How to Develop Propionic Acid Derivatives for Specialized Uses?

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propionic Acid Derivatives Background and Objectives

Propionic acid derivatives have emerged as a significant class of compounds with diverse applications across various industries. The development of these derivatives has been driven by the unique properties of propionic acid, a naturally occurring carboxylic acid with a wide range of biological and industrial uses. Over the past few decades, researchers and industry professionals have been exploring novel ways to modify and enhance the properties of propionic acid through derivatization, leading to a surge in specialized applications.

The evolution of propionic acid derivatives can be traced back to the early 20th century when scientists first began to investigate the potential of this simple organic compound. Initially, the focus was primarily on its preservative properties in food and feed industries. However, as our understanding of organic chemistry and biochemistry advanced, so did the potential applications of propionic acid derivatives.

In recent years, the development of propionic acid derivatives has gained momentum due to increasing demand for sustainable and eco-friendly solutions across various sectors. The versatility of these compounds has led to their adoption in pharmaceuticals, agrochemicals, cosmetics, and advanced materials. This growing interest has spurred research into novel synthesis methods and the exploration of structure-activity relationships to tailor derivatives for specific applications.

The primary objective in developing propionic acid derivatives for specialized uses is to enhance the inherent properties of propionic acid while introducing new functionalities. This involves modifying the carboxylic acid group or introducing additional functional groups to create compounds with improved stability, solubility, or reactivity. Researchers aim to develop derivatives that can address specific challenges in target industries, such as improving drug delivery systems, enhancing crop protection formulations, or creating more effective preservatives.

Another key goal is to optimize the production processes for these derivatives, focusing on green chemistry principles and sustainable manufacturing practices. This includes exploring bio-based production methods, utilizing renewable resources, and developing more efficient synthetic routes to reduce environmental impact and production costs.

As we look towards the future, the development of propionic acid derivatives is expected to continue evolving, driven by advancements in synthetic methodologies, computational chemistry, and a deeper understanding of structure-function relationships. The ongoing research in this field aims to unlock new applications and improve existing ones, potentially revolutionizing various industries and contributing to more sustainable and efficient solutions across multiple sectors.

The evolution of propionic acid derivatives can be traced back to the early 20th century when scientists first began to investigate the potential of this simple organic compound. Initially, the focus was primarily on its preservative properties in food and feed industries. However, as our understanding of organic chemistry and biochemistry advanced, so did the potential applications of propionic acid derivatives.

In recent years, the development of propionic acid derivatives has gained momentum due to increasing demand for sustainable and eco-friendly solutions across various sectors. The versatility of these compounds has led to their adoption in pharmaceuticals, agrochemicals, cosmetics, and advanced materials. This growing interest has spurred research into novel synthesis methods and the exploration of structure-activity relationships to tailor derivatives for specific applications.

The primary objective in developing propionic acid derivatives for specialized uses is to enhance the inherent properties of propionic acid while introducing new functionalities. This involves modifying the carboxylic acid group or introducing additional functional groups to create compounds with improved stability, solubility, or reactivity. Researchers aim to develop derivatives that can address specific challenges in target industries, such as improving drug delivery systems, enhancing crop protection formulations, or creating more effective preservatives.

Another key goal is to optimize the production processes for these derivatives, focusing on green chemistry principles and sustainable manufacturing practices. This includes exploring bio-based production methods, utilizing renewable resources, and developing more efficient synthetic routes to reduce environmental impact and production costs.

As we look towards the future, the development of propionic acid derivatives is expected to continue evolving, driven by advancements in synthetic methodologies, computational chemistry, and a deeper understanding of structure-function relationships. The ongoing research in this field aims to unlock new applications and improve existing ones, potentially revolutionizing various industries and contributing to more sustainable and efficient solutions across multiple sectors.

Market Analysis for Specialized Propionic Acid Derivatives

The market for specialized propionic acid derivatives is experiencing significant growth, driven by increasing demand across various industries. These derivatives find applications in pharmaceuticals, food preservation, herbicides, and personal care products, among others. The global market size for propionic acid derivatives was valued at approximately $1.2 billion in 2020 and is projected to reach $1.8 billion by 2025, growing at a CAGR of 8.5% during the forecast period.

In the pharmaceutical sector, propionic acid derivatives are utilized as active pharmaceutical ingredients (APIs) and excipients. The rising prevalence of chronic diseases and the growing aging population are fueling the demand for these compounds in drug formulations. Additionally, the increasing focus on preventive healthcare and personalized medicine is expected to create new opportunities for specialized propionic acid derivatives in this sector.

The food industry represents another significant market for propionic acid derivatives, particularly as preservatives. With the growing consumer preference for clean-label and natural food products, there is a rising demand for propionic acid-based preservatives as alternatives to synthetic options. This trend is particularly evident in bakery products, dairy, and processed meats, where these derivatives help extend shelf life and maintain product quality.

In agriculture, propionic acid derivatives are gaining traction as effective herbicides and plant growth regulators. The shift towards sustainable farming practices and the need for increased crop yields are driving the adoption of these compounds. The market is witnessing a surge in demand for environmentally friendly and biodegradable herbicides, presenting opportunities for innovative propionic acid-based solutions.

The personal care and cosmetics industry is another growing market for specialized propionic acid derivatives. These compounds are used in various products, including skin care formulations, hair care products, and fragrances. The increasing consumer focus on natural and organic personal care products is expected to boost the demand for propionic acid derivatives as preservatives and active ingredients in this sector.

Geographically, North America and Europe currently dominate the market for specialized propionic acid derivatives, owing to the presence of established pharmaceutical and food industries. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing disposable incomes, and growing awareness about health and wellness products.

In the pharmaceutical sector, propionic acid derivatives are utilized as active pharmaceutical ingredients (APIs) and excipients. The rising prevalence of chronic diseases and the growing aging population are fueling the demand for these compounds in drug formulations. Additionally, the increasing focus on preventive healthcare and personalized medicine is expected to create new opportunities for specialized propionic acid derivatives in this sector.

The food industry represents another significant market for propionic acid derivatives, particularly as preservatives. With the growing consumer preference for clean-label and natural food products, there is a rising demand for propionic acid-based preservatives as alternatives to synthetic options. This trend is particularly evident in bakery products, dairy, and processed meats, where these derivatives help extend shelf life and maintain product quality.

In agriculture, propionic acid derivatives are gaining traction as effective herbicides and plant growth regulators. The shift towards sustainable farming practices and the need for increased crop yields are driving the adoption of these compounds. The market is witnessing a surge in demand for environmentally friendly and biodegradable herbicides, presenting opportunities for innovative propionic acid-based solutions.

The personal care and cosmetics industry is another growing market for specialized propionic acid derivatives. These compounds are used in various products, including skin care formulations, hair care products, and fragrances. The increasing consumer focus on natural and organic personal care products is expected to boost the demand for propionic acid derivatives as preservatives and active ingredients in this sector.

Geographically, North America and Europe currently dominate the market for specialized propionic acid derivatives, owing to the presence of established pharmaceutical and food industries. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing disposable incomes, and growing awareness about health and wellness products.

Current Challenges in Propionic Acid Derivative Development

The development of propionic acid derivatives for specialized uses faces several significant challenges that researchers and industry professionals must address. One of the primary obstacles is the complexity of synthesizing novel derivatives with desired properties while maintaining cost-effectiveness and scalability. The intricate molecular structures of these compounds often require multi-step synthesis processes, which can be time-consuming and resource-intensive.

Another major challenge lies in the optimization of reaction conditions to achieve high yields and purity. Propionic acid derivatives are sensitive to various factors such as temperature, pressure, and catalyst selection, making it difficult to establish consistent and reproducible manufacturing processes. This variability can lead to inconsistent product quality and increased production costs.

The environmental impact of producing propionic acid derivatives is also a growing concern. Traditional synthesis methods often involve the use of hazardous solvents and generate significant waste. Developing greener, more sustainable production techniques that align with increasingly stringent environmental regulations is a pressing challenge for the industry.

Ensuring the stability and shelf-life of propionic acid derivatives, particularly for specialized applications, presents another hurdle. These compounds can be prone to degradation under certain conditions, which may limit their effectiveness in end-use products. Researchers must develop innovative formulation strategies and packaging solutions to maintain the integrity of these derivatives throughout their lifecycle.

The regulatory landscape poses additional challenges, especially when developing derivatives for use in sensitive applications such as food preservation or pharmaceuticals. Navigating the complex approval processes and meeting stringent safety standards require extensive testing and documentation, which can significantly extend development timelines and increase costs.

Furthermore, the identification of new, high-value applications for propionic acid derivatives remains an ongoing challenge. While these compounds have shown promise in various fields, unlocking their full potential requires continuous exploration of novel uses and markets. This necessitates close collaboration between researchers, industry partners, and end-users to align development efforts with market needs.

Lastly, the competitive nature of the specialty chemicals market demands continuous innovation to maintain a technological edge. Researchers must constantly push the boundaries of molecular design and synthesis techniques to create derivatives with superior properties that can outperform existing solutions. This relentless pursuit of innovation puts pressure on R&D teams to deliver breakthroughs while managing resource constraints and market uncertainties.

Another major challenge lies in the optimization of reaction conditions to achieve high yields and purity. Propionic acid derivatives are sensitive to various factors such as temperature, pressure, and catalyst selection, making it difficult to establish consistent and reproducible manufacturing processes. This variability can lead to inconsistent product quality and increased production costs.

The environmental impact of producing propionic acid derivatives is also a growing concern. Traditional synthesis methods often involve the use of hazardous solvents and generate significant waste. Developing greener, more sustainable production techniques that align with increasingly stringent environmental regulations is a pressing challenge for the industry.

Ensuring the stability and shelf-life of propionic acid derivatives, particularly for specialized applications, presents another hurdle. These compounds can be prone to degradation under certain conditions, which may limit their effectiveness in end-use products. Researchers must develop innovative formulation strategies and packaging solutions to maintain the integrity of these derivatives throughout their lifecycle.

The regulatory landscape poses additional challenges, especially when developing derivatives for use in sensitive applications such as food preservation or pharmaceuticals. Navigating the complex approval processes and meeting stringent safety standards require extensive testing and documentation, which can significantly extend development timelines and increase costs.

Furthermore, the identification of new, high-value applications for propionic acid derivatives remains an ongoing challenge. While these compounds have shown promise in various fields, unlocking their full potential requires continuous exploration of novel uses and markets. This necessitates close collaboration between researchers, industry partners, and end-users to align development efforts with market needs.

Lastly, the competitive nature of the specialty chemicals market demands continuous innovation to maintain a technological edge. Researchers must constantly push the boundaries of molecular design and synthesis techniques to create derivatives with superior properties that can outperform existing solutions. This relentless pursuit of innovation puts pressure on R&D teams to deliver breakthroughs while managing resource constraints and market uncertainties.

Existing Synthesis Methods for Specialized Derivatives

01 Synthesis of propionic acid derivatives

Various methods for synthesizing propionic acid derivatives are described. These methods may involve different reaction conditions, catalysts, and starting materials to produce a range of propionic acid-based compounds with diverse applications in pharmaceuticals, agriculture, and industry.- Synthesis of propionic acid derivatives: Various methods for synthesizing propionic acid derivatives are described. These processes may involve different starting materials, reaction conditions, and catalysts to produce a range of propionic acid-based compounds with diverse applications in pharmaceuticals, agriculture, and industry.

- Pharmaceutical applications of propionic acid derivatives: Propionic acid derivatives are utilized in pharmaceutical formulations for their therapeutic properties. These compounds may exhibit anti-inflammatory, analgesic, or other medicinal effects, making them valuable ingredients in various drug products.

- Agricultural uses of propionic acid derivatives: In agriculture, propionic acid derivatives find applications as herbicides, fungicides, or plant growth regulators. These compounds may be formulated into various agricultural products to enhance crop protection and yield.

- Industrial applications of propionic acid derivatives: Propionic acid derivatives are used in various industrial processes, including as intermediates in chemical synthesis, additives in polymers, or components in specialty chemicals. Their unique properties make them valuable in diverse manufacturing sectors.

- Biotechnological production of propionic acid derivatives: Biotechnological methods for producing propionic acid derivatives are explored, utilizing microorganisms or enzymatic processes. These approaches may offer more sustainable and environmentally friendly alternatives to traditional chemical synthesis methods.

02 Pharmaceutical applications of propionic acid derivatives

Propionic acid derivatives are utilized in pharmaceutical formulations for their therapeutic properties. These compounds may exhibit anti-inflammatory, analgesic, or other medicinal effects, making them valuable ingredients in various drug formulations.Expand Specific Solutions03 Agricultural uses of propionic acid derivatives

In agriculture, propionic acid derivatives find applications as herbicides, fungicides, or plant growth regulators. These compounds may be formulated into various agricultural products to enhance crop protection and yield.Expand Specific Solutions04 Industrial applications of propionic acid derivatives

Propionic acid derivatives are used in various industrial processes, including as intermediates in chemical synthesis, additives in polymers, or components in specialty chemicals. Their unique properties make them valuable in diverse manufacturing applications.Expand Specific Solutions05 Biotechnological production of propionic acid derivatives

Biotechnological methods for producing propionic acid derivatives are explored, utilizing microorganisms or enzymatic processes. These approaches may offer more sustainable and environmentally friendly alternatives to traditional chemical synthesis methods.Expand Specific Solutions

Key Players in Propionic Acid Derivative Industry

The development of propionic acid derivatives for specialized uses is in a growth phase, with increasing market demand driven by diverse applications across industries. The global market size for these derivatives is expanding, particularly in sectors like pharmaceuticals, food additives, and specialty chemicals. Technologically, the field is advancing rapidly, with companies like LG Chem, Dow Global Technologies, and BASF leading innovation. These firms are investing heavily in R&D to enhance product efficiency and explore novel applications. Emerging players such as Novomer are introducing sustainable production methods, indicating a shift towards eco-friendly processes. The involvement of research institutions like Korea Research Institute of Chemical Technology and University of Queensland suggests ongoing efforts to improve synthesis techniques and expand the range of specialized applications.

LG Chem Ltd.

Technical Solution: LG Chem has made significant strides in developing propionic acid derivatives for specialized uses, particularly in the field of high-performance polymers and electronic materials. Their approach involves the synthesis of propionic acid-based monomers that can be polymerized to form advanced materials with unique properties[7]. LG Chem has developed a range of propionic acid derivatives that serve as key components in the production of flexible displays, high-capacity batteries, and lightweight automotive parts. Their process utilizes green chemistry principles, incorporating catalysts that enable reactions under milder conditions and reduce the use of harmful solvents[8]. Additionally, LG Chem has invested in biotechnology to produce bio-based propionic acid, which serves as a sustainable feedstock for their derivative production[9].

Strengths: Focus on high-value applications in electronics and automotive industries, integration of green chemistry principles. Weaknesses: Potentially higher production costs for specialized derivatives and reliance on complex synthesis routes.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has developed a novel approach to propionic acid derivatives, focusing on high-performance materials for industrial applications. Their technology involves a proprietary catalytic process that allows for the direct conversion of propylene to propionic acid derivatives with high selectivity[4]. This process reduces the number of steps in traditional production methods, leading to improved energy efficiency and reduced carbon footprint. Dow has also developed specialized formulations of propionic acid derivatives for use in coatings, adhesives, and sealants, offering enhanced durability and chemical resistance[5]. Their research extends to the development of bio-based propionic acid derivatives, aligning with the growing demand for sustainable chemical solutions[6].

Strengths: Efficient production process, specialized formulations for industrial applications, and focus on sustainability. Weaknesses: Potential limitations in scaling up the novel catalytic process and dependency on propylene availability.

Innovative Approaches in Propionic Acid Modification

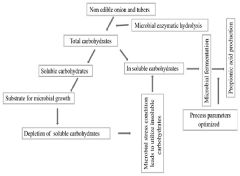

Method for production of propionic acid from inulins

PatentPendingIN202141042851A

Innovation

- A single-step process optimizing enzymatic hydrolysis of inulin from onion waste and non-edible tubers to convert insoluble carbohydrates into fermentable sugars, followed by microbial fermentation to produce propionic acid, addressing issues like bi-product formation and downstream processing through optimized microbial growth conditions and stress parameters.

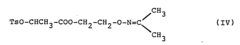

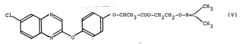

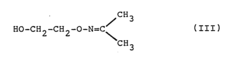

Process for the preparation of propionic-acid derivatives

PatentInactiveEP0276741A2

Innovation

- A process involving the reaction of alkyl 2-[(p-tolylsulfonyl) oxy] propionate with isopropylideneaminooxyethanol using titanium or zirconium catalysts, followed by conversion to 2-[(isopropylideneamino) oxy] ethyl 2- [p- [(6-chloro-2-quinoxalinyl) oxy] phenoxy] propionate, utilizing specific catalysts and solvents, and optimizing reaction conditions to achieve high yields and enantiomeric purity.

Environmental Impact of Propionic Acid Derivative Production

The production of propionic acid derivatives for specialized uses carries significant environmental implications that must be carefully considered. The manufacturing process often involves the use of petrochemical feedstocks and energy-intensive reactions, which can contribute to greenhouse gas emissions and air pollution. Additionally, the synthesis of these compounds may generate hazardous waste streams that require proper treatment and disposal to prevent soil and water contamination.

One of the primary environmental concerns is the potential for accidental releases during production, storage, or transportation. Propionic acid and its derivatives can be corrosive and harmful to aquatic ecosystems if spilled into water bodies. To mitigate these risks, stringent safety protocols and containment measures are essential throughout the supply chain.

The energy consumption associated with the production of propionic acid derivatives is another critical environmental factor. The use of fossil fuels in the manufacturing process contributes to carbon dioxide emissions, exacerbating climate change concerns. However, there is a growing trend towards the adoption of renewable energy sources and more efficient production technologies to reduce the carbon footprint of these operations.

Water usage and wastewater management are also significant environmental considerations. The production processes often require substantial amounts of water for cooling and cleaning, potentially straining local water resources. Proper wastewater treatment is crucial to remove organic contaminants and ensure that effluents meet regulatory standards before discharge.

In recent years, there has been an increased focus on developing more sustainable production methods for propionic acid derivatives. This includes exploring bio-based feedstocks as alternatives to petrochemical sources, which could potentially reduce the overall environmental impact. Additionally, the implementation of green chemistry principles, such as atom economy and the use of less hazardous reagents, is gaining traction in the industry.

The environmental impact of packaging and transportation of propionic acid derivatives should not be overlooked. The use of recyclable or biodegradable packaging materials and optimizing logistics to reduce transportation distances can help minimize the overall environmental footprint of these products.

As regulations become more stringent, manufacturers are increasingly adopting life cycle assessment (LCA) approaches to evaluate and improve the environmental performance of their production processes. This holistic view allows for the identification of hotspots in the production chain where environmental impacts can be most effectively reduced.

One of the primary environmental concerns is the potential for accidental releases during production, storage, or transportation. Propionic acid and its derivatives can be corrosive and harmful to aquatic ecosystems if spilled into water bodies. To mitigate these risks, stringent safety protocols and containment measures are essential throughout the supply chain.

The energy consumption associated with the production of propionic acid derivatives is another critical environmental factor. The use of fossil fuels in the manufacturing process contributes to carbon dioxide emissions, exacerbating climate change concerns. However, there is a growing trend towards the adoption of renewable energy sources and more efficient production technologies to reduce the carbon footprint of these operations.

Water usage and wastewater management are also significant environmental considerations. The production processes often require substantial amounts of water for cooling and cleaning, potentially straining local water resources. Proper wastewater treatment is crucial to remove organic contaminants and ensure that effluents meet regulatory standards before discharge.

In recent years, there has been an increased focus on developing more sustainable production methods for propionic acid derivatives. This includes exploring bio-based feedstocks as alternatives to petrochemical sources, which could potentially reduce the overall environmental impact. Additionally, the implementation of green chemistry principles, such as atom economy and the use of less hazardous reagents, is gaining traction in the industry.

The environmental impact of packaging and transportation of propionic acid derivatives should not be overlooked. The use of recyclable or biodegradable packaging materials and optimizing logistics to reduce transportation distances can help minimize the overall environmental footprint of these products.

As regulations become more stringent, manufacturers are increasingly adopting life cycle assessment (LCA) approaches to evaluate and improve the environmental performance of their production processes. This holistic view allows for the identification of hotspots in the production chain where environmental impacts can be most effectively reduced.

Regulatory Framework for Specialized Chemical Development

The regulatory framework for specialized chemical development, particularly in the context of propionic acid derivatives, is a complex and evolving landscape that significantly impacts the research, production, and commercialization processes. At the global level, organizations such as the International Council of Chemical Associations (ICCA) provide overarching guidelines for the safe management of chemicals throughout their lifecycle.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating the development and use of specialized chemicals under the Toxic Substances Control Act (TSCA). The TSCA requires manufacturers to submit premanufacture notices (PMNs) for new chemical substances, including propionic acid derivatives, before they can be produced or imported for commercial purposes. This process involves rigorous safety assessments and may result in restrictions or additional testing requirements.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation imposes stringent requirements on chemical manufacturers and importers. Under REACH, companies must register substances produced or imported in quantities of one tonne or more per year with the European Chemicals Agency (ECHA). For propionic acid derivatives intended for specialized uses, this often involves extensive documentation of their properties, potential risks, and safe use guidelines.

In Asia, countries like China and Japan have their own regulatory frameworks. China's Measures for Environmental Management of New Chemical Substances (MEP Order 7) requires notification and registration of new chemical substances before their production or import. Japan's Chemical Substances Control Law (CSCL) similarly mandates evaluation and registration of new chemical substances.

For pharmaceutical applications of propionic acid derivatives, additional regulatory considerations come into play. The U.S. Food and Drug Administration (FDA), the European Medicines Agency (EMA), and other national health authorities have specific requirements for drug development, including Good Manufacturing Practices (GMP) and extensive clinical trials to demonstrate safety and efficacy.

When developing propionic acid derivatives for food-related applications, such as preservatives, regulations become even more stringent. The FDA's Food Additive Regulations and the EU's Food Additives Regulation (EC) No 1333/2008 govern the approval and use of such substances in food products. These regulations often require extensive toxicological studies and safety assessments before a new derivative can be approved for use in food.

Environmental regulations also play a significant role in the development of specialized chemicals. Many countries have implemented policies to promote green chemistry and sustainable development. This has led to increased scrutiny of production processes and waste management practices, encouraging the development of more environmentally friendly synthesis routes for propionic acid derivatives.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating the development and use of specialized chemicals under the Toxic Substances Control Act (TSCA). The TSCA requires manufacturers to submit premanufacture notices (PMNs) for new chemical substances, including propionic acid derivatives, before they can be produced or imported for commercial purposes. This process involves rigorous safety assessments and may result in restrictions or additional testing requirements.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation imposes stringent requirements on chemical manufacturers and importers. Under REACH, companies must register substances produced or imported in quantities of one tonne or more per year with the European Chemicals Agency (ECHA). For propionic acid derivatives intended for specialized uses, this often involves extensive documentation of their properties, potential risks, and safe use guidelines.

In Asia, countries like China and Japan have their own regulatory frameworks. China's Measures for Environmental Management of New Chemical Substances (MEP Order 7) requires notification and registration of new chemical substances before their production or import. Japan's Chemical Substances Control Law (CSCL) similarly mandates evaluation and registration of new chemical substances.

For pharmaceutical applications of propionic acid derivatives, additional regulatory considerations come into play. The U.S. Food and Drug Administration (FDA), the European Medicines Agency (EMA), and other national health authorities have specific requirements for drug development, including Good Manufacturing Practices (GMP) and extensive clinical trials to demonstrate safety and efficacy.

When developing propionic acid derivatives for food-related applications, such as preservatives, regulations become even more stringent. The FDA's Food Additive Regulations and the EU's Food Additives Regulation (EC) No 1333/2008 govern the approval and use of such substances in food products. These regulations often require extensive toxicological studies and safety assessments before a new derivative can be approved for use in food.

Environmental regulations also play a significant role in the development of specialized chemicals. Many countries have implemented policies to promote green chemistry and sustainable development. This has led to increased scrutiny of production processes and waste management practices, encouraging the development of more environmentally friendly synthesis routes for propionic acid derivatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!