How to Boost Polycarbonate’s Sustainability Metrics?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polycarbonate Sustainability Background and Objectives

Polycarbonate, a versatile thermoplastic polymer, has been widely used in various industries since its commercial introduction in the 1960s. Known for its exceptional impact resistance, optical clarity, and heat resistance, polycarbonate has found applications in automotive, electronics, construction, and consumer goods sectors. However, as global awareness of environmental issues has grown, the sustainability of polycarbonate production and usage has come under scrutiny.

The primary objective of enhancing polycarbonate's sustainability metrics is to address the environmental concerns associated with its lifecycle. This includes reducing the carbon footprint of production processes, minimizing energy consumption, and improving end-of-life management. Additionally, there is a pressing need to develop more eco-friendly alternatives to the traditional bisphenol A (BPA) based polycarbonates, which have raised health and environmental concerns.

The evolution of polycarbonate technology has been marked by continuous efforts to improve its properties and reduce its environmental impact. Early developments focused on enhancing mechanical and thermal properties, while recent trends have shifted towards sustainability. Key milestones include the introduction of BPA-free polycarbonates, the development of bio-based alternatives, and advancements in recycling technologies.

Current technological goals in polycarbonate sustainability encompass several areas. Firstly, there is a drive to increase the use of recycled content in polycarbonate production, aiming to create a more circular economy for this material. Secondly, researchers are exploring novel synthesis routes that utilize renewable resources or CO2 as a feedstock, potentially reducing the reliance on petroleum-based raw materials.

Another critical objective is to improve the biodegradability and compostability of polycarbonate products, particularly for single-use applications. This involves developing new additives or modifying the polymer structure to enhance its environmental degradation without compromising its desirable properties during use.

The industry is also focusing on enhancing the energy efficiency of polycarbonate production processes. This includes optimizing reaction conditions, exploring alternative catalysts, and implementing more efficient heat recovery systems. Additionally, there is a growing emphasis on developing polycarbonates with improved recyclability, allowing for easier separation and reprocessing of end-of-life products.

As we look to the future, the overarching goal is to transform polycarbonate into a more sustainable material that aligns with circular economy principles. This involves not only technological advancements but also changes in product design, manufacturing processes, and consumer behavior. By addressing these challenges, the industry aims to secure polycarbonate's position as a valuable and environmentally responsible material in the years to come.

The primary objective of enhancing polycarbonate's sustainability metrics is to address the environmental concerns associated with its lifecycle. This includes reducing the carbon footprint of production processes, minimizing energy consumption, and improving end-of-life management. Additionally, there is a pressing need to develop more eco-friendly alternatives to the traditional bisphenol A (BPA) based polycarbonates, which have raised health and environmental concerns.

The evolution of polycarbonate technology has been marked by continuous efforts to improve its properties and reduce its environmental impact. Early developments focused on enhancing mechanical and thermal properties, while recent trends have shifted towards sustainability. Key milestones include the introduction of BPA-free polycarbonates, the development of bio-based alternatives, and advancements in recycling technologies.

Current technological goals in polycarbonate sustainability encompass several areas. Firstly, there is a drive to increase the use of recycled content in polycarbonate production, aiming to create a more circular economy for this material. Secondly, researchers are exploring novel synthesis routes that utilize renewable resources or CO2 as a feedstock, potentially reducing the reliance on petroleum-based raw materials.

Another critical objective is to improve the biodegradability and compostability of polycarbonate products, particularly for single-use applications. This involves developing new additives or modifying the polymer structure to enhance its environmental degradation without compromising its desirable properties during use.

The industry is also focusing on enhancing the energy efficiency of polycarbonate production processes. This includes optimizing reaction conditions, exploring alternative catalysts, and implementing more efficient heat recovery systems. Additionally, there is a growing emphasis on developing polycarbonates with improved recyclability, allowing for easier separation and reprocessing of end-of-life products.

As we look to the future, the overarching goal is to transform polycarbonate into a more sustainable material that aligns with circular economy principles. This involves not only technological advancements but also changes in product design, manufacturing processes, and consumer behavior. By addressing these challenges, the industry aims to secure polycarbonate's position as a valuable and environmentally responsible material in the years to come.

Market Demand for Sustainable Polycarbonate Solutions

The market demand for sustainable polycarbonate solutions has been steadily increasing in recent years, driven by growing environmental concerns and stricter regulations on plastic usage. Polycarbonate, a versatile thermoplastic known for its durability and optical clarity, has long been a popular choice in various industries. However, its sustainability profile has come under scrutiny, prompting a shift towards more eco-friendly alternatives.

Consumer awareness and preferences have played a significant role in shaping this demand. End-users are increasingly seeking products that align with their environmental values, putting pressure on manufacturers to adopt sustainable practices and materials. This trend is particularly evident in sectors such as automotive, electronics, and packaging, where polycarbonate is widely used.

The automotive industry, for instance, has been actively exploring sustainable polycarbonate solutions to reduce vehicle weight and improve fuel efficiency while meeting stringent environmental standards. Similarly, the electronics sector is looking for ways to incorporate recycled or bio-based polycarbonates in device casings and components to appeal to environmentally conscious consumers.

Regulatory pressures have also been a key driver in the market demand for sustainable polycarbonate solutions. Governments worldwide are implementing stricter regulations on plastic waste and carbon emissions, compelling industries to seek more sustainable alternatives. The European Union's Circular Economy Action Plan and similar initiatives in other regions have set ambitious targets for plastic recycling and reduction, directly impacting the polycarbonate market.

The packaging industry, another major consumer of polycarbonate, is experiencing a significant shift towards sustainable solutions. With single-use plastics facing bans in many jurisdictions, there is a growing demand for recyclable, reusable, or biodegradable polycarbonate alternatives in food packaging, beverage containers, and other consumer goods.

Market research indicates that the global sustainable plastics market, including sustainable polycarbonate solutions, is expected to grow substantially in the coming years. This growth is attributed to the increasing adoption of circular economy principles, the rise of bio-based and recycled materials, and advancements in chemical recycling technologies.

Companies across the value chain are responding to this market demand by investing in research and development of sustainable polycarbonate solutions. This includes efforts to improve the recyclability of existing polycarbonate products, develop bio-based alternatives, and create closed-loop recycling systems for polycarbonate waste.

The demand for sustainable polycarbonate solutions also extends to emerging markets, where rapid industrialization and urbanization are driving the need for durable yet environmentally friendly materials. As these economies develop, there is a growing emphasis on leapfrogging to more sustainable technologies, creating new opportunities for innovative polycarbonate solutions.

Consumer awareness and preferences have played a significant role in shaping this demand. End-users are increasingly seeking products that align with their environmental values, putting pressure on manufacturers to adopt sustainable practices and materials. This trend is particularly evident in sectors such as automotive, electronics, and packaging, where polycarbonate is widely used.

The automotive industry, for instance, has been actively exploring sustainable polycarbonate solutions to reduce vehicle weight and improve fuel efficiency while meeting stringent environmental standards. Similarly, the electronics sector is looking for ways to incorporate recycled or bio-based polycarbonates in device casings and components to appeal to environmentally conscious consumers.

Regulatory pressures have also been a key driver in the market demand for sustainable polycarbonate solutions. Governments worldwide are implementing stricter regulations on plastic waste and carbon emissions, compelling industries to seek more sustainable alternatives. The European Union's Circular Economy Action Plan and similar initiatives in other regions have set ambitious targets for plastic recycling and reduction, directly impacting the polycarbonate market.

The packaging industry, another major consumer of polycarbonate, is experiencing a significant shift towards sustainable solutions. With single-use plastics facing bans in many jurisdictions, there is a growing demand for recyclable, reusable, or biodegradable polycarbonate alternatives in food packaging, beverage containers, and other consumer goods.

Market research indicates that the global sustainable plastics market, including sustainable polycarbonate solutions, is expected to grow substantially in the coming years. This growth is attributed to the increasing adoption of circular economy principles, the rise of bio-based and recycled materials, and advancements in chemical recycling technologies.

Companies across the value chain are responding to this market demand by investing in research and development of sustainable polycarbonate solutions. This includes efforts to improve the recyclability of existing polycarbonate products, develop bio-based alternatives, and create closed-loop recycling systems for polycarbonate waste.

The demand for sustainable polycarbonate solutions also extends to emerging markets, where rapid industrialization and urbanization are driving the need for durable yet environmentally friendly materials. As these economies develop, there is a growing emphasis on leapfrogging to more sustainable technologies, creating new opportunities for innovative polycarbonate solutions.

Current Challenges in Polycarbonate Sustainability

Polycarbonate, a widely used engineering thermoplastic, faces significant sustainability challenges in today's environmentally conscious market. The primary issue lies in its production process, which traditionally relies on bisphenol A (BPA) and phosgene, both of which raise environmental and health concerns. BPA, in particular, has been linked to potential endocrine disruption, leading to increased scrutiny and regulatory pressure.

The energy-intensive manufacturing process of polycarbonate contributes substantially to its carbon footprint. The high temperatures and pressures required for polymerization result in significant energy consumption and associated greenhouse gas emissions. This aspect of production conflicts with global efforts to reduce industrial carbon emissions and transition to more sustainable manufacturing practices.

Another major challenge is the end-of-life management of polycarbonate products. While theoretically recyclable, the practical recycling of polycarbonate is often hindered by contamination issues and the presence of additives. The lack of efficient recycling infrastructure and processes leads to a significant portion of polycarbonate waste ending up in landfills or incineration facilities, contributing to environmental pollution and resource depletion.

The durability of polycarbonate, while advantageous in many applications, poses a paradox for sustainability. Its long-lasting nature means that products persist in the environment for extended periods when not properly managed at the end of their lifecycle. This persistence contributes to the accumulation of plastic waste in ecosystems, particularly in marine environments.

Additives used to enhance polycarbonate's properties, such as flame retardants and UV stabilizers, further complicate its sustainability profile. These additives can leach into the environment during use or disposal, potentially causing ecological harm. The presence of these chemicals also makes recycling more challenging and can limit the applications of recycled polycarbonate.

The global demand for more sustainable materials has put pressure on polycarbonate manufacturers to innovate. There is a growing need for bio-based alternatives to traditional petroleum-derived polycarbonate, as well as for improved recycling technologies. However, developing these alternatives while maintaining the desirable properties of polycarbonate remains a significant technical challenge.

Regulatory compliance presents another hurdle for polycarbonate sustainability. Evolving regulations around plastic use, recycling requirements, and chemical safety standards necessitate continuous adaptation in production processes and product formulations. Meeting these regulatory demands while maintaining cost-effectiveness and performance is a complex balancing act for manufacturers.

The energy-intensive manufacturing process of polycarbonate contributes substantially to its carbon footprint. The high temperatures and pressures required for polymerization result in significant energy consumption and associated greenhouse gas emissions. This aspect of production conflicts with global efforts to reduce industrial carbon emissions and transition to more sustainable manufacturing practices.

Another major challenge is the end-of-life management of polycarbonate products. While theoretically recyclable, the practical recycling of polycarbonate is often hindered by contamination issues and the presence of additives. The lack of efficient recycling infrastructure and processes leads to a significant portion of polycarbonate waste ending up in landfills or incineration facilities, contributing to environmental pollution and resource depletion.

The durability of polycarbonate, while advantageous in many applications, poses a paradox for sustainability. Its long-lasting nature means that products persist in the environment for extended periods when not properly managed at the end of their lifecycle. This persistence contributes to the accumulation of plastic waste in ecosystems, particularly in marine environments.

Additives used to enhance polycarbonate's properties, such as flame retardants and UV stabilizers, further complicate its sustainability profile. These additives can leach into the environment during use or disposal, potentially causing ecological harm. The presence of these chemicals also makes recycling more challenging and can limit the applications of recycled polycarbonate.

The global demand for more sustainable materials has put pressure on polycarbonate manufacturers to innovate. There is a growing need for bio-based alternatives to traditional petroleum-derived polycarbonate, as well as for improved recycling technologies. However, developing these alternatives while maintaining the desirable properties of polycarbonate remains a significant technical challenge.

Regulatory compliance presents another hurdle for polycarbonate sustainability. Evolving regulations around plastic use, recycling requirements, and chemical safety standards necessitate continuous adaptation in production processes and product formulations. Meeting these regulatory demands while maintaining cost-effectiveness and performance is a complex balancing act for manufacturers.

Existing Strategies for Enhancing Polycarbonate Sustainability

01 Life Cycle Assessment (LCA) for Polycarbonate

Life Cycle Assessment is used to evaluate the environmental impact of polycarbonate throughout its entire lifecycle, from raw material extraction to disposal. This comprehensive analysis helps in quantifying sustainability metrics such as carbon footprint, energy consumption, and resource depletion associated with polycarbonate production and use.- Life Cycle Assessment (LCA) for Polycarbonate: Life Cycle Assessment is used to evaluate the environmental impact of polycarbonate throughout its entire lifecycle, from raw material extraction to disposal. This comprehensive analysis helps in quantifying sustainability metrics such as carbon footprint, energy consumption, and resource depletion associated with polycarbonate production and use.

- Recycling and Circular Economy Metrics: Sustainability metrics for polycarbonate include recycling rates, recyclability, and circular economy indicators. These metrics assess the material's ability to be reused, recycled, or repurposed, reducing waste and promoting a more sustainable use of resources in polycarbonate production and consumption.

- Energy Efficiency and Emissions Reduction: Metrics related to energy efficiency in polycarbonate production processes and the reduction of greenhouse gas emissions are crucial sustainability indicators. These include measurements of energy consumption per unit of production, use of renewable energy sources, and quantification of emissions reductions achieved through process improvements.

- Biodegradability and Environmental Impact: Sustainability metrics for polycarbonate include assessments of its biodegradability and overall environmental impact. This involves measuring the material's decomposition rate in various environments, its potential for microplastic formation, and its effects on ecosystems when released into the environment.

- Sustainable Sourcing and Production: Metrics for sustainable sourcing and production of polycarbonate focus on the use of bio-based or recycled raw materials, water consumption in manufacturing processes, and the implementation of green chemistry principles. These indicators help in assessing the overall sustainability of polycarbonate from its inception to final product.

02 Recycling and Circular Economy Metrics

Sustainability metrics for polycarbonate include recycling rates, recyclability, and circular economy indicators. These metrics assess the material's ability to be reused, recycled, or repurposed, contributing to reduced waste and improved resource efficiency in the polycarbonate industry.Expand Specific Solutions03 Energy Efficiency and Emissions Reduction

Metrics focusing on energy consumption during polycarbonate production and processing, as well as associated greenhouse gas emissions, are crucial sustainability indicators. These metrics help in tracking improvements in manufacturing processes and identifying areas for reducing environmental impact.Expand Specific Solutions04 Bio-based and Sustainable Feedstock Usage

Sustainability metrics for polycarbonate include the percentage of bio-based or sustainably sourced raw materials used in production. This metric assesses the shift from fossil-based to renewable resources, contributing to reduced environmental impact and improved sustainability of polycarbonate materials.Expand Specific Solutions05 Durability and Longevity Metrics

Metrics related to the durability, lifespan, and performance of polycarbonate products are important sustainability indicators. These metrics assess the material's ability to withstand wear and tear, resist degradation, and maintain its properties over time, thereby reducing the need for frequent replacement and minimizing waste generation.Expand Specific Solutions

Key Players in Sustainable Polycarbonate Industry

The polycarbonate sustainability market is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The global market size is projected to expand significantly in the coming years, with major players like Covestro, SABIC, and LG Chem leading innovation efforts. Technologically, the industry is advancing rapidly, focusing on bio-based alternatives, recycling processes, and improved energy efficiency. Companies such as Mitsubishi Engineering-Plastics and Teijin are developing novel sustainable solutions, while Wanhua Chemical and Kingfa Sci. & Tech. are investing in research to enhance polycarbonate's eco-friendly properties. The competitive landscape is characterized by intense R&D activities and strategic partnerships to meet growing sustainability demands.

Covestro Deutschland AG

Technical Solution: Covestro has developed a groundbreaking approach to boost polycarbonate's sustainability metrics through their innovative mass balance concept. This method allows for the attribution of bio-based or recycled feedstock to selected products, reducing the carbon footprint of polycarbonate production[1]. They have also introduced partially bio-based polycarbonates, incorporating up to 71% bio-circular attributed content[2]. Additionally, Covestro has implemented a chemical recycling process for post-consumer polycarbonate waste, enabling the production of high-quality recycled materials that meet virgin material standards[3]. Their commitment to sustainability extends to energy-efficient manufacturing processes and the use of renewable energy in production facilities.

Strengths: Industry leader in sustainable polycarbonate solutions, innovative mass balance approach, high percentage of bio-based content. Weaknesses: Potential higher costs associated with bio-based and recycled materials, dependency on availability of sustainable feedstock.

SABIC Global Technologies BV

Technical Solution: SABIC has developed LEXAN polycarbonate resins with recycled content, significantly improving sustainability metrics. Their portfolio includes grades with up to 30% post-consumer recycled content[4]. SABIC's TRUCIRCLE portfolio offers certified circular polycarbonates produced using feedstock from difficult-to-recycle plastic waste[5]. They have also introduced bio-based polycarbonates, partially derived from renewable resources. SABIC's LNP ELCRIN iQ compounds, made from upcycled PET bottles, offer a lower carbon footprint compared to virgin polycarbonate resins[6]. The company has invested in advanced recycling technologies and collaborates with partners across the value chain to close the loop on plastic waste.

Strengths: Wide range of sustainable polycarbonate solutions, strong focus on circular economy, established recycling infrastructure. Weaknesses: Limited availability of high-quality recycled feedstock, potential variations in material properties compared to virgin resins.

Innovative Approaches to Polycarbonate Sustainability

Polycarbonate having high fluidity and production method therefor

PatentWO2015047046A1

Innovation

- Incorporating an aliphatic polyhydric alcohol-substituted diphenol compound into the polycarbonate backbone, specifically through a diphenol mixture with a bisphenol compound, to enhance fluidity while maintaining desirable physical properties like toughness and transparency.

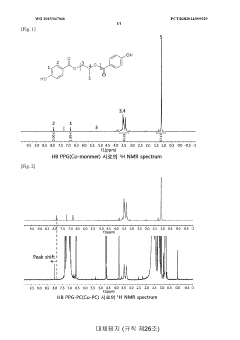

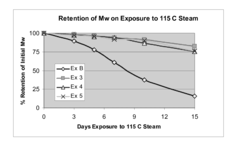

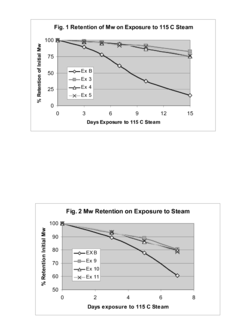

Thermoplastic polyestercarbonate composition

PatentInactiveUS20090186966A1

Innovation

- A thermoplastic composition comprising a polyestercarbonate copolymer with a specific ratio of carbonate and ester units, combined with a multifunctional epoxy compound, which enhances hydrolytic stability and retains molecular weight even under steam exposure, maintaining transparency and impact strength.

Life Cycle Assessment of Polycarbonate Products

Life Cycle Assessment (LCA) is a crucial tool for evaluating the environmental impact of polycarbonate products throughout their entire lifecycle. This comprehensive approach considers all stages, from raw material extraction to end-of-life disposal, providing valuable insights into the sustainability metrics of polycarbonate.

The LCA process for polycarbonate products typically begins with the extraction and processing of raw materials, primarily bisphenol A (BPA) and phosgene. This stage accounts for a significant portion of the product's environmental footprint, including energy consumption and greenhouse gas emissions. The manufacturing phase follows, where these raw materials are polymerized to form polycarbonate. This stage often involves high energy inputs and potential chemical emissions, which are carefully quantified in the assessment.

Distribution and transportation of polycarbonate products contribute to the overall environmental impact, primarily through fuel consumption and associated emissions. The use phase of polycarbonate products varies widely depending on the application, ranging from short-lived packaging to long-lasting automotive components. This diversity in product lifespan significantly influences the overall sustainability profile.

End-of-life scenarios for polycarbonate products are a critical aspect of the LCA. Options include recycling, incineration, and landfilling. Recycling offers the potential to reduce the environmental burden by displacing virgin material production. However, the effectiveness of recycling depends on factors such as collection rates, contamination levels, and the quality of the recycled material.

LCA studies on polycarbonate products have revealed several key findings. Firstly, the production phase typically dominates the environmental impact, highlighting the importance of efficient manufacturing processes and renewable energy sources. Secondly, the durability of polycarbonate in certain applications can offset initial production impacts through extended product lifespans. Lastly, end-of-life management, particularly effective recycling programs, can significantly improve the overall sustainability profile.

To boost polycarbonate's sustainability metrics, LCA results suggest focusing on several areas. Improving energy efficiency in production, increasing the use of recycled content, and enhancing end-of-life recycling infrastructure are primary targets. Additionally, designing products for easier disassembly and recycling can further improve sustainability outcomes. Innovations in bio-based alternatives for BPA and greener polymerization processes are also promising avenues for reducing environmental impact.

By conducting thorough Life Cycle Assessments, manufacturers and policymakers can make informed decisions to enhance the sustainability of polycarbonate products. These assessments provide a scientific basis for identifying hotspots in the lifecycle and guiding targeted improvements, ultimately contributing to more sustainable production and consumption patterns in the polycarbonate industry.

The LCA process for polycarbonate products typically begins with the extraction and processing of raw materials, primarily bisphenol A (BPA) and phosgene. This stage accounts for a significant portion of the product's environmental footprint, including energy consumption and greenhouse gas emissions. The manufacturing phase follows, where these raw materials are polymerized to form polycarbonate. This stage often involves high energy inputs and potential chemical emissions, which are carefully quantified in the assessment.

Distribution and transportation of polycarbonate products contribute to the overall environmental impact, primarily through fuel consumption and associated emissions. The use phase of polycarbonate products varies widely depending on the application, ranging from short-lived packaging to long-lasting automotive components. This diversity in product lifespan significantly influences the overall sustainability profile.

End-of-life scenarios for polycarbonate products are a critical aspect of the LCA. Options include recycling, incineration, and landfilling. Recycling offers the potential to reduce the environmental burden by displacing virgin material production. However, the effectiveness of recycling depends on factors such as collection rates, contamination levels, and the quality of the recycled material.

LCA studies on polycarbonate products have revealed several key findings. Firstly, the production phase typically dominates the environmental impact, highlighting the importance of efficient manufacturing processes and renewable energy sources. Secondly, the durability of polycarbonate in certain applications can offset initial production impacts through extended product lifespans. Lastly, end-of-life management, particularly effective recycling programs, can significantly improve the overall sustainability profile.

To boost polycarbonate's sustainability metrics, LCA results suggest focusing on several areas. Improving energy efficiency in production, increasing the use of recycled content, and enhancing end-of-life recycling infrastructure are primary targets. Additionally, designing products for easier disassembly and recycling can further improve sustainability outcomes. Innovations in bio-based alternatives for BPA and greener polymerization processes are also promising avenues for reducing environmental impact.

By conducting thorough Life Cycle Assessments, manufacturers and policymakers can make informed decisions to enhance the sustainability of polycarbonate products. These assessments provide a scientific basis for identifying hotspots in the lifecycle and guiding targeted improvements, ultimately contributing to more sustainable production and consumption patterns in the polycarbonate industry.

Regulatory Framework for Sustainable Plastics

The regulatory framework for sustainable plastics plays a crucial role in boosting polycarbonate's sustainability metrics. As governments and international organizations increasingly focus on environmental protection and circular economy principles, the plastics industry faces mounting pressure to adapt and innovate.

In the European Union, the Circular Economy Action Plan and the European Strategy for Plastics in a Circular Economy set ambitious targets for plastic recycling and reuse. These regulations aim to reduce single-use plastics, increase the recyclability of plastic products, and promote the use of recycled content in new products. For polycarbonate manufacturers, this translates into a need to develop more sustainable production processes and improve the recyclability of their products.

The United States has implemented various state-level regulations, such as California's Rigid Plastic Packaging Container (RPPC) program, which mandates minimum recycled content in certain plastic packaging. These regulations drive innovation in polycarbonate production and recycling technologies, encouraging manufacturers to invest in sustainable practices.

In Asia, countries like Japan and South Korea have introduced extended producer responsibility (EPR) systems for plastic waste management. These systems hold manufacturers accountable for the entire lifecycle of their products, including disposal and recycling. This regulatory approach incentivizes polycarbonate producers to design products with improved recyclability and to invest in recycling infrastructure.

Global initiatives, such as the Basel Convention's Plastic Waste Amendments, aim to reduce the transboundary movement of plastic waste and promote local recycling efforts. This has implications for the polycarbonate industry, as it necessitates the development of more efficient local recycling technologies and infrastructure.

The regulatory landscape also includes standards and certifications for sustainable plastics. For instance, the Global Recycled Standard (GRS) and the Recycled Claim Standard (RCS) provide frameworks for verifying recycled content in products. These standards help polycarbonate manufacturers demonstrate their commitment to sustainability and meet the growing demand for eco-friendly materials.

As regulations continue to evolve, the polycarbonate industry must stay proactive in adapting to new requirements. This includes investing in research and development to improve recycling technologies, exploring bio-based alternatives, and implementing more sustainable production processes. By aligning with regulatory frameworks, polycarbonate manufacturers can not only comply with legal requirements but also gain a competitive edge in an increasingly environmentally conscious market.

In the European Union, the Circular Economy Action Plan and the European Strategy for Plastics in a Circular Economy set ambitious targets for plastic recycling and reuse. These regulations aim to reduce single-use plastics, increase the recyclability of plastic products, and promote the use of recycled content in new products. For polycarbonate manufacturers, this translates into a need to develop more sustainable production processes and improve the recyclability of their products.

The United States has implemented various state-level regulations, such as California's Rigid Plastic Packaging Container (RPPC) program, which mandates minimum recycled content in certain plastic packaging. These regulations drive innovation in polycarbonate production and recycling technologies, encouraging manufacturers to invest in sustainable practices.

In Asia, countries like Japan and South Korea have introduced extended producer responsibility (EPR) systems for plastic waste management. These systems hold manufacturers accountable for the entire lifecycle of their products, including disposal and recycling. This regulatory approach incentivizes polycarbonate producers to design products with improved recyclability and to invest in recycling infrastructure.

Global initiatives, such as the Basel Convention's Plastic Waste Amendments, aim to reduce the transboundary movement of plastic waste and promote local recycling efforts. This has implications for the polycarbonate industry, as it necessitates the development of more efficient local recycling technologies and infrastructure.

The regulatory landscape also includes standards and certifications for sustainable plastics. For instance, the Global Recycled Standard (GRS) and the Recycled Claim Standard (RCS) provide frameworks for verifying recycled content in products. These standards help polycarbonate manufacturers demonstrate their commitment to sustainability and meet the growing demand for eco-friendly materials.

As regulations continue to evolve, the polycarbonate industry must stay proactive in adapting to new requirements. This includes investing in research and development to improve recycling technologies, exploring bio-based alternatives, and implementing more sustainable production processes. By aligning with regulatory frameworks, polycarbonate manufacturers can not only comply with legal requirements but also gain a competitive edge in an increasingly environmentally conscious market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!