How to Implement Propionic Acid in Construction Materials?

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propionic Acid in Construction: Background and Objectives

Propionic acid, a naturally occurring carboxylic acid, has recently gained attention in the construction industry for its potential applications in enhancing building materials. This organic compound, with its unique chemical properties, presents an innovative approach to addressing longstanding challenges in construction technology.

The evolution of construction materials has been driven by the need for improved durability, sustainability, and performance. In this context, propionic acid emerges as a promising additive that could revolutionize the way we approach material science in construction. Its ability to inhibit microbial growth and potentially enhance certain material properties aligns with the industry's growing focus on creating more resilient and environmentally friendly structures.

The primary objective of implementing propionic acid in construction materials is to explore its multifaceted benefits. These include its potential as a bio-based admixture for concrete, its role in developing self-healing materials, and its application in preserving wood and other organic building components. By integrating propionic acid into construction materials, researchers and industry professionals aim to address issues such as material degradation, microbial contamination, and the environmental impact of traditional construction practices.

The technical landscape surrounding propionic acid in construction is rapidly evolving. Recent advancements in polymer science and material engineering have opened new avenues for incorporating organic compounds like propionic acid into building materials. This integration is expected to lead to the development of smart materials that can adapt to environmental conditions, self-repair, and maintain their integrity over extended periods.

As the construction industry faces increasing pressure to adopt sustainable practices and reduce its carbon footprint, the exploration of bio-based additives like propionic acid becomes crucial. This aligns with global trends towards green building and circular economy principles in construction. The potential of propionic acid to be derived from renewable sources further enhances its appeal as a sustainable solution in the construction sector.

The implementation of propionic acid in construction materials represents a convergence of chemistry, materials science, and civil engineering. This interdisciplinary approach is essential for addressing the complex challenges faced by the modern construction industry. By leveraging the properties of propionic acid, researchers and industry professionals aim to create a new generation of construction materials that are not only more durable and efficient but also environmentally responsible.

The evolution of construction materials has been driven by the need for improved durability, sustainability, and performance. In this context, propionic acid emerges as a promising additive that could revolutionize the way we approach material science in construction. Its ability to inhibit microbial growth and potentially enhance certain material properties aligns with the industry's growing focus on creating more resilient and environmentally friendly structures.

The primary objective of implementing propionic acid in construction materials is to explore its multifaceted benefits. These include its potential as a bio-based admixture for concrete, its role in developing self-healing materials, and its application in preserving wood and other organic building components. By integrating propionic acid into construction materials, researchers and industry professionals aim to address issues such as material degradation, microbial contamination, and the environmental impact of traditional construction practices.

The technical landscape surrounding propionic acid in construction is rapidly evolving. Recent advancements in polymer science and material engineering have opened new avenues for incorporating organic compounds like propionic acid into building materials. This integration is expected to lead to the development of smart materials that can adapt to environmental conditions, self-repair, and maintain their integrity over extended periods.

As the construction industry faces increasing pressure to adopt sustainable practices and reduce its carbon footprint, the exploration of bio-based additives like propionic acid becomes crucial. This aligns with global trends towards green building and circular economy principles in construction. The potential of propionic acid to be derived from renewable sources further enhances its appeal as a sustainable solution in the construction sector.

The implementation of propionic acid in construction materials represents a convergence of chemistry, materials science, and civil engineering. This interdisciplinary approach is essential for addressing the complex challenges faced by the modern construction industry. By leveraging the properties of propionic acid, researchers and industry professionals aim to create a new generation of construction materials that are not only more durable and efficient but also environmentally responsible.

Market Analysis for Propionic Acid-Enhanced Materials

The market for propionic acid-enhanced construction materials is experiencing significant growth, driven by the increasing demand for sustainable and durable building solutions. Propionic acid, known for its antimicrobial properties and ability to enhance material performance, is finding its way into various construction applications, particularly in concrete and cement-based products.

The global construction industry, valued at over $11 trillion in 2021, is projected to grow at a CAGR of 7.3% from 2022 to 2030. Within this expansive market, the segment for specialty chemicals in construction materials is gaining traction, with propionic acid emerging as a key player. The market size for propionic acid in construction materials was estimated at $320 million in 2021 and is expected to reach $450 million by 2026, growing at a CAGR of 7.1%.

Key factors driving the demand for propionic acid-enhanced materials include the need for mold-resistant building products, especially in humid climates, and the push for longer-lasting infrastructure. The residential construction sector, particularly in North America and Europe, shows the highest adoption rate for these materials, accounting for approximately 40% of the market share.

Commercial and industrial construction segments are also showing increased interest, with a focus on enhancing the durability of structures in harsh environments. The Asia-Pacific region, led by China and India, is expected to be the fastest-growing market for propionic acid-enhanced materials, driven by rapid urbanization and infrastructure development.

The market is characterized by a growing awareness of the long-term cost benefits of using propionic acid-enhanced materials. While the initial cost may be higher, the extended lifespan and reduced maintenance requirements of these materials are attracting attention from both private developers and public infrastructure projects.

Environmental regulations and green building standards are further propelling the market growth. Propionic acid's natural origin and biodegradability align well with sustainable construction practices, making it an attractive option for eco-conscious builders and developers.

However, the market faces challenges such as the volatility in raw material prices and the need for extensive education among end-users about the benefits of propionic acid-enhanced materials. Overcoming these hurdles will be crucial for sustained market expansion in the coming years.

The global construction industry, valued at over $11 trillion in 2021, is projected to grow at a CAGR of 7.3% from 2022 to 2030. Within this expansive market, the segment for specialty chemicals in construction materials is gaining traction, with propionic acid emerging as a key player. The market size for propionic acid in construction materials was estimated at $320 million in 2021 and is expected to reach $450 million by 2026, growing at a CAGR of 7.1%.

Key factors driving the demand for propionic acid-enhanced materials include the need for mold-resistant building products, especially in humid climates, and the push for longer-lasting infrastructure. The residential construction sector, particularly in North America and Europe, shows the highest adoption rate for these materials, accounting for approximately 40% of the market share.

Commercial and industrial construction segments are also showing increased interest, with a focus on enhancing the durability of structures in harsh environments. The Asia-Pacific region, led by China and India, is expected to be the fastest-growing market for propionic acid-enhanced materials, driven by rapid urbanization and infrastructure development.

The market is characterized by a growing awareness of the long-term cost benefits of using propionic acid-enhanced materials. While the initial cost may be higher, the extended lifespan and reduced maintenance requirements of these materials are attracting attention from both private developers and public infrastructure projects.

Environmental regulations and green building standards are further propelling the market growth. Propionic acid's natural origin and biodegradability align well with sustainable construction practices, making it an attractive option for eco-conscious builders and developers.

However, the market faces challenges such as the volatility in raw material prices and the need for extensive education among end-users about the benefits of propionic acid-enhanced materials. Overcoming these hurdles will be crucial for sustained market expansion in the coming years.

Current Challenges in Propionic Acid Implementation

The implementation of propionic acid in construction materials faces several significant challenges that hinder its widespread adoption. One of the primary obstacles is the corrosive nature of propionic acid, which can potentially degrade certain building materials over time. This corrosiveness raises concerns about the long-term durability and structural integrity of constructions incorporating propionic acid-based solutions.

Another challenge lies in the volatility of propionic acid, which can lead to issues with odor and air quality in enclosed spaces. This characteristic makes it particularly problematic for indoor applications, limiting its use in interior construction materials. The potential health and safety risks associated with prolonged exposure to propionic acid vapors further complicate its implementation in residential and commercial buildings.

The integration of propionic acid into existing construction processes and materials presents technical difficulties. Achieving uniform distribution and optimal concentration levels within various building materials requires sophisticated formulation techniques. Moreover, ensuring compatibility with other common construction additives and materials without compromising their properties poses a significant challenge for researchers and manufacturers.

Cost considerations also play a crucial role in the implementation of propionic acid in construction materials. The production and purification processes for propionic acid can be relatively expensive, potentially increasing the overall cost of construction projects. This economic factor may deter widespread adoption, especially in price-sensitive markets or large-scale developments.

Environmental concerns present another hurdle in the implementation process. While propionic acid is biodegradable, its production often relies on petrochemical processes, raising questions about sustainability and carbon footprint. The construction industry's growing focus on eco-friendly materials and practices necessitates addressing these environmental implications to gain broader acceptance.

Regulatory compliance and standardization pose additional challenges. The use of propionic acid in construction materials may require new or modified building codes and standards. Obtaining necessary approvals from regulatory bodies and ensuring compliance with diverse international regulations can be a complex and time-consuming process, potentially slowing down the adoption of propionic acid-based solutions in the construction sector.

Lastly, there is a general lack of awareness and understanding about the potential benefits and applications of propionic acid in construction materials among industry professionals. This knowledge gap can lead to resistance to change and reluctance to adopt new technologies, further impeding the implementation of propionic acid in construction practices.

Another challenge lies in the volatility of propionic acid, which can lead to issues with odor and air quality in enclosed spaces. This characteristic makes it particularly problematic for indoor applications, limiting its use in interior construction materials. The potential health and safety risks associated with prolonged exposure to propionic acid vapors further complicate its implementation in residential and commercial buildings.

The integration of propionic acid into existing construction processes and materials presents technical difficulties. Achieving uniform distribution and optimal concentration levels within various building materials requires sophisticated formulation techniques. Moreover, ensuring compatibility with other common construction additives and materials without compromising their properties poses a significant challenge for researchers and manufacturers.

Cost considerations also play a crucial role in the implementation of propionic acid in construction materials. The production and purification processes for propionic acid can be relatively expensive, potentially increasing the overall cost of construction projects. This economic factor may deter widespread adoption, especially in price-sensitive markets or large-scale developments.

Environmental concerns present another hurdle in the implementation process. While propionic acid is biodegradable, its production often relies on petrochemical processes, raising questions about sustainability and carbon footprint. The construction industry's growing focus on eco-friendly materials and practices necessitates addressing these environmental implications to gain broader acceptance.

Regulatory compliance and standardization pose additional challenges. The use of propionic acid in construction materials may require new or modified building codes and standards. Obtaining necessary approvals from regulatory bodies and ensuring compliance with diverse international regulations can be a complex and time-consuming process, potentially slowing down the adoption of propionic acid-based solutions in the construction sector.

Lastly, there is a general lack of awareness and understanding about the potential benefits and applications of propionic acid in construction materials among industry professionals. This knowledge gap can lead to resistance to change and reluctance to adopt new technologies, further impeding the implementation of propionic acid in construction practices.

Existing Methods for Incorporating Propionic Acid

01 Production methods of propionic acid

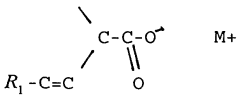

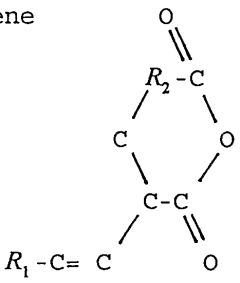

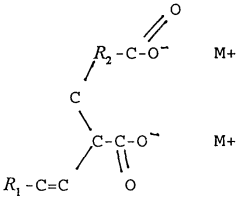

Various methods are employed for the production of propionic acid, including fermentation processes, chemical synthesis, and catalytic reactions. These methods often involve the use of specific microorganisms, catalysts, or chemical precursors to efficiently produce propionic acid on an industrial scale.- Production methods of propionic acid: Various methods for producing propionic acid are described, including fermentation processes, chemical synthesis routes, and catalytic reactions. These methods aim to improve yield, efficiency, and purity of propionic acid production for industrial applications.

- Applications of propionic acid in food preservation: Propionic acid and its salts are widely used as food preservatives due to their antimicrobial properties. They are effective against molds and bacteria, extending the shelf life of various food products, particularly in bakery goods and dairy products.

- Use of propionic acid in pharmaceutical formulations: Propionic acid and its derivatives find applications in pharmaceutical formulations. They are used as excipients, pH adjusters, and in some cases, as active pharmaceutical ingredients for various therapeutic purposes.

- Industrial applications of propionic acid: Propionic acid has diverse industrial applications beyond food and pharmaceuticals. It is used in the production of plastics, herbicides, and as a chemical intermediate in various manufacturing processes. Its properties make it valuable in industries such as agriculture and polymer production.

- Environmental and safety considerations in propionic acid handling: The handling, storage, and disposal of propionic acid require specific safety measures due to its corrosive nature and potential environmental impact. Proper containment, neutralization techniques, and waste management practices are essential for safe industrial use of propionic acid.

02 Applications of propionic acid in food preservation

Propionic acid is widely used as a food preservative due to its antimicrobial properties. It is effective in inhibiting the growth of mold and certain bacteria, making it valuable in extending the shelf life of various food products, particularly baked goods and dairy products.Expand Specific Solutions03 Use of propionic acid in pharmaceutical industry

Propionic acid and its derivatives find applications in the pharmaceutical industry. They are used in the synthesis of various drugs and as intermediates in the production of pharmaceutical compounds. The acid's properties make it useful in formulations for certain medications and treatments.Expand Specific Solutions04 Environmental and agricultural applications

Propionic acid is utilized in environmental and agricultural contexts. It serves as a component in herbicides and pesticides, and is also used in soil treatment applications. Additionally, it plays a role in certain waste treatment processes and as a preservative for animal feed.Expand Specific Solutions05 Industrial uses and derivatives of propionic acid

Propionic acid has various industrial applications beyond food and pharmaceuticals. It is used in the production of plastics, as a chemical intermediate in the synthesis of other compounds, and in the manufacturing of solvents and fragrances. Its derivatives also find use in diverse industrial processes.Expand Specific Solutions

Key Players in Propionic Acid and Construction Industries

The implementation of propionic acid in construction materials is an emerging field in the early stages of development. The market size is relatively small but growing as more companies recognize the potential benefits of using propionic acid for applications like concrete admixtures and anti-corrosion coatings. While the technology is still maturing, several key players are advancing research and development efforts. Companies like Nippon Shokubai, LG Chem, and Dow Global Technologies are leveraging their chemical expertise to explore propionic acid formulations. Academic institutions such as Nanjing Tech University and Xiamen University are also contributing fundamental research. As the technology progresses, we can expect increased commercial applications and market growth in the coming years.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has developed a novel approach to incorporate propionic acid into construction materials, particularly focusing on cement-based composites. Their method involves the use of propionic acid as a retarding admixture in cement mixtures, which helps to control the setting time and improve workability[1]. The company has also explored the use of propionic acid derivatives as biocides in construction materials, enhancing their resistance to microbial growth and extending the lifespan of structures[2]. Additionally, Dow has investigated the potential of propionic acid as a precursor for producing bio-based polymers that can be used as additives in construction materials, improving their durability and sustainability[3].

Strengths: Improved workability of cement mixtures, enhanced microbial resistance, and potential for sustainable bio-based additives. Weaknesses: Potential cost increase due to specialized additives and possible limitations in extreme environmental conditions.

Bayer AG

Technical Solution: Bayer AG has developed innovative techniques for incorporating propionic acid into construction materials, focusing on its use as a preservative and anti-microbial agent. Their approach involves encapsulating propionic acid in polymer matrices, allowing for controlled release in building materials such as paints, sealants, and insulation[1]. This method enhances the longevity of construction materials by preventing mold and bacterial growth. Bayer has also explored the use of propionic acid derivatives in the production of polyurethane foams for insulation, improving their fire-retardant properties and thermal efficiency[2]. Furthermore, the company has investigated the potential of propionic acid as a curing agent for epoxy resins used in high-performance coatings for concrete structures, enhancing their durability and chemical resistance[3].

Strengths: Enhanced preservation properties, improved fire resistance, and increased durability of construction materials. Weaknesses: Potential environmental concerns related to chemical additives and possible increased production costs.

Innovative Approaches to Propionic Acid Integration

Synergistic enhancement of calcium propionate

PatentWO2008103416A8

Innovation

- A composition combining solubilized propionic acid or its salts with a dual cationic surfactant mixture, such as Maquat 2525 M, is used to create a stable solution for immediate and residual fungicidal action on surfaces, incorporating a cellulose ether for film-forming properties, applied in industrial processes and products for enhanced fungal resistance.

Anti-corrosion additive for compositions in contact with iron-based substrates

PatentWO2004106256A1

Innovation

- An alkali-based salt solution of dioic acid, specifically a disodium-based salt of butane dioic acid, is used as an anti-corrosive additive, which can be mixed with concrete or applied to existing structures to reduce water permeability and prevent corrosion on re-bar surfaces, formed through specific chemical reactions and processing steps.

Environmental Impact and Sustainability Considerations

The implementation of propionic acid in construction materials presents both environmental challenges and sustainability opportunities. When considering the environmental impact, it is crucial to assess the entire lifecycle of propionic acid-enhanced construction materials, from production to disposal. The manufacturing process of propionic acid involves petrochemical feedstocks, which can contribute to greenhouse gas emissions and resource depletion. However, the use of propionic acid in construction materials can potentially extend the lifespan of structures, reducing the need for frequent replacements and thereby conserving resources in the long term.

One of the primary environmental benefits of incorporating propionic acid into construction materials is its ability to inhibit microbial growth. This property can significantly reduce the use of harmful biocides and chemical treatments traditionally applied to prevent mold and bacterial growth in buildings. By minimizing the need for these toxic substances, propionic acid-enhanced materials can contribute to improved indoor air quality and reduced environmental contamination.

From a sustainability perspective, the use of propionic acid in construction materials aligns with the principles of circular economy. The enhanced durability and resistance to degradation offered by propionic acid can lead to longer-lasting buildings and infrastructure, reducing waste generation and the demand for new construction materials over time. This longevity factor is particularly important in the context of sustainable urban development and resource conservation.

However, the potential leaching of propionic acid from construction materials into the environment must be carefully evaluated. While propionic acid is biodegradable and occurs naturally in some environments, its concentrated release could potentially impact local ecosystems, particularly aquatic habitats. Proper encapsulation techniques and controlled release mechanisms should be developed to mitigate this risk and ensure the long-term environmental safety of propionic acid-enhanced materials.

The sustainability of propionic acid implementation also depends on its sourcing and production methods. Research into bio-based production of propionic acid, using renewable feedstocks and fermentation processes, shows promise in reducing the environmental footprint of its manufacture. This shift towards bio-based production could significantly enhance the overall sustainability profile of propionic acid use in construction materials.

Furthermore, the potential for propionic acid to improve the recyclability and end-of-life management of construction materials should be explored. If propionic acid can facilitate the separation and recovery of different material components at the end of a building's life, it could contribute to more efficient recycling processes and reduce construction waste sent to landfills.

One of the primary environmental benefits of incorporating propionic acid into construction materials is its ability to inhibit microbial growth. This property can significantly reduce the use of harmful biocides and chemical treatments traditionally applied to prevent mold and bacterial growth in buildings. By minimizing the need for these toxic substances, propionic acid-enhanced materials can contribute to improved indoor air quality and reduced environmental contamination.

From a sustainability perspective, the use of propionic acid in construction materials aligns with the principles of circular economy. The enhanced durability and resistance to degradation offered by propionic acid can lead to longer-lasting buildings and infrastructure, reducing waste generation and the demand for new construction materials over time. This longevity factor is particularly important in the context of sustainable urban development and resource conservation.

However, the potential leaching of propionic acid from construction materials into the environment must be carefully evaluated. While propionic acid is biodegradable and occurs naturally in some environments, its concentrated release could potentially impact local ecosystems, particularly aquatic habitats. Proper encapsulation techniques and controlled release mechanisms should be developed to mitigate this risk and ensure the long-term environmental safety of propionic acid-enhanced materials.

The sustainability of propionic acid implementation also depends on its sourcing and production methods. Research into bio-based production of propionic acid, using renewable feedstocks and fermentation processes, shows promise in reducing the environmental footprint of its manufacture. This shift towards bio-based production could significantly enhance the overall sustainability profile of propionic acid use in construction materials.

Furthermore, the potential for propionic acid to improve the recyclability and end-of-life management of construction materials should be explored. If propionic acid can facilitate the separation and recovery of different material components at the end of a building's life, it could contribute to more efficient recycling processes and reduce construction waste sent to landfills.

Regulatory Framework for Chemical Additives in Construction

The regulatory framework for chemical additives in construction materials is a critical aspect of implementing propionic acid in the industry. This framework encompasses a complex set of rules, standards, and guidelines that govern the use of chemical substances in building materials. In the context of propionic acid, these regulations aim to ensure safety, environmental protection, and performance standards are met.

At the international level, organizations such as the International Organization for Standardization (ISO) and the European Committee for Standardization (CEN) play crucial roles in setting global standards for construction materials. These standards often include specifications for chemical additives, their permissible levels, and testing methods to verify compliance.

In the United States, the Environmental Protection Agency (EPA) regulates chemical substances under the Toxic Substances Control Act (TSCA). The EPA maintains an inventory of existing chemical substances and requires manufacturers to submit premanufacture notices for new chemical substances, including those intended for use in construction materials. Additionally, the Occupational Safety and Health Administration (OSHA) sets standards for worker exposure to chemicals, which would apply to the handling and use of propionic acid in construction settings.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is another significant framework that affects the use of chemical additives in construction materials. Under REACH, manufacturers must register chemicals, assess their hazards, and communicate safety information to users. For propionic acid to be used in construction materials within the EU, it would need to comply with REACH requirements.

Building codes and standards at national and local levels also play a crucial role in regulating chemical additives. These codes often reference specific standards for construction materials, which may include limitations on chemical content or performance requirements that indirectly affect the use of additives like propionic acid. For instance, the International Building Code (IBC) in the United States and the Eurocodes in Europe provide guidelines that influence the selection and use of construction materials.

Certification systems for green building, such as LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method), have their own criteria for chemical additives in construction materials. These systems often promote the use of low-emission materials and may require disclosure of chemical ingredients, potentially affecting the adoption of propionic acid in construction materials.

To successfully implement propionic acid in construction materials, manufacturers and developers must navigate this complex regulatory landscape. This involves conducting thorough assessments of the chemical's properties, potential environmental and health impacts, and ensuring compliance with relevant standards and regulations across different jurisdictions. Ongoing monitoring of regulatory changes and active engagement with regulatory bodies are essential to maintain compliance and adapt to evolving requirements in the use of chemical additives like propionic acid in the construction industry.

At the international level, organizations such as the International Organization for Standardization (ISO) and the European Committee for Standardization (CEN) play crucial roles in setting global standards for construction materials. These standards often include specifications for chemical additives, their permissible levels, and testing methods to verify compliance.

In the United States, the Environmental Protection Agency (EPA) regulates chemical substances under the Toxic Substances Control Act (TSCA). The EPA maintains an inventory of existing chemical substances and requires manufacturers to submit premanufacture notices for new chemical substances, including those intended for use in construction materials. Additionally, the Occupational Safety and Health Administration (OSHA) sets standards for worker exposure to chemicals, which would apply to the handling and use of propionic acid in construction settings.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is another significant framework that affects the use of chemical additives in construction materials. Under REACH, manufacturers must register chemicals, assess their hazards, and communicate safety information to users. For propionic acid to be used in construction materials within the EU, it would need to comply with REACH requirements.

Building codes and standards at national and local levels also play a crucial role in regulating chemical additives. These codes often reference specific standards for construction materials, which may include limitations on chemical content or performance requirements that indirectly affect the use of additives like propionic acid. For instance, the International Building Code (IBC) in the United States and the Eurocodes in Europe provide guidelines that influence the selection and use of construction materials.

Certification systems for green building, such as LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method), have their own criteria for chemical additives in construction materials. These systems often promote the use of low-emission materials and may require disclosure of chemical ingredients, potentially affecting the adoption of propionic acid in construction materials.

To successfully implement propionic acid in construction materials, manufacturers and developers must navigate this complex regulatory landscape. This involves conducting thorough assessments of the chemical's properties, potential environmental and health impacts, and ensuring compliance with relevant standards and regulations across different jurisdictions. Ongoing monitoring of regulatory changes and active engagement with regulatory bodies are essential to maintain compliance and adapt to evolving requirements in the use of chemical additives like propionic acid in the construction industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!