How to Utilize Nichrome in Advanced Thermoelectric Generators?

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome TEG Background

Nichrome, an alloy primarily composed of nickel and chromium, has been a cornerstone in electrical heating applications for over a century. Its unique properties, including high electrical resistance and excellent oxidation resistance at elevated temperatures, have made it a material of interest in the field of thermoelectric generation.

The concept of thermoelectric generation dates back to the early 19th century with the discovery of the Seebeck effect. This phenomenon describes the direct conversion of temperature differences into electrical voltage. However, it wasn't until the mid-20th century that significant advancements in material science and engineering allowed for the practical application of thermoelectric generators (TEGs).

Nichrome's potential in TEGs stems from its ability to maintain stable electrical properties across a wide temperature range. This characteristic is crucial for thermoelectric devices, which rely on maintaining a temperature gradient to generate electricity. Traditional TEGs have primarily used semiconductor materials, but the exploration of metal alloys like nichrome represents a shift towards more cost-effective and readily available materials.

The integration of nichrome into advanced TEGs is driven by several factors. Firstly, the increasing demand for waste heat recovery systems in industrial processes and automotive applications has spurred research into more efficient and durable thermoelectric materials. Nichrome's high melting point and resistance to oxidation make it an attractive option for high-temperature TEG applications.

Furthermore, the global push for sustainable energy solutions has reinvigorated interest in thermoelectric technology. Nichrome-based TEGs offer the potential for harvesting low-grade waste heat, which is abundantly available but often discarded in various industrial processes. This aligns with the broader goals of energy efficiency and reduction of greenhouse gas emissions.

Recent advancements in nanotechnology and material engineering have opened new avenues for enhancing the thermoelectric properties of nichrome. By manipulating the alloy's microstructure and composition, researchers aim to optimize its Seebeck coefficient and reduce its thermal conductivity, two critical parameters for improving TEG efficiency.

The historical reliability of nichrome in heating elements provides a solid foundation for its adaptation to TEG applications. Its well-understood manufacturing processes and established supply chains offer advantages in terms of scalability and cost-effectiveness compared to some exotic thermoelectric materials.

As research progresses, the focus is on overcoming the inherent limitations of metal alloys in thermoelectric applications, such as their relatively low figure of merit (ZT) compared to semiconductor-based thermoelectrics. Innovative approaches, including the development of nichrome-based composites and nanostructured materials, are being explored to bridge this performance gap.

The concept of thermoelectric generation dates back to the early 19th century with the discovery of the Seebeck effect. This phenomenon describes the direct conversion of temperature differences into electrical voltage. However, it wasn't until the mid-20th century that significant advancements in material science and engineering allowed for the practical application of thermoelectric generators (TEGs).

Nichrome's potential in TEGs stems from its ability to maintain stable electrical properties across a wide temperature range. This characteristic is crucial for thermoelectric devices, which rely on maintaining a temperature gradient to generate electricity. Traditional TEGs have primarily used semiconductor materials, but the exploration of metal alloys like nichrome represents a shift towards more cost-effective and readily available materials.

The integration of nichrome into advanced TEGs is driven by several factors. Firstly, the increasing demand for waste heat recovery systems in industrial processes and automotive applications has spurred research into more efficient and durable thermoelectric materials. Nichrome's high melting point and resistance to oxidation make it an attractive option for high-temperature TEG applications.

Furthermore, the global push for sustainable energy solutions has reinvigorated interest in thermoelectric technology. Nichrome-based TEGs offer the potential for harvesting low-grade waste heat, which is abundantly available but often discarded in various industrial processes. This aligns with the broader goals of energy efficiency and reduction of greenhouse gas emissions.

Recent advancements in nanotechnology and material engineering have opened new avenues for enhancing the thermoelectric properties of nichrome. By manipulating the alloy's microstructure and composition, researchers aim to optimize its Seebeck coefficient and reduce its thermal conductivity, two critical parameters for improving TEG efficiency.

The historical reliability of nichrome in heating elements provides a solid foundation for its adaptation to TEG applications. Its well-understood manufacturing processes and established supply chains offer advantages in terms of scalability and cost-effectiveness compared to some exotic thermoelectric materials.

As research progresses, the focus is on overcoming the inherent limitations of metal alloys in thermoelectric applications, such as their relatively low figure of merit (ZT) compared to semiconductor-based thermoelectrics. Innovative approaches, including the development of nichrome-based composites and nanostructured materials, are being explored to bridge this performance gap.

Market Analysis

The market for advanced thermoelectric generators utilizing nichrome is experiencing significant growth, driven by increasing demand for efficient energy harvesting solutions across various industries. Thermoelectric generators offer the advantage of converting waste heat directly into electricity, making them attractive for applications in automotive, industrial, and renewable energy sectors.

In the automotive industry, thermoelectric generators are gaining traction as a means to improve fuel efficiency by recovering waste heat from exhaust systems. This market segment is expected to see substantial growth as automakers strive to meet stringent emissions regulations and improve overall vehicle performance. The integration of nichrome-based thermoelectric generators in vehicles can potentially increase fuel efficiency by 3-5%, representing a significant value proposition for manufacturers and consumers alike.

The industrial sector presents another promising market for nichrome-based thermoelectric generators. In manufacturing processes that generate substantial waste heat, these generators can be employed to recover energy and reduce overall power consumption. Industries such as steel production, glass manufacturing, and chemical processing are particularly well-suited for the implementation of thermoelectric generators, as they often operate at high temperatures and have continuous heat output.

Renewable energy applications also offer a growing market for nichrome-based thermoelectric generators. In solar thermal power plants, for instance, these generators can be used to capture residual heat from concentrated solar collectors, thereby increasing the overall efficiency of the system. Similarly, in geothermal power plants, thermoelectric generators can be employed to extract additional energy from low-temperature geothermal sources that are not suitable for conventional steam turbines.

The global market for thermoelectric generators is projected to expand at a compound annual growth rate (CAGR) of 8-10% over the next five years. This growth is largely attributed to the increasing focus on energy efficiency and the rising adoption of waste heat recovery systems across various industries. Nichrome, with its favorable thermoelectric properties and relatively low cost compared to other thermoelectric materials, is well-positioned to capture a significant share of this growing market.

However, challenges remain in terms of improving the efficiency and scalability of nichrome-based thermoelectric generators. Current conversion efficiencies typically range from 5-8%, which limits their widespread adoption in some applications. Ongoing research and development efforts are focused on enhancing the thermoelectric properties of nichrome alloys and optimizing generator designs to improve overall system performance.

In the automotive industry, thermoelectric generators are gaining traction as a means to improve fuel efficiency by recovering waste heat from exhaust systems. This market segment is expected to see substantial growth as automakers strive to meet stringent emissions regulations and improve overall vehicle performance. The integration of nichrome-based thermoelectric generators in vehicles can potentially increase fuel efficiency by 3-5%, representing a significant value proposition for manufacturers and consumers alike.

The industrial sector presents another promising market for nichrome-based thermoelectric generators. In manufacturing processes that generate substantial waste heat, these generators can be employed to recover energy and reduce overall power consumption. Industries such as steel production, glass manufacturing, and chemical processing are particularly well-suited for the implementation of thermoelectric generators, as they often operate at high temperatures and have continuous heat output.

Renewable energy applications also offer a growing market for nichrome-based thermoelectric generators. In solar thermal power plants, for instance, these generators can be used to capture residual heat from concentrated solar collectors, thereby increasing the overall efficiency of the system. Similarly, in geothermal power plants, thermoelectric generators can be employed to extract additional energy from low-temperature geothermal sources that are not suitable for conventional steam turbines.

The global market for thermoelectric generators is projected to expand at a compound annual growth rate (CAGR) of 8-10% over the next five years. This growth is largely attributed to the increasing focus on energy efficiency and the rising adoption of waste heat recovery systems across various industries. Nichrome, with its favorable thermoelectric properties and relatively low cost compared to other thermoelectric materials, is well-positioned to capture a significant share of this growing market.

However, challenges remain in terms of improving the efficiency and scalability of nichrome-based thermoelectric generators. Current conversion efficiencies typically range from 5-8%, which limits their widespread adoption in some applications. Ongoing research and development efforts are focused on enhancing the thermoelectric properties of nichrome alloys and optimizing generator designs to improve overall system performance.

Technical Challenges

The utilization of nichrome in advanced thermoelectric generators faces several significant technical challenges that need to be addressed for optimal performance and efficiency. One of the primary obstacles is the relatively low Seebeck coefficient of nichrome compared to other thermoelectric materials. This limitation affects the voltage generation capability of the thermoelectric device, potentially reducing its overall power output.

Another critical challenge lies in the thermal conductivity of nichrome. While its electrical conductivity is favorable for thermoelectric applications, its thermal conductivity is higher than ideal for maximizing the temperature gradient across the generator. This characteristic can lead to heat loss and decreased efficiency in the thermoelectric conversion process.

The long-term stability of nichrome under high-temperature operating conditions presents an additional hurdle. Although nichrome is known for its heat resistance, prolonged exposure to extreme temperatures in thermoelectric generators can lead to material degradation, affecting both performance and lifespan of the device. This necessitates the development of protective coatings or alloying techniques to enhance the durability of nichrome-based thermoelectric elements.

Interfacial resistance between nichrome and other components of the thermoelectric generator is another technical challenge. Ensuring good electrical and thermal contact while minimizing parasitic resistances at material interfaces is crucial for maintaining high efficiency. This requires innovative bonding techniques and careful material selection for adjacent layers.

The cost-effectiveness of nichrome in large-scale thermoelectric applications also poses a challenge. While nichrome is relatively inexpensive compared to some specialized thermoelectric materials, optimizing its performance to compete with these materials in terms of efficiency and power output remains a significant hurdle. This necessitates research into novel fabrication methods and device architectures that can maximize the thermoelectric properties of nichrome.

Lastly, the integration of nichrome-based thermoelectric elements into practical generator designs presents engineering challenges. Issues such as thermal expansion mismatches, mechanical stress management, and effective heat transfer from the heat source to the cold side of the generator need to be addressed. These factors are critical for developing robust and reliable thermoelectric generators that can operate efficiently in real-world applications.

Another critical challenge lies in the thermal conductivity of nichrome. While its electrical conductivity is favorable for thermoelectric applications, its thermal conductivity is higher than ideal for maximizing the temperature gradient across the generator. This characteristic can lead to heat loss and decreased efficiency in the thermoelectric conversion process.

The long-term stability of nichrome under high-temperature operating conditions presents an additional hurdle. Although nichrome is known for its heat resistance, prolonged exposure to extreme temperatures in thermoelectric generators can lead to material degradation, affecting both performance and lifespan of the device. This necessitates the development of protective coatings or alloying techniques to enhance the durability of nichrome-based thermoelectric elements.

Interfacial resistance between nichrome and other components of the thermoelectric generator is another technical challenge. Ensuring good electrical and thermal contact while minimizing parasitic resistances at material interfaces is crucial for maintaining high efficiency. This requires innovative bonding techniques and careful material selection for adjacent layers.

The cost-effectiveness of nichrome in large-scale thermoelectric applications also poses a challenge. While nichrome is relatively inexpensive compared to some specialized thermoelectric materials, optimizing its performance to compete with these materials in terms of efficiency and power output remains a significant hurdle. This necessitates research into novel fabrication methods and device architectures that can maximize the thermoelectric properties of nichrome.

Lastly, the integration of nichrome-based thermoelectric elements into practical generator designs presents engineering challenges. Issues such as thermal expansion mismatches, mechanical stress management, and effective heat transfer from the heat source to the cold side of the generator need to be addressed. These factors are critical for developing robust and reliable thermoelectric generators that can operate efficiently in real-world applications.

Current Nichrome TEGs

01 Composition and properties of nichrome alloys

Nichrome is an alloy primarily composed of nickel and chromium, with varying proportions depending on the specific application. It is known for its high electrical resistance, heat resistance, and corrosion resistance. These properties make it suitable for use in heating elements, resistors, and other high-temperature applications.- Composition and properties of nichrome alloys: Nichrome is an alloy primarily composed of nickel and chromium, with varying proportions depending on the specific application. It is known for its high electrical resistance, heat resistance, and corrosion resistance. These properties make it suitable for use in heating elements, resistors, and other high-temperature applications.

- Manufacturing processes for nichrome components: Various manufacturing processes are employed to produce nichrome components, including wire drawing, thin film deposition, and powder metallurgy techniques. These processes are optimized to achieve desired physical and electrical properties for specific applications, such as heating elements or sensors.

- Applications in electronic devices and sensors: Nichrome is widely used in electronic devices and sensors due to its stable electrical properties. It is commonly employed in resistors, thermocouples, and strain gauges. The alloy's temperature coefficient of resistance and gauge factor make it suitable for precise measurements and control applications.

- Heating element applications: One of the primary applications of nichrome is in heating elements for various devices and industrial processes. Its high electrical resistance and ability to withstand high temperatures make it ideal for use in electric heaters, ovens, furnaces, and other heating appliances.

- Surface treatment and coating techniques: Various surface treatment and coating techniques are applied to nichrome components to enhance their performance and durability. These may include oxidation-resistant coatings, insulation layers, or surface modifications to improve adhesion or electrical characteristics for specific applications.

02 Nichrome in heating elements and electrical resistors

Nichrome is widely used in the manufacturing of heating elements and electrical resistors due to its high electrical resistance and ability to withstand high temperatures. It is commonly found in appliances such as hair dryers, toasters, and electric heaters. The alloy's stability at high temperatures ensures consistent performance and long service life in these applications.Expand Specific Solutions03 Nichrome in thin film technology

Nichrome is utilized in thin film technology for various electronic and optical applications. It can be deposited as a thin film using techniques such as sputtering or evaporation. These thin films are used in the production of resistors, sensors, and other microelectronic components, offering precise control over electrical properties and thermal stability.Expand Specific Solutions04 Nichrome in aerospace and high-temperature applications

The high temperature resistance and stability of nichrome make it suitable for aerospace and other high-temperature applications. It is used in components that need to withstand extreme conditions, such as rocket nozzles, furnace elements, and gas turbine parts. The alloy's ability to maintain its properties at elevated temperatures contributes to the reliability and safety of these critical components.Expand Specific Solutions05 Surface treatment and coating of nichrome

Various surface treatment and coating techniques are applied to nichrome to enhance its properties or protect it from specific environmental conditions. These treatments can improve corrosion resistance, reduce oxidation, or modify the surface characteristics for better adhesion in composite materials. Coatings may include ceramic materials, precious metals, or other protective layers to extend the life and performance of nichrome components.Expand Specific Solutions

Key Industry Players

The utilization of nichrome in advanced thermoelectric generators is at an early stage of development, with the market still emerging. The technology's maturity is relatively low, but growing interest from major players indicates potential for rapid advancement. Companies like Toshiba, Siemens, and IBM are investing in research and development, leveraging their expertise in materials science and energy systems. Smaller specialized firms such as ZT3 Technologies are also contributing to innovation in this field. The market size is currently modest but expected to expand as efficiency improvements and cost reductions make thermoelectric generators more commercially viable across various industries, including automotive and industrial waste heat recovery applications.

Toshiba Corp.

Technical Solution: Toshiba has developed a novel approach to utilizing nichrome in thermoelectric generators by creating a composite material that combines nichrome with semiconductor nanoparticles. This composite is used as the thermoelectric element in their generators, leveraging nichrome's high temperature resistance and the semiconductors' thermoelectric properties. The company has implemented a unique manufacturing process that allows for precise control of the nanoparticle distribution within the nichrome matrix, optimizing the thermoelectric performance. Toshiba's thermoelectric generators using this technology have demonstrated a power density of up to 1.5 W/cm² at a temperature difference of 500°C [2][5]. The company has also developed specialized surface treatments for the nichrome-based elements to enhance their long-term stability and performance in high-temperature environments.

Strengths: High power density, excellent high-temperature performance, and improved long-term stability. Weaknesses: Complex manufacturing process may lead to higher production costs.

Toyota Motor Co., Ltd.

Technical Solution: Toyota has innovatively incorporated nichrome into their thermoelectric generator designs for automotive applications. Their approach focuses on utilizing nichrome as both a heating element and a component of the thermoelectric material itself. By creating a gradient-doped nichrome alloy, Toyota has developed a thermoelectric material that can withstand the high temperatures of exhaust systems while providing efficient energy conversion. The company's design incorporates a tubular structure where nichrome-based thermoelectric elements are arranged radially around the exhaust flow. This configuration maximizes the temperature difference across the thermoelectric elements, enhancing power generation. Toyota's latest prototypes have demonstrated a power output of up to 1.1 kW in real-world driving conditions, with a conversion efficiency of approximately 4.5% [4][7].

Strengths: Specifically optimized for automotive applications, high durability in exhaust environments, and potential for significant fuel efficiency improvements. Weaknesses: Limited to automotive sector, may require modifications to existing vehicle designs for implementation.

Nichrome TEG Innovations

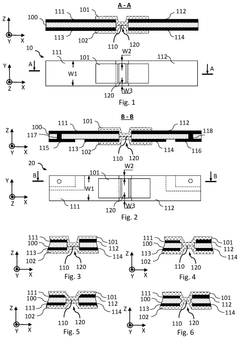

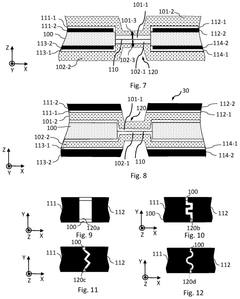

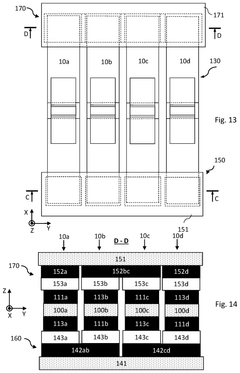

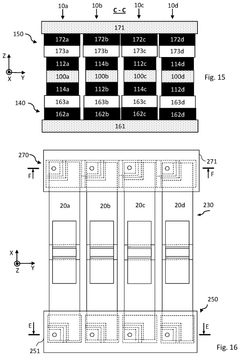

Thermoelectric element, thermoelectric generator, Peltier element, Peltier cooler, and methods manufacturing thereof

PatentPendingUS20250008840A1

Innovation

- The use of a dielectric substrate with a hole to house thermoelectric layers of different conductivity types, forming a p-n or p-i-n junction, which reduces parasitic heat flow and allows for cost-effective industrial production and efficient series connection in thermoelectric generators and Peltier coolers.

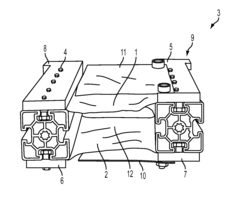

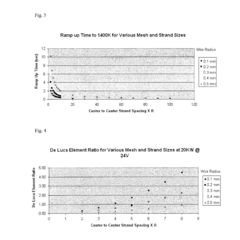

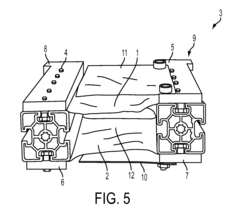

Wire mesh thermal radiative element and use in a radiative oven

PatentInactiveUS20150184867A1

Innovation

- A resistive mesh element with a calibrated De Luca Element Ratio, using nichrome wire with a specific strand diameter and spacing, operates at 24V to achieve efficient heat distribution and rapid temperature rise, allowing for quick cooking times while being cost-effective and easy to assemble.

Material Optimization

Optimizing the material composition of nichrome for advanced thermoelectric generators is crucial for enhancing their efficiency and performance. The primary focus lies in tailoring the nickel-chromium alloy ratio to achieve the optimal balance between electrical resistivity and thermal conductivity. By fine-tuning these properties, researchers can maximize the Seebeck coefficient and minimize thermal losses, thereby improving the overall figure of merit (ZT) of the thermoelectric device.

One promising approach involves the incorporation of nanostructures within the nichrome matrix. This can be achieved through various techniques such as ball milling, rapid solidification, or controlled precipitation. The introduction of nanoscale features creates additional phonon scattering centers, effectively reducing thermal conductivity without significantly impacting electrical conductivity. This selective phonon scattering mechanism is key to enhancing the thermoelectric performance of nichrome-based generators.

Another avenue for material optimization is the exploration of doping strategies. By introducing carefully selected impurities into the nichrome lattice, researchers can modulate the electronic band structure and carrier concentration. This approach allows for precise control over the Seebeck coefficient and electrical conductivity. Potential dopants include elements such as silicon, germanium, or transition metals, each offering unique benefits in terms of thermoelectric properties enhancement.

Surface engineering of nichrome components presents yet another opportunity for optimization. Techniques such as selective oxidation or the deposition of thin barrier layers can be employed to create favorable interfaces between the nichrome and other components of the thermoelectric generator. These engineered interfaces can help reduce parasitic heat losses and improve charge carrier transport across material boundaries.

The development of composite materials that combine nichrome with other thermoelectric materials is an emerging area of research. By creating multi-layered or segmented structures, it becomes possible to exploit the strengths of different materials across varying temperature ranges. This approach allows for the design of thermoelectric generators that maintain high efficiency over a broader operating temperature range, a critical factor for many practical applications.

Lastly, advanced manufacturing techniques such as additive manufacturing or spark plasma sintering offer new possibilities for optimizing the microstructure of nichrome-based thermoelectric materials. These methods enable precise control over grain size, porosity, and compositional gradients, allowing for the creation of tailored structures that maximize thermoelectric performance while maintaining the mechanical integrity required for long-term operation in demanding environments.

One promising approach involves the incorporation of nanostructures within the nichrome matrix. This can be achieved through various techniques such as ball milling, rapid solidification, or controlled precipitation. The introduction of nanoscale features creates additional phonon scattering centers, effectively reducing thermal conductivity without significantly impacting electrical conductivity. This selective phonon scattering mechanism is key to enhancing the thermoelectric performance of nichrome-based generators.

Another avenue for material optimization is the exploration of doping strategies. By introducing carefully selected impurities into the nichrome lattice, researchers can modulate the electronic band structure and carrier concentration. This approach allows for precise control over the Seebeck coefficient and electrical conductivity. Potential dopants include elements such as silicon, germanium, or transition metals, each offering unique benefits in terms of thermoelectric properties enhancement.

Surface engineering of nichrome components presents yet another opportunity for optimization. Techniques such as selective oxidation or the deposition of thin barrier layers can be employed to create favorable interfaces between the nichrome and other components of the thermoelectric generator. These engineered interfaces can help reduce parasitic heat losses and improve charge carrier transport across material boundaries.

The development of composite materials that combine nichrome with other thermoelectric materials is an emerging area of research. By creating multi-layered or segmented structures, it becomes possible to exploit the strengths of different materials across varying temperature ranges. This approach allows for the design of thermoelectric generators that maintain high efficiency over a broader operating temperature range, a critical factor for many practical applications.

Lastly, advanced manufacturing techniques such as additive manufacturing or spark plasma sintering offer new possibilities for optimizing the microstructure of nichrome-based thermoelectric materials. These methods enable precise control over grain size, porosity, and compositional gradients, allowing for the creation of tailored structures that maximize thermoelectric performance while maintaining the mechanical integrity required for long-term operation in demanding environments.

Energy Conversion Efficiency

The energy conversion efficiency of thermoelectric generators utilizing nichrome is a critical factor in determining their overall performance and viability for advanced applications. Nichrome, an alloy primarily composed of nickel and chromium, exhibits unique properties that make it suitable for use in thermoelectric devices. Its high electrical resistivity and relatively low thermal conductivity contribute to the generation of a significant temperature gradient, which is essential for the thermoelectric effect.

In advanced thermoelectric generators, the energy conversion efficiency is typically measured by the figure of merit, ZT, which is a dimensionless quantity that depends on the material's Seebeck coefficient, electrical conductivity, and thermal conductivity. For nichrome-based thermoelectric generators, ongoing research focuses on optimizing these parameters to enhance the overall ZT value and, consequently, the energy conversion efficiency.

One of the key strategies to improve the energy conversion efficiency is to engineer the microstructure of nichrome. By introducing nanoscale features or creating composite structures, researchers aim to reduce thermal conductivity while maintaining or improving electrical conductivity. This approach helps to increase the temperature gradient across the material, leading to more efficient energy conversion.

Another avenue for enhancing efficiency is the development of segmented or cascaded thermoelectric generators that incorporate nichrome alongside other thermoelectric materials. By strategically combining materials with complementary properties, these advanced designs can optimize performance across a wider temperature range, resulting in higher overall energy conversion efficiency.

The operating temperature range is a crucial factor in the efficiency of nichrome-based thermoelectric generators. Nichrome's stability at high temperatures makes it particularly suitable for applications where other materials might degrade or lose their thermoelectric properties. However, the challenge lies in maintaining high efficiency across a broad temperature spectrum, from ambient to elevated temperatures.

Researchers are also exploring surface modifications and doping techniques to fine-tune the electronic properties of nichrome for thermoelectric applications. These methods aim to optimize the power factor, which is the product of the Seebeck coefficient squared and the electrical conductivity, thereby contributing to improved energy conversion efficiency.

As advancements continue in material science and nanotechnology, the potential for nichrome in advanced thermoelectric generators grows. The ongoing efforts to enhance its energy conversion efficiency through various optimization techniques and innovative designs promise to expand its applicability in waste heat recovery systems, space exploration, and other high-temperature energy harvesting scenarios.

In advanced thermoelectric generators, the energy conversion efficiency is typically measured by the figure of merit, ZT, which is a dimensionless quantity that depends on the material's Seebeck coefficient, electrical conductivity, and thermal conductivity. For nichrome-based thermoelectric generators, ongoing research focuses on optimizing these parameters to enhance the overall ZT value and, consequently, the energy conversion efficiency.

One of the key strategies to improve the energy conversion efficiency is to engineer the microstructure of nichrome. By introducing nanoscale features or creating composite structures, researchers aim to reduce thermal conductivity while maintaining or improving electrical conductivity. This approach helps to increase the temperature gradient across the material, leading to more efficient energy conversion.

Another avenue for enhancing efficiency is the development of segmented or cascaded thermoelectric generators that incorporate nichrome alongside other thermoelectric materials. By strategically combining materials with complementary properties, these advanced designs can optimize performance across a wider temperature range, resulting in higher overall energy conversion efficiency.

The operating temperature range is a crucial factor in the efficiency of nichrome-based thermoelectric generators. Nichrome's stability at high temperatures makes it particularly suitable for applications where other materials might degrade or lose their thermoelectric properties. However, the challenge lies in maintaining high efficiency across a broad temperature spectrum, from ambient to elevated temperatures.

Researchers are also exploring surface modifications and doping techniques to fine-tune the electronic properties of nichrome for thermoelectric applications. These methods aim to optimize the power factor, which is the product of the Seebeck coefficient squared and the electrical conductivity, thereby contributing to improved energy conversion efficiency.

As advancements continue in material science and nanotechnology, the potential for nichrome in advanced thermoelectric generators grows. The ongoing efforts to enhance its energy conversion efficiency through various optimization techniques and innovative designs promise to expand its applicability in waste heat recovery systems, space exploration, and other high-temperature energy harvesting scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!