How biofuels influence PHEV engine innovations

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biofuel-PHEV Integration Goals

The integration of biofuels with Plug-in Hybrid Electric Vehicles (PHEVs) represents a significant step towards sustainable transportation. This synergy aims to reduce greenhouse gas emissions, enhance energy security, and improve overall vehicle efficiency. The primary goal is to develop PHEV engines that can effectively utilize biofuels while maintaining or improving performance, reliability, and environmental benefits.

One of the key objectives is to optimize engine combustion processes for biofuel compatibility. This involves redesigning fuel injection systems, adjusting compression ratios, and modifying engine control units to accommodate the unique properties of biofuels. The goal is to achieve complete combustion, minimize emissions, and maximize energy extraction from biofuels.

Another crucial aim is to enhance the flexibility of PHEV powertrains to seamlessly switch between different fuel types. This includes developing advanced fuel sensing technologies and adaptive engine management systems that can automatically adjust engine parameters based on the fuel composition. The ultimate goal is to create a "flex-fuel" PHEV that can run efficiently on various blends of conventional fuels and biofuels without compromising performance or fuel economy.

Improving the cold-start performance of biofuel-powered PHEVs is also a significant objective. Biofuels, particularly those with high ethanol content, can present challenges in cold weather conditions. Engineers are working on innovative solutions such as advanced heating systems for fuel lines and tanks, as well as improved ignition systems to ensure reliable starts in all weather conditions.

Durability and longevity of engine components when exposed to biofuels is another critical focus area. The goal is to develop materials and coatings that can withstand the potentially corrosive nature of some biofuels, ensuring that PHEV engines maintain their performance and reliability over extended periods of use with biofuel blends.

Lastly, there is a strong emphasis on integrating biofuel compatibility with the electric powertrain of PHEVs. This includes optimizing the interplay between the internal combustion engine and electric motor to maximize overall efficiency when using biofuels. The aim is to develop intelligent power management systems that can leverage the strengths of both biofuels and electric propulsion to deliver superior performance and environmental benefits.

One of the key objectives is to optimize engine combustion processes for biofuel compatibility. This involves redesigning fuel injection systems, adjusting compression ratios, and modifying engine control units to accommodate the unique properties of biofuels. The goal is to achieve complete combustion, minimize emissions, and maximize energy extraction from biofuels.

Another crucial aim is to enhance the flexibility of PHEV powertrains to seamlessly switch between different fuel types. This includes developing advanced fuel sensing technologies and adaptive engine management systems that can automatically adjust engine parameters based on the fuel composition. The ultimate goal is to create a "flex-fuel" PHEV that can run efficiently on various blends of conventional fuels and biofuels without compromising performance or fuel economy.

Improving the cold-start performance of biofuel-powered PHEVs is also a significant objective. Biofuels, particularly those with high ethanol content, can present challenges in cold weather conditions. Engineers are working on innovative solutions such as advanced heating systems for fuel lines and tanks, as well as improved ignition systems to ensure reliable starts in all weather conditions.

Durability and longevity of engine components when exposed to biofuels is another critical focus area. The goal is to develop materials and coatings that can withstand the potentially corrosive nature of some biofuels, ensuring that PHEV engines maintain their performance and reliability over extended periods of use with biofuel blends.

Lastly, there is a strong emphasis on integrating biofuel compatibility with the electric powertrain of PHEVs. This includes optimizing the interplay between the internal combustion engine and electric motor to maximize overall efficiency when using biofuels. The aim is to develop intelligent power management systems that can leverage the strengths of both biofuels and electric propulsion to deliver superior performance and environmental benefits.

Market Demand for Biofuel PHEVs

The market demand for biofuel-powered Plug-in Hybrid Electric Vehicles (PHEVs) has been steadily growing in recent years, driven by increasing environmental concerns and the push for sustainable transportation solutions. This trend is particularly evident in regions with strong biofuel production capabilities, such as Brazil, the United States, and parts of Europe.

Consumer interest in biofuel PHEVs is primarily fueled by the desire for reduced carbon emissions and improved fuel efficiency. These vehicles offer the flexibility of running on both electricity and biofuels, providing an attractive option for environmentally conscious consumers who still require the range and convenience of traditional combustion engines.

Government policies and incentives have played a crucial role in stimulating market demand for biofuel PHEVs. Many countries have implemented tax breaks, subsidies, and other financial incentives to encourage the adoption of these vehicles. For instance, Sweden has introduced tax exemptions for biofuel vehicles, while Brazil has long-standing policies promoting the use of ethanol in flex-fuel vehicles.

The automotive industry has responded to this growing demand by increasing investment in biofuel PHEV technology. Major manufacturers such as Toyota, Ford, and Volkswagen have expanded their biofuel PHEV offerings, with a focus on developing engines that can efficiently utilize various biofuel blends.

Market research indicates that the global biofuel PHEV market is expected to experience significant growth in the coming years. This growth is attributed to factors such as increasing awareness of environmental issues, rising fuel prices, and advancements in biofuel production technologies.

However, the market demand for biofuel PHEVs faces several challenges. The availability and distribution of biofuels vary greatly between regions, which can impact consumer adoption rates. Additionally, concerns about food security and land use for biofuel production have led to debates about the sustainability of certain biofuel sources.

Despite these challenges, the overall market trajectory for biofuel PHEVs remains positive. As biofuel production technologies improve and become more cost-effective, and as governments continue to support the transition to cleaner transportation options, the demand for these vehicles is expected to grow.

In conclusion, the market demand for biofuel PHEVs is driven by a combination of environmental concerns, government policies, and technological advancements. While challenges exist, the potential for growth in this sector remains strong, particularly as the automotive industry continues to innovate and improve biofuel PHEV technologies.

Consumer interest in biofuel PHEVs is primarily fueled by the desire for reduced carbon emissions and improved fuel efficiency. These vehicles offer the flexibility of running on both electricity and biofuels, providing an attractive option for environmentally conscious consumers who still require the range and convenience of traditional combustion engines.

Government policies and incentives have played a crucial role in stimulating market demand for biofuel PHEVs. Many countries have implemented tax breaks, subsidies, and other financial incentives to encourage the adoption of these vehicles. For instance, Sweden has introduced tax exemptions for biofuel vehicles, while Brazil has long-standing policies promoting the use of ethanol in flex-fuel vehicles.

The automotive industry has responded to this growing demand by increasing investment in biofuel PHEV technology. Major manufacturers such as Toyota, Ford, and Volkswagen have expanded their biofuel PHEV offerings, with a focus on developing engines that can efficiently utilize various biofuel blends.

Market research indicates that the global biofuel PHEV market is expected to experience significant growth in the coming years. This growth is attributed to factors such as increasing awareness of environmental issues, rising fuel prices, and advancements in biofuel production technologies.

However, the market demand for biofuel PHEVs faces several challenges. The availability and distribution of biofuels vary greatly between regions, which can impact consumer adoption rates. Additionally, concerns about food security and land use for biofuel production have led to debates about the sustainability of certain biofuel sources.

Despite these challenges, the overall market trajectory for biofuel PHEVs remains positive. As biofuel production technologies improve and become more cost-effective, and as governments continue to support the transition to cleaner transportation options, the demand for these vehicles is expected to grow.

In conclusion, the market demand for biofuel PHEVs is driven by a combination of environmental concerns, government policies, and technological advancements. While challenges exist, the potential for growth in this sector remains strong, particularly as the automotive industry continues to innovate and improve biofuel PHEV technologies.

Biofuel Challenges in PHEVs

The integration of biofuels in Plug-in Hybrid Electric Vehicles (PHEVs) presents a unique set of challenges that significantly influence engine innovations. One of the primary obstacles is the variability in biofuel composition, which can differ based on feedstock and production methods. This inconsistency requires PHEV engines to be more adaptable and robust, capable of efficiently combusting a wide range of fuel blends without compromising performance or emissions.

Another significant challenge is the corrosive nature of certain biofuels, particularly those with higher ethanol content. This characteristic necessitates the development of more durable materials for engine components, fuel systems, and storage tanks. Engineers must innovate to create corrosion-resistant alloys and coatings that can withstand long-term exposure to biofuels without degradation.

The hygroscopic properties of biofuels also pose a substantial challenge for PHEV engines. Biofuels tend to absorb moisture from the atmosphere, which can lead to phase separation in fuel tanks and potential damage to engine components. This issue drives innovation in fuel system design, including advanced filtration systems and water separation technologies to maintain fuel quality and protect engine integrity.

Biofuels typically have lower energy density compared to conventional fossil fuels, which can impact the overall range and performance of PHEVs. This challenge pushes engineers to develop more efficient combustion strategies and engine designs that can extract maximum energy from biofuels. Innovations in direct injection systems, variable compression ratios, and advanced engine control algorithms are being pursued to optimize biofuel utilization.

Cold-start performance is another area where biofuels present challenges for PHEV engines. Many biofuels, especially those with higher ethanol content, have higher vaporization temperatures, making cold starts more difficult. This has led to innovations in engine heating systems, fuel preconditioning technologies, and advanced ignition systems designed to improve cold-start reliability with biofuel blends.

Emissions control is a critical challenge when integrating biofuels into PHEV engines. While biofuels can offer reduced greenhouse gas emissions over their lifecycle, they can also lead to increased emissions of certain pollutants, such as aldehydes. This drives innovation in exhaust aftertreatment systems, catalytic converters, and engine management software to ensure PHEVs meet stringent emissions standards across various biofuel blends.

Lastly, the challenge of optimizing engine performance across both electric and biofuel operation modes in PHEVs requires sophisticated control strategies. Engineers are developing advanced hybrid powertrain management systems that can seamlessly transition between electric and biofuel power sources while maintaining optimal efficiency and performance. This involves complex algorithms that consider factors such as battery state of charge, fuel composition, and driving conditions to determine the most efficient power delivery strategy.

Another significant challenge is the corrosive nature of certain biofuels, particularly those with higher ethanol content. This characteristic necessitates the development of more durable materials for engine components, fuel systems, and storage tanks. Engineers must innovate to create corrosion-resistant alloys and coatings that can withstand long-term exposure to biofuels without degradation.

The hygroscopic properties of biofuels also pose a substantial challenge for PHEV engines. Biofuels tend to absorb moisture from the atmosphere, which can lead to phase separation in fuel tanks and potential damage to engine components. This issue drives innovation in fuel system design, including advanced filtration systems and water separation technologies to maintain fuel quality and protect engine integrity.

Biofuels typically have lower energy density compared to conventional fossil fuels, which can impact the overall range and performance of PHEVs. This challenge pushes engineers to develop more efficient combustion strategies and engine designs that can extract maximum energy from biofuels. Innovations in direct injection systems, variable compression ratios, and advanced engine control algorithms are being pursued to optimize biofuel utilization.

Cold-start performance is another area where biofuels present challenges for PHEV engines. Many biofuels, especially those with higher ethanol content, have higher vaporization temperatures, making cold starts more difficult. This has led to innovations in engine heating systems, fuel preconditioning technologies, and advanced ignition systems designed to improve cold-start reliability with biofuel blends.

Emissions control is a critical challenge when integrating biofuels into PHEV engines. While biofuels can offer reduced greenhouse gas emissions over their lifecycle, they can also lead to increased emissions of certain pollutants, such as aldehydes. This drives innovation in exhaust aftertreatment systems, catalytic converters, and engine management software to ensure PHEVs meet stringent emissions standards across various biofuel blends.

Lastly, the challenge of optimizing engine performance across both electric and biofuel operation modes in PHEVs requires sophisticated control strategies. Engineers are developing advanced hybrid powertrain management systems that can seamlessly transition between electric and biofuel power sources while maintaining optimal efficiency and performance. This involves complex algorithms that consider factors such as battery state of charge, fuel composition, and driving conditions to determine the most efficient power delivery strategy.

Current Biofuel PHEV Solutions

01 Advanced control systems for PHEV engines

Innovative control systems are being developed to optimize the performance of PHEV engines. These systems integrate advanced algorithms and sensors to manage power distribution between the electric motor and internal combustion engine, improving overall efficiency and reducing emissions. The control systems also adapt to driving conditions and user preferences, enhancing the vehicle's responsiveness and fuel economy.- Advanced control systems for PHEV engines: Innovative control systems are being developed to optimize the performance of PHEV engines. These systems integrate advanced algorithms and sensors to manage power distribution between the electric motor and internal combustion engine, improving overall efficiency and reducing emissions. The control systems also adapt to driving conditions and user preferences, enhancing the vehicle's responsiveness and fuel economy.

- Improved battery management and charging technologies: PHEV engine innovations include advancements in battery management systems and charging technologies. These improvements focus on extending battery life, increasing charging speed, and optimizing energy storage capacity. New battery chemistries and intelligent charging algorithms are being implemented to enhance the electric range and overall performance of PHEVs.

- Enhanced thermal management systems: Innovative thermal management systems are being developed for PHEV engines to improve efficiency and longevity. These systems regulate the temperature of various components, including the battery, electric motor, and internal combustion engine, to ensure optimal performance under different operating conditions. Advanced cooling and heating techniques are employed to maintain ideal temperature ranges for each component.

- Integration of artificial intelligence and machine learning: PHEV engine innovations are incorporating artificial intelligence and machine learning technologies to enhance vehicle performance and user experience. These advanced systems analyze driving patterns, traffic conditions, and energy consumption to optimize power management and predict maintenance needs. AI-driven features also improve navigation and route planning for maximizing electric range and overall efficiency.

- Lightweight materials and design optimization: Innovations in PHEV engines include the use of lightweight materials and optimized designs to improve overall vehicle efficiency. Advanced composites, high-strength alloys, and innovative manufacturing techniques are being employed to reduce the weight of engine components and vehicle structures. These improvements contribute to increased fuel efficiency, extended electric range, and enhanced performance of PHEVs.

02 Improved battery management and charging technologies

PHEV engine innovations include advancements in battery management and charging technologies. These improvements focus on extending battery life, increasing energy density, and reducing charging times. New battery chemistries and smart charging algorithms are being developed to enhance the electric range of PHEVs and improve overall vehicle performance.Expand Specific Solutions03 Integration of renewable energy sources

Innovations in PHEV engines are exploring the integration of renewable energy sources. This includes the development of solar-powered charging systems and the use of regenerative braking to capture and store energy. These advancements aim to reduce the reliance on grid electricity and further decrease the carbon footprint of PHEVs.Expand Specific Solutions04 Enhanced thermal management systems

PHEV engine innovations include improved thermal management systems for both the electric and combustion components. These systems optimize the operating temperature of batteries, electric motors, and internal combustion engines, leading to increased efficiency and longevity of components. Advanced cooling and heat recovery technologies are being implemented to maximize energy utilization.Expand Specific Solutions05 Artificial intelligence and machine learning integration

The integration of artificial intelligence and machine learning algorithms is a key innovation in PHEV engines. These technologies are being used to predict and optimize energy consumption, adapt to driving patterns, and improve overall vehicle performance. AI-powered systems can also enhance predictive maintenance capabilities, reducing downtime and improving reliability.Expand Specific Solutions

Key Biofuel-PHEV Manufacturers

The biofuels influence on PHEV engine innovations is in a dynamic growth phase, with increasing market size and technological advancements. The industry is transitioning from early-stage research to commercial applications, driven by environmental concerns and energy security. Key players like Shell, Gevo, and Virent are at the forefront of developing innovative biofuel technologies for PHEVs. Established automotive companies such as GM and emerging startups are collaborating to integrate these advancements into engine designs. The technology's maturity varies, with some biofuel solutions nearing commercial readiness while others remain in experimental stages, indicating a diverse and competitive landscape.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed advanced biofuel formulations specifically tailored for PHEVs, focusing on optimizing engine performance and reducing emissions. Their research includes the development of high-octane biofuel blends that can improve engine efficiency by up to 10% compared to conventional gasoline [1]. Shell's biofuel innovations also incorporate cellulosic ethanol and hydrotreated vegetable oil (HVO) technologies, which can reduce greenhouse gas emissions by up to 90% compared to fossil fuels [2]. The company has invested in pilot plants to test these fuels in real-world PHEV applications, demonstrating improved cold-start performance and reduced particulate emissions [3].

Strengths: Extensive R&D capabilities, global reach for testing and implementation. Weaknesses: Potential conflict with traditional oil business, regulatory challenges in different markets.

Gevo, Inc.

Technical Solution: Gevo specializes in renewable hydrocarbons, particularly isobutanol-based fuels for PHEVs. Their innovative approach involves converting renewable feedstocks into isobutanol, which can be further processed into high-performance biofuels. Gevo's biofuels are designed to be "drop-in" replacements for petroleum-based fuels, requiring minimal modifications to existing PHEV engines [4]. The company has demonstrated that their isobutanol-derived fuels can increase octane ratings and improve fuel economy by up to 7% in PHEVs [5]. Gevo's technology also allows for the production of renewable jet fuel and gasoline components, providing a versatile solution for different transportation sectors [6].

Strengths: Innovative isobutanol technology, versatile fuel applications. Weaknesses: Scale-up challenges, dependency on feedstock availability and prices.

Biofuel-PHEV Engine Patents

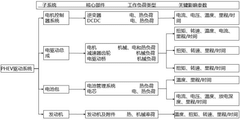

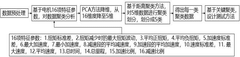

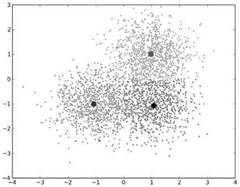

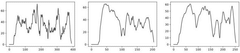

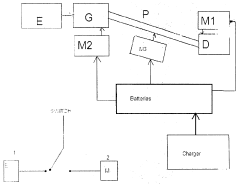

Method for testing and detecting reliability of whole plug-in hybrid electric automobile

PatentPendingCN119915526A

Innovation

- A special vehicle reliability test and detection method is designed, including vehicle structure test and detection, power and transmission test and environmental test test parts. Through market user surveys and real user load spectrum data analysis, the reliability target of PHEV cars is determined, and K-mean clustering analysis technology is used to construct typical test conditions to ensure that the test method is equivalent to user requirements.

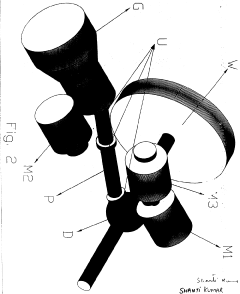

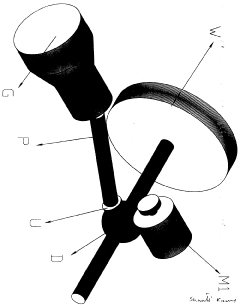

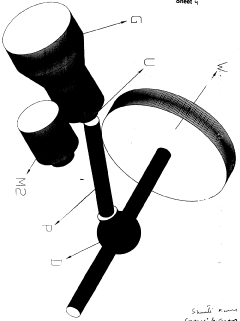

Hybrid vehicle.

PatentInactiveIN1132DEL2006A

Innovation

- A PHEV design that allows easy switching between engine and electric modes using a simple selector switch and a propeller shaft with universal joints and sprocket collar for power transmission, eliminating the need for extensive electronic controls and enabling user-controlled mode transitions.

Environmental Impact Assessment

The environmental impact of biofuels in Plug-in Hybrid Electric Vehicles (PHEVs) is a complex and multifaceted issue that requires careful consideration. Biofuels, when used in PHEV engines, can potentially reduce greenhouse gas emissions and dependence on fossil fuels. However, their production and use also present environmental challenges that must be addressed.

One of the primary benefits of biofuels in PHEVs is the potential reduction in carbon dioxide emissions. When compared to conventional fossil fuels, biofuels can offer a lower carbon footprint, as the plants used to produce them absorb CO2 during growth. This carbon sequestration effect can help mitigate the overall impact of vehicle emissions on climate change. Additionally, the use of biofuels in PHEVs can contribute to improved air quality in urban areas, as they typically produce fewer particulate matter and sulfur emissions than traditional petroleum-based fuels.

However, the environmental impact of biofuel production must also be considered. Large-scale cultivation of biofuel crops can lead to land-use changes, potentially resulting in deforestation and loss of biodiversity. This is particularly concerning in regions where natural habitats are converted to agricultural land for biofuel production. Furthermore, the intensive farming practices often associated with biofuel crops can lead to soil degradation, increased water consumption, and pollution from fertilizers and pesticides.

The water footprint of biofuel production is another significant environmental concern. Depending on the type of biofuel and production method, substantial amounts of water may be required for crop irrigation and processing. This can strain local water resources, particularly in water-scarce regions, and potentially lead to conflicts with other water uses such as agriculture for food production and ecosystem maintenance.

Energy balance is a crucial factor in assessing the environmental impact of biofuels in PHEVs. The energy required to produce, transport, and process biofuels must be considered against the energy they provide when used in vehicles. Some biofuels have a more favorable energy balance than others, and ongoing research aims to improve the efficiency of biofuel production to enhance their overall environmental benefits.

The impact on food security is another important consideration. The use of food crops for biofuel production can potentially compete with food production, leading to increased food prices and potential shortages in some regions. This has led to a focus on developing second and third-generation biofuels that use non-food crops or waste materials, which could help mitigate these concerns.

In conclusion, while biofuels offer potential environmental benefits for PHEV engines, their overall impact must be carefully assessed. A comprehensive life-cycle analysis, considering factors such as production methods, land use, water consumption, and energy balance, is essential to fully understand and optimize the environmental performance of biofuels in PHEVs. Continued research and innovation in biofuel production and PHEV engine technology are crucial to maximizing the environmental benefits while minimizing negative impacts.

One of the primary benefits of biofuels in PHEVs is the potential reduction in carbon dioxide emissions. When compared to conventional fossil fuels, biofuels can offer a lower carbon footprint, as the plants used to produce them absorb CO2 during growth. This carbon sequestration effect can help mitigate the overall impact of vehicle emissions on climate change. Additionally, the use of biofuels in PHEVs can contribute to improved air quality in urban areas, as they typically produce fewer particulate matter and sulfur emissions than traditional petroleum-based fuels.

However, the environmental impact of biofuel production must also be considered. Large-scale cultivation of biofuel crops can lead to land-use changes, potentially resulting in deforestation and loss of biodiversity. This is particularly concerning in regions where natural habitats are converted to agricultural land for biofuel production. Furthermore, the intensive farming practices often associated with biofuel crops can lead to soil degradation, increased water consumption, and pollution from fertilizers and pesticides.

The water footprint of biofuel production is another significant environmental concern. Depending on the type of biofuel and production method, substantial amounts of water may be required for crop irrigation and processing. This can strain local water resources, particularly in water-scarce regions, and potentially lead to conflicts with other water uses such as agriculture for food production and ecosystem maintenance.

Energy balance is a crucial factor in assessing the environmental impact of biofuels in PHEVs. The energy required to produce, transport, and process biofuels must be considered against the energy they provide when used in vehicles. Some biofuels have a more favorable energy balance than others, and ongoing research aims to improve the efficiency of biofuel production to enhance their overall environmental benefits.

The impact on food security is another important consideration. The use of food crops for biofuel production can potentially compete with food production, leading to increased food prices and potential shortages in some regions. This has led to a focus on developing second and third-generation biofuels that use non-food crops or waste materials, which could help mitigate these concerns.

In conclusion, while biofuels offer potential environmental benefits for PHEV engines, their overall impact must be carefully assessed. A comprehensive life-cycle analysis, considering factors such as production methods, land use, water consumption, and energy balance, is essential to fully understand and optimize the environmental performance of biofuels in PHEVs. Continued research and innovation in biofuel production and PHEV engine technology are crucial to maximizing the environmental benefits while minimizing negative impacts.

Biofuel Supply Chain Analysis

The biofuel supply chain plays a crucial role in the development and adoption of biofuels for Plug-in Hybrid Electric Vehicles (PHEVs). This complex network encompasses various stages, from feedstock production to end-user consumption, each influencing the overall efficiency and sustainability of biofuel utilization in PHEV engines.

At the beginning of the supply chain, feedstock production involves the cultivation of crops such as corn, sugarcane, and soybeans, as well as the collection of agricultural residues and waste materials. The choice of feedstock significantly impacts the environmental footprint and economic viability of biofuel production. Sustainable farming practices and efficient land use are essential considerations in this stage.

Following feedstock production, the next step involves transportation and storage of raw materials. This stage requires careful logistics planning to minimize costs and reduce greenhouse gas emissions associated with transportation. Efficient storage facilities are crucial to maintain the quality of feedstock and prevent degradation.

The conversion process transforms feedstock into biofuels through various technologies such as fermentation, transesterification, or thermochemical processes. The selection of conversion technology depends on the type of feedstock and desired biofuel output. Continuous innovation in conversion processes aims to improve efficiency and reduce production costs.

Distribution and blending of biofuels represent critical stages in the supply chain. Infrastructure for biofuel distribution, including specialized storage tanks and transportation systems, must be developed to ensure seamless integration with existing fuel distribution networks. Blending facilities mix biofuels with conventional fuels to meet regulatory requirements and engine specifications.

The final stage of the supply chain involves retail distribution and end-user consumption. This stage requires collaboration between fuel retailers, automakers, and consumers to ensure the availability and compatibility of biofuels with PHEV engines. Consumer education and awareness programs play a vital role in promoting the adoption of biofuels.

Throughout the supply chain, quality control and standardization are essential to maintain consistent biofuel properties and ensure compatibility with PHEV engines. Regulatory frameworks and certification systems help enforce quality standards and promote sustainable practices across the supply chain.

The biofuel supply chain's efficiency and sustainability directly impact PHEV engine innovations. As the supply chain evolves, it drives research and development in engine technologies to optimize performance with various biofuel blends. This symbiotic relationship between the supply chain and engine innovations continues to shape the future of PHEVs and their role in sustainable transportation.

At the beginning of the supply chain, feedstock production involves the cultivation of crops such as corn, sugarcane, and soybeans, as well as the collection of agricultural residues and waste materials. The choice of feedstock significantly impacts the environmental footprint and economic viability of biofuel production. Sustainable farming practices and efficient land use are essential considerations in this stage.

Following feedstock production, the next step involves transportation and storage of raw materials. This stage requires careful logistics planning to minimize costs and reduce greenhouse gas emissions associated with transportation. Efficient storage facilities are crucial to maintain the quality of feedstock and prevent degradation.

The conversion process transforms feedstock into biofuels through various technologies such as fermentation, transesterification, or thermochemical processes. The selection of conversion technology depends on the type of feedstock and desired biofuel output. Continuous innovation in conversion processes aims to improve efficiency and reduce production costs.

Distribution and blending of biofuels represent critical stages in the supply chain. Infrastructure for biofuel distribution, including specialized storage tanks and transportation systems, must be developed to ensure seamless integration with existing fuel distribution networks. Blending facilities mix biofuels with conventional fuels to meet regulatory requirements and engine specifications.

The final stage of the supply chain involves retail distribution and end-user consumption. This stage requires collaboration between fuel retailers, automakers, and consumers to ensure the availability and compatibility of biofuels with PHEV engines. Consumer education and awareness programs play a vital role in promoting the adoption of biofuels.

Throughout the supply chain, quality control and standardization are essential to maintain consistent biofuel properties and ensure compatibility with PHEV engines. Regulatory frameworks and certification systems help enforce quality standards and promote sustainable practices across the supply chain.

The biofuel supply chain's efficiency and sustainability directly impact PHEV engine innovations. As the supply chain evolves, it drives research and development in engine technologies to optimize performance with various biofuel blends. This symbiotic relationship between the supply chain and engine innovations continues to shape the future of PHEVs and their role in sustainable transportation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!