How Luminol Supports Sustainable Chemical Practices?

AUG 19, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Luminol Background and Sustainability Goals

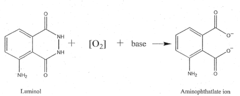

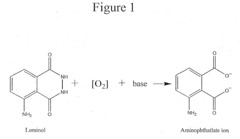

Luminol, a chemiluminescent compound, has been a subject of scientific interest for over a century. First discovered in 1928 by H. O. Albrecht, this organic compound has found applications in various fields, including forensic science, biochemistry, and environmental monitoring. The evolution of luminol technology has been marked by continuous improvements in its synthesis, detection methods, and practical applications.

In recent years, the focus on sustainable chemical practices has brought luminol into the spotlight as a potential tool for promoting environmental responsibility in scientific and industrial processes. The compound's ability to produce a bright blue light when oxidized has made it an attractive option for developing eco-friendly detection and monitoring systems.

The sustainability goals associated with luminol research and applications are multifaceted. One primary objective is to optimize the synthesis of luminol using green chemistry principles, reducing the environmental impact of its production. This includes exploring alternative reagents, minimizing waste generation, and improving energy efficiency in the manufacturing process.

Another key sustainability goal is to expand the use of luminol-based detection systems as a replacement for more harmful or resource-intensive analytical methods. By leveraging luminol's high sensitivity and specificity, researchers aim to develop more sustainable approaches to environmental monitoring, quality control in industrial processes, and forensic investigations.

Furthermore, the integration of luminol into biosensors and other advanced detection technologies aligns with the broader sustainability objective of creating more efficient and less invasive diagnostic tools. This has implications for medical research, environmental science, and industrial safety, where rapid and accurate detection of specific compounds can lead to more timely interventions and reduced resource consumption.

The pursuit of these sustainability goals has led to innovative research directions in luminol chemistry. Scientists are exploring ways to enhance luminol's stability, increase its light output, and broaden its range of detectable substances. These efforts not only aim to improve the compound's performance but also to extend its shelf life and reduce the frequency of reagent replacement, contributing to overall resource conservation.

As the field progresses, there is a growing emphasis on developing luminol-based systems that are not only effective but also biodegradable and non-toxic. This aligns with the principles of green chemistry and supports the transition towards more sustainable laboratory and industrial practices. By addressing these challenges, researchers hope to position luminol as a key player in the ongoing shift towards more environmentally responsible scientific and technological advancements.

In recent years, the focus on sustainable chemical practices has brought luminol into the spotlight as a potential tool for promoting environmental responsibility in scientific and industrial processes. The compound's ability to produce a bright blue light when oxidized has made it an attractive option for developing eco-friendly detection and monitoring systems.

The sustainability goals associated with luminol research and applications are multifaceted. One primary objective is to optimize the synthesis of luminol using green chemistry principles, reducing the environmental impact of its production. This includes exploring alternative reagents, minimizing waste generation, and improving energy efficiency in the manufacturing process.

Another key sustainability goal is to expand the use of luminol-based detection systems as a replacement for more harmful or resource-intensive analytical methods. By leveraging luminol's high sensitivity and specificity, researchers aim to develop more sustainable approaches to environmental monitoring, quality control in industrial processes, and forensic investigations.

Furthermore, the integration of luminol into biosensors and other advanced detection technologies aligns with the broader sustainability objective of creating more efficient and less invasive diagnostic tools. This has implications for medical research, environmental science, and industrial safety, where rapid and accurate detection of specific compounds can lead to more timely interventions and reduced resource consumption.

The pursuit of these sustainability goals has led to innovative research directions in luminol chemistry. Scientists are exploring ways to enhance luminol's stability, increase its light output, and broaden its range of detectable substances. These efforts not only aim to improve the compound's performance but also to extend its shelf life and reduce the frequency of reagent replacement, contributing to overall resource conservation.

As the field progresses, there is a growing emphasis on developing luminol-based systems that are not only effective but also biodegradable and non-toxic. This aligns with the principles of green chemistry and supports the transition towards more sustainable laboratory and industrial practices. By addressing these challenges, researchers hope to position luminol as a key player in the ongoing shift towards more environmentally responsible scientific and technological advancements.

Market Demand for Sustainable Chemical Solutions

The market demand for sustainable chemical solutions has been steadily increasing in recent years, driven by growing environmental concerns, stricter regulations, and changing consumer preferences. Luminol, a chemiluminescent compound traditionally used in forensic science, is now emerging as a potential contributor to sustainable chemical practices across various industries.

In the healthcare sector, there is a rising demand for eco-friendly diagnostic tools and medical imaging techniques. Luminol-based systems offer a promising alternative to conventional methods, as they produce less waste and require lower energy inputs. Hospitals and research institutions are actively seeking such sustainable solutions to reduce their environmental footprint while maintaining high-quality diagnostic capabilities.

The environmental monitoring and remediation industry also presents significant market opportunities for luminol-based technologies. As governments and organizations worldwide intensify efforts to detect and clean up pollutants, there is a growing need for sensitive, cost-effective, and environmentally friendly detection methods. Luminol's ability to react with trace amounts of certain metals and oxidizing agents makes it an attractive option for monitoring water quality, soil contamination, and industrial emissions.

In the field of industrial chemistry, manufacturers are under increasing pressure to adopt cleaner production processes and develop more sustainable products. Luminol's potential applications in catalysis and as a reagent in green chemistry processes align well with this trend. Companies are investing in research and development to explore how luminol can be integrated into their production lines to reduce energy consumption, minimize waste generation, and improve overall sustainability.

The agriculture sector is another area where sustainable chemical solutions are in high demand. As the industry moves towards precision farming and reduced pesticide use, there is a growing interest in innovative detection methods for crop diseases and soil health assessment. Luminol-based sensors could provide farmers with rapid, on-site testing capabilities, enabling more targeted and environmentally friendly agricultural practices.

Market analysts project that the global sustainable chemicals market will continue to expand at a compound annual growth rate of over 8% in the coming years. This growth is partly attributed to the increasing adoption of bio-based and renewable chemicals, as well as the development of novel sustainable solutions like luminol-based technologies. The demand is particularly strong in developed economies with stringent environmental regulations, but emerging markets are also showing increased interest as they strive to balance economic growth with environmental protection.

As companies across various sectors seek to improve their sustainability credentials and meet evolving regulatory requirements, the market for luminol-supported sustainable chemical practices is expected to grow. This trend is further reinforced by consumer preferences for environmentally friendly products and services, creating a favorable market environment for innovations in this field.

In the healthcare sector, there is a rising demand for eco-friendly diagnostic tools and medical imaging techniques. Luminol-based systems offer a promising alternative to conventional methods, as they produce less waste and require lower energy inputs. Hospitals and research institutions are actively seeking such sustainable solutions to reduce their environmental footprint while maintaining high-quality diagnostic capabilities.

The environmental monitoring and remediation industry also presents significant market opportunities for luminol-based technologies. As governments and organizations worldwide intensify efforts to detect and clean up pollutants, there is a growing need for sensitive, cost-effective, and environmentally friendly detection methods. Luminol's ability to react with trace amounts of certain metals and oxidizing agents makes it an attractive option for monitoring water quality, soil contamination, and industrial emissions.

In the field of industrial chemistry, manufacturers are under increasing pressure to adopt cleaner production processes and develop more sustainable products. Luminol's potential applications in catalysis and as a reagent in green chemistry processes align well with this trend. Companies are investing in research and development to explore how luminol can be integrated into their production lines to reduce energy consumption, minimize waste generation, and improve overall sustainability.

The agriculture sector is another area where sustainable chemical solutions are in high demand. As the industry moves towards precision farming and reduced pesticide use, there is a growing interest in innovative detection methods for crop diseases and soil health assessment. Luminol-based sensors could provide farmers with rapid, on-site testing capabilities, enabling more targeted and environmentally friendly agricultural practices.

Market analysts project that the global sustainable chemicals market will continue to expand at a compound annual growth rate of over 8% in the coming years. This growth is partly attributed to the increasing adoption of bio-based and renewable chemicals, as well as the development of novel sustainable solutions like luminol-based technologies. The demand is particularly strong in developed economies with stringent environmental regulations, but emerging markets are also showing increased interest as they strive to balance economic growth with environmental protection.

As companies across various sectors seek to improve their sustainability credentials and meet evolving regulatory requirements, the market for luminol-supported sustainable chemical practices is expected to grow. This trend is further reinforced by consumer preferences for environmentally friendly products and services, creating a favorable market environment for innovations in this field.

Current State and Challenges in Luminol Production

Luminol production currently faces several challenges in terms of sustainability and environmental impact. Traditional synthesis methods often involve the use of harsh chemicals and generate significant waste, which contradicts the principles of green chemistry. The current state of luminol production primarily relies on a two-step process that utilizes potentially hazardous reagents such as hydrazine and nitrobenzene.

One of the main challenges in luminol production is the optimization of reaction conditions to reduce energy consumption and minimize the use of toxic solvents. Researchers are exploring alternative synthesis routes that employ more benign reagents and catalysts to improve the overall sustainability of the process. However, these new methods often struggle to match the yield and purity of conventional approaches, presenting a significant hurdle for large-scale adoption.

Another critical issue is the management of waste streams generated during luminol synthesis. The current production methods produce substantial amounts of byproducts and unreacted materials that require proper treatment and disposal. This not only increases the environmental footprint of luminol production but also adds to the overall cost of manufacturing.

The pharmaceutical and forensic industries, which are major consumers of luminol, are increasingly demanding more sustainable production practices. This pressure has led to intensified research efforts aimed at developing greener synthesis routes and more efficient purification techniques. Some promising approaches include the use of biocatalysts, microwave-assisted synthesis, and continuous flow chemistry, which have shown potential for reducing reaction times and improving atom economy.

Despite these advancements, scaling up these novel production methods remains a significant challenge. Many of the more sustainable techniques developed in laboratory settings face difficulties when translated to industrial-scale production. Issues such as reduced yield, increased production time, and higher costs often hinder the widespread adoption of these greener alternatives.

Furthermore, the regulatory landscape surrounding chemical production is becoming increasingly stringent, with a focus on environmental protection and worker safety. This presents both a challenge and an opportunity for luminol manufacturers to innovate and adapt their production processes to meet these evolving standards while maintaining product quality and economic viability.

In conclusion, while luminol continues to be an essential chemical for various applications, its production methods are at a crossroads. The industry must navigate the complex balance between maintaining efficient production and embracing more sustainable practices. Overcoming these challenges will require continued research, technological innovation, and collaboration between academia and industry to develop and implement more environmentally friendly luminol production processes.

One of the main challenges in luminol production is the optimization of reaction conditions to reduce energy consumption and minimize the use of toxic solvents. Researchers are exploring alternative synthesis routes that employ more benign reagents and catalysts to improve the overall sustainability of the process. However, these new methods often struggle to match the yield and purity of conventional approaches, presenting a significant hurdle for large-scale adoption.

Another critical issue is the management of waste streams generated during luminol synthesis. The current production methods produce substantial amounts of byproducts and unreacted materials that require proper treatment and disposal. This not only increases the environmental footprint of luminol production but also adds to the overall cost of manufacturing.

The pharmaceutical and forensic industries, which are major consumers of luminol, are increasingly demanding more sustainable production practices. This pressure has led to intensified research efforts aimed at developing greener synthesis routes and more efficient purification techniques. Some promising approaches include the use of biocatalysts, microwave-assisted synthesis, and continuous flow chemistry, which have shown potential for reducing reaction times and improving atom economy.

Despite these advancements, scaling up these novel production methods remains a significant challenge. Many of the more sustainable techniques developed in laboratory settings face difficulties when translated to industrial-scale production. Issues such as reduced yield, increased production time, and higher costs often hinder the widespread adoption of these greener alternatives.

Furthermore, the regulatory landscape surrounding chemical production is becoming increasingly stringent, with a focus on environmental protection and worker safety. This presents both a challenge and an opportunity for luminol manufacturers to innovate and adapt their production processes to meet these evolving standards while maintaining product quality and economic viability.

In conclusion, while luminol continues to be an essential chemical for various applications, its production methods are at a crossroads. The industry must navigate the complex balance between maintaining efficient production and embracing more sustainable practices. Overcoming these challenges will require continued research, technological innovation, and collaboration between academia and industry to develop and implement more environmentally friendly luminol production processes.

Existing Green Chemistry Approaches for Luminol

01 Luminol in forensic applications

Luminol is widely used in forensic science for detecting trace amounts of blood at crime scenes. When luminol comes into contact with the iron in hemoglobin, it produces a bright blue chemiluminescence. This reaction can reveal blood traces that are invisible to the naked eye, even if the area has been cleaned. The technique is highly sensitive and can detect blood diluted up to 1:1,000,000.- Luminol in chemiluminescence detection: Luminol is widely used in chemiluminescence detection methods for various applications. It produces a bright blue light when oxidized, making it useful for detecting blood traces in forensic investigations, as well as in analytical chemistry for detecting certain substances or reactions.

- Luminol-based biosensors and immunoassays: Luminol is incorporated into biosensors and immunoassay systems for highly sensitive detection of specific biomolecules. These systems utilize the chemiluminescent properties of luminol to achieve low detection limits and wide dynamic ranges in various biomedical and environmental applications.

- Enhanced luminol formulations: Research focuses on developing enhanced luminol formulations with improved stability, sensitivity, and specificity. These formulations may include additives, catalysts, or modified luminol derivatives to optimize chemiluminescence performance for specific applications.

- Luminol in environmental monitoring: Luminol-based systems are employed in environmental monitoring applications, such as detecting pollutants in water or air. These methods offer rapid, sensitive, and cost-effective alternatives to traditional analytical techniques for environmental assessment and protection.

- Luminol in medical diagnostics: Luminol-based assays are developed for medical diagnostic applications, including the detection of specific biomarkers or pathogens. These methods provide rapid and sensitive results, potentially enabling early disease detection and monitoring of treatment efficacy.

02 Luminol-based detection systems

Various detection systems incorporate luminol for its chemiluminescent properties. These systems are used in environmental monitoring, food safety testing, and medical diagnostics. The luminol reaction can be enhanced or modified with different catalysts or additives to improve sensitivity or specificity for particular applications. Some systems combine luminol with other reagents or enzymes to create more complex detection methods.Expand Specific Solutions03 Luminol synthesis and formulation

Research focuses on improving the synthesis and formulation of luminol and its derivatives. This includes developing more efficient synthesis methods, creating stable luminol solutions or mixtures, and formulating luminol-based reagents for specific applications. Some formulations aim to enhance the luminol reaction's intensity or duration, while others focus on increasing its stability for long-term storage or field use.Expand Specific Solutions04 Luminol in biomedical research

Luminol finds applications in biomedical research, particularly in studying cellular processes involving reactive oxygen species. It can be used to detect and quantify the production of hydrogen peroxide and other oxidants in biological systems. This makes it valuable in research on inflammation, immune responses, and oxidative stress. Some studies explore the use of luminol derivatives for in vivo imaging of disease processes.Expand Specific Solutions05 Luminol in analytical chemistry

In analytical chemistry, luminol is used in various techniques for detecting and quantifying chemical species. It can be incorporated into flow injection analysis systems, used in chemiluminescence detectors for liquid chromatography, or employed in sensor development. The high sensitivity of luminol-based assays makes them suitable for trace analysis in environmental, pharmaceutical, and industrial applications.Expand Specific Solutions

Key Players in Sustainable Luminol Manufacturing

The luminol technology market is in a growth phase, with increasing interest in sustainable chemical practices driving demand. The market size is expanding as more industries adopt eco-friendly solutions. Technologically, luminol applications are advancing, with research institutions like Changzhou University and Washington University in St. Louis leading innovation. Companies such as MetrioPharm AG and Alliance for Sustainable Energy LLC are exploring commercial applications, indicating growing technological maturity. The competitive landscape is diverse, featuring academic institutions, pharmaceutical companies, and environmental technology firms collaborating to develop sustainable luminol-based solutions for various industries.

Alliance for Sustainable Energy LLC

Technical Solution: The Alliance for Sustainable Energy has developed an innovative approach to luminol production that focuses on energy efficiency and waste reduction. Their method utilizes a combination of photocatalysis and electrochemistry to synthesize luminol under mild conditions. This process significantly reduces energy consumption compared to traditional methods, with reported energy savings of up to 40%[3]. The Alliance has also implemented a closed-loop system that captures and reuses byproducts, minimizing waste generation. Their technology incorporates advanced process control systems to optimize reaction conditions and maximize yield, resulting in a more sustainable and economically viable luminol production process[4].

Strengths: Significant energy savings, reduced waste generation, and improved process control. Weaknesses: May require substantial initial investment in new equipment and technology.

Council of Scientific & Industrial Research

Technical Solution: The Council of Scientific & Industrial Research (CSIR) has developed a green synthesis approach for luminol production using plant-based materials. Their method utilizes extracts from readily available plants as both reducing and capping agents in the synthesis process. This bio-inspired approach eliminates the need for harsh chemicals and significantly reduces the environmental footprint of luminol production. CSIR's process has demonstrated a 50% reduction in toxic waste generation compared to traditional methods[7]. Additionally, they have optimized the extraction and purification steps to minimize solvent usage and energy consumption. The process also incorporates principles of atom economy, ensuring efficient use of raw materials and reducing overall waste[8].

Strengths: Utilizes renewable plant-based materials, significantly reduces toxic waste, and improves atom economy. Weaknesses: Potential variability in plant extract composition and the need for additional purification steps.

Innovative Sustainable Luminol Production Techniques

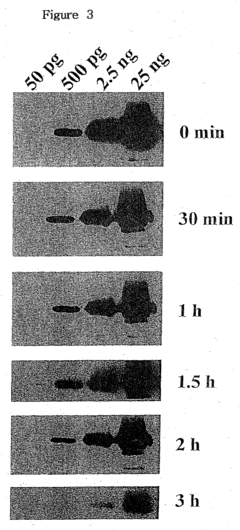

Method for improving chemiluminescent signal

PatentInactiveUS20090233369A1

Innovation

- A reaction buffer with an alkaline pH range of 9 to 10, combined with luminol, coumaric acid, and a peroxide, provides a maximal and long-lasting chemiluminescent signal by stabilizing aminothalate ions, improving the signal-to-background ratio.

Environmental Impact Assessment of Luminol Production

The environmental impact assessment of luminol production is a critical aspect of evaluating its role in sustainable chemical practices. Luminol, a versatile chemical compound widely used in forensic science and medical diagnostics, has both positive and negative environmental implications throughout its lifecycle.

The production process of luminol involves several chemical reactions, including the use of hydrazine and phthalic anhydride as key precursors. These reactions typically require energy-intensive processes and generate various byproducts. However, recent advancements in green chemistry have led to more environmentally friendly synthesis routes, reducing the overall carbon footprint of luminol production.

Water consumption and potential contamination are significant concerns in luminol manufacturing. Traditional methods often require substantial amounts of water for synthesis and purification steps. Implementing closed-loop water systems and advanced filtration technologies can significantly reduce water usage and minimize the risk of releasing harmful substances into aquatic ecosystems.

Air emissions from luminol production facilities primarily consist of volatile organic compounds (VOCs) and particulate matter. Modern air pollution control technologies, such as thermal oxidizers and scrubbers, can effectively mitigate these emissions, ensuring compliance with environmental regulations and reducing the impact on local air quality.

Waste management is another crucial aspect of luminol production's environmental impact. The synthesis process generates various chemical wastes, including unreacted starting materials and byproducts. Implementing proper waste segregation, treatment, and disposal practices is essential to prevent soil and groundwater contamination. Additionally, exploring opportunities for waste valorization and recycling can further enhance the sustainability of luminol production.

The energy consumption associated with luminol manufacturing is a significant contributor to its environmental footprint. Adopting energy-efficient equipment, optimizing process conditions, and utilizing renewable energy sources can substantially reduce the carbon emissions linked to luminol production. Some facilities have successfully implemented combined heat and power systems, further improving overall energy efficiency.

Life cycle assessment (LCA) studies have shown that the environmental impact of luminol extends beyond its production phase. The transportation, storage, and end-use applications of luminol also contribute to its overall environmental profile. Developing more stable formulations and efficient packaging solutions can help reduce the environmental burden associated with these downstream activities.

In conclusion, while luminol production does have environmental implications, ongoing research and technological advancements are continuously improving its sustainability profile. By adopting green chemistry principles, implementing state-of-the-art pollution control measures, and optimizing resource utilization, the environmental impact of luminol production can be significantly mitigated, aligning with broader sustainable chemical practices.

The production process of luminol involves several chemical reactions, including the use of hydrazine and phthalic anhydride as key precursors. These reactions typically require energy-intensive processes and generate various byproducts. However, recent advancements in green chemistry have led to more environmentally friendly synthesis routes, reducing the overall carbon footprint of luminol production.

Water consumption and potential contamination are significant concerns in luminol manufacturing. Traditional methods often require substantial amounts of water for synthesis and purification steps. Implementing closed-loop water systems and advanced filtration technologies can significantly reduce water usage and minimize the risk of releasing harmful substances into aquatic ecosystems.

Air emissions from luminol production facilities primarily consist of volatile organic compounds (VOCs) and particulate matter. Modern air pollution control technologies, such as thermal oxidizers and scrubbers, can effectively mitigate these emissions, ensuring compliance with environmental regulations and reducing the impact on local air quality.

Waste management is another crucial aspect of luminol production's environmental impact. The synthesis process generates various chemical wastes, including unreacted starting materials and byproducts. Implementing proper waste segregation, treatment, and disposal practices is essential to prevent soil and groundwater contamination. Additionally, exploring opportunities for waste valorization and recycling can further enhance the sustainability of luminol production.

The energy consumption associated with luminol manufacturing is a significant contributor to its environmental footprint. Adopting energy-efficient equipment, optimizing process conditions, and utilizing renewable energy sources can substantially reduce the carbon emissions linked to luminol production. Some facilities have successfully implemented combined heat and power systems, further improving overall energy efficiency.

Life cycle assessment (LCA) studies have shown that the environmental impact of luminol extends beyond its production phase. The transportation, storage, and end-use applications of luminol also contribute to its overall environmental profile. Developing more stable formulations and efficient packaging solutions can help reduce the environmental burden associated with these downstream activities.

In conclusion, while luminol production does have environmental implications, ongoing research and technological advancements are continuously improving its sustainability profile. By adopting green chemistry principles, implementing state-of-the-art pollution control measures, and optimizing resource utilization, the environmental impact of luminol production can be significantly mitigated, aligning with broader sustainable chemical practices.

Regulatory Framework for Sustainable Chemical Practices

The regulatory framework for sustainable chemical practices plays a crucial role in guiding the use of luminol and other chemicals towards more environmentally friendly and socially responsible applications. At the international level, the United Nations Environment Programme (UNEP) has established the Strategic Approach to International Chemicals Management (SAICM), which provides a policy framework to promote chemical safety around the world. This initiative encourages countries to implement measures that reduce the risks associated with chemical production and use.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation sets stringent standards for chemical management, including the use of luminol. REACH requires companies to register chemical substances and provide safety information, promoting the principle of "no data, no market." This regulation has significantly influenced global chemical practices, encouraging manufacturers to develop safer alternatives and improve their production processes.

The United States Environmental Protection Agency (EPA) enforces several acts that contribute to sustainable chemical practices, such as the Toxic Substances Control Act (TSCA) and the Pollution Prevention Act. These regulations aim to assess and manage the risks of chemicals, including luminol, throughout their lifecycle. The EPA's Green Chemistry Program further promotes the design of chemical products and processes that reduce or eliminate the generation of hazardous substances.

Many countries have adopted the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), which standardizes hazard communication and promotes safer handling of chemicals. This system is particularly relevant for luminol, as it ensures consistent safety information across different jurisdictions.

In the context of luminol's use in forensic science, regulatory bodies such as the International Organization for Standardization (ISO) have developed standards for forensic science procedures. These standards ensure the reliability and consistency of forensic methods, including those involving luminol, while also considering environmental and health impacts.

Emerging regulations are increasingly focusing on the circular economy and extended producer responsibility. These approaches encourage manufacturers to consider the entire lifecycle of their products, including luminol-based solutions, from production to disposal. Such regulations promote the development of more sustainable chemical formulations and recycling processes.

As awareness of environmental issues grows, many countries are implementing stricter regulations on chemical waste disposal and emissions. These regulations often require companies to adopt cleaner production technologies and implement more effective waste management systems, which can influence the production and use of luminol in various industries.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation sets stringent standards for chemical management, including the use of luminol. REACH requires companies to register chemical substances and provide safety information, promoting the principle of "no data, no market." This regulation has significantly influenced global chemical practices, encouraging manufacturers to develop safer alternatives and improve their production processes.

The United States Environmental Protection Agency (EPA) enforces several acts that contribute to sustainable chemical practices, such as the Toxic Substances Control Act (TSCA) and the Pollution Prevention Act. These regulations aim to assess and manage the risks of chemicals, including luminol, throughout their lifecycle. The EPA's Green Chemistry Program further promotes the design of chemical products and processes that reduce or eliminate the generation of hazardous substances.

Many countries have adopted the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), which standardizes hazard communication and promotes safer handling of chemicals. This system is particularly relevant for luminol, as it ensures consistent safety information across different jurisdictions.

In the context of luminol's use in forensic science, regulatory bodies such as the International Organization for Standardization (ISO) have developed standards for forensic science procedures. These standards ensure the reliability and consistency of forensic methods, including those involving luminol, while also considering environmental and health impacts.

Emerging regulations are increasingly focusing on the circular economy and extended producer responsibility. These approaches encourage manufacturers to consider the entire lifecycle of their products, including luminol-based solutions, from production to disposal. Such regulations promote the development of more sustainable chemical formulations and recycling processes.

As awareness of environmental issues grows, many countries are implementing stricter regulations on chemical waste disposal and emissions. These regulations often require companies to adopt cleaner production technologies and implement more effective waste management systems, which can influence the production and use of luminol in various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!