PHEV supply chain logistics optimization

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHEV Supply Chain Evolution

The evolution of the PHEV (Plug-in Hybrid Electric Vehicle) supply chain has been marked by significant technological advancements and strategic shifts in the automotive industry. Initially, the PHEV supply chain was characterized by a linear structure, with limited integration between traditional automotive suppliers and emerging electric vehicle component manufacturers.

As PHEVs gained traction in the market, the supply chain began to transform, adopting a more complex and interconnected network. This evolution was driven by the need to optimize the production and distribution of both conventional internal combustion engine components and electric powertrain elements. The integration of these two distinct supply chains posed unique challenges and opportunities for logistics optimization.

One of the key developments in the PHEV supply chain evolution was the emergence of specialized suppliers focusing on battery technology, power electronics, and electric motors. These new entrants brought expertise in areas critical to PHEV performance, necessitating a reconfiguration of existing supplier relationships and logistics networks.

The increasing demand for PHEVs also led to the establishment of regional production hubs, aimed at reducing transportation costs and improving supply chain responsiveness. This shift towards localized production required significant investments in infrastructure and the development of new logistics strategies to manage the flow of components and finished vehicles.

Another notable aspect of the PHEV supply chain evolution was the growing emphasis on sustainability and circular economy principles. This led to the implementation of reverse logistics systems for battery recycling and the incorporation of more environmentally friendly materials and processes throughout the supply chain.

The digital transformation of the automotive industry has also played a crucial role in shaping the PHEV supply chain. The adoption of advanced technologies such as Internet of Things (IoT), artificial intelligence, and blockchain has enabled greater visibility, traceability, and efficiency in supply chain operations. These technologies have facilitated real-time monitoring of inventory levels, predictive maintenance of production equipment, and optimization of transportation routes.

As the PHEV market has matured, there has been a trend towards greater collaboration and partnerships between automotive manufacturers, suppliers, and technology companies. This collaborative approach has led to the development of more integrated and agile supply chain networks, capable of responding quickly to changes in demand and technological advancements.

The ongoing evolution of the PHEV supply chain continues to focus on improving cost-effectiveness, reducing environmental impact, and enhancing overall efficiency. As the automotive industry transitions towards electrification, the lessons learned from PHEV supply chain optimization are proving invaluable in shaping the future of electric vehicle production and distribution.

As PHEVs gained traction in the market, the supply chain began to transform, adopting a more complex and interconnected network. This evolution was driven by the need to optimize the production and distribution of both conventional internal combustion engine components and electric powertrain elements. The integration of these two distinct supply chains posed unique challenges and opportunities for logistics optimization.

One of the key developments in the PHEV supply chain evolution was the emergence of specialized suppliers focusing on battery technology, power electronics, and electric motors. These new entrants brought expertise in areas critical to PHEV performance, necessitating a reconfiguration of existing supplier relationships and logistics networks.

The increasing demand for PHEVs also led to the establishment of regional production hubs, aimed at reducing transportation costs and improving supply chain responsiveness. This shift towards localized production required significant investments in infrastructure and the development of new logistics strategies to manage the flow of components and finished vehicles.

Another notable aspect of the PHEV supply chain evolution was the growing emphasis on sustainability and circular economy principles. This led to the implementation of reverse logistics systems for battery recycling and the incorporation of more environmentally friendly materials and processes throughout the supply chain.

The digital transformation of the automotive industry has also played a crucial role in shaping the PHEV supply chain. The adoption of advanced technologies such as Internet of Things (IoT), artificial intelligence, and blockchain has enabled greater visibility, traceability, and efficiency in supply chain operations. These technologies have facilitated real-time monitoring of inventory levels, predictive maintenance of production equipment, and optimization of transportation routes.

As the PHEV market has matured, there has been a trend towards greater collaboration and partnerships between automotive manufacturers, suppliers, and technology companies. This collaborative approach has led to the development of more integrated and agile supply chain networks, capable of responding quickly to changes in demand and technological advancements.

The ongoing evolution of the PHEV supply chain continues to focus on improving cost-effectiveness, reducing environmental impact, and enhancing overall efficiency. As the automotive industry transitions towards electrification, the lessons learned from PHEV supply chain optimization are proving invaluable in shaping the future of electric vehicle production and distribution.

Market Demand Analysis

The market demand for PHEV supply chain logistics optimization has been steadily increasing in recent years, driven by the growing adoption of plug-in hybrid electric vehicles (PHEVs) worldwide. As automotive manufacturers ramp up PHEV production to meet stringent emissions regulations and consumer preferences for more environmentally friendly vehicles, the need for efficient and cost-effective supply chain management has become paramount.

The global PHEV market has experienced significant growth, with sales projected to reach 6.9 million units by 2026, according to a report by MarketsandMarkets. This rapid expansion has created a pressing demand for optimized logistics solutions tailored to the unique requirements of PHEV production and distribution. The complexity of PHEV supply chains, which involve both traditional automotive components and specialized electric powertrain elements, necessitates sophisticated logistics strategies to ensure smooth operations and minimize costs.

One of the key drivers of market demand for PHEV supply chain logistics optimization is the need to reduce overall production costs. As PHEVs still command a price premium over conventional vehicles, manufacturers are seeking ways to streamline their supply chains to improve cost-competitiveness. Optimized logistics can lead to significant savings in inventory management, transportation, and warehousing, ultimately contributing to more affordable PHEVs for consumers.

Another factor fueling the demand for logistics optimization is the increasing pressure on automotive companies to reduce their carbon footprint. By implementing more efficient supply chain practices, PHEV manufacturers can not only lower their operational costs but also enhance their environmental credentials. This aligns with the broader industry trend towards sustainability and supports the overall mission of PHEVs to reduce greenhouse gas emissions.

The geographical expansion of PHEV production and sales markets has also intensified the need for advanced logistics solutions. As manufacturers establish production facilities in new regions and expand their distribution networks, they require flexible and scalable supply chain strategies that can adapt to diverse market conditions and regulatory environments.

Furthermore, the ongoing global semiconductor shortage has highlighted the critical importance of robust and resilient supply chains in the automotive industry. PHEV manufacturers, in particular, have been impacted by this shortage due to the higher electronic content in their vehicles. This has led to increased demand for logistics optimization solutions that can help mitigate supply chain disruptions and ensure a steady flow of components.

In response to these market demands, there is a growing interest in advanced technologies such as artificial intelligence, machine learning, and blockchain for supply chain optimization. These technologies offer the potential to enhance visibility, improve forecasting accuracy, and enable real-time decision-making in PHEV supply chain management.

The global PHEV market has experienced significant growth, with sales projected to reach 6.9 million units by 2026, according to a report by MarketsandMarkets. This rapid expansion has created a pressing demand for optimized logistics solutions tailored to the unique requirements of PHEV production and distribution. The complexity of PHEV supply chains, which involve both traditional automotive components and specialized electric powertrain elements, necessitates sophisticated logistics strategies to ensure smooth operations and minimize costs.

One of the key drivers of market demand for PHEV supply chain logistics optimization is the need to reduce overall production costs. As PHEVs still command a price premium over conventional vehicles, manufacturers are seeking ways to streamline their supply chains to improve cost-competitiveness. Optimized logistics can lead to significant savings in inventory management, transportation, and warehousing, ultimately contributing to more affordable PHEVs for consumers.

Another factor fueling the demand for logistics optimization is the increasing pressure on automotive companies to reduce their carbon footprint. By implementing more efficient supply chain practices, PHEV manufacturers can not only lower their operational costs but also enhance their environmental credentials. This aligns with the broader industry trend towards sustainability and supports the overall mission of PHEVs to reduce greenhouse gas emissions.

The geographical expansion of PHEV production and sales markets has also intensified the need for advanced logistics solutions. As manufacturers establish production facilities in new regions and expand their distribution networks, they require flexible and scalable supply chain strategies that can adapt to diverse market conditions and regulatory environments.

Furthermore, the ongoing global semiconductor shortage has highlighted the critical importance of robust and resilient supply chains in the automotive industry. PHEV manufacturers, in particular, have been impacted by this shortage due to the higher electronic content in their vehicles. This has led to increased demand for logistics optimization solutions that can help mitigate supply chain disruptions and ensure a steady flow of components.

In response to these market demands, there is a growing interest in advanced technologies such as artificial intelligence, machine learning, and blockchain for supply chain optimization. These technologies offer the potential to enhance visibility, improve forecasting accuracy, and enable real-time decision-making in PHEV supply chain management.

Current Challenges

The optimization of PHEV (Plug-in Hybrid Electric Vehicle) supply chain logistics faces several significant challenges in the current landscape. One of the primary obstacles is the complexity of managing dual powertrain components. PHEVs require both traditional internal combustion engine parts and electric drivetrain components, leading to a more intricate supply chain network that demands careful coordination and synchronization.

The volatility of raw material prices, particularly for battery components such as lithium, cobalt, and nickel, poses another substantial challenge. These fluctuations can significantly impact production costs and supply chain planning, making it difficult to maintain consistent pricing and profit margins.

Geopolitical tensions and trade disputes have introduced additional uncertainties into the global supply chain for PHEVs. Tariffs, export restrictions, and changing regulations can disrupt established supply routes and necessitate rapid adaptations in sourcing strategies.

The need for specialized infrastructure to support PHEV production and distribution presents logistical hurdles. This includes the requirement for charging stations along transportation routes and at distribution centers, as well as specialized handling and storage facilities for high-voltage batteries.

Quality control and safety management throughout the supply chain are critical challenges, especially concerning battery components. Strict regulations and the potential risks associated with lithium-ion batteries demand rigorous testing and monitoring processes, which can introduce delays and additional costs.

The integration of new technologies, such as advanced battery management systems and power electronics, requires continuous adaptation of supply chain processes. Suppliers and manufacturers must constantly update their capabilities to keep pace with rapidly evolving PHEV technologies.

Forecasting demand for PHEVs remains challenging due to varying consumer adoption rates, government incentives, and competing alternative fuel technologies. This uncertainty complicates inventory management and production planning across the supply chain.

Lastly, the push for sustainability and reduced carbon footprint in supply chain operations adds another layer of complexity. PHEV manufacturers are under pressure to implement green logistics practices, which may require significant investments in new transportation methods, packaging solutions, and supply chain redesign.

The volatility of raw material prices, particularly for battery components such as lithium, cobalt, and nickel, poses another substantial challenge. These fluctuations can significantly impact production costs and supply chain planning, making it difficult to maintain consistent pricing and profit margins.

Geopolitical tensions and trade disputes have introduced additional uncertainties into the global supply chain for PHEVs. Tariffs, export restrictions, and changing regulations can disrupt established supply routes and necessitate rapid adaptations in sourcing strategies.

The need for specialized infrastructure to support PHEV production and distribution presents logistical hurdles. This includes the requirement for charging stations along transportation routes and at distribution centers, as well as specialized handling and storage facilities for high-voltage batteries.

Quality control and safety management throughout the supply chain are critical challenges, especially concerning battery components. Strict regulations and the potential risks associated with lithium-ion batteries demand rigorous testing and monitoring processes, which can introduce delays and additional costs.

The integration of new technologies, such as advanced battery management systems and power electronics, requires continuous adaptation of supply chain processes. Suppliers and manufacturers must constantly update their capabilities to keep pace with rapidly evolving PHEV technologies.

Forecasting demand for PHEVs remains challenging due to varying consumer adoption rates, government incentives, and competing alternative fuel technologies. This uncertainty complicates inventory management and production planning across the supply chain.

Lastly, the push for sustainability and reduced carbon footprint in supply chain operations adds another layer of complexity. PHEV manufacturers are under pressure to implement green logistics practices, which may require significant investments in new transportation methods, packaging solutions, and supply chain redesign.

Optimization Strategies

01 Supply chain network optimization for PHEVs

Optimizing the supply chain network for Plug-in Hybrid Electric Vehicles (PHEVs) involves strategic planning of production facilities, distribution centers, and transportation routes. This approach aims to reduce costs, improve efficiency, and minimize environmental impact across the entire supply chain.- Supply chain network optimization for PHEVs: Optimizing the supply chain network for Plug-in Hybrid Electric Vehicles (PHEVs) involves strategic planning of production facilities, distribution centers, and transportation routes. This includes considering factors such as production capacity, demand forecasting, and geographical distribution of suppliers and customers to minimize costs and improve efficiency.

- Inventory management and demand forecasting for PHEV components: Effective inventory management and accurate demand forecasting are crucial for PHEV supply chain optimization. This involves implementing advanced algorithms and data analytics to predict component requirements, manage stock levels, and reduce carrying costs while ensuring adequate supply for production needs.

- Sustainable and green logistics for PHEV supply chains: Implementing sustainable and green logistics practices in PHEV supply chains focuses on reducing environmental impact through eco-friendly transportation methods, optimizing routes to minimize emissions, and incorporating renewable energy sources in logistics operations.

- Digital transformation and IoT integration in PHEV logistics: Leveraging digital technologies and Internet of Things (IoT) devices in PHEV supply chain logistics enables real-time tracking of components, predictive maintenance of logistics assets, and enhanced visibility across the entire supply chain, leading to improved efficiency and reduced operational costs.

- Collaborative supply chain management for PHEVs: Implementing collaborative supply chain management strategies for PHEVs involves fostering partnerships between manufacturers, suppliers, and logistics providers. This approach aims to improve information sharing, streamline processes, and enhance overall supply chain responsiveness and flexibility.

02 Inventory management and demand forecasting

Implementing advanced inventory management systems and demand forecasting techniques specifically tailored for PHEV components and finished vehicles. This includes real-time tracking, just-in-time delivery, and predictive analytics to optimize stock levels and reduce carrying costs.Expand Specific Solutions03 Sustainable and green logistics practices

Incorporating sustainable and green logistics practices in PHEV supply chains, such as using electric vehicles for transportation, optimizing route planning to reduce emissions, and implementing reverse logistics for battery recycling and component reuse.Expand Specific Solutions04 Digital transformation and IoT integration

Leveraging digital technologies and Internet of Things (IoT) devices to enhance visibility, traceability, and control throughout the PHEV supply chain. This includes implementing blockchain for secure data sharing, using AI for predictive maintenance, and employing smart sensors for real-time monitoring.Expand Specific Solutions05 Collaborative supply chain management

Fostering collaboration among suppliers, manufacturers, and distributors in the PHEV supply chain through shared platforms, integrated planning systems, and joint risk management strategies. This approach aims to improve overall supply chain resilience and responsiveness to market changes.Expand Specific Solutions

Key Industry Players

The PHEV supply chain logistics optimization market is in a growth phase, driven by increasing adoption of hybrid vehicles and the need for efficient supply chain management. The market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is evolving rapidly, with companies like Ford Global Technologies LLC, IBM, and Bosch leading innovation. These firms are developing advanced solutions integrating AI, IoT, and data analytics to optimize PHEV supply chains. Academic institutions such as Beijing University of Technology and Tianjin University are contributing to research and development, fostering industry-academia collaborations. The competitive landscape is diverse, with automotive manufacturers, technology giants, and specialized logistics firms vying for market share.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced PHEV supply chain logistics optimization system that integrates real-time data analytics, predictive modeling, and AI-driven decision-making processes. The system utilizes a network of IoT sensors throughout the supply chain to monitor inventory levels, production rates, and transportation status. Machine learning algorithms analyze this data to predict demand fluctuations and potential disruptions, allowing for proactive adjustments to production schedules and logistics routes[1]. Ford's system also incorporates blockchain technology to enhance transparency and traceability across the supply chain, ensuring efficient tracking of components and reducing the risk of counterfeit parts[2]. Additionally, the company has implemented a dynamic pricing model for its logistics services, optimizing cost-efficiency based on real-time market conditions and capacity utilization[3].

Strengths: Comprehensive integration of advanced technologies, real-time adaptability, and enhanced transparency. Weaknesses: High initial implementation costs and potential complexity in managing multiple technological systems simultaneously.

International Business Machines Corp.

Technical Solution: IBM has developed a cutting-edge PHEV supply chain logistics optimization solution leveraging its expertise in cloud computing, AI, and blockchain technologies. The system utilizes IBM's Watson AI platform to analyze vast amounts of data from various sources, including weather patterns, traffic conditions, and market trends, to optimize routing and inventory management[4]. IBM's blockchain-based solution ensures secure and transparent tracking of components throughout the supply chain, reducing delays and improving overall efficiency[5]. The company has also implemented a digital twin technology that creates virtual replicas of the entire supply chain, allowing for real-time simulations and scenario planning to identify potential bottlenecks and optimize resource allocation[6]. Furthermore, IBM's quantum computing capabilities are being explored to solve complex optimization problems in logistics that are beyond the reach of classical computers[7].

Strengths: Cutting-edge AI and blockchain integration, powerful data analytics capabilities, and potential for quantum computing applications. Weaknesses: Reliance on proprietary technologies may limit interoperability with some existing systems.

Innovative Solutions

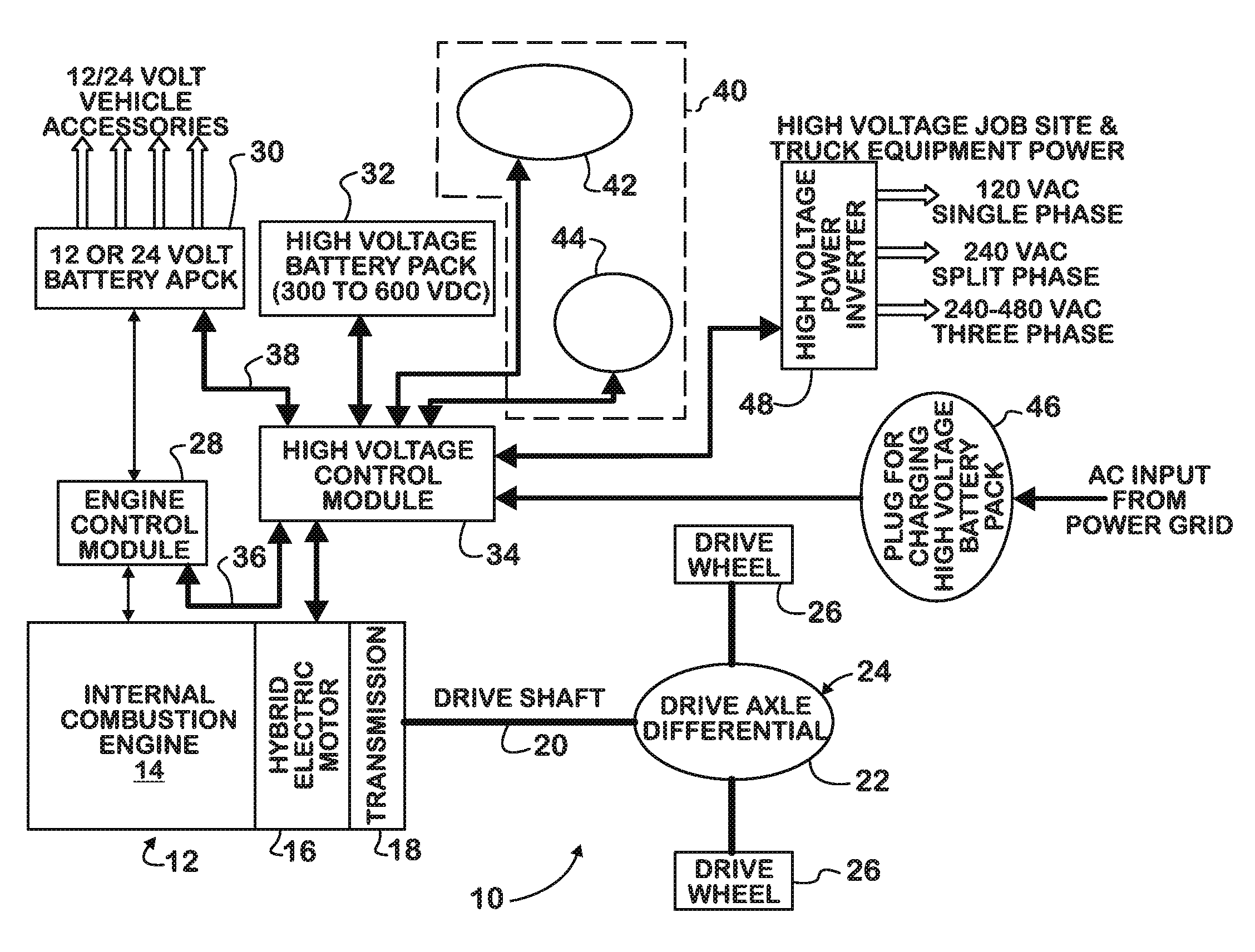

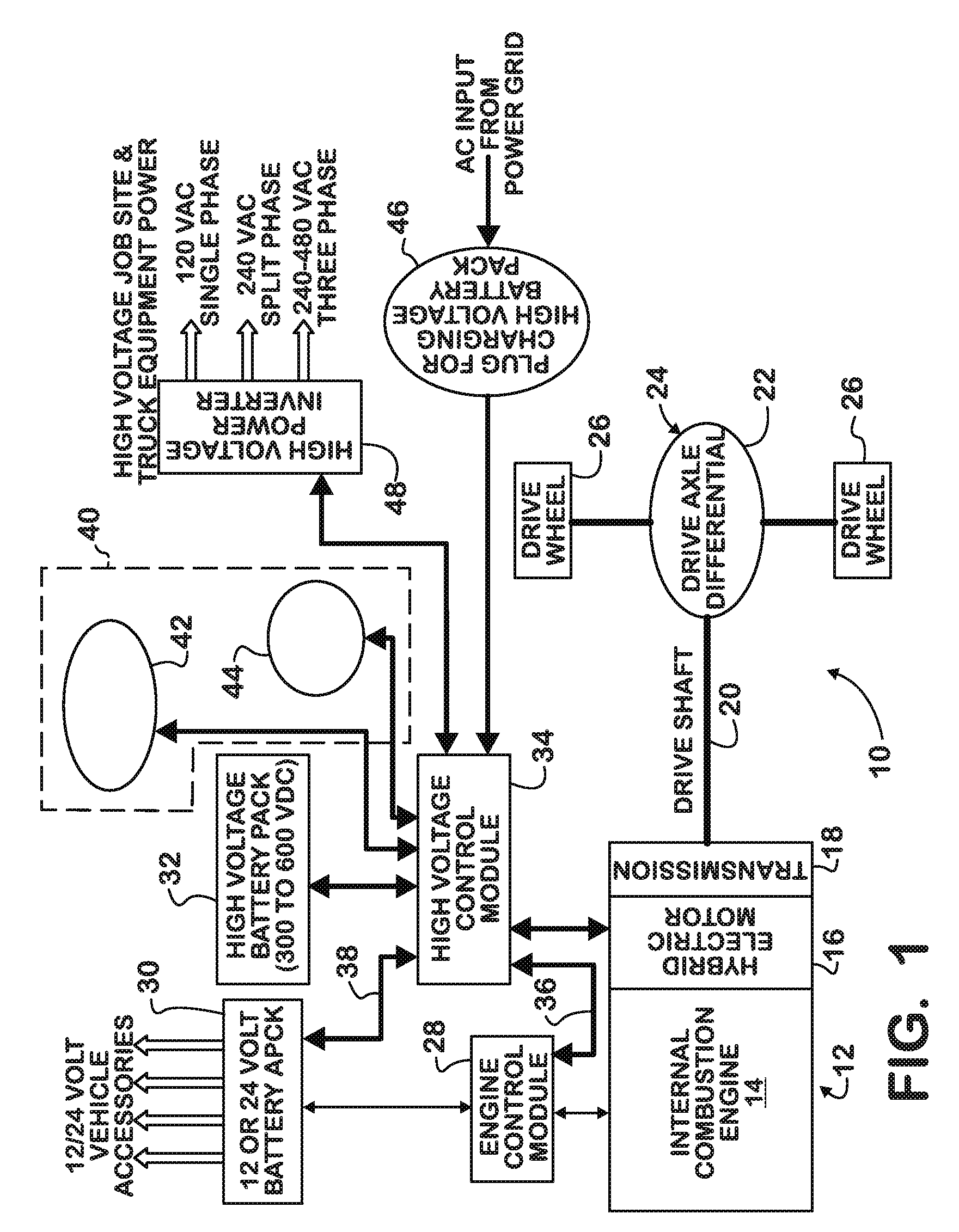

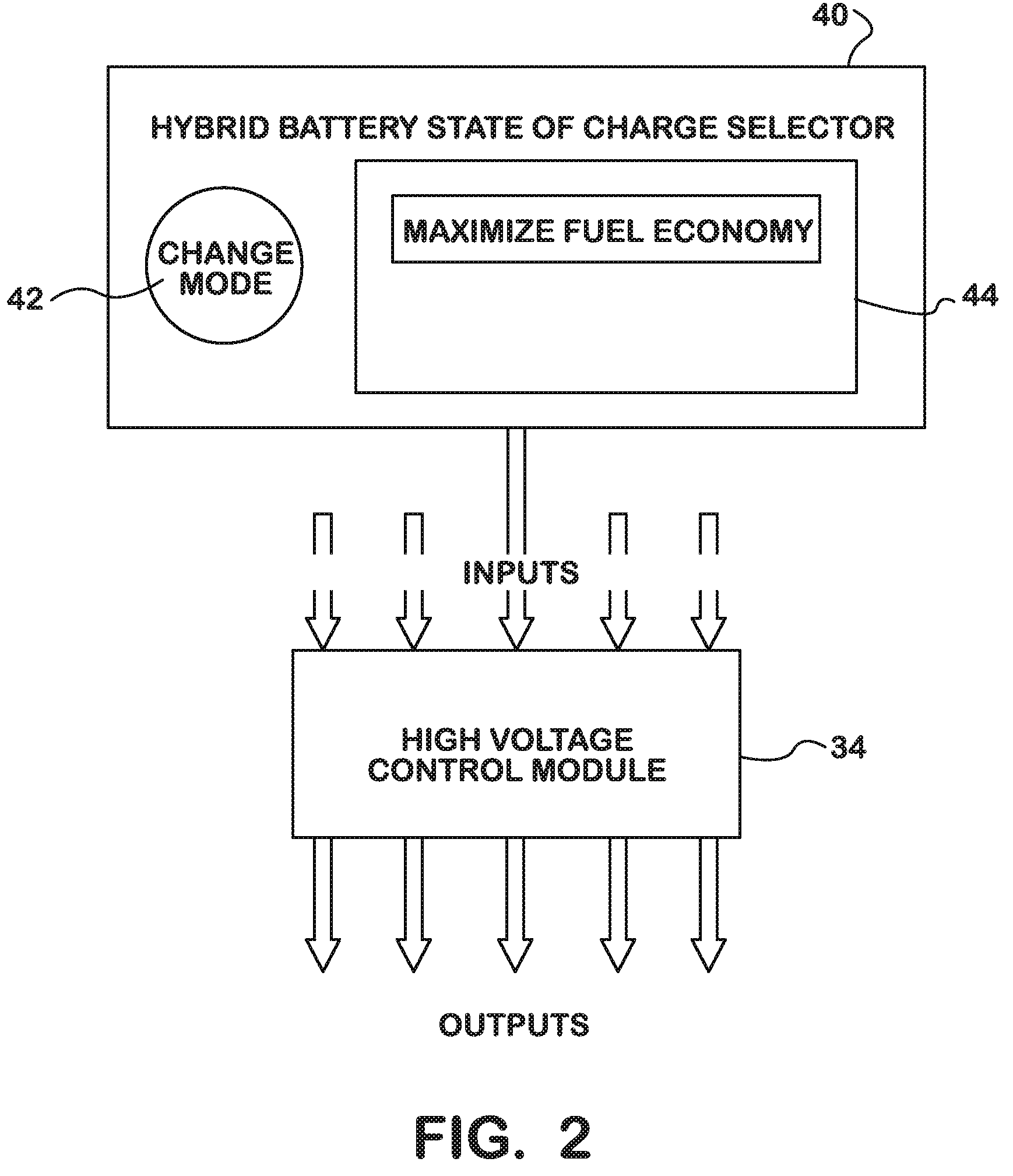

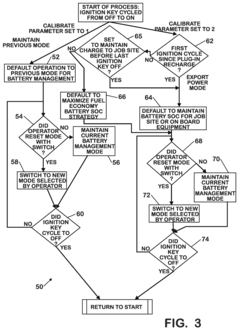

Battery pack management strategy in a hybrid electric motor vehicle

PatentInactiveUS7904217B2

Innovation

- A software algorithm in the high-voltage control module allows operators to choose between 'Maximize Fuel Economy' and 'Maintain Charge To Job Site' strategies, with options to override defaults, enabling flexible battery pack SOC management depending on calibratable parameters and specific battery chemistry and capacity.

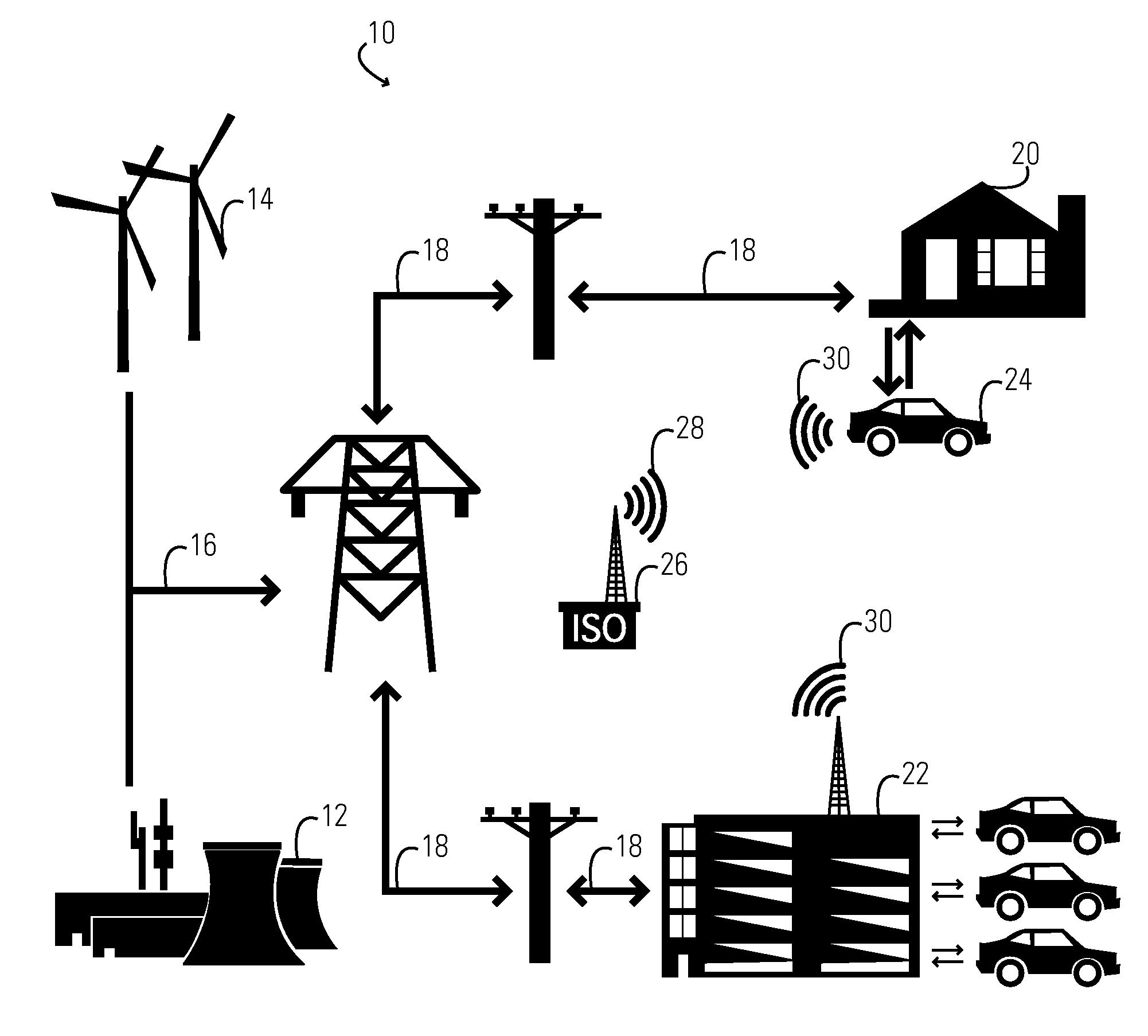

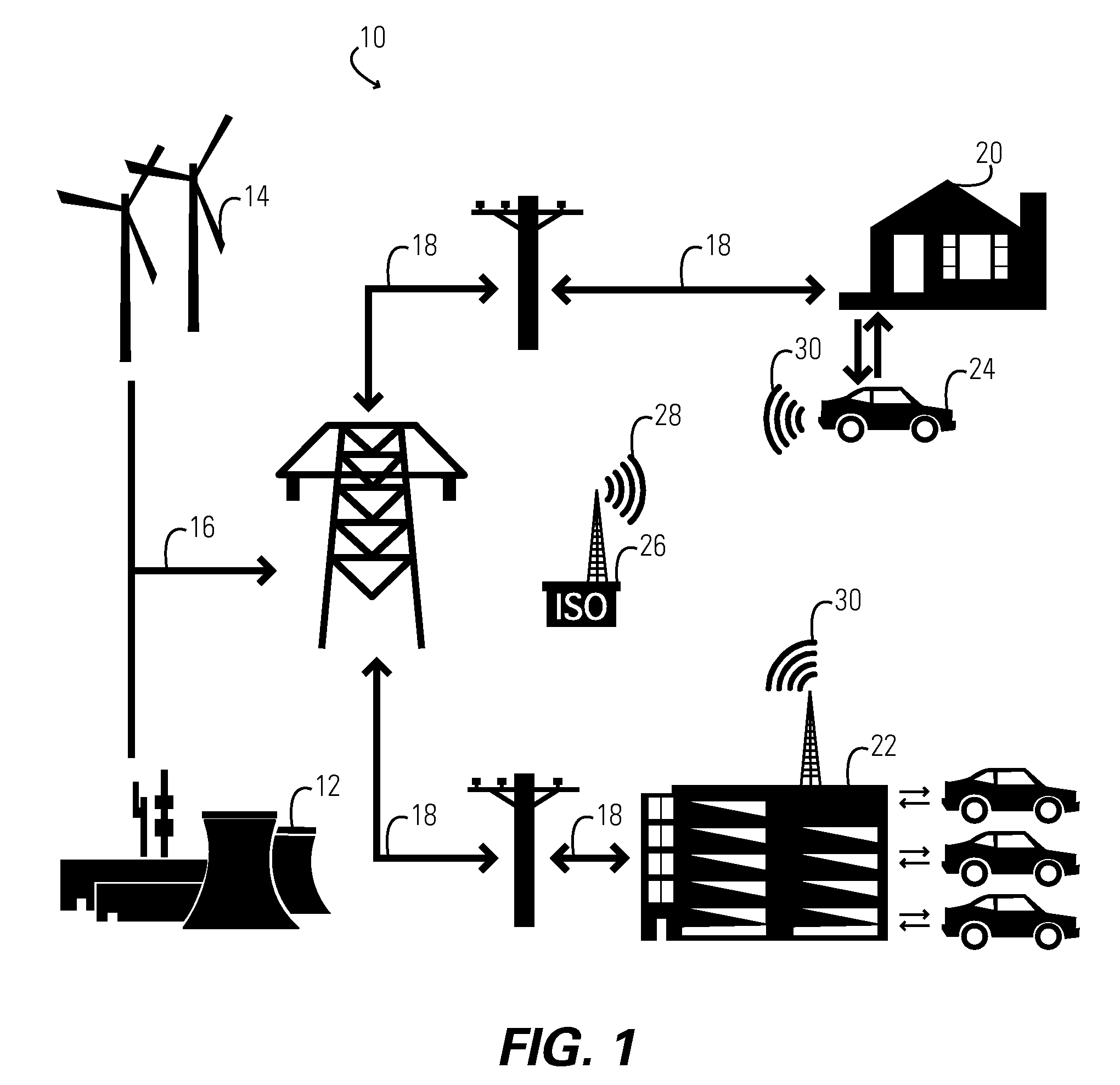

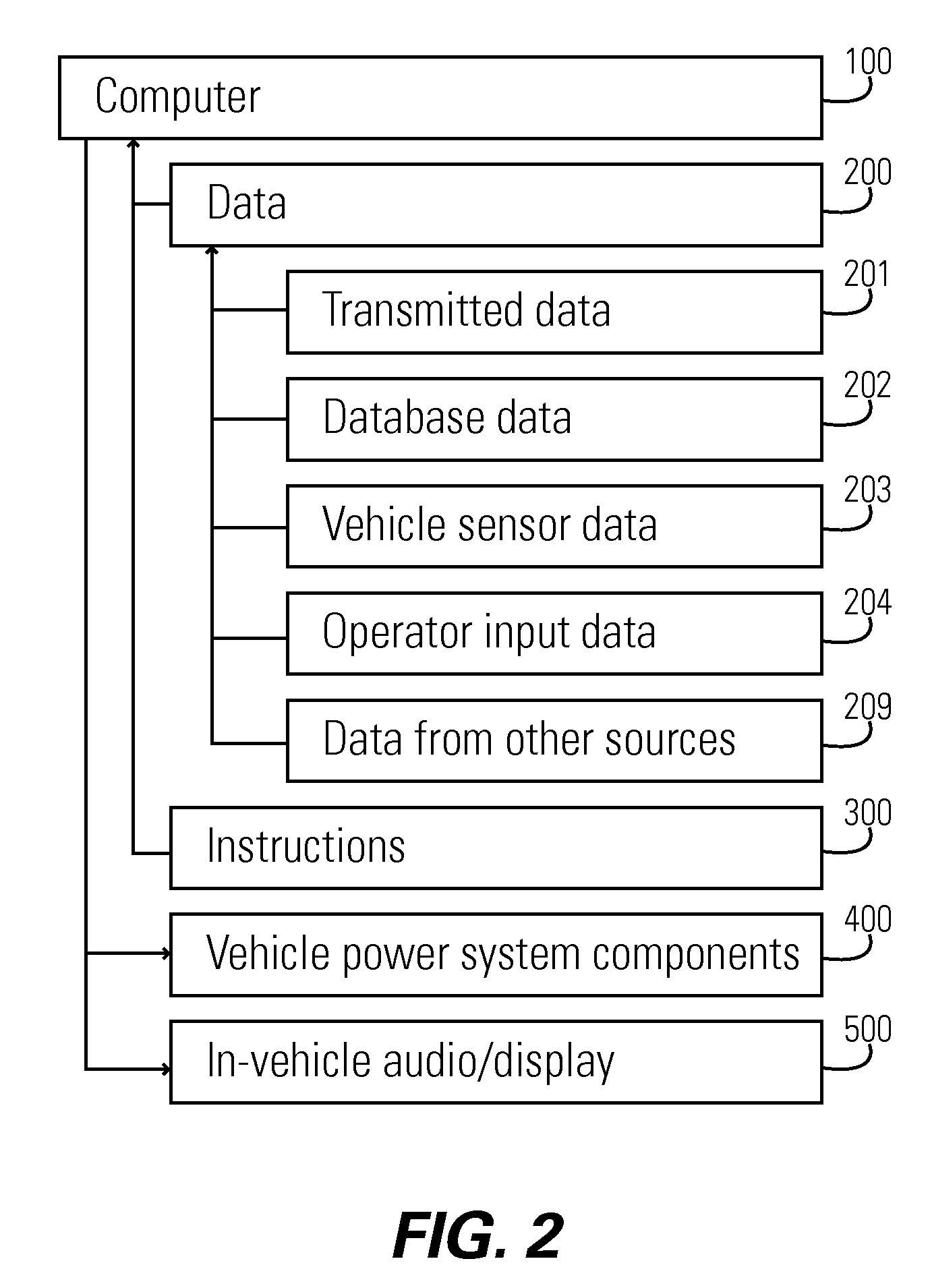

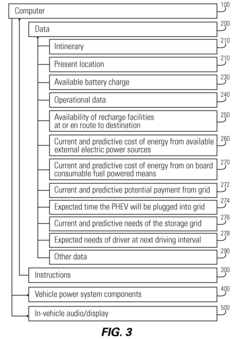

Plugin hybrid electric vehicle with v2g optimization system

PatentActiveUS20090229900A1

Innovation

- A system that includes a plug-in hybrid electric vehicle (PHEV) with a computer that receives data on expected grid conditions and driver needs, controlling battery charging and discharging to optimize state of charge, allowing the vehicle to act as a power source or storage unit, and providing economic benefits to drivers.

Sustainability Impact

The sustainability impact of PHEV supply chain logistics optimization is significant and multifaceted. By streamlining the supply chain and improving logistics efficiency, PHEVs can contribute to reduced environmental footprint and enhanced economic viability.

One of the primary sustainability benefits is the reduction in greenhouse gas emissions. Optimized logistics lead to fewer transportation routes, decreased fuel consumption, and lower carbon emissions. This aligns with global efforts to combat climate change and meets increasingly stringent environmental regulations. Moreover, efficient supply chain management can minimize waste generation and promote the use of recyclable materials, further reducing the environmental impact.

From an economic perspective, optimized logistics can significantly reduce operational costs. This includes lower transportation expenses, reduced inventory holding costs, and improved resource utilization. These cost savings can be passed on to consumers, making PHEVs more affordable and accelerating their adoption. Additionally, streamlined supply chains can enhance the overall resilience of the PHEV industry, making it better equipped to handle disruptions and market fluctuations.

The social dimension of sustainability is also positively impacted. Improved logistics can lead to better working conditions in the supply chain, as well as create new job opportunities in areas such as advanced logistics management and green transportation. Furthermore, the increased affordability and accessibility of PHEVs can contribute to improved air quality in urban areas, benefiting public health.

Optimized supply chain logistics can also drive innovation in the PHEV industry. This includes the development of new technologies for tracking and managing inventory, as well as advanced analytics for predicting demand and optimizing routes. Such innovations not only improve efficiency but also create opportunities for sustainable growth and competitiveness in the global market.

The circular economy concept is another area where PHEV supply chain optimization can have a significant impact. By implementing reverse logistics and efficient recycling processes, the industry can minimize resource depletion and promote the reuse of valuable materials. This approach not only reduces environmental impact but also creates new value streams within the supply chain.

In conclusion, the sustainability impact of PHEV supply chain logistics optimization extends beyond environmental benefits. It encompasses economic viability, social responsibility, and technological innovation, contributing to a more sustainable and resilient automotive industry.

One of the primary sustainability benefits is the reduction in greenhouse gas emissions. Optimized logistics lead to fewer transportation routes, decreased fuel consumption, and lower carbon emissions. This aligns with global efforts to combat climate change and meets increasingly stringent environmental regulations. Moreover, efficient supply chain management can minimize waste generation and promote the use of recyclable materials, further reducing the environmental impact.

From an economic perspective, optimized logistics can significantly reduce operational costs. This includes lower transportation expenses, reduced inventory holding costs, and improved resource utilization. These cost savings can be passed on to consumers, making PHEVs more affordable and accelerating their adoption. Additionally, streamlined supply chains can enhance the overall resilience of the PHEV industry, making it better equipped to handle disruptions and market fluctuations.

The social dimension of sustainability is also positively impacted. Improved logistics can lead to better working conditions in the supply chain, as well as create new job opportunities in areas such as advanced logistics management and green transportation. Furthermore, the increased affordability and accessibility of PHEVs can contribute to improved air quality in urban areas, benefiting public health.

Optimized supply chain logistics can also drive innovation in the PHEV industry. This includes the development of new technologies for tracking and managing inventory, as well as advanced analytics for predicting demand and optimizing routes. Such innovations not only improve efficiency but also create opportunities for sustainable growth and competitiveness in the global market.

The circular economy concept is another area where PHEV supply chain optimization can have a significant impact. By implementing reverse logistics and efficient recycling processes, the industry can minimize resource depletion and promote the reuse of valuable materials. This approach not only reduces environmental impact but also creates new value streams within the supply chain.

In conclusion, the sustainability impact of PHEV supply chain logistics optimization extends beyond environmental benefits. It encompasses economic viability, social responsibility, and technological innovation, contributing to a more sustainable and resilient automotive industry.

Regulatory Compliance

Regulatory compliance plays a crucial role in the optimization of PHEV supply chain logistics. As governments worldwide implement stricter environmental regulations and emissions standards, manufacturers and suppliers must adapt their operations to ensure compliance while maintaining efficiency.

One of the primary regulatory challenges in PHEV supply chain logistics is the management of battery components. Many countries have specific regulations governing the transportation, storage, and disposal of lithium-ion batteries, which are essential to PHEVs. These regulations often require specialized packaging, labeling, and handling procedures to mitigate safety risks associated with battery transportation.

Emissions standards also significantly impact PHEV supply chain logistics. Manufacturers must ensure that their vehicles meet increasingly stringent emissions requirements in various markets. This necessitates careful planning and coordination throughout the supply chain to ensure that components and materials meet the necessary specifications for compliance.

Another important aspect of regulatory compliance in PHEV logistics is the traceability of components and materials. Many jurisdictions require detailed documentation of the origin and composition of key components, particularly those related to battery technology. This demands robust tracking systems and transparent information sharing across the supply chain.

The global nature of PHEV supply chains adds complexity to regulatory compliance. Different countries and regions may have varying regulations, requiring manufacturers to navigate a complex landscape of legal requirements. This often necessitates the development of flexible supply chain strategies that can adapt to diverse regulatory environments.

Compliance with trade regulations and tariffs is also a critical consideration in PHEV supply chain optimization. The automotive industry is subject to various trade agreements and restrictions, which can impact the sourcing of components and the movement of finished vehicles across borders. Supply chain managers must stay informed about changing trade policies and adjust their logistics strategies accordingly.

Furthermore, data protection and cybersecurity regulations are becoming increasingly relevant to PHEV supply chains. As vehicles become more connected and data-driven, manufacturers must ensure that their supply chain processes comply with data privacy laws and protect sensitive information throughout the logistics network.

To address these regulatory challenges, PHEV manufacturers and suppliers are investing in advanced compliance management systems. These systems help track regulatory requirements across different markets, monitor changes in legislation, and ensure that all aspects of the supply chain meet the necessary standards. Additionally, many companies are forming dedicated compliance teams to oversee regulatory issues and coordinate with various stakeholders in the supply chain.

One of the primary regulatory challenges in PHEV supply chain logistics is the management of battery components. Many countries have specific regulations governing the transportation, storage, and disposal of lithium-ion batteries, which are essential to PHEVs. These regulations often require specialized packaging, labeling, and handling procedures to mitigate safety risks associated with battery transportation.

Emissions standards also significantly impact PHEV supply chain logistics. Manufacturers must ensure that their vehicles meet increasingly stringent emissions requirements in various markets. This necessitates careful planning and coordination throughout the supply chain to ensure that components and materials meet the necessary specifications for compliance.

Another important aspect of regulatory compliance in PHEV logistics is the traceability of components and materials. Many jurisdictions require detailed documentation of the origin and composition of key components, particularly those related to battery technology. This demands robust tracking systems and transparent information sharing across the supply chain.

The global nature of PHEV supply chains adds complexity to regulatory compliance. Different countries and regions may have varying regulations, requiring manufacturers to navigate a complex landscape of legal requirements. This often necessitates the development of flexible supply chain strategies that can adapt to diverse regulatory environments.

Compliance with trade regulations and tariffs is also a critical consideration in PHEV supply chain optimization. The automotive industry is subject to various trade agreements and restrictions, which can impact the sourcing of components and the movement of finished vehicles across borders. Supply chain managers must stay informed about changing trade policies and adjust their logistics strategies accordingly.

Furthermore, data protection and cybersecurity regulations are becoming increasingly relevant to PHEV supply chains. As vehicles become more connected and data-driven, manufacturers must ensure that their supply chain processes comply with data privacy laws and protect sensitive information throughout the logistics network.

To address these regulatory challenges, PHEV manufacturers and suppliers are investing in advanced compliance management systems. These systems help track regulatory requirements across different markets, monitor changes in legislation, and ensure that all aspects of the supply chain meet the necessary standards. Additionally, many companies are forming dedicated compliance teams to oversee regulatory issues and coordinate with various stakeholders in the supply chain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!