweight parts that were previously difficult or impossible to manufacture using conventional methods.

One of the key milestones in this evolution was the development of advanced materials suitable for 3D printing in automotive applications. These materials, including high-performance polymers and metal alloys, enabled the production of functional parts that could withstand the rigorous demands of vehicle operation.

The integration of 3D printing into PHEV battery manufacturing marked another significant advancement. This technology allowed for the creation of intricate cooling channels and optimized battery casings, leading to improved thermal management and increased energy density in PHEV battery packs.

As 3D printing capabilities expanded, manufacturers began to explore its potential for mass customization. This shift allowed for the production of personalized components and interior elements, enhancing the overall customer experience without significantly impacting production costs or timelines.

The adoption of large-scale 3D printing systems in PHEV manufacturing facilities represented a turning point in the industry. These systems enabled the production of larger structural components, reducing assembly time and improving overall vehicle integrity.

Recent developments have seen the emergence of multi-material 3D printing techniques in PHEV production. This innovation allows for the creation of complex parts with varying material properties within a single component, further optimizing weight, strength, and functionality.

The latest frontier in this evolution is the integration of 3D printing with artificial intelligence and machine learning. These technologies work in tandem to continuously optimize part designs and manufacturing processes, pushing the boundaries of what's possible in PHEV production.

As we look to the future, the role of 3D printing in PHEV manufacturing is set to expand further. Emerging technologies such as 4D printing, which allows for the creation of parts that can change shape or properties over time, promise to bring even more innovation to the field, potentially revolutionizing aspects like adaptive aerodynamics and self-repairing components in PHEVs.

The journey of 3D printing in PHEV manufacturing began with rapid prototyping, allowing designers and engineers to quickly iterate and test new components. As the technology matured, its application expanded to include the production of complex, lightweight parts that were previously difficult or impossible to manufacture using conventional methods.

One of the key milestones in this evolution was the development of advanced materials suitable for 3D printing in automotive applications. These materials, including high-performance polymers and metal alloys, enabled the production of functional parts that could withstand the rigorous demands of vehicle operation.

The integration of 3D printing into PHEV battery manufacturing marked another significant advancement. This technology allowed for the creation of intricate cooling channels and optimized battery casings, leading to improved thermal management and increased energy density in PHEV battery packs.

As 3D printing capabilities expanded, manufacturers began to explore its potential for mass customization. This shift allowed for the production of personalized components and interior elements, enhancing the overall customer experience without significantly impacting production costs or timelines.

The adoption of large-scale 3D printing systems in PHEV manufacturing facilities represented a turning point in the industry. These systems enabled the production of larger structural components, reducing assembly time and improving overall vehicle integrity.

Recent developments have seen the emergence of multi-material 3D printing techniques in PHEV production. This innovation allows for the creation of complex parts with varying material properties within a single component, further optimizing weight, strength, and functionality.

The latest frontier in this evolution is the integration of 3D printing with artificial intelligence and machine learning. These technologies work in tandem to continuously optimize part designs and manufacturing processes, pushing the boundaries of what's possible in PHEV production.

As we look to the future, the role of 3D printing in PHEV manufacturing is set to expand further. Emerging technologies such as 4D printing, which allows for the creation of parts that can change shape or properties over time, promise to bring even more innovation to the field, potentially revolutionizing aspects like adaptive aerodynamics and self-repairing components in PHEVs.

PHEV Market Demand Analysis

The market demand for Plug-in Hybrid Electric Vehicles (PHEVs) has been steadily growing in recent years, driven by increasing environmental awareness, government incentives, and advancements in battery technology. As consumers seek more fuel-efficient and environmentally friendly transportation options, PHEVs have emerged as a compelling alternative to traditional internal combustion engine vehicles.

Global PHEV sales have shown a significant upward trend, with major automotive markets such as China, Europe, and North America leading the adoption. The PHEV market is expected to continue its growth trajectory, with projections indicating a compound annual growth rate (CAGR) of over 30% in the coming years. This robust growth is supported by stringent emissions regulations, tax incentives, and the expanding charging infrastructure across various regions.

Consumer preferences are shifting towards PHEVs due to their ability to offer both electric-only driving for short commutes and the flexibility of a gasoline engine for longer trips. This dual-powertrain configuration addresses range anxiety concerns associated with pure electric vehicles while still providing substantial fuel economy benefits. As battery technology improves and costs decrease, PHEVs are becoming increasingly attractive to a broader range of consumers.

The automotive industry is responding to this demand by expanding PHEV model offerings across various vehicle segments, from compact cars to SUVs and luxury vehicles. Major automakers are investing heavily in PHEV technology development and production capacity to meet the growing market demand and comply with increasingly stringent emissions standards.

However, challenges remain in the PHEV market. The higher upfront costs compared to conventional vehicles continue to be a barrier for some consumers, despite long-term savings on fuel costs. Additionally, the availability and convenience of charging infrastructure, particularly in urban areas, remain concerns for potential PHEV buyers.

The integration of 3D printing in PHEV manufacturing has the potential to address some of these challenges by enabling more efficient and cost-effective production processes. 3D printing can facilitate the creation of complex, lightweight components, potentially reducing vehicle weight and improving fuel efficiency. It also allows for greater design flexibility and customization, which could lead to more attractive and functional PHEV models tailored to specific market segments.

As the PHEV market continues to evolve, the demand for innovative manufacturing solutions that can improve production efficiency, reduce costs, and enhance vehicle performance is expected to grow. The application of 3D printing in PHEV manufacturing aligns with these market needs, potentially revolutionizing the production process and contributing to the overall growth and competitiveness of the PHEV market.

Global PHEV sales have shown a significant upward trend, with major automotive markets such as China, Europe, and North America leading the adoption. The PHEV market is expected to continue its growth trajectory, with projections indicating a compound annual growth rate (CAGR) of over 30% in the coming years. This robust growth is supported by stringent emissions regulations, tax incentives, and the expanding charging infrastructure across various regions.

Consumer preferences are shifting towards PHEVs due to their ability to offer both electric-only driving for short commutes and the flexibility of a gasoline engine for longer trips. This dual-powertrain configuration addresses range anxiety concerns associated with pure electric vehicles while still providing substantial fuel economy benefits. As battery technology improves and costs decrease, PHEVs are becoming increasingly attractive to a broader range of consumers.

The automotive industry is responding to this demand by expanding PHEV model offerings across various vehicle segments, from compact cars to SUVs and luxury vehicles. Major automakers are investing heavily in PHEV technology development and production capacity to meet the growing market demand and comply with increasingly stringent emissions standards.

However, challenges remain in the PHEV market. The higher upfront costs compared to conventional vehicles continue to be a barrier for some consumers, despite long-term savings on fuel costs. Additionally, the availability and convenience of charging infrastructure, particularly in urban areas, remain concerns for potential PHEV buyers.

The integration of 3D printing in PHEV manufacturing has the potential to address some of these challenges by enabling more efficient and cost-effective production processes. 3D printing can facilitate the creation of complex, lightweight components, potentially reducing vehicle weight and improving fuel efficiency. It also allows for greater design flexibility and customization, which could lead to more attractive and functional PHEV models tailored to specific market segments.

As the PHEV market continues to evolve, the demand for innovative manufacturing solutions that can improve production efficiency, reduce costs, and enhance vehicle performance is expected to grow. The application of 3D printing in PHEV manufacturing aligns with these market needs, potentially revolutionizing the production process and contributing to the overall growth and competitiveness of the PHEV market.

3D Printing Challenges in PHEV

The integration of 3D printing technology into Plug-in Hybrid Electric Vehicle (PHEV) manufacturing presents several significant challenges that need to be addressed. One of the primary obstacles is the scalability of 3D printing processes for mass production. While 3D printing excels in producing complex, customized parts, it often struggles with the high-volume requirements of automotive manufacturing. The speed of production and the ability to maintain consistent quality across large batches remain areas of concern.

Material limitations pose another substantial challenge. The automotive industry demands materials with specific mechanical, thermal, and chemical properties to meet stringent safety and performance standards. Currently, the range of 3D printable materials that can meet these requirements is limited, particularly for components that are subjected to high stress or extreme conditions. Developing new materials that are both suitable for 3D printing and capable of meeting automotive standards is an ongoing challenge.

Quality control and certification present additional hurdles. Traditional manufacturing processes have well-established quality control procedures and certification standards. However, 3D printed parts may exhibit different material properties or structural characteristics compared to conventionally manufactured components. Establishing new testing protocols and certification processes for 3D printed automotive parts is crucial to ensure reliability and safety.

The integration of 3D printing into existing manufacturing workflows is another significant challenge. PHEVs are complex systems that require precise coordination between various components. Incorporating 3D printed parts into this ecosystem requires careful planning and may necessitate redesigning certain aspects of the vehicle or manufacturing process. This integration challenge extends to supply chain management, as 3D printing could potentially disrupt traditional supplier relationships and logistics.

Cost considerations also play a crucial role in the adoption of 3D printing for PHEV manufacturing. While 3D printing can reduce costs for low-volume, highly customized parts, it may not always be cost-effective for large-scale production. The initial investment in 3D printing equipment, materials, and training can be substantial, and the per-unit cost of 3D printed parts may still exceed that of traditionally manufactured components in many cases.

Lastly, there are challenges related to intellectual property and design security. 3D printing relies heavily on digital design files, which can be vulnerable to theft or unauthorized reproduction. Protecting proprietary designs and ensuring that 3D printed parts are not counterfeited or produced without proper licensing is a growing concern in the automotive industry. Developing robust digital rights management systems and secure file transfer protocols is essential to address these issues.

Material limitations pose another substantial challenge. The automotive industry demands materials with specific mechanical, thermal, and chemical properties to meet stringent safety and performance standards. Currently, the range of 3D printable materials that can meet these requirements is limited, particularly for components that are subjected to high stress or extreme conditions. Developing new materials that are both suitable for 3D printing and capable of meeting automotive standards is an ongoing challenge.

Quality control and certification present additional hurdles. Traditional manufacturing processes have well-established quality control procedures and certification standards. However, 3D printed parts may exhibit different material properties or structural characteristics compared to conventionally manufactured components. Establishing new testing protocols and certification processes for 3D printed automotive parts is crucial to ensure reliability and safety.

The integration of 3D printing into existing manufacturing workflows is another significant challenge. PHEVs are complex systems that require precise coordination between various components. Incorporating 3D printed parts into this ecosystem requires careful planning and may necessitate redesigning certain aspects of the vehicle or manufacturing process. This integration challenge extends to supply chain management, as 3D printing could potentially disrupt traditional supplier relationships and logistics.

Cost considerations also play a crucial role in the adoption of 3D printing for PHEV manufacturing. While 3D printing can reduce costs for low-volume, highly customized parts, it may not always be cost-effective for large-scale production. The initial investment in 3D printing equipment, materials, and training can be substantial, and the per-unit cost of 3D printed parts may still exceed that of traditionally manufactured components in many cases.

Lastly, there are challenges related to intellectual property and design security. 3D printing relies heavily on digital design files, which can be vulnerable to theft or unauthorized reproduction. Protecting proprietary designs and ensuring that 3D printed parts are not counterfeited or produced without proper licensing is a growing concern in the automotive industry. Developing robust digital rights management systems and secure file transfer protocols is essential to address these issues.

Current 3D Printing Solutions

01 3D printing methods and systems

Various methods and systems for 3D printing, including advanced techniques for improving print quality, speed, and efficiency. These may involve novel printing mechanisms, material handling systems, or control algorithms to enhance the overall printing process.- 3D printing methods and systems: Various methods and systems for 3D printing, including advancements in printing techniques, materials, and equipment. These innovations aim to improve print quality, speed, and efficiency across different applications.

- Materials for 3D printing: Development of new materials and compositions specifically designed for 3D printing applications. This includes improved polymers, composites, and other substances that enhance the properties and performance of 3D printed objects.

- 3D printing in manufacturing and production: Integration of 3D printing technologies into manufacturing and production processes. This includes applications in rapid prototyping, customized production, and on-demand manufacturing across various industries.

- 3D printing for medical and biomedical applications: Utilization of 3D printing in medical and biomedical fields, including the creation of prosthetics, implants, and tissue engineering scaffolds. This also covers advancements in bioprinting and personalized medicine.

- Software and control systems for 3D printing: Development of software solutions and control systems specifically designed for 3D printing processes. This includes advancements in modeling, slicing, and printer control software to improve print accuracy and efficiency.

02 Materials for 3D printing

Development of new materials and compositions specifically designed for 3D printing applications. This includes innovative filaments, resins, and powders that offer improved mechanical properties, durability, or functional characteristics in printed objects.Expand Specific Solutions03 Post-processing techniques for 3D printed objects

Methods and systems for enhancing the properties of 3D printed objects after the printing process. This may include surface treatments, curing processes, or finishing techniques to improve strength, appearance, or functionality of the printed items.Expand Specific Solutions04 Specialized 3D printing applications

Innovative uses of 3D printing technology in specific fields such as medicine, aerospace, or consumer products. These applications may involve custom-designed printers or processes tailored to produce specialized components or structures.Expand Specific Solutions05 Integration of 3D printing with other technologies

Combining 3D printing with other advanced manufacturing or design technologies to create hybrid systems. This may include integration with robotics, AI-driven design optimization, or IoT connectivity for improved production efficiency and product customization.Expand Specific Solutions

Key Players in 3D Printed PHEV

The 3D printing revolution in PHEV manufacturing is in its early growth stage, with a rapidly expanding market and evolving technological landscape. The industry is experiencing significant advancements, driven by key players like Divergent Technologies, which has developed an end-to-end digital manufacturing system for automotive applications. Universities such as Huazhong University of Science & Technology and the University of Freiburg are contributing to research and development, while companies like Nikon Corp. and Mitsubishi Heavy Industries are exploring industrial applications. The technology's maturity varies across different aspects of PHEV manufacturing, with some areas showing promising results in prototyping and small-scale production, while others are still in the experimental phase.

Divergent Technologies, Inc.

Technical Solution: Divergent Technologies has pioneered the Divergent Adaptive Production System (DAPS), a revolutionary approach to vehicle manufacturing that heavily incorporates 3D printing. For PHEV production, DAPS utilizes advanced metal 3D printing to create complex structural components of the vehicle chassis. The system prints individual nodes that are then connected by carbon fiber tubes, forming a lightweight yet strong vehicle structure[1][5]. This modular approach allows for rapid design iterations and customization of PHEV models. Divergent's technology enables the production of vehicle structures that are up to 50% lighter than traditional stamped metal designs, significantly improving the energy efficiency of PHEVs[2]. The company's 3D printing process also integrates AI-driven generative design to optimize part topology for weight reduction and performance enhancement[3].

Strengths: Significant weight reduction, improved design flexibility, and faster time-to-market for new PHEV models. Weaknesses: Potential challenges in scaling to mass production and integration with existing automotive manufacturing processes.

The Regents of the University of California

Technical Solution: The University of California system has conducted extensive research on 3D printing applications for PHEV manufacturing across multiple campuses. At UC Berkeley, researchers have developed a novel 3D printing technique called computed axial lithography (CAL) that allows for the rapid production of complex polymer parts with smooth surfaces, ideal for PHEV interior components and fluid systems[1]. UC San Diego has focused on 3D printing of advanced battery materials, including solid-state electrolytes and high-capacity electrodes, which could revolutionize PHEV energy storage systems[2]. UC Irvine's work on 3D-printed metamaterials has applications in creating lightweight, energy-absorbing structures for PHEV safety systems[3]. Additionally, UCLA has pioneered 3D-printed graphene supercapacitors that could provide rapid energy storage and release for PHEV power management[4].

Strengths: Diverse research portfolio covering multiple aspects of PHEV manufacturing, potential for breakthrough technologies in energy storage and lightweight structures. Weaknesses: Academic research may require significant development and partnerships for commercial implementation in PHEV production.

Core 3D Printing Innovations

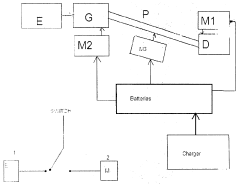

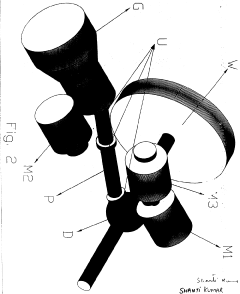

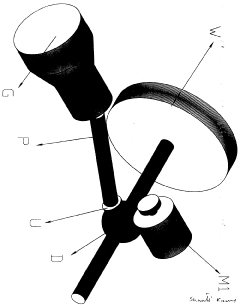

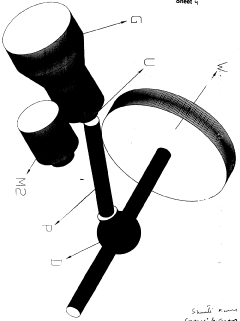

Hybrid vehicle.

PatentInactiveIN1132DEL2006A

Innovation

- A PHEV design that allows easy switching between engine and electric modes using a simple selector switch and a propeller shaft with universal joints and sprocket collar for power transmission, eliminating the need for extensive electronic controls and enabling user-controlled mode transitions.

Additive manufactured hybrid automotive dashboard using polyethylene blended with abs

PatentPendingIN202341072817A

Innovation

- The fusion of Polyethylene (PE) and Acrylonitrile Butadiene Styrene (ABS) through additive manufacturing, allowing for the creation of hybrid dashboards that leverage the strengths of both materials in terms of strength, durability, and aesthetics, while reducing material waste and enabling on-demand production.

Sustainability Impact

The integration of 3D printing technology into PHEV (Plug-in Hybrid Electric Vehicle) manufacturing processes has significant implications for sustainability. This innovative approach addresses several environmental concerns associated with traditional automotive production methods.

Firstly, 3D printing enables a substantial reduction in material waste. Unlike subtractive manufacturing techniques, additive manufacturing processes used in 3D printing only utilize the exact amount of material needed for each component. This precision minimizes excess material consumption and reduces the environmental impact of raw material extraction and processing.

Furthermore, 3D printing facilitates the production of lightweight components, which is crucial for improving the energy efficiency of PHEVs. By optimizing the internal structures of parts through complex geometries that are only possible with 3D printing, manufacturers can create components that maintain strength while significantly reducing weight. This weight reduction directly translates to improved fuel economy and reduced emissions during the vehicle's operational life.

The localization of production is another sustainability benefit of 3D printing in PHEV manufacturing. By enabling on-demand, decentralized production of components, 3D printing reduces the need for long-distance transportation of parts. This localization decreases the carbon footprint associated with logistics and supply chain operations, contributing to overall emissions reduction in the automotive industry.

Additionally, 3D printing technology supports the principles of a circular economy in PHEV manufacturing. The ability to easily recycle and reuse materials in the 3D printing process promotes a more sustainable approach to resource management. Failed prints or obsolete parts can be ground down and reprocessed, minimizing waste and reducing the demand for virgin materials.

The customization capabilities of 3D printing also contribute to sustainability by potentially extending the lifespan of PHEVs. Manufacturers can produce replacement parts on-demand, even for older models, reducing the likelihood of vehicles being scrapped due to unavailable components. This approach not only extends the useful life of vehicles but also reduces the environmental impact associated with premature vehicle replacement.

Lastly, 3D printing enables rapid prototyping and iterative design processes, which can lead to more efficient and environmentally friendly PHEV designs. This agility in the development phase allows manufacturers to optimize vehicle performance and sustainability features more quickly and cost-effectively than traditional methods, potentially accelerating the adoption of more sustainable transportation solutions.

Firstly, 3D printing enables a substantial reduction in material waste. Unlike subtractive manufacturing techniques, additive manufacturing processes used in 3D printing only utilize the exact amount of material needed for each component. This precision minimizes excess material consumption and reduces the environmental impact of raw material extraction and processing.

Furthermore, 3D printing facilitates the production of lightweight components, which is crucial for improving the energy efficiency of PHEVs. By optimizing the internal structures of parts through complex geometries that are only possible with 3D printing, manufacturers can create components that maintain strength while significantly reducing weight. This weight reduction directly translates to improved fuel economy and reduced emissions during the vehicle's operational life.

The localization of production is another sustainability benefit of 3D printing in PHEV manufacturing. By enabling on-demand, decentralized production of components, 3D printing reduces the need for long-distance transportation of parts. This localization decreases the carbon footprint associated with logistics and supply chain operations, contributing to overall emissions reduction in the automotive industry.

Additionally, 3D printing technology supports the principles of a circular economy in PHEV manufacturing. The ability to easily recycle and reuse materials in the 3D printing process promotes a more sustainable approach to resource management. Failed prints or obsolete parts can be ground down and reprocessed, minimizing waste and reducing the demand for virgin materials.

The customization capabilities of 3D printing also contribute to sustainability by potentially extending the lifespan of PHEVs. Manufacturers can produce replacement parts on-demand, even for older models, reducing the likelihood of vehicles being scrapped due to unavailable components. This approach not only extends the useful life of vehicles but also reduces the environmental impact associated with premature vehicle replacement.

Lastly, 3D printing enables rapid prototyping and iterative design processes, which can lead to more efficient and environmentally friendly PHEV designs. This agility in the development phase allows manufacturers to optimize vehicle performance and sustainability features more quickly and cost-effectively than traditional methods, potentially accelerating the adoption of more sustainable transportation solutions.

Cost-Benefit Analysis

The integration of 3D printing technology into PHEV manufacturing processes presents a complex cost-benefit scenario that requires careful analysis. Initial implementation costs for 3D printing equipment and training can be substantial, often ranging from $100,000 to $1 million depending on the scale and sophistication of the machinery. However, these upfront investments can lead to significant long-term savings in production costs.

One of the primary benefits is the reduction in material waste. Traditional manufacturing methods can result in up to 30% material waste, while 3D printing can reduce this to less than 10%. For PHEV components, which often involve expensive and rare materials, this waste reduction translates to substantial cost savings over time.

Labor costs also see a notable decrease with the adoption of 3D printing. Automated 3D printing processes require fewer human operators, potentially reducing labor costs by 20-50% in certain production lines. This efficiency gain must be balanced against the need for skilled technicians to operate and maintain the 3D printing equipment.

The flexibility of 3D printing allows for rapid prototyping and customization, significantly reducing the time-to-market for new PHEV models or components. This agility can result in a competitive advantage, potentially increasing market share and revenue. Studies suggest that companies implementing 3D printing in automotive manufacturing can reduce product development cycles by up to 70%.

Energy consumption is another factor to consider. While 3D printers consume electricity, they often require less energy than traditional manufacturing processes for complex parts. Some estimates suggest energy savings of up to 50% for certain components, contributing to both cost reduction and environmental sustainability goals.

Inventory and logistics costs can be dramatically reduced through on-demand production capabilities. By printing components as needed, manufacturers can minimize warehouse space requirements and reduce the costs associated with storing and managing large inventories. This just-in-time production model can lead to savings of 15-20% in inventory-related expenses.

Quality improvements and reduced defect rates are additional benefits that impact the cost-benefit analysis. 3D printing allows for more precise production of complex geometries, potentially reducing defect rates by up to 90% for certain components. This improvement in quality can lead to decreased warranty claims and enhanced customer satisfaction, indirectly contributing to long-term cost savings and brand value.

One of the primary benefits is the reduction in material waste. Traditional manufacturing methods can result in up to 30% material waste, while 3D printing can reduce this to less than 10%. For PHEV components, which often involve expensive and rare materials, this waste reduction translates to substantial cost savings over time.

Labor costs also see a notable decrease with the adoption of 3D printing. Automated 3D printing processes require fewer human operators, potentially reducing labor costs by 20-50% in certain production lines. This efficiency gain must be balanced against the need for skilled technicians to operate and maintain the 3D printing equipment.

The flexibility of 3D printing allows for rapid prototyping and customization, significantly reducing the time-to-market for new PHEV models or components. This agility can result in a competitive advantage, potentially increasing market share and revenue. Studies suggest that companies implementing 3D printing in automotive manufacturing can reduce product development cycles by up to 70%.

Energy consumption is another factor to consider. While 3D printers consume electricity, they often require less energy than traditional manufacturing processes for complex parts. Some estimates suggest energy savings of up to 50% for certain components, contributing to both cost reduction and environmental sustainability goals.

Inventory and logistics costs can be dramatically reduced through on-demand production capabilities. By printing components as needed, manufacturers can minimize warehouse space requirements and reduce the costs associated with storing and managing large inventories. This just-in-time production model can lead to savings of 15-20% in inventory-related expenses.

Quality improvements and reduced defect rates are additional benefits that impact the cost-benefit analysis. 3D printing allows for more precise production of complex geometries, potentially reducing defect rates by up to 90% for certain components. This improvement in quality can lead to decreased warranty claims and enhanced customer satisfaction, indirectly contributing to long-term cost savings and brand value.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!