How PHEV technology promotes sustainable mining practices

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHEV in Mining: Background and Objectives

Plug-in Hybrid Electric Vehicle (PHEV) technology has emerged as a promising solution to address the environmental challenges faced by the mining industry. The evolution of PHEV technology in mining operations can be traced back to the early 2000s when the industry began exploring ways to reduce its carbon footprint and improve energy efficiency. As global awareness of climate change and sustainability increased, mining companies started to recognize the potential of hybrid technologies to mitigate their environmental impact.

The primary objective of implementing PHEV technology in mining is to promote sustainable practices by reducing greenhouse gas emissions, improving energy efficiency, and lowering operational costs. This aligns with the broader industry goals of minimizing environmental impact, enhancing safety, and maintaining profitability in an increasingly competitive global market.

PHEV technology combines the benefits of both electric and conventional internal combustion engines, making it particularly suitable for mining applications. In the mining context, PHEVs can operate on electric power for short-range, low-load operations, switching to the internal combustion engine for high-power tasks or when extended range is required. This flexibility addresses the unique challenges of mining environments, where vehicles often need to operate in remote locations with limited charging infrastructure.

The development of PHEV technology for mining has been driven by several key factors. Firstly, stringent environmental regulations and increasing pressure from stakeholders have compelled mining companies to adopt cleaner technologies. Secondly, the volatility of fuel prices has incentivized the industry to seek more cost-effective and efficient energy solutions. Lastly, advancements in battery technology and power electronics have made PHEV systems more viable and reliable for heavy-duty mining applications.

As the technology has progressed, PHEV systems in mining have evolved from simple parallel hybrid configurations to more sophisticated series-parallel and power-split architectures. These advancements have led to improved energy recovery through regenerative braking, optimized power management, and enhanced overall system efficiency. The integration of PHEV technology has expanded from light-duty vehicles to heavy-duty mining equipment, including haul trucks, loaders, and excavators.

Looking ahead, the future trajectory of PHEV technology in mining is focused on further improving energy density, extending battery life, and enhancing system integration. Research and development efforts are also directed towards developing more robust and reliable PHEV systems capable of withstanding the harsh conditions typical of mining environments. The ultimate goal is to create a seamless transition towards fully electric mining operations, with PHEV technology serving as a crucial stepping stone in this transformation.

The primary objective of implementing PHEV technology in mining is to promote sustainable practices by reducing greenhouse gas emissions, improving energy efficiency, and lowering operational costs. This aligns with the broader industry goals of minimizing environmental impact, enhancing safety, and maintaining profitability in an increasingly competitive global market.

PHEV technology combines the benefits of both electric and conventional internal combustion engines, making it particularly suitable for mining applications. In the mining context, PHEVs can operate on electric power for short-range, low-load operations, switching to the internal combustion engine for high-power tasks or when extended range is required. This flexibility addresses the unique challenges of mining environments, where vehicles often need to operate in remote locations with limited charging infrastructure.

The development of PHEV technology for mining has been driven by several key factors. Firstly, stringent environmental regulations and increasing pressure from stakeholders have compelled mining companies to adopt cleaner technologies. Secondly, the volatility of fuel prices has incentivized the industry to seek more cost-effective and efficient energy solutions. Lastly, advancements in battery technology and power electronics have made PHEV systems more viable and reliable for heavy-duty mining applications.

As the technology has progressed, PHEV systems in mining have evolved from simple parallel hybrid configurations to more sophisticated series-parallel and power-split architectures. These advancements have led to improved energy recovery through regenerative braking, optimized power management, and enhanced overall system efficiency. The integration of PHEV technology has expanded from light-duty vehicles to heavy-duty mining equipment, including haul trucks, loaders, and excavators.

Looking ahead, the future trajectory of PHEV technology in mining is focused on further improving energy density, extending battery life, and enhancing system integration. Research and development efforts are also directed towards developing more robust and reliable PHEV systems capable of withstanding the harsh conditions typical of mining environments. The ultimate goal is to create a seamless transition towards fully electric mining operations, with PHEV technology serving as a crucial stepping stone in this transformation.

Market Demand for Sustainable Mining Solutions

The mining industry is experiencing a significant shift towards sustainable practices, driven by environmental concerns, regulatory pressures, and the need for operational efficiency. This has created a growing market demand for sustainable mining solutions, with Plug-in Hybrid Electric Vehicle (PHEV) technology emerging as a promising avenue to address these challenges.

The global mining equipment market is projected to reach $165 billion by 2025, with a substantial portion dedicated to sustainable solutions. Mining companies are increasingly recognizing the importance of reducing their carbon footprint and improving energy efficiency. This has led to a surge in demand for electrified mining vehicles, including PHEVs, which offer a balance between traditional diesel power and clean electric propulsion.

PHEV technology in mining equipment addresses several key market needs. Firstly, it helps mining companies meet stringent emissions regulations imposed by governments worldwide. Many countries have set ambitious targets for reducing greenhouse gas emissions, and the mining sector is under pressure to comply. PHEVs offer a practical solution by significantly reducing emissions without compromising on performance.

Secondly, there is a growing demand for cost-effective operations in the mining industry. PHEV technology can lead to substantial fuel savings, especially in underground mining operations where ventilation costs are a major concern. The ability to operate in electric mode for extended periods reduces the need for diesel fuel and minimizes the release of harmful exhaust gases, thereby lowering ventilation requirements and associated costs.

Safety is another critical factor driving the demand for PHEV technology in mining. Electric operation results in reduced noise levels and heat generation, creating a safer working environment for miners. This aligns with the industry's increasing focus on worker health and safety, making PHEV-equipped vehicles an attractive option for mining companies looking to improve their safety records.

Furthermore, the market is seeing a rise in demand for flexible and versatile mining equipment. PHEV technology allows for seamless switching between electric and diesel modes, providing the adaptability needed in various mining environments. This flexibility is particularly valuable in remote mining locations where access to charging infrastructure may be limited.

The push for sustainable mining practices is also influenced by stakeholder expectations. Investors, local communities, and consumers are increasingly scrutinizing mining companies' environmental performance. Adopting PHEV technology demonstrates a commitment to sustainability, which can enhance a company's reputation and social license to operate.

As the mining industry continues to evolve, the demand for PHEV technology is expected to grow further. Mining companies are seeking solutions that not only address current sustainability challenges but also future-proof their operations against tightening regulations and changing market expectations. This presents significant opportunities for PHEV technology providers to innovate and expand their offerings in the mining sector.

The global mining equipment market is projected to reach $165 billion by 2025, with a substantial portion dedicated to sustainable solutions. Mining companies are increasingly recognizing the importance of reducing their carbon footprint and improving energy efficiency. This has led to a surge in demand for electrified mining vehicles, including PHEVs, which offer a balance between traditional diesel power and clean electric propulsion.

PHEV technology in mining equipment addresses several key market needs. Firstly, it helps mining companies meet stringent emissions regulations imposed by governments worldwide. Many countries have set ambitious targets for reducing greenhouse gas emissions, and the mining sector is under pressure to comply. PHEVs offer a practical solution by significantly reducing emissions without compromising on performance.

Secondly, there is a growing demand for cost-effective operations in the mining industry. PHEV technology can lead to substantial fuel savings, especially in underground mining operations where ventilation costs are a major concern. The ability to operate in electric mode for extended periods reduces the need for diesel fuel and minimizes the release of harmful exhaust gases, thereby lowering ventilation requirements and associated costs.

Safety is another critical factor driving the demand for PHEV technology in mining. Electric operation results in reduced noise levels and heat generation, creating a safer working environment for miners. This aligns with the industry's increasing focus on worker health and safety, making PHEV-equipped vehicles an attractive option for mining companies looking to improve their safety records.

Furthermore, the market is seeing a rise in demand for flexible and versatile mining equipment. PHEV technology allows for seamless switching between electric and diesel modes, providing the adaptability needed in various mining environments. This flexibility is particularly valuable in remote mining locations where access to charging infrastructure may be limited.

The push for sustainable mining practices is also influenced by stakeholder expectations. Investors, local communities, and consumers are increasingly scrutinizing mining companies' environmental performance. Adopting PHEV technology demonstrates a commitment to sustainability, which can enhance a company's reputation and social license to operate.

As the mining industry continues to evolve, the demand for PHEV technology is expected to grow further. Mining companies are seeking solutions that not only address current sustainability challenges but also future-proof their operations against tightening regulations and changing market expectations. This presents significant opportunities for PHEV technology providers to innovate and expand their offerings in the mining sector.

Current State of PHEV in Mining Industry

The adoption of Plug-in Hybrid Electric Vehicle (PHEV) technology in the mining industry is gaining momentum as companies seek to reduce their environmental footprint and operational costs. Currently, several major mining corporations have begun integrating PHEV systems into their heavy-duty vehicles and equipment fleets. These hybrid systems combine traditional diesel engines with electric motors and battery packs, allowing for significant reductions in fuel consumption and emissions.

In open-pit mining operations, PHEV haul trucks have shown promising results. These vehicles utilize electric drive systems for low-speed operations and when traveling downhill, while the diesel engine provides power for uphill climbs and high-load situations. This dual-power approach has led to fuel savings of up to 30% in some cases, with corresponding reductions in greenhouse gas emissions.

Underground mining presents unique challenges for PHEV implementation due to ventilation requirements and space constraints. However, progress is being made in this area as well. Several manufacturers have developed PHEV load-haul-dump (LHD) machines and utility vehicles specifically designed for underground use. These vehicles can operate on battery power alone for extended periods, reducing the need for diesel exhaust ventilation and improving air quality for workers.

The current state of PHEV technology in mining also extends to auxiliary equipment such as light vehicles, bulldozers, and excavators. Many mining sites are now using PHEV pickup trucks and SUVs for personnel transportation and light-duty tasks. Some companies have even begun testing PHEV versions of larger earthmoving equipment, though these applications are still in the early stages of development.

Charging infrastructure remains a critical component of PHEV implementation in mining. Many sites are installing fast-charging stations at strategic locations, allowing vehicles to recharge during shift changes or other operational pauses. Some operations are exploring the use of renewable energy sources, such as solar or wind power, to charge their PHEV fleets, further enhancing the sustainability benefits of the technology.

While the adoption of PHEV technology in mining is promising, it is not without challenges. The harsh operating conditions and heavy-duty requirements of mining equipment pose significant engineering hurdles. Additionally, the high initial costs of PHEV systems can be a barrier to widespread adoption, particularly for smaller mining operations. However, as technology improves and economies of scale are realized, these challenges are expected to diminish over time.

In open-pit mining operations, PHEV haul trucks have shown promising results. These vehicles utilize electric drive systems for low-speed operations and when traveling downhill, while the diesel engine provides power for uphill climbs and high-load situations. This dual-power approach has led to fuel savings of up to 30% in some cases, with corresponding reductions in greenhouse gas emissions.

Underground mining presents unique challenges for PHEV implementation due to ventilation requirements and space constraints. However, progress is being made in this area as well. Several manufacturers have developed PHEV load-haul-dump (LHD) machines and utility vehicles specifically designed for underground use. These vehicles can operate on battery power alone for extended periods, reducing the need for diesel exhaust ventilation and improving air quality for workers.

The current state of PHEV technology in mining also extends to auxiliary equipment such as light vehicles, bulldozers, and excavators. Many mining sites are now using PHEV pickup trucks and SUVs for personnel transportation and light-duty tasks. Some companies have even begun testing PHEV versions of larger earthmoving equipment, though these applications are still in the early stages of development.

Charging infrastructure remains a critical component of PHEV implementation in mining. Many sites are installing fast-charging stations at strategic locations, allowing vehicles to recharge during shift changes or other operational pauses. Some operations are exploring the use of renewable energy sources, such as solar or wind power, to charge their PHEV fleets, further enhancing the sustainability benefits of the technology.

While the adoption of PHEV technology in mining is promising, it is not without challenges. The harsh operating conditions and heavy-duty requirements of mining equipment pose significant engineering hurdles. Additionally, the high initial costs of PHEV systems can be a barrier to widespread adoption, particularly for smaller mining operations. However, as technology improves and economies of scale are realized, these challenges are expected to diminish over time.

Existing PHEV Solutions for Mining Operations

01 Hybrid powertrain control systems

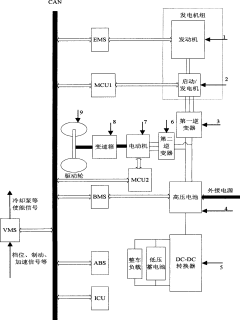

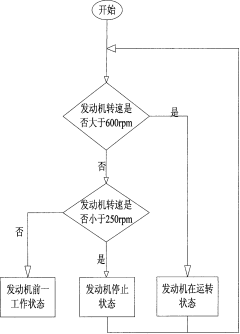

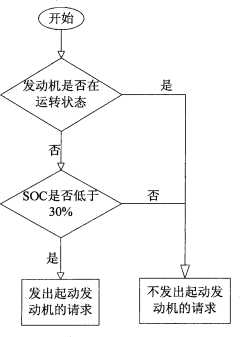

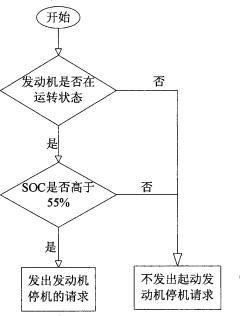

Advanced control systems for managing power distribution between internal combustion engines and electric motors in PHEVs. These systems optimize fuel efficiency, performance, and emissions by intelligently switching between power sources based on driving conditions and battery state of charge.- Hybrid powertrain control systems: Advanced control systems for managing power distribution between electric motors and internal combustion engines in PHEVs. These systems optimize energy efficiency, performance, and emissions by intelligently switching between power sources based on driving conditions and battery state of charge.

- Battery management and charging technologies: Innovative battery management systems and charging technologies for PHEVs, including fast charging capabilities, battery health monitoring, and intelligent charge scheduling. These advancements aim to improve battery life, charging efficiency, and overall vehicle range.

- Regenerative braking systems: Enhanced regenerative braking systems that capture and store kinetic energy during deceleration, converting it into electrical energy to recharge the battery. These systems improve overall energy efficiency and extend the electric driving range of PHEVs.

- Thermal management for PHEV components: Advanced thermal management solutions for critical PHEV components, including batteries, electric motors, and power electronics. These systems help maintain optimal operating temperatures, improve efficiency, and extend the lifespan of key components.

- Integration of renewable energy sources: Innovative technologies for integrating renewable energy sources, such as solar panels, into PHEV charging systems. These advancements aim to reduce reliance on grid electricity and improve the overall environmental impact of PHEVs.

02 Battery management and charging technologies

Innovative battery management systems and charging technologies for PHEVs, including fast charging capabilities, battery health monitoring, and energy recovery systems. These advancements aim to improve battery life, charging efficiency, and overall vehicle range.Expand Specific Solutions03 Regenerative braking systems

Enhanced regenerative braking systems that capture and store kinetic energy during deceleration, converting it into electrical energy to recharge the battery. These systems improve overall energy efficiency and extend the electric driving range of PHEVs.Expand Specific Solutions04 Thermal management for PHEV components

Advanced thermal management solutions for various PHEV components, including batteries, electric motors, and power electronics. These systems help maintain optimal operating temperatures, improve efficiency, and extend the lifespan of critical components.Expand Specific Solutions05 Integration of renewable energy sources

Technologies for integrating renewable energy sources, such as solar panels, into PHEV charging systems. These innovations aim to reduce reliance on grid electricity and further decrease the carbon footprint of PHEVs.Expand Specific Solutions

Key Players in Mining PHEV Development

The competition landscape for PHEV technology in sustainable mining practices is evolving rapidly. The industry is in a growth phase, with increasing market size as mining companies seek to reduce their environmental impact. The technology's maturity is advancing, with major players like Ford Global Technologies, Liebherr-Mining Equipment, and Komatsu Ltd. investing in research and development. Automotive giants such as Chery Automobile and Guangzhou Automobile Group are also entering this space, leveraging their expertise in PHEV technology. Universities like North China Electric Power University and Beijing University of Technology are contributing to technological advancements. The market is characterized by a mix of established mining equipment manufacturers and new entrants from the automotive sector, indicating a dynamic and competitive environment.

Ford Global Technologies LLC

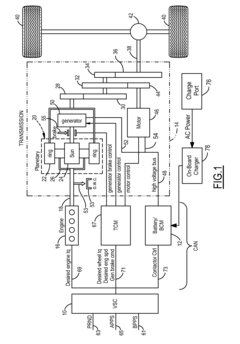

Technical Solution: While primarily known for passenger vehicles, Ford has applied its PHEV technology to develop sustainable solutions for mining support vehicles. Their system combines a fuel-efficient EcoBoost engine with electric motors and advanced lithium-ion batteries. Ford's PHEV mining vehicles can operate in electric-only mode for short distances within the mine, switching to hybrid mode for longer trips. The technology includes regenerative braking and an intelligent power split system that optimizes the use of electric and combustion power based on driving conditions and load[7]. Ford has also developed telematics systems that allow mine operators to monitor vehicle performance and emissions in real-time, enabling more efficient fleet management[8].

Strengths: Versatility in applications, from light-duty to medium-duty mining support vehicles, and integration with existing fleet management systems. Weaknesses: Limited experience in heavy-duty mining equipment compared to specialized mining equipment manufacturers.

Liebherr-Mining Equipment Colmar SAS

Technical Solution: Liebherr has developed a PHEV mining truck that combines a diesel engine with an electric drive system. The truck uses regenerative braking to capture energy during downhill operations, storing it in batteries for later use. This system can reduce fuel consumption by up to 30% compared to conventional diesel trucks[1]. The PHEV technology allows the truck to operate in full electric mode for short distances, reducing emissions in sensitive areas of the mine. Liebherr's system also includes an intelligent power management system that optimizes the use of diesel and electric power based on the truck's operating conditions and load[2].

Strengths: Significant fuel savings, reduced emissions, and ability to operate in zero-emission mode. Weaknesses: Higher initial cost and complexity of the hybrid system compared to traditional diesel trucks.

Core Innovations in Mining-Specific PHEV Tech

Control method of externally rechargeable type mixed power automobile generator group

PatentInactiveCN101519074A

Innovation

- The vehicle controller receives CAN messages, determines the status of the engine and high-voltage battery, realizes intelligent start-stop control of the generator set, and monitors faults in different working modes to ensure maximum efficiency of the generator set and protection of the high-voltage battery.

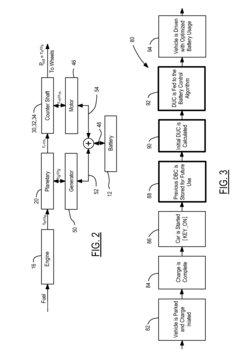

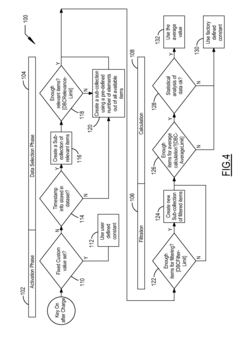

Adaptive Initial Estimation and Dynamic Determination and Update of Distance Until Charge of a Plug-In Hybrid Electric Vehicle

PatentActiveUS20110184600A1

Innovation

- A method and system that dynamically control battery usage based on the estimated or user-provided 'distance until charge' (DUC) value, utilizing historical data and real-time information from navigation systems to optimize battery depletion and charging strategies.

Environmental Impact Assessment of PHEV Mining

The environmental impact assessment of PHEV (Plug-in Hybrid Electric Vehicle) mining is a crucial aspect of evaluating the sustainability of this technology in mining operations. PHEVs offer significant potential for reducing the environmental footprint of mining activities, particularly in terms of emissions reduction and energy efficiency.

One of the primary benefits of PHEV technology in mining is the substantial reduction in greenhouse gas emissions. Traditional mining equipment relies heavily on diesel fuel, contributing to high levels of carbon dioxide and other pollutants. PHEVs, by incorporating electric power alongside conventional engines, can significantly decrease these emissions. Studies have shown that PHEVs can reduce CO2 emissions by up to 50% compared to conventional diesel-powered equipment, depending on the specific application and operating conditions.

Air quality improvements are another notable environmental benefit of PHEV mining. The reduction in diesel exhaust emissions leads to decreased levels of particulate matter, nitrogen oxides, and other harmful pollutants in the mining environment. This not only contributes to better air quality for workers but also minimizes the impact on surrounding ecosystems and communities.

Noise pollution, a common concern in mining operations, is also addressed by PHEV technology. Electric motors are inherently quieter than diesel engines, resulting in reduced noise levels during operation. This can have positive effects on wildlife in the vicinity of mining sites and improve working conditions for miners.

Energy efficiency is a key factor in the environmental assessment of PHEV mining. These vehicles can recover energy through regenerative braking, a feature particularly beneficial in mining operations that involve frequent stops and starts or downhill travel with heavy loads. This energy recovery contributes to overall reduced fuel consumption and increased operational efficiency.

The use of PHEVs in mining also has implications for water conservation. Traditional mining equipment often requires significant amounts of water for cooling systems. PHEVs, with their more efficient powertrains and reduced heat generation, can potentially decrease water consumption in mining operations, contributing to more sustainable water management practices.

However, the environmental impact assessment must also consider the lifecycle of PHEV batteries. The production and disposal of these batteries involve environmental considerations, including resource extraction and potential hazardous waste. Proper management and recycling programs for PHEV batteries in mining applications are essential to mitigate these concerns and ensure a truly sustainable approach.

One of the primary benefits of PHEV technology in mining is the substantial reduction in greenhouse gas emissions. Traditional mining equipment relies heavily on diesel fuel, contributing to high levels of carbon dioxide and other pollutants. PHEVs, by incorporating electric power alongside conventional engines, can significantly decrease these emissions. Studies have shown that PHEVs can reduce CO2 emissions by up to 50% compared to conventional diesel-powered equipment, depending on the specific application and operating conditions.

Air quality improvements are another notable environmental benefit of PHEV mining. The reduction in diesel exhaust emissions leads to decreased levels of particulate matter, nitrogen oxides, and other harmful pollutants in the mining environment. This not only contributes to better air quality for workers but also minimizes the impact on surrounding ecosystems and communities.

Noise pollution, a common concern in mining operations, is also addressed by PHEV technology. Electric motors are inherently quieter than diesel engines, resulting in reduced noise levels during operation. This can have positive effects on wildlife in the vicinity of mining sites and improve working conditions for miners.

Energy efficiency is a key factor in the environmental assessment of PHEV mining. These vehicles can recover energy through regenerative braking, a feature particularly beneficial in mining operations that involve frequent stops and starts or downhill travel with heavy loads. This energy recovery contributes to overall reduced fuel consumption and increased operational efficiency.

The use of PHEVs in mining also has implications for water conservation. Traditional mining equipment often requires significant amounts of water for cooling systems. PHEVs, with their more efficient powertrains and reduced heat generation, can potentially decrease water consumption in mining operations, contributing to more sustainable water management practices.

However, the environmental impact assessment must also consider the lifecycle of PHEV batteries. The production and disposal of these batteries involve environmental considerations, including resource extraction and potential hazardous waste. Proper management and recycling programs for PHEV batteries in mining applications are essential to mitigate these concerns and ensure a truly sustainable approach.

Economic Viability of PHEV in Mining Sector

The economic viability of Plug-in Hybrid Electric Vehicles (PHEVs) in the mining sector is a critical factor in promoting sustainable mining practices. As the industry faces increasing pressure to reduce its environmental impact and operational costs, PHEVs offer a promising solution that balances performance with sustainability.

The initial investment in PHEV technology for mining operations can be substantial, with higher upfront costs compared to traditional diesel-powered vehicles. However, the long-term economic benefits are significant. PHEVs can dramatically reduce fuel consumption, which is a major operational expense in mining. The ability to operate on electric power for shorter distances or during idling periods can lead to substantial savings in fuel costs over time.

Maintenance costs for PHEVs in mining applications are generally lower than those for conventional vehicles. Electric drivetrains have fewer moving parts, reducing wear and tear and extending the lifespan of key components. This translates to less frequent maintenance intervals and lower overall maintenance expenses, contributing to improved economic viability.

The mining sector's unique operational environment presents both challenges and opportunities for PHEV adoption. The heavy-duty nature of mining vehicles requires robust battery systems and powerful electric motors. While this increases the initial cost, it also provides an opportunity for significant energy recovery through regenerative braking during downhill operations, further enhancing fuel efficiency and economic benefits.

Government incentives and carbon pricing mechanisms play a crucial role in the economic equation. Many jurisdictions offer tax breaks, grants, or other financial incentives for adopting low-emission vehicles, which can help offset the higher initial costs of PHEVs. Additionally, as carbon pricing becomes more prevalent, the reduced emissions from PHEVs can translate into direct financial benefits through lower carbon taxes or increased carbon credits.

The scalability of PHEV technology in mining operations is another factor contributing to its economic viability. As more vehicles in a mining fleet are converted to PHEVs, the infrastructure costs for charging stations and energy management systems can be spread across a larger base, improving the overall return on investment.

Lastly, the potential for PHEVs to enhance a mining company's reputation and social license to operate should not be underestimated. The adoption of sustainable technologies can improve relationships with local communities and regulators, potentially leading to faster project approvals and reduced operational disruptions, which have significant economic implications.

The initial investment in PHEV technology for mining operations can be substantial, with higher upfront costs compared to traditional diesel-powered vehicles. However, the long-term economic benefits are significant. PHEVs can dramatically reduce fuel consumption, which is a major operational expense in mining. The ability to operate on electric power for shorter distances or during idling periods can lead to substantial savings in fuel costs over time.

Maintenance costs for PHEVs in mining applications are generally lower than those for conventional vehicles. Electric drivetrains have fewer moving parts, reducing wear and tear and extending the lifespan of key components. This translates to less frequent maintenance intervals and lower overall maintenance expenses, contributing to improved economic viability.

The mining sector's unique operational environment presents both challenges and opportunities for PHEV adoption. The heavy-duty nature of mining vehicles requires robust battery systems and powerful electric motors. While this increases the initial cost, it also provides an opportunity for significant energy recovery through regenerative braking during downhill operations, further enhancing fuel efficiency and economic benefits.

Government incentives and carbon pricing mechanisms play a crucial role in the economic equation. Many jurisdictions offer tax breaks, grants, or other financial incentives for adopting low-emission vehicles, which can help offset the higher initial costs of PHEVs. Additionally, as carbon pricing becomes more prevalent, the reduced emissions from PHEVs can translate into direct financial benefits through lower carbon taxes or increased carbon credits.

The scalability of PHEV technology in mining operations is another factor contributing to its economic viability. As more vehicles in a mining fleet are converted to PHEVs, the infrastructure costs for charging stations and energy management systems can be spread across a larger base, improving the overall return on investment.

Lastly, the potential for PHEVs to enhance a mining company's reputation and social license to operate should not be underestimated. The adoption of sustainable technologies can improve relationships with local communities and regulators, potentially leading to faster project approvals and reduced operational disruptions, which have significant economic implications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!