How PHEV affects electric vehicle battery lifecycle

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHEV Battery Evolution

The evolution of Plug-in Hybrid Electric Vehicle (PHEV) batteries has been a critical factor in shaping the electric vehicle landscape. Initially, PHEVs utilized nickel-metal hydride (NiMH) batteries, which offered improved energy density compared to lead-acid batteries but still had limitations in terms of weight and capacity. As technology progressed, lithium-ion batteries emerged as the preferred choice for PHEVs due to their higher energy density, longer lifespan, and faster charging capabilities.

The transition to lithium-ion batteries marked a significant milestone in PHEV battery evolution. These batteries allowed for increased electric-only range, reduced overall vehicle weight, and improved performance. Manufacturers began experimenting with different lithium-ion chemistries, such as lithium iron phosphate (LFP) and lithium nickel manganese cobalt oxide (NMC), to optimize battery characteristics for specific PHEV applications.

As PHEV technology matured, battery management systems (BMS) became increasingly sophisticated. Advanced BMS allowed for more efficient use of battery capacity, improved thermal management, and enhanced overall battery longevity. This development played a crucial role in extending the lifecycle of PHEV batteries and addressing concerns about battery degradation over time.

The integration of regenerative braking systems further contributed to the evolution of PHEV batteries. By capturing energy typically lost during braking and converting it back into electricity, these systems helped extend the electric range of PHEVs and reduce the overall strain on the battery, potentially prolonging its lifespan.

Recent advancements in PHEV battery technology have focused on increasing energy density while reducing costs. Solid-state batteries have emerged as a promising future technology, offering the potential for even higher energy density, faster charging times, and improved safety compared to traditional lithium-ion batteries. Although still in the development stage, solid-state batteries could represent the next major leap in PHEV battery evolution.

The ongoing evolution of PHEV batteries has also been driven by efforts to improve sustainability and reduce environmental impact. Manufacturers are exploring ways to enhance battery recyclability and develop more eco-friendly production processes. Additionally, research into alternative battery chemistries, such as sodium-ion batteries, aims to address concerns about the long-term availability and environmental impact of lithium-based batteries.

As PHEV battery technology continues to advance, it is expected to have a significant impact on the overall electric vehicle battery lifecycle. Improved energy density and longevity of PHEV batteries may lead to extended vehicle lifespans and reduced need for battery replacements. Furthermore, advancements in PHEV battery technology often translate to improvements in fully electric vehicle batteries, contributing to the broader evolution of electric mobility solutions.

The transition to lithium-ion batteries marked a significant milestone in PHEV battery evolution. These batteries allowed for increased electric-only range, reduced overall vehicle weight, and improved performance. Manufacturers began experimenting with different lithium-ion chemistries, such as lithium iron phosphate (LFP) and lithium nickel manganese cobalt oxide (NMC), to optimize battery characteristics for specific PHEV applications.

As PHEV technology matured, battery management systems (BMS) became increasingly sophisticated. Advanced BMS allowed for more efficient use of battery capacity, improved thermal management, and enhanced overall battery longevity. This development played a crucial role in extending the lifecycle of PHEV batteries and addressing concerns about battery degradation over time.

The integration of regenerative braking systems further contributed to the evolution of PHEV batteries. By capturing energy typically lost during braking and converting it back into electricity, these systems helped extend the electric range of PHEVs and reduce the overall strain on the battery, potentially prolonging its lifespan.

Recent advancements in PHEV battery technology have focused on increasing energy density while reducing costs. Solid-state batteries have emerged as a promising future technology, offering the potential for even higher energy density, faster charging times, and improved safety compared to traditional lithium-ion batteries. Although still in the development stage, solid-state batteries could represent the next major leap in PHEV battery evolution.

The ongoing evolution of PHEV batteries has also been driven by efforts to improve sustainability and reduce environmental impact. Manufacturers are exploring ways to enhance battery recyclability and develop more eco-friendly production processes. Additionally, research into alternative battery chemistries, such as sodium-ion batteries, aims to address concerns about the long-term availability and environmental impact of lithium-based batteries.

As PHEV battery technology continues to advance, it is expected to have a significant impact on the overall electric vehicle battery lifecycle. Improved energy density and longevity of PHEV batteries may lead to extended vehicle lifespans and reduced need for battery replacements. Furthermore, advancements in PHEV battery technology often translate to improvements in fully electric vehicle batteries, contributing to the broader evolution of electric mobility solutions.

EV Market Trends

The electric vehicle (EV) market has been experiencing significant growth and transformation in recent years, with Plug-in Hybrid Electric Vehicles (PHEVs) playing a crucial role in this evolution. As consumers increasingly prioritize environmental sustainability and governments worldwide implement stricter emissions regulations, the demand for electric vehicles, including PHEVs, has surged.

PHEVs have emerged as a transitional technology, bridging the gap between traditional internal combustion engine vehicles and fully electric vehicles. This hybrid approach has gained traction among consumers who seek the benefits of electric driving without the range anxiety associated with pure EVs. The market share of PHEVs has been steadily increasing, particularly in regions with well-developed charging infrastructure.

The impact of PHEVs on the overall EV market is multifaceted. On one hand, they have contributed to the broader adoption of electric vehicle technology by offering a more familiar driving experience to consumers accustomed to conventional vehicles. This has helped accelerate the transition towards electrification in the automotive industry. On the other hand, the presence of PHEVs has also influenced battery technology development and production scales.

The battery lifecycle of PHEVs differs from that of pure EVs due to their dual powertrain nature. PHEV batteries typically have smaller capacities and experience different usage patterns, which can affect their longevity and performance over time. This has led to specialized research and development efforts focused on optimizing battery life and efficiency for hybrid applications.

Market trends indicate that while PHEVs continue to play a significant role in the EV landscape, there is a gradual shift towards fully electric vehicles as battery technology improves and charging infrastructure expands. However, PHEVs remain an important segment, particularly in markets where charging infrastructure is still developing or for consumers with specific driving needs that benefit from the flexibility of a hybrid powertrain.

The presence of PHEVs in the market has also influenced consumer behavior and charging patterns. PHEV owners tend to have different charging habits compared to pure EV owners, often relying more on home charging and less on public charging infrastructure. This has implications for the development and distribution of charging networks and affects the overall electric vehicle ecosystem.

As the EV market continues to evolve, the role of PHEVs in shaping battery lifecycle management and recycling processes becomes increasingly important. The diverse range of battery sizes and chemistries used in PHEVs presents both challenges and opportunities for the development of efficient recycling and second-life applications for EV batteries.

PHEVs have emerged as a transitional technology, bridging the gap between traditional internal combustion engine vehicles and fully electric vehicles. This hybrid approach has gained traction among consumers who seek the benefits of electric driving without the range anxiety associated with pure EVs. The market share of PHEVs has been steadily increasing, particularly in regions with well-developed charging infrastructure.

The impact of PHEVs on the overall EV market is multifaceted. On one hand, they have contributed to the broader adoption of electric vehicle technology by offering a more familiar driving experience to consumers accustomed to conventional vehicles. This has helped accelerate the transition towards electrification in the automotive industry. On the other hand, the presence of PHEVs has also influenced battery technology development and production scales.

The battery lifecycle of PHEVs differs from that of pure EVs due to their dual powertrain nature. PHEV batteries typically have smaller capacities and experience different usage patterns, which can affect their longevity and performance over time. This has led to specialized research and development efforts focused on optimizing battery life and efficiency for hybrid applications.

Market trends indicate that while PHEVs continue to play a significant role in the EV landscape, there is a gradual shift towards fully electric vehicles as battery technology improves and charging infrastructure expands. However, PHEVs remain an important segment, particularly in markets where charging infrastructure is still developing or for consumers with specific driving needs that benefit from the flexibility of a hybrid powertrain.

The presence of PHEVs in the market has also influenced consumer behavior and charging patterns. PHEV owners tend to have different charging habits compared to pure EV owners, often relying more on home charging and less on public charging infrastructure. This has implications for the development and distribution of charging networks and affects the overall electric vehicle ecosystem.

As the EV market continues to evolve, the role of PHEVs in shaping battery lifecycle management and recycling processes becomes increasingly important. The diverse range of battery sizes and chemistries used in PHEVs presents both challenges and opportunities for the development of efficient recycling and second-life applications for EV batteries.

PHEV Battery Challenges

Plug-in Hybrid Electric Vehicles (PHEVs) present unique challenges in the context of electric vehicle battery lifecycles. The dual nature of PHEVs, combining both internal combustion engines and electric powertrains, introduces complexities that affect battery performance, longevity, and overall lifecycle management.

One of the primary challenges is the irregular charging patterns associated with PHEVs. Unlike pure electric vehicles, PHEV users may rely more heavily on the gasoline engine, leading to inconsistent battery usage and charging cycles. This unpredictable usage pattern can accelerate battery degradation, potentially shortening the overall lifespan of the battery pack.

The frequent transitions between electric and gasoline modes in PHEVs also contribute to increased thermal stress on the battery. Rapid changes in power demand can cause temperature fluctuations, which may lead to accelerated aging of battery cells. Managing these thermal cycles effectively is crucial for maintaining battery health and extending its useful life.

Another significant challenge is the optimization of battery size for PHEVs. Manufacturers must balance the desire for extended electric range with the need for a compact, lightweight battery pack that doesn't compromise vehicle performance or fuel efficiency when operating in hybrid mode. This balancing act often results in smaller battery capacities compared to pure electric vehicles, which can lead to more frequent charging cycles and potentially faster degradation.

The dual powertrain nature of PHEVs also complicates battery management systems (BMS). These systems must be sophisticated enough to handle the complex interplay between electric and gasoline power sources, ensuring optimal battery performance and longevity while maximizing overall vehicle efficiency. Developing robust BMS algorithms that can adapt to various driving conditions and usage patterns is a significant technical challenge.

Furthermore, the lifecycle assessment of PHEV batteries is more complex than that of pure electric vehicles. The environmental impact of battery production and end-of-life disposal must be weighed against the potential emissions reductions achieved through electric driving. This assessment is complicated by the varying usage patterns of PHEVs, which can significantly impact the overall environmental footprint of the vehicle over its lifetime.

Lastly, the end-of-life management of PHEV batteries presents unique challenges. The potentially shorter lifespan of these batteries, coupled with their smaller capacity, may affect the economic viability of second-life applications commonly considered for pure electric vehicle batteries. Developing effective recycling and repurposing strategies specifically tailored to PHEV batteries is crucial for minimizing environmental impact and maximizing resource recovery.

One of the primary challenges is the irregular charging patterns associated with PHEVs. Unlike pure electric vehicles, PHEV users may rely more heavily on the gasoline engine, leading to inconsistent battery usage and charging cycles. This unpredictable usage pattern can accelerate battery degradation, potentially shortening the overall lifespan of the battery pack.

The frequent transitions between electric and gasoline modes in PHEVs also contribute to increased thermal stress on the battery. Rapid changes in power demand can cause temperature fluctuations, which may lead to accelerated aging of battery cells. Managing these thermal cycles effectively is crucial for maintaining battery health and extending its useful life.

Another significant challenge is the optimization of battery size for PHEVs. Manufacturers must balance the desire for extended electric range with the need for a compact, lightweight battery pack that doesn't compromise vehicle performance or fuel efficiency when operating in hybrid mode. This balancing act often results in smaller battery capacities compared to pure electric vehicles, which can lead to more frequent charging cycles and potentially faster degradation.

The dual powertrain nature of PHEVs also complicates battery management systems (BMS). These systems must be sophisticated enough to handle the complex interplay between electric and gasoline power sources, ensuring optimal battery performance and longevity while maximizing overall vehicle efficiency. Developing robust BMS algorithms that can adapt to various driving conditions and usage patterns is a significant technical challenge.

Furthermore, the lifecycle assessment of PHEV batteries is more complex than that of pure electric vehicles. The environmental impact of battery production and end-of-life disposal must be weighed against the potential emissions reductions achieved through electric driving. This assessment is complicated by the varying usage patterns of PHEVs, which can significantly impact the overall environmental footprint of the vehicle over its lifetime.

Lastly, the end-of-life management of PHEV batteries presents unique challenges. The potentially shorter lifespan of these batteries, coupled with their smaller capacity, may affect the economic viability of second-life applications commonly considered for pure electric vehicle batteries. Developing effective recycling and repurposing strategies specifically tailored to PHEV batteries is crucial for minimizing environmental impact and maximizing resource recovery.

Current PHEV Solutions

01 Battery Management Systems

Advanced battery management systems are crucial for optimizing the lifecycle of electric vehicle batteries. These systems monitor and control various parameters such as temperature, charge/discharge rates, and cell balancing to extend battery life, improve performance, and ensure safety. They also provide real-time data on battery health and performance, enabling predictive maintenance and efficient battery utilization.- Battery Management Systems: Advanced battery management systems are crucial for optimizing the lifecycle of electric vehicle batteries. These systems monitor and control various parameters such as temperature, charge/discharge rates, and cell balancing to ensure optimal performance and longevity. They also provide real-time data on battery health and performance, enabling predictive maintenance and efficient battery utilization throughout its lifecycle.

- Battery Recycling and Second-Life Applications: Developing efficient recycling processes and exploring second-life applications for electric vehicle batteries are essential aspects of their lifecycle management. This includes methods for safely dismantling and recycling battery components, as well as repurposing batteries for stationary energy storage applications after their automotive life. These strategies help to maximize the value of batteries and minimize environmental impact.

- Battery Thermal Management: Effective thermal management is critical for extending the lifecycle of electric vehicle batteries. This involves innovative cooling and heating systems to maintain optimal operating temperatures, preventing degradation due to extreme temperatures. Advanced thermal management solutions can significantly improve battery performance, longevity, and safety throughout its lifecycle.

- Battery Health Monitoring and Diagnostics: Implementing sophisticated health monitoring and diagnostic systems is crucial for managing the lifecycle of electric vehicle batteries. These systems use advanced sensors and algorithms to assess battery condition, predict potential issues, and provide accurate estimations of remaining battery life. This enables proactive maintenance and optimized battery usage strategies.

- Battery Charging Infrastructure and Protocols: Developing efficient charging infrastructure and smart charging protocols is essential for maximizing the lifecycle of electric vehicle batteries. This includes fast-charging technologies, wireless charging solutions, and intelligent charging strategies that consider factors such as battery health, grid load, and user behavior to optimize charging patterns and extend battery life.

02 Battery Recycling and Second-Life Applications

As electric vehicle batteries reach the end of their automotive life, recycling and repurposing become essential aspects of their lifecycle. Advanced recycling techniques are being developed to recover valuable materials from used batteries. Additionally, batteries with reduced capacity for automotive use can find second-life applications in stationary energy storage systems, further extending their overall lifecycle and reducing environmental impact.Expand Specific Solutions03 Charging Infrastructure and Protocols

The development of efficient charging infrastructure and smart charging protocols plays a significant role in extending battery life. Fast charging technologies, bidirectional charging capabilities, and intelligent charging algorithms help optimize the charging process, reduce battery degradation, and improve overall lifecycle. Integration with renewable energy sources for charging also contributes to the sustainability of electric vehicle battery systems.Expand Specific Solutions04 Battery Design and Materials Innovation

Ongoing research in battery design and materials aims to improve the lifecycle of electric vehicle batteries. This includes the development of new electrode materials, electrolytes, and cell designs that enhance energy density, cycle life, and thermal stability. Innovations in solid-state batteries and other advanced battery technologies promise to further extend the lifespan and performance of electric vehicle batteries.Expand Specific Solutions05 Predictive Maintenance and Diagnostics

Advanced diagnostic tools and predictive maintenance techniques are being developed to monitor battery health throughout its lifecycle. These technologies use machine learning algorithms and data analytics to predict potential issues, optimize maintenance schedules, and provide insights for improving battery design and usage patterns. This proactive approach helps extend battery life and enhances the overall reliability of electric vehicles.Expand Specific Solutions

Key PHEV Manufacturers

The competition landscape for PHEV's impact on electric vehicle battery lifecycle is evolving rapidly, reflecting the industry's growth stage. The market is expanding, driven by increasing demand for eco-friendly vehicles and government incentives. Technologically, PHEVs are in a transitional phase between traditional combustion engines and fully electric vehicles. Major players like Ford, Hyundai, Kia, and Toyota are investing heavily in PHEV technology, focusing on improving battery longevity and efficiency. Emerging companies such as Tanktwo and Smartville are developing innovative solutions for battery management and recycling, addressing the critical aspect of battery lifecycle. The involvement of established automotive giants alongside specialized tech firms indicates a competitive and dynamic market with significant potential for technological advancements and market growth.

Ford Global Technologies LLC

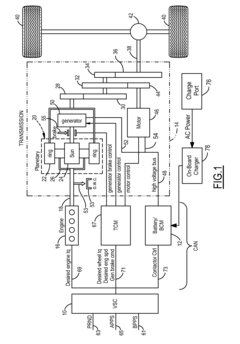

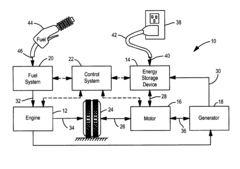

Technical Solution: Ford's PHEV strategy focuses on optimizing battery lifecycle through advanced powertrain control and user-centric features. Their EcoBoost plug-in hybrid system uses a power-split architecture that allows for seamless transitions between electric and hybrid modes, reducing stress on the battery[1]. Ford has also implemented a feature called "Geofencing" in their PHEVs, which automatically switches to all-electric mode in designated low-emission zones, similar to BMW's system[3]. To extend battery life, Ford utilizes an advanced Battery Management System (BMS) that continuously monitors cell voltages, temperatures, and state of charge to optimize performance and longevity[5]. Additionally, Ford has developed a unique "EV Coaching" feature in their infotainment systems, which provides drivers with real-time feedback on their driving style to maximize electric range and minimize battery degradation[7].

Strengths: User-friendly features to optimize battery use, advanced BMS for battery longevity. Weaknesses: Reliance on driver behavior for optimal performance may lead to inconsistent results.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai's PHEV technology focuses on maximizing electric range while minimizing battery degradation. Their latest PHEVs feature a unique transmission-mounted electric device (TMED) that allows for more efficient power delivery and reduced mechanical losses[2]. Hyundai has also developed an intelligent Green Zone Drive Mode that automatically switches to EV mode in designated areas, similar to competitors' geofencing features[4]. To extend battery life, Hyundai employs a sophisticated Battery Thermal Management System (BTMS) that uses liquid cooling to maintain optimal battery temperature across various operating conditions[6]. Additionally, Hyundai has implemented predictive energy management systems that use route information and driving patterns to optimize the use of electric and gasoline power, reducing unnecessary battery cycling[8]. The company is also exploring Vehicle-to-Grid (V2G) technology for their PHEVs, which could potentially extend battery life by allowing for more controlled charging and discharging cycles[9].

Strengths: Efficient TMED system, advanced BTMS for optimal battery temperature control. Weaknesses: V2G technology still in early stages, potential for increased complexity.

Battery Lifecycle Analysis

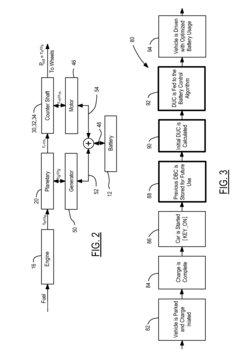

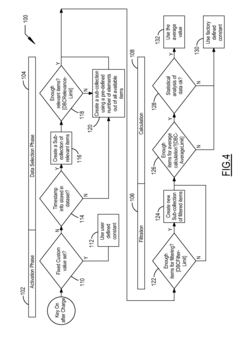

Adaptive Initial Estimation and Dynamic Determination and Update of Distance Until Charge of a Plug-In Hybrid Electric Vehicle

PatentActiveUS20110184600A1

Innovation

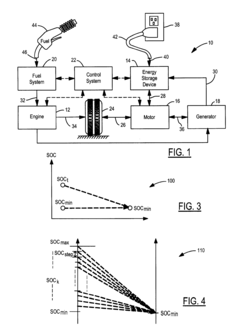

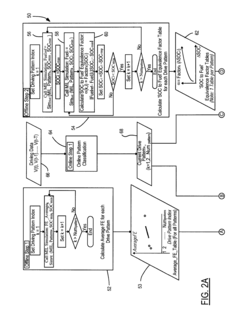

- A method and system that dynamically control battery usage based on the estimated or user-provided 'distance until charge' (DUC) value, utilizing historical data and real-time information from navigation systems to optimize battery depletion and charging strategies.

Plug-in hybrid electric vehicle and method of control for providing distance to empty and equivalent trip fuel economy information

PatentActiveUS8406948B2

Innovation

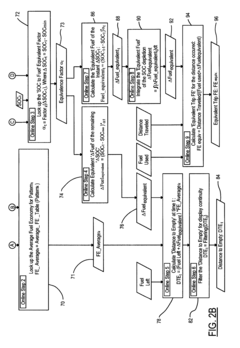

- A method for calculating DTE and equivalent Trip Fuel Economy (FE) that involves a controller determining the battery equivalent fuel amount using an equivalence factor based on SOC and driving conditions, and converting electricity consumption into fuel consumption for a unified efficiency index in miles per gallon (MPG), leveraging existing driving pattern identification and high-fidelity PHEV models to provide accurate and adaptive readouts.

Environmental Impact

The environmental impact of Plug-in Hybrid Electric Vehicles (PHEVs) on electric vehicle battery lifecycle is a complex and multifaceted issue. PHEVs, by their dual-powertrain nature, present unique challenges and opportunities in terms of battery lifecycle management and overall environmental footprint.

PHEVs typically have smaller battery packs compared to full electric vehicles, which can lead to reduced environmental impact during the manufacturing phase. The production of lithium-ion batteries is resource-intensive and energy-demanding, contributing significantly to the carbon footprint of electric vehicles. With PHEVs requiring smaller batteries, the initial environmental cost of production is potentially lower.

However, the environmental benefits of PHEVs during the use phase are heavily dependent on driving patterns and charging behaviors. When used primarily in electric mode for short trips and regularly charged, PHEVs can significantly reduce emissions compared to conventional vehicles. Conversely, if driven predominantly using the internal combustion engine, their environmental advantages diminish.

The battery lifecycle in PHEVs is influenced by the frequency of charge-discharge cycles and depth of discharge. PHEVs often experience more frequent and shallower discharge cycles compared to full electric vehicles, which can potentially extend battery life. This prolonged lifespan could reduce the need for battery replacement, thereby decreasing the overall environmental impact associated with battery production and disposal.

End-of-life management of PHEV batteries presents both challenges and opportunities. As these batteries often retain significant capacity after their automotive life, they have potential for second-life applications such as stationary energy storage. This repurposing can extend the useful life of the batteries, maximizing resource utilization and reducing waste.

The recycling of PHEV batteries is crucial for recovering valuable materials and minimizing environmental impact. However, the complexity of PHEV battery systems, which may include different chemistries and configurations, can complicate recycling processes. Developing efficient and economically viable recycling technologies for these diverse battery types is essential for closing the loop in the battery lifecycle.

The overall environmental impact of PHEVs on battery lifecycle must also consider the broader energy context. The carbon intensity of the electricity grid used for charging significantly affects the lifecycle emissions of PHEVs. In regions with clean energy grids, PHEVs can offer substantial environmental benefits, while in areas heavily reliant on fossil fuels, the advantages may be less pronounced.

In conclusion, while PHEVs present certain environmental advantages in terms of battery lifecycle, their impact is highly context-dependent. Optimizing their environmental benefits requires careful consideration of production methods, use patterns, energy sources, and end-of-life management strategies.

PHEVs typically have smaller battery packs compared to full electric vehicles, which can lead to reduced environmental impact during the manufacturing phase. The production of lithium-ion batteries is resource-intensive and energy-demanding, contributing significantly to the carbon footprint of electric vehicles. With PHEVs requiring smaller batteries, the initial environmental cost of production is potentially lower.

However, the environmental benefits of PHEVs during the use phase are heavily dependent on driving patterns and charging behaviors. When used primarily in electric mode for short trips and regularly charged, PHEVs can significantly reduce emissions compared to conventional vehicles. Conversely, if driven predominantly using the internal combustion engine, their environmental advantages diminish.

The battery lifecycle in PHEVs is influenced by the frequency of charge-discharge cycles and depth of discharge. PHEVs often experience more frequent and shallower discharge cycles compared to full electric vehicles, which can potentially extend battery life. This prolonged lifespan could reduce the need for battery replacement, thereby decreasing the overall environmental impact associated with battery production and disposal.

End-of-life management of PHEV batteries presents both challenges and opportunities. As these batteries often retain significant capacity after their automotive life, they have potential for second-life applications such as stationary energy storage. This repurposing can extend the useful life of the batteries, maximizing resource utilization and reducing waste.

The recycling of PHEV batteries is crucial for recovering valuable materials and minimizing environmental impact. However, the complexity of PHEV battery systems, which may include different chemistries and configurations, can complicate recycling processes. Developing efficient and economically viable recycling technologies for these diverse battery types is essential for closing the loop in the battery lifecycle.

The overall environmental impact of PHEVs on battery lifecycle must also consider the broader energy context. The carbon intensity of the electricity grid used for charging significantly affects the lifecycle emissions of PHEVs. In regions with clean energy grids, PHEVs can offer substantial environmental benefits, while in areas heavily reliant on fossil fuels, the advantages may be less pronounced.

In conclusion, while PHEVs present certain environmental advantages in terms of battery lifecycle, their impact is highly context-dependent. Optimizing their environmental benefits requires careful consideration of production methods, use patterns, energy sources, and end-of-life management strategies.

Charging Infrastructure

The charging infrastructure plays a crucial role in the lifecycle of electric vehicle batteries, including those in Plug-in Hybrid Electric Vehicles (PHEVs). As PHEVs combine both electric and internal combustion engine technologies, their impact on charging infrastructure is unique and multifaceted.

PHEVs typically have smaller battery capacities compared to full battery electric vehicles (BEVs), which influences their charging requirements. This reduced battery size often translates to shorter charging times and less strain on the charging infrastructure. However, the frequency of charging may be higher for PHEVs, as users tend to maximize their electric-only driving range.

The availability and accessibility of charging infrastructure significantly affect PHEV battery lifecycle. Adequate charging options encourage more frequent electric mode usage, potentially extending the overall lifespan of the vehicle's battery by reducing reliance on the internal combustion engine. Conversely, limited charging infrastructure may lead to increased use of the gasoline engine, potentially underutilizing the battery and affecting its long-term performance.

Fast charging capabilities in PHEVs, while less common than in BEVs, can impact battery degradation. Rapid charging generates more heat, which can accelerate battery aging if used frequently. However, the smaller battery size of PHEVs may mitigate some of these effects compared to larger BEV batteries.

The integration of smart charging technologies is particularly relevant for PHEVs. These systems can optimize charging schedules based on grid demand, potentially reducing stress on both the battery and the electrical infrastructure. This intelligent management can contribute to prolonging battery life by avoiding peak charging times and maintaining optimal charge levels.

Public charging infrastructure development also influences PHEV battery lifecycles. As more charging stations become available, PHEV users are more likely to rely on electric power, potentially extending battery life through regular, controlled charging cycles. However, this increased usage may also lead to more charge-discharge cycles, which could impact long-term battery capacity.

The type of charging infrastructure available also affects PHEV battery performance. Level 2 chargers, commonly found in public spaces and homes, provide a balance between charging speed and battery stress, making them well-suited for PHEV needs. The growing adoption of workplace charging further supports optimal PHEV battery usage patterns.

In conclusion, the relationship between PHEVs and charging infrastructure is dynamic and complex. While PHEVs may place less immediate demand on charging networks compared to BEVs, their unique usage patterns and potential for frequent charging highlight the importance of widespread, accessible, and intelligent charging solutions in maximizing battery lifecycle and overall vehicle efficiency.

PHEVs typically have smaller battery capacities compared to full battery electric vehicles (BEVs), which influences their charging requirements. This reduced battery size often translates to shorter charging times and less strain on the charging infrastructure. However, the frequency of charging may be higher for PHEVs, as users tend to maximize their electric-only driving range.

The availability and accessibility of charging infrastructure significantly affect PHEV battery lifecycle. Adequate charging options encourage more frequent electric mode usage, potentially extending the overall lifespan of the vehicle's battery by reducing reliance on the internal combustion engine. Conversely, limited charging infrastructure may lead to increased use of the gasoline engine, potentially underutilizing the battery and affecting its long-term performance.

Fast charging capabilities in PHEVs, while less common than in BEVs, can impact battery degradation. Rapid charging generates more heat, which can accelerate battery aging if used frequently. However, the smaller battery size of PHEVs may mitigate some of these effects compared to larger BEV batteries.

The integration of smart charging technologies is particularly relevant for PHEVs. These systems can optimize charging schedules based on grid demand, potentially reducing stress on both the battery and the electrical infrastructure. This intelligent management can contribute to prolonging battery life by avoiding peak charging times and maintaining optimal charge levels.

Public charging infrastructure development also influences PHEV battery lifecycles. As more charging stations become available, PHEV users are more likely to rely on electric power, potentially extending battery life through regular, controlled charging cycles. However, this increased usage may also lead to more charge-discharge cycles, which could impact long-term battery capacity.

The type of charging infrastructure available also affects PHEV battery performance. Level 2 chargers, commonly found in public spaces and homes, provide a balance between charging speed and battery stress, making them well-suited for PHEV needs. The growing adoption of workplace charging further supports optimal PHEV battery usage patterns.

In conclusion, the relationship between PHEVs and charging infrastructure is dynamic and complex. While PHEVs may place less immediate demand on charging networks compared to BEVs, their unique usage patterns and potential for frequent charging highlight the importance of widespread, accessible, and intelligent charging solutions in maximizing battery lifecycle and overall vehicle efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!