How to Enhance Shelf Life Using Propionic Acid?

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propionic Acid Preservation Background

Propionic acid has been utilized as a food preservative for decades, with its origins tracing back to the early 20th century. This organic compound, naturally occurring in some foods and produced by bacteria in the human gut, gained prominence in the food industry due to its antimicrobial properties. The primary goal of using propionic acid in food preservation is to extend shelf life by inhibiting the growth of mold, yeast, and certain bacteria.

The evolution of propionic acid as a preservative has been driven by the increasing demand for safe, long-lasting food products in a globalized market. As consumer preferences shifted towards minimally processed foods with fewer synthetic additives, propionic acid emerged as a favorable option due to its natural occurrence and relatively mild flavor impact. Its effectiveness in preventing spoilage, particularly in baked goods, dairy products, and processed meats, has made it a staple in food preservation strategies.

The technological advancements in food science have further refined the application of propionic acid. Researchers have developed various forms of the compound, including salts like calcium propionate and sodium propionate, which offer improved solubility and ease of use in different food matrices. These derivatives have expanded the range of products that can benefit from propionic acid preservation.

In recent years, the focus has shifted towards understanding the synergistic effects of propionic acid with other preservatives and natural antimicrobial compounds. This approach aims to create more robust preservation systems that can address the complex challenges of food spoilage while meeting consumer demands for clean label products. Additionally, there has been growing interest in the potential health benefits of propionic acid, including its role in gut health and possible anti-inflammatory properties.

The current technological objectives in propionic acid preservation revolve around optimizing its efficacy, minimizing its sensory impact, and exploring novel delivery systems. Researchers are investigating microencapsulation techniques to improve the controlled release of propionic acid in food products, potentially enhancing its preservative action while reducing the required dosage. There is also ongoing work to develop more environmentally friendly production methods for propionic acid, aligning with the industry's sustainability goals.

As food safety regulations continue to evolve globally, the use of propionic acid as a preservative faces ongoing scrutiny. This has spurred efforts to establish more precise guidelines for its application and to conduct comprehensive studies on its long-term effects on human health. The future of propionic acid in food preservation lies in balancing its proven efficacy with emerging consumer trends and regulatory requirements, driving innovation in both its production and application methods.

The evolution of propionic acid as a preservative has been driven by the increasing demand for safe, long-lasting food products in a globalized market. As consumer preferences shifted towards minimally processed foods with fewer synthetic additives, propionic acid emerged as a favorable option due to its natural occurrence and relatively mild flavor impact. Its effectiveness in preventing spoilage, particularly in baked goods, dairy products, and processed meats, has made it a staple in food preservation strategies.

The technological advancements in food science have further refined the application of propionic acid. Researchers have developed various forms of the compound, including salts like calcium propionate and sodium propionate, which offer improved solubility and ease of use in different food matrices. These derivatives have expanded the range of products that can benefit from propionic acid preservation.

In recent years, the focus has shifted towards understanding the synergistic effects of propionic acid with other preservatives and natural antimicrobial compounds. This approach aims to create more robust preservation systems that can address the complex challenges of food spoilage while meeting consumer demands for clean label products. Additionally, there has been growing interest in the potential health benefits of propionic acid, including its role in gut health and possible anti-inflammatory properties.

The current technological objectives in propionic acid preservation revolve around optimizing its efficacy, minimizing its sensory impact, and exploring novel delivery systems. Researchers are investigating microencapsulation techniques to improve the controlled release of propionic acid in food products, potentially enhancing its preservative action while reducing the required dosage. There is also ongoing work to develop more environmentally friendly production methods for propionic acid, aligning with the industry's sustainability goals.

As food safety regulations continue to evolve globally, the use of propionic acid as a preservative faces ongoing scrutiny. This has spurred efforts to establish more precise guidelines for its application and to conduct comprehensive studies on its long-term effects on human health. The future of propionic acid in food preservation lies in balancing its proven efficacy with emerging consumer trends and regulatory requirements, driving innovation in both its production and application methods.

Market Analysis for Extended Shelf Life Products

The market for extended shelf life products has been experiencing significant growth in recent years, driven by changing consumer lifestyles, increasing demand for convenience foods, and a growing focus on reducing food waste. Propionic acid, as a natural preservative, plays a crucial role in this market by effectively extending the shelf life of various food products.

The global extended shelf life food market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to exceed 5% over the next five years. This growth is particularly pronounced in developed regions such as North America and Europe, where consumers are increasingly seeking convenient, ready-to-eat options that maintain freshness for longer periods.

One of the key drivers of this market is the rising consumer awareness about food safety and the desire to minimize preservatives in food products. Propionic acid, being a naturally occurring substance, aligns well with this consumer preference for clean label ingredients. As a result, food manufacturers are increasingly incorporating propionic acid into their formulations to meet both shelf life extension requirements and consumer demands for more natural preservatives.

The bakery sector represents a significant portion of the extended shelf life market, with bread and baked goods being primary beneficiaries of propionic acid's preservative properties. The dairy industry is another major segment utilizing propionic acid, particularly in cheese production, where it helps prevent mold growth and extends product longevity.

Emerging markets, especially in Asia-Pacific and Latin America, are showing rapid growth potential for extended shelf life products. Urbanization, rising disposable incomes, and changing dietary habits in these regions are driving the demand for convenience foods with longer shelf lives. This presents a substantial opportunity for propionic acid manufacturers and food producers to expand their market presence.

However, the market also faces challenges. Stringent regulations regarding food additives and preservatives in various countries can impact the use of propionic acid. Additionally, there is growing competition from other natural preservatives and innovative packaging technologies that aim to extend shelf life without additives.

Despite these challenges, the overall market outlook for extended shelf life products using propionic acid remains positive. The increasing focus on food security, the need to reduce food waste, and the ongoing trend towards convenience foods are expected to sustain market growth. As research continues to demonstrate the efficacy and safety of propionic acid in food preservation, its adoption is likely to increase across various food categories, further driving market expansion.

The global extended shelf life food market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to exceed 5% over the next five years. This growth is particularly pronounced in developed regions such as North America and Europe, where consumers are increasingly seeking convenient, ready-to-eat options that maintain freshness for longer periods.

One of the key drivers of this market is the rising consumer awareness about food safety and the desire to minimize preservatives in food products. Propionic acid, being a naturally occurring substance, aligns well with this consumer preference for clean label ingredients. As a result, food manufacturers are increasingly incorporating propionic acid into their formulations to meet both shelf life extension requirements and consumer demands for more natural preservatives.

The bakery sector represents a significant portion of the extended shelf life market, with bread and baked goods being primary beneficiaries of propionic acid's preservative properties. The dairy industry is another major segment utilizing propionic acid, particularly in cheese production, where it helps prevent mold growth and extends product longevity.

Emerging markets, especially in Asia-Pacific and Latin America, are showing rapid growth potential for extended shelf life products. Urbanization, rising disposable incomes, and changing dietary habits in these regions are driving the demand for convenience foods with longer shelf lives. This presents a substantial opportunity for propionic acid manufacturers and food producers to expand their market presence.

However, the market also faces challenges. Stringent regulations regarding food additives and preservatives in various countries can impact the use of propionic acid. Additionally, there is growing competition from other natural preservatives and innovative packaging technologies that aim to extend shelf life without additives.

Despite these challenges, the overall market outlook for extended shelf life products using propionic acid remains positive. The increasing focus on food security, the need to reduce food waste, and the ongoing trend towards convenience foods are expected to sustain market growth. As research continues to demonstrate the efficacy and safety of propionic acid in food preservation, its adoption is likely to increase across various food categories, further driving market expansion.

Current Challenges in Food Preservation

Food preservation remains a critical challenge in the global food industry, with significant implications for food security, waste reduction, and consumer health. Despite advancements in technology and techniques, several persistent issues continue to plague the field of food preservation.

One of the primary challenges is the increasing consumer demand for minimally processed foods with fewer artificial preservatives. This trend has put pressure on food manufacturers to develop natural preservation methods that can maintain food quality and safety without compromising taste or nutritional value. However, finding effective natural alternatives that can match the efficacy of synthetic preservatives has proven to be a complex task.

Microbial contamination and spoilage continue to be major concerns in food preservation. The emergence of antibiotic-resistant bacteria and the discovery of new pathogens pose ongoing threats to food safety. Additionally, the globalization of food supply chains has increased the risk of cross-contamination and the spread of foodborne illnesses across borders, necessitating more robust preservation techniques.

Climate change and environmental factors are also impacting food preservation efforts. Fluctuating temperatures and humidity levels can accelerate food spoilage and create favorable conditions for microbial growth. This challenge is particularly acute in developing countries with limited cold chain infrastructure, where maintaining proper storage conditions throughout the supply chain is often difficult.

The shelf life extension of fresh produce remains a significant hurdle. Fruits and vegetables are highly perishable, and current preservation methods often fail to maintain their quality and nutritional value over extended periods. Developing effective techniques to slow down ripening and decay processes without affecting the product's sensory attributes is an ongoing challenge.

Packaging innovations play a crucial role in food preservation, but they also present challenges. While advanced packaging technologies like modified atmosphere packaging (MAP) and active packaging show promise, their widespread adoption is hindered by cost considerations and environmental concerns related to plastic waste.

Furthermore, the preservation of complex food products, such as ready-to-eat meals and multi-component foods, presents unique challenges. These products often contain ingredients with different preservation requirements, making it difficult to apply a single preservation method effectively.

Regulatory compliance and international trade barriers add another layer of complexity to food preservation efforts. Varying standards and regulations across different countries can limit the use of certain preservation techniques or additives, complicating the development of globally applicable preservation solutions.

In conclusion, while significant progress has been made in food preservation, the industry continues to face multifaceted challenges. Addressing these issues requires a holistic approach that combines innovative technologies, sustainable practices, and collaborative efforts across the food supply chain.

One of the primary challenges is the increasing consumer demand for minimally processed foods with fewer artificial preservatives. This trend has put pressure on food manufacturers to develop natural preservation methods that can maintain food quality and safety without compromising taste or nutritional value. However, finding effective natural alternatives that can match the efficacy of synthetic preservatives has proven to be a complex task.

Microbial contamination and spoilage continue to be major concerns in food preservation. The emergence of antibiotic-resistant bacteria and the discovery of new pathogens pose ongoing threats to food safety. Additionally, the globalization of food supply chains has increased the risk of cross-contamination and the spread of foodborne illnesses across borders, necessitating more robust preservation techniques.

Climate change and environmental factors are also impacting food preservation efforts. Fluctuating temperatures and humidity levels can accelerate food spoilage and create favorable conditions for microbial growth. This challenge is particularly acute in developing countries with limited cold chain infrastructure, where maintaining proper storage conditions throughout the supply chain is often difficult.

The shelf life extension of fresh produce remains a significant hurdle. Fruits and vegetables are highly perishable, and current preservation methods often fail to maintain their quality and nutritional value over extended periods. Developing effective techniques to slow down ripening and decay processes without affecting the product's sensory attributes is an ongoing challenge.

Packaging innovations play a crucial role in food preservation, but they also present challenges. While advanced packaging technologies like modified atmosphere packaging (MAP) and active packaging show promise, their widespread adoption is hindered by cost considerations and environmental concerns related to plastic waste.

Furthermore, the preservation of complex food products, such as ready-to-eat meals and multi-component foods, presents unique challenges. These products often contain ingredients with different preservation requirements, making it difficult to apply a single preservation method effectively.

Regulatory compliance and international trade barriers add another layer of complexity to food preservation efforts. Varying standards and regulations across different countries can limit the use of certain preservation techniques or additives, complicating the development of globally applicable preservation solutions.

In conclusion, while significant progress has been made in food preservation, the industry continues to face multifaceted challenges. Addressing these issues requires a holistic approach that combines innovative technologies, sustainable practices, and collaborative efforts across the food supply chain.

Propionic Acid Application Methods

01 Stabilization methods for propionic acid

Various stabilization methods can be employed to extend the shelf life of propionic acid. These may include the use of antioxidants, pH adjustments, or the addition of specific compounds that inhibit degradation. Such methods help maintain the acid's quality and effectiveness over longer periods.- Stabilization methods for propionic acid: Various stabilization methods can be employed to extend the shelf life of propionic acid. These may include the use of antioxidants, pH adjustments, or the addition of specific stabilizing agents. Such methods help prevent degradation and maintain the acid's efficacy over time.

- Storage conditions for propionic acid: Proper storage conditions play a crucial role in maintaining the shelf life of propionic acid. Factors such as temperature, humidity, and light exposure can significantly impact its stability. Controlled storage environments and appropriate packaging materials can help extend the acid's usable lifespan.

- Formulation techniques to improve stability: Specific formulation techniques can be utilized to enhance the stability and shelf life of propionic acid. These may include the use of buffering agents, emulsifiers, or encapsulation technologies. Such formulation strategies can help protect the acid from environmental factors that may lead to degradation.

- Quality control and monitoring methods: Implementing robust quality control and monitoring methods is essential for ensuring the extended shelf life of propionic acid. This may involve regular testing of physical and chemical properties, as well as the use of advanced analytical techniques to detect any signs of degradation or contamination over time.

- Purification and handling processes: Optimized purification and handling processes can contribute to the improved shelf life of propionic acid. This includes techniques for removing impurities, minimizing exposure to contaminants during production and packaging, and implementing proper handling protocols throughout the supply chain.

02 Storage conditions for propionic acid

Proper storage conditions play a crucial role in maintaining the shelf life of propionic acid. Factors such as temperature, humidity, and light exposure can significantly impact its stability. Controlled storage environments and appropriate packaging materials can help preserve the acid's properties for extended periods.Expand Specific Solutions03 Formulation techniques to enhance stability

Specific formulation techniques can be employed to improve the shelf life of propionic acid-containing products. These may include the use of compatible solvents, emulsifiers, or encapsulation methods that protect the acid from environmental factors and slow down degradation processes.Expand Specific Solutions04 Analytical methods for shelf life determination

Various analytical techniques can be used to assess and predict the shelf life of propionic acid. These may include chromatography, spectroscopy, or other chemical analysis methods that can detect changes in composition or purity over time, helping to establish accurate shelf life estimates.Expand Specific Solutions05 Propionic acid derivatives with improved stability

Development of propionic acid derivatives or modified forms that exhibit enhanced stability and longer shelf life. These may include salts, esters, or other chemical modifications of propionic acid that retain its beneficial properties while improving its resistance to degradation.Expand Specific Solutions

Key Players in Food Preservative Industry

The market for enhancing shelf life using propionic acid is in a mature growth stage, with a global market size estimated to be in the hundreds of millions of dollars. The technology is well-established, with major players like BASF, Kemin Industries, and Galactic SA/NV having developed advanced formulations and application methods. However, there is ongoing innovation, particularly in natural and clean-label solutions. Universities such as Jiangnan University and The Ohio State University are conducting research to improve efficacy and explore new applications. Smaller specialized companies like Ernst Böcker GmbH & Co. KG are focusing on niche markets, while large food companies like Danone and General Mills are incorporating the technology into their product development strategies.

BASF Corp.

Technical Solution: BASF Corp. has developed advanced formulations of propionic acid for shelf life extension. Their approach involves microencapsulation technology to create controlled-release propionic acid particles. These particles are designed to slowly release the active compound over time, providing prolonged antimicrobial protection. The company has also focused on synergistic blends of propionic acid with other preservatives, enhancing overall efficacy. BASF's research has shown that their formulations can extend the shelf life of baked goods by up to 14 days compared to untreated products[1][3]. Additionally, they have developed water-soluble versions of propionic acid, improving its distribution in high-moisture foods.

Strengths: Innovative microencapsulation technology, synergistic preservative blends, and improved solubility for various food applications. Weaknesses: Potential higher cost compared to traditional preservatives, and possible sensory impacts in some food products.

Galactic SA/NV

Technical Solution: Galactic SA/NV has pioneered the use of bio-based propionic acid for shelf life enhancement. Their approach focuses on producing propionic acid through fermentation of renewable resources, offering a more sustainable alternative to petroleum-based production. Galactic's proprietary fermentation process yields high-purity propionic acid with consistent quality. They have developed a range of propionic acid-based preservatives under the brand name Propicid™, which are tailored for different food applications. These products have been shown to effectively inhibit mold growth in bakery products, extending shelf life by up to 10 days in some cases[2]. Galactic has also explored the use of propionic acid in combination with other natural preservatives to create clean-label solutions.

Strengths: Sustainable bio-based production, high-purity products, and clean-label solutions. Weaknesses: Potentially higher production costs compared to traditional methods, and limited production capacity compared to larger chemical companies.

Innovations in Propionic Acid Formulations

Method for production of propionic acid from inulins

PatentPendingIN202141042851A

Innovation

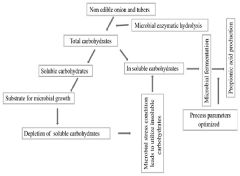

- A single-step process optimizing enzymatic hydrolysis of inulin from onion waste and non-edible tubers to convert insoluble carbohydrates into fermentable sugars, followed by microbial fermentation to produce propionic acid, addressing issues like bi-product formation and downstream processing through optimized microbial growth conditions and stress parameters.

Food product preservation treatment method

PatentWO2020158906A1

Innovation

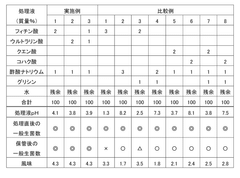

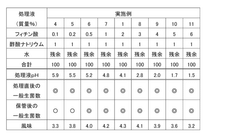

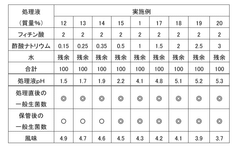

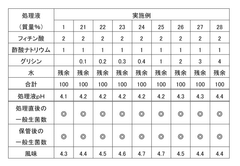

- A food preservation method involving a treatment liquid containing sodium acetate and one or more phosphoric acid compounds (phytic acid or ultraphosphoric acid) that inhibits microorganism growth without adding acidity, while maintaining the original flavor, using a solution with a balanced composition of these compounds and optionally glycine to enhance flavor.

Regulatory Framework for Food Preservatives

The regulatory framework for food preservatives, including propionic acid, is a complex and evolving system designed to ensure food safety and quality while protecting consumer health. In the United States, the Food and Drug Administration (FDA) is the primary regulatory body overseeing the use of food additives, including preservatives. The FDA has established specific guidelines for the use of propionic acid and its salts in food products, classifying them as Generally Recognized as Safe (GRAS) substances.

Under the Federal Food, Drug, and Cosmetic Act, propionic acid is approved for use as a food additive with specific limitations. The Code of Federal Regulations (CFR) Title 21, Part 184, Subpart B, Section 184.1081 outlines the regulatory status of propionic acid. It specifies that propionic acid can be used in food with no limitation other than current good manufacturing practice. However, when used in meat and meat products, its use level is limited to 0.5% in combination with other GRAS preservatives.

The European Union (EU) has its own regulatory framework for food additives, including propionic acid. The European Food Safety Authority (EFSA) is responsible for evaluating the safety of food additives. In the EU, propionic acid is designated as E280 and is permitted for use in various food categories with specific maximum levels. For instance, it is allowed in bread and rolls at a maximum level of 3000 mg/kg.

Internationally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides global food standards, guidelines, and codes of practice. The Codex General Standard for Food Additives (GSFA) includes provisions for the use of propionic acid and its salts in various food categories.

Regulatory bodies also require proper labeling of food products containing preservatives. In most jurisdictions, propionic acid must be declared on the ingredient list, either by its specific name or by its E number (E280). This transparency allows consumers to make informed choices about the products they purchase and consume.

It's important to note that regulations regarding food preservatives are subject to periodic review and updates based on new scientific evidence and changing consumer preferences. Manufacturers using propionic acid to enhance shelf life must stay informed about these regulatory changes and ensure compliance with the most current standards in their target markets.

Under the Federal Food, Drug, and Cosmetic Act, propionic acid is approved for use as a food additive with specific limitations. The Code of Federal Regulations (CFR) Title 21, Part 184, Subpart B, Section 184.1081 outlines the regulatory status of propionic acid. It specifies that propionic acid can be used in food with no limitation other than current good manufacturing practice. However, when used in meat and meat products, its use level is limited to 0.5% in combination with other GRAS preservatives.

The European Union (EU) has its own regulatory framework for food additives, including propionic acid. The European Food Safety Authority (EFSA) is responsible for evaluating the safety of food additives. In the EU, propionic acid is designated as E280 and is permitted for use in various food categories with specific maximum levels. For instance, it is allowed in bread and rolls at a maximum level of 3000 mg/kg.

Internationally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides global food standards, guidelines, and codes of practice. The Codex General Standard for Food Additives (GSFA) includes provisions for the use of propionic acid and its salts in various food categories.

Regulatory bodies also require proper labeling of food products containing preservatives. In most jurisdictions, propionic acid must be declared on the ingredient list, either by its specific name or by its E number (E280). This transparency allows consumers to make informed choices about the products they purchase and consume.

It's important to note that regulations regarding food preservatives are subject to periodic review and updates based on new scientific evidence and changing consumer preferences. Manufacturers using propionic acid to enhance shelf life must stay informed about these regulatory changes and ensure compliance with the most current standards in their target markets.

Environmental Impact of Propionic Acid Use

The use of propionic acid as a food preservative has significant environmental implications that warrant careful consideration. While it effectively extends shelf life and reduces food waste, its production and application processes can impact the environment in various ways.

Propionic acid is primarily produced through petrochemical processes, which rely on non-renewable fossil fuel resources. The manufacturing process involves energy-intensive operations and generates greenhouse gas emissions, contributing to climate change. However, recent advancements in biotechnology have led to the development of more sustainable production methods using renewable resources and fermentation processes, potentially reducing the carbon footprint associated with propionic acid production.

When applied to food products, propionic acid can enter the environment through various pathways. Residual amounts may be present in food waste or packaging materials, eventually reaching landfills or wastewater treatment facilities. In aquatic environments, propionic acid is generally biodegradable and does not persist or bioaccumulate. However, high concentrations in industrial effluents can temporarily alter local ecosystems and affect aquatic organisms.

The use of propionic acid in agriculture, particularly as a grain preservative, raises concerns about soil and water contamination. While it is considered less harmful than many synthetic pesticides, improper application or disposal can lead to localized environmental impacts. Research has shown that propionic acid can affect soil microbial communities, potentially influencing nutrient cycling and soil health.

From a lifecycle perspective, the environmental benefits of propionic acid use in food preservation may outweigh its production-related impacts. By extending shelf life and reducing food spoilage, it helps minimize food waste, which is a significant contributor to greenhouse gas emissions and resource depletion. This reduction in food waste can lead to more efficient use of agricultural land, water, and energy resources throughout the food supply chain.

To mitigate environmental concerns, ongoing research focuses on developing greener production methods and optimizing application techniques. Innovations in bio-based production, using renewable feedstocks and engineered microorganisms, show promise in reducing the environmental footprint of propionic acid manufacturing. Additionally, efforts to improve application efficiency and develop targeted delivery systems aim to minimize excess use and environmental release.

As sustainability becomes increasingly important in the food industry, the environmental impact of propionic acid use is likely to face greater scrutiny. Future developments may include the integration of life cycle assessments in product formulations, the adoption of circular economy principles in production processes, and the exploration of alternative, naturally-derived preservatives with similar efficacy but reduced environmental impact.

Propionic acid is primarily produced through petrochemical processes, which rely on non-renewable fossil fuel resources. The manufacturing process involves energy-intensive operations and generates greenhouse gas emissions, contributing to climate change. However, recent advancements in biotechnology have led to the development of more sustainable production methods using renewable resources and fermentation processes, potentially reducing the carbon footprint associated with propionic acid production.

When applied to food products, propionic acid can enter the environment through various pathways. Residual amounts may be present in food waste or packaging materials, eventually reaching landfills or wastewater treatment facilities. In aquatic environments, propionic acid is generally biodegradable and does not persist or bioaccumulate. However, high concentrations in industrial effluents can temporarily alter local ecosystems and affect aquatic organisms.

The use of propionic acid in agriculture, particularly as a grain preservative, raises concerns about soil and water contamination. While it is considered less harmful than many synthetic pesticides, improper application or disposal can lead to localized environmental impacts. Research has shown that propionic acid can affect soil microbial communities, potentially influencing nutrient cycling and soil health.

From a lifecycle perspective, the environmental benefits of propionic acid use in food preservation may outweigh its production-related impacts. By extending shelf life and reducing food spoilage, it helps minimize food waste, which is a significant contributor to greenhouse gas emissions and resource depletion. This reduction in food waste can lead to more efficient use of agricultural land, water, and energy resources throughout the food supply chain.

To mitigate environmental concerns, ongoing research focuses on developing greener production methods and optimizing application techniques. Innovations in bio-based production, using renewable feedstocks and engineered microorganisms, show promise in reducing the environmental footprint of propionic acid manufacturing. Additionally, efforts to improve application efficiency and develop targeted delivery systems aim to minimize excess use and environmental release.

As sustainability becomes increasingly important in the food industry, the environmental impact of propionic acid use is likely to face greater scrutiny. Future developments may include the integration of life cycle assessments in product formulations, the adoption of circular economy principles in production processes, and the exploration of alternative, naturally-derived preservatives with similar efficacy but reduced environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!