Nichrome's Role in Developing Sustainable Heating Solutions

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Evolution

Nichrome, an alloy primarily composed of nickel and chromium, has played a pivotal role in the evolution of sustainable heating solutions. Its journey began in the early 20th century when it was first developed as a high-resistance electrical conductor. The unique properties of nichrome, including its high melting point and resistance to oxidation, quickly made it a preferred material for heating elements.

In the 1920s and 1930s, nichrome found widespread use in domestic appliances such as toasters, hair dryers, and electric heaters. This marked the beginning of its contribution to more energy-efficient heating solutions compared to traditional methods. As environmental concerns grew in the latter half of the 20th century, nichrome's role in sustainable heating became more pronounced.

The 1970s energy crisis sparked renewed interest in energy-efficient technologies. Nichrome's ability to rapidly heat up and maintain consistent temperatures made it an ideal candidate for developing more efficient heating systems. This period saw the integration of nichrome elements in advanced HVAC systems and industrial heating applications, contributing to significant energy savings.

The 1990s and early 2000s witnessed a surge in research focused on optimizing nichrome alloys for even greater efficiency. Scientists and engineers experimented with various compositions, adding elements like iron or aluminum to enhance specific properties. These advancements led to the development of nichrome variants with improved durability and energy conversion rates.

In recent years, the push for sustainable technologies has further elevated nichrome's importance. Its application in electric vehicle heating systems has been crucial in extending battery life and overall vehicle efficiency. Moreover, nichrome has been instrumental in the development of energy-efficient radiant heating panels for buildings, contributing to reduced carbon footprints in the construction industry.

The evolution of nichrome in sustainable heating solutions has also seen its integration with smart technologies. Modern nichrome-based heating systems often incorporate advanced controls and sensors, allowing for precise temperature regulation and energy management. This synergy between traditional materials and cutting-edge technology represents a significant step towards more sustainable heating practices.

Looking ahead, ongoing research into nanoscale modifications of nichrome promises even greater advancements. These developments aim to further improve heat distribution and energy efficiency, potentially revolutionizing sustainable heating solutions across various sectors.

In the 1920s and 1930s, nichrome found widespread use in domestic appliances such as toasters, hair dryers, and electric heaters. This marked the beginning of its contribution to more energy-efficient heating solutions compared to traditional methods. As environmental concerns grew in the latter half of the 20th century, nichrome's role in sustainable heating became more pronounced.

The 1970s energy crisis sparked renewed interest in energy-efficient technologies. Nichrome's ability to rapidly heat up and maintain consistent temperatures made it an ideal candidate for developing more efficient heating systems. This period saw the integration of nichrome elements in advanced HVAC systems and industrial heating applications, contributing to significant energy savings.

The 1990s and early 2000s witnessed a surge in research focused on optimizing nichrome alloys for even greater efficiency. Scientists and engineers experimented with various compositions, adding elements like iron or aluminum to enhance specific properties. These advancements led to the development of nichrome variants with improved durability and energy conversion rates.

In recent years, the push for sustainable technologies has further elevated nichrome's importance. Its application in electric vehicle heating systems has been crucial in extending battery life and overall vehicle efficiency. Moreover, nichrome has been instrumental in the development of energy-efficient radiant heating panels for buildings, contributing to reduced carbon footprints in the construction industry.

The evolution of nichrome in sustainable heating solutions has also seen its integration with smart technologies. Modern nichrome-based heating systems often incorporate advanced controls and sensors, allowing for precise temperature regulation and energy management. This synergy between traditional materials and cutting-edge technology represents a significant step towards more sustainable heating practices.

Looking ahead, ongoing research into nanoscale modifications of nichrome promises even greater advancements. These developments aim to further improve heat distribution and energy efficiency, potentially revolutionizing sustainable heating solutions across various sectors.

Sustainable Heating Market

The sustainable heating market has experienced significant growth in recent years, driven by increasing environmental concerns and the global push towards cleaner energy solutions. This market encompasses a wide range of technologies and products designed to provide efficient and eco-friendly heating for residential, commercial, and industrial applications. The demand for sustainable heating solutions is primarily fueled by stringent government regulations aimed at reducing carbon emissions, rising energy costs, and growing consumer awareness of the environmental impact of traditional heating systems.

In the residential sector, there is a notable shift towards heat pumps, solar thermal systems, and biomass boilers. These technologies offer homeowners the opportunity to reduce their carbon footprint while potentially lowering long-term energy costs. The commercial and industrial sectors are also embracing sustainable heating solutions, with a focus on large-scale heat pump systems, district heating networks, and waste heat recovery systems.

The market for sustainable heating solutions is characterized by regional variations, influenced by factors such as climate, energy infrastructure, and local policies. Northern European countries, for instance, have been at the forefront of adopting district heating systems and geothermal heat pumps. In contrast, Southern European nations have shown a preference for solar thermal technologies due to their abundant sunlight.

Emerging economies, particularly in Asia and Latin America, are presenting significant growth opportunities for sustainable heating technologies. As these regions continue to urbanize and industrialize, there is an increasing emphasis on implementing energy-efficient and environmentally friendly heating solutions from the outset, rather than retrofitting existing infrastructure.

The sustainable heating market is not without its challenges. High initial costs of installation, particularly for residential applications, remain a significant barrier to widespread adoption. Additionally, the intermittent nature of some renewable energy sources used in sustainable heating systems necessitates the development of efficient energy storage solutions to ensure consistent heat supply.

Despite these challenges, the market outlook remains positive. Technological advancements, such as the integration of smart controls and Internet of Things (IoT) capabilities, are enhancing the efficiency and appeal of sustainable heating systems. Furthermore, government incentives and subsidies in many countries are helping to offset initial costs and accelerate market growth.

As the sustainable heating market continues to evolve, there is a growing focus on hybrid systems that combine multiple technologies to optimize efficiency and reliability. This trend is expected to drive further innovation and collaboration among industry players, ultimately leading to more comprehensive and adaptable sustainable heating solutions.

In the residential sector, there is a notable shift towards heat pumps, solar thermal systems, and biomass boilers. These technologies offer homeowners the opportunity to reduce their carbon footprint while potentially lowering long-term energy costs. The commercial and industrial sectors are also embracing sustainable heating solutions, with a focus on large-scale heat pump systems, district heating networks, and waste heat recovery systems.

The market for sustainable heating solutions is characterized by regional variations, influenced by factors such as climate, energy infrastructure, and local policies. Northern European countries, for instance, have been at the forefront of adopting district heating systems and geothermal heat pumps. In contrast, Southern European nations have shown a preference for solar thermal technologies due to their abundant sunlight.

Emerging economies, particularly in Asia and Latin America, are presenting significant growth opportunities for sustainable heating technologies. As these regions continue to urbanize and industrialize, there is an increasing emphasis on implementing energy-efficient and environmentally friendly heating solutions from the outset, rather than retrofitting existing infrastructure.

The sustainable heating market is not without its challenges. High initial costs of installation, particularly for residential applications, remain a significant barrier to widespread adoption. Additionally, the intermittent nature of some renewable energy sources used in sustainable heating systems necessitates the development of efficient energy storage solutions to ensure consistent heat supply.

Despite these challenges, the market outlook remains positive. Technological advancements, such as the integration of smart controls and Internet of Things (IoT) capabilities, are enhancing the efficiency and appeal of sustainable heating systems. Furthermore, government incentives and subsidies in many countries are helping to offset initial costs and accelerate market growth.

As the sustainable heating market continues to evolve, there is a growing focus on hybrid systems that combine multiple technologies to optimize efficiency and reliability. This trend is expected to drive further innovation and collaboration among industry players, ultimately leading to more comprehensive and adaptable sustainable heating solutions.

Nichrome Tech Challenges

Nichrome, a nickel-chromium alloy, faces several technical challenges in its application for developing sustainable heating solutions. One of the primary issues is the material's susceptibility to oxidation at high temperatures, which can lead to reduced performance and shortened lifespan of heating elements. This oxidation process not only affects the electrical resistance of the alloy but also compromises its structural integrity over time.

Another significant challenge lies in the thermal expansion properties of nichrome. As the material heats up, it expands, which can cause stress and deformation in heating systems. This thermal expansion must be carefully managed to prevent warping or breakage of heating elements, especially in applications requiring precise temperature control or rapid heating cycles.

The energy efficiency of nichrome-based heating solutions also presents a technical hurdle. While nichrome is known for its high electrical resistance, which makes it suitable for heating applications, there is a constant push to improve its energy conversion efficiency. Researchers are exploring ways to optimize the alloy composition and structure to maximize heat output while minimizing energy input, a critical factor in developing more sustainable heating technologies.

Durability and longevity of nichrome heating elements pose another challenge, particularly in harsh environments or applications requiring frequent thermal cycling. The repeated heating and cooling can lead to material fatigue and eventual failure. Enhancing the alloy's resistance to thermal fatigue and improving its overall lifespan is crucial for creating more sustainable and long-lasting heating solutions.

The manufacturing process of nichrome heating elements also presents technical difficulties. Achieving consistent quality and precise dimensions in the production of thin nichrome wires or sheets used in heating elements can be challenging. Variations in composition or thickness can lead to uneven heating and reduced performance. Developing more advanced manufacturing techniques to ensure uniformity and quality control is essential for improving the reliability of nichrome-based heating systems.

Environmental concerns related to the production and disposal of nichrome heating elements are also becoming increasingly important. The mining and processing of nickel and chromium have significant environmental impacts. Finding more sustainable sourcing methods and developing recycling processes for used nichrome elements are critical challenges that need to be addressed to improve the overall sustainability of nichrome-based heating solutions.

Another significant challenge lies in the thermal expansion properties of nichrome. As the material heats up, it expands, which can cause stress and deformation in heating systems. This thermal expansion must be carefully managed to prevent warping or breakage of heating elements, especially in applications requiring precise temperature control or rapid heating cycles.

The energy efficiency of nichrome-based heating solutions also presents a technical hurdle. While nichrome is known for its high electrical resistance, which makes it suitable for heating applications, there is a constant push to improve its energy conversion efficiency. Researchers are exploring ways to optimize the alloy composition and structure to maximize heat output while minimizing energy input, a critical factor in developing more sustainable heating technologies.

Durability and longevity of nichrome heating elements pose another challenge, particularly in harsh environments or applications requiring frequent thermal cycling. The repeated heating and cooling can lead to material fatigue and eventual failure. Enhancing the alloy's resistance to thermal fatigue and improving its overall lifespan is crucial for creating more sustainable and long-lasting heating solutions.

The manufacturing process of nichrome heating elements also presents technical difficulties. Achieving consistent quality and precise dimensions in the production of thin nichrome wires or sheets used in heating elements can be challenging. Variations in composition or thickness can lead to uneven heating and reduced performance. Developing more advanced manufacturing techniques to ensure uniformity and quality control is essential for improving the reliability of nichrome-based heating systems.

Environmental concerns related to the production and disposal of nichrome heating elements are also becoming increasingly important. The mining and processing of nickel and chromium have significant environmental impacts. Finding more sustainable sourcing methods and developing recycling processes for used nichrome elements are critical challenges that need to be addressed to improve the overall sustainability of nichrome-based heating solutions.

Current Nichrome Solutions

01 Composition and properties of nichrome alloys

Nichrome is an alloy primarily composed of nickel and chromium, with varying proportions depending on the specific application. It is known for its high electrical resistance, heat resistance, and corrosion resistance. These properties make it suitable for use in heating elements, resistors, and other high-temperature applications.- Composition and properties of nichrome alloys: Nichrome is an alloy primarily composed of nickel and chromium, with varying proportions depending on the specific application. It is known for its high electrical resistance, heat resistance, and corrosion resistance. These properties make it suitable for use in heating elements, resistors, and other high-temperature applications.

- Nichrome in heating elements and electrical resistors: Nichrome is widely used in the manufacturing of heating elements and electrical resistors due to its high electrical resistance and ability to withstand high temperatures. It is commonly found in appliances such as hair dryers, toasters, and electric heaters. The alloy's stability at high temperatures ensures consistent performance and longevity of these devices.

- Nichrome in thin film technology: Nichrome is utilized in thin film technology for various applications, including the production of resistive elements in microelectronics and sensors. The alloy can be deposited as a thin film using techniques such as sputtering or evaporation, allowing for precise control of electrical properties in miniaturized devices.

- Nichrome in aerospace and high-temperature applications: The high temperature resistance and stability of nichrome make it suitable for aerospace and other high-temperature applications. It is used in components that require reliable performance under extreme conditions, such as in aircraft engines, rocket nozzles, and industrial furnaces.

- Surface treatment and coating of nichrome: Various surface treatment and coating techniques are applied to nichrome to enhance its properties or protect it from environmental factors. These treatments can improve corrosion resistance, reduce oxidation, or modify the surface characteristics for specific applications. Examples include oxidation-resistant coatings and surface passivation techniques.

02 Manufacturing processes for nichrome components

Various manufacturing processes are employed to produce nichrome components, including wire drawing, thin film deposition, and powder metallurgy. These processes allow for the creation of nichrome elements in different forms such as wires, films, and powders, each suited for specific applications in electronics and heating systems.Expand Specific Solutions03 Applications in heating elements and resistors

Nichrome is widely used in the production of heating elements and resistors due to its high electrical resistance and heat-resistant properties. It is commonly found in household appliances, industrial heaters, and electronic devices where precise temperature control or electrical resistance is required.Expand Specific Solutions04 Use in thin film technology and sensors

Nichrome is utilized in thin film technology for the creation of precise resistive elements and sensors. These thin films are employed in various electronic applications, including temperature sensors, strain gauges, and microelectronic devices, where accurate and stable resistance values are crucial.Expand Specific Solutions05 Innovations in nichrome-based materials and coatings

Ongoing research and development efforts focus on improving nichrome-based materials and coatings. These innovations aim to enhance the alloy's properties, such as oxidation resistance, thermal stability, and electrical characteristics, for use in advanced applications in aerospace, energy, and electronics industries.Expand Specific Solutions

Key Nichrome Players

The development of sustainable heating solutions using Nichrome is in a growth phase, with increasing market demand driven by environmental concerns and energy efficiency requirements. The global market for advanced heating technologies is expanding, estimated to reach several billion dollars by 2025. While the technology is relatively mature, ongoing research focuses on improving efficiency and sustainability. Key players like Xi'an Thermal Power Research Institute, Yancheng Xinyang Electric Heating Material, and Sunamp Ltd. are actively innovating in this space. Established companies such as Arkema France SA and Kyocera Corp. are also contributing to advancements, leveraging their expertise in materials science and electronics to enhance Nichrome-based heating solutions.

Arkema France SA

Technical Solution: Arkema has developed innovative nichrome-based heating solutions that focus on sustainability. Their approach involves using advanced nichrome alloys with improved electrical resistance properties, allowing for more efficient heat generation[1]. The company has also implemented a thin-film deposition technique to create ultra-thin nichrome layers on various substrates, reducing material usage while maintaining heating performance[3]. Arkema's research has led to the development of nichrome-based heating elements with enhanced durability and corrosion resistance, extending the lifespan of heating systems and reducing waste[5]. Additionally, they have explored the integration of nichrome heating elements with smart control systems to optimize energy consumption in industrial and residential applications[7].

Strengths: Advanced alloy formulations, thin-film technology, improved durability, and smart integration. Weaknesses: Potentially higher initial costs, reliance on rare earth elements for some alloy compositions.

Kyocera Corp.

Technical Solution: Kyocera has made significant strides in developing sustainable heating solutions using nichrome technology. The company has focused on creating highly efficient nichrome heating elements for various applications, including automotive, industrial, and consumer electronics[2]. Kyocera's approach involves optimizing the nichrome wire composition and geometry to achieve rapid heating and uniform temperature distribution[4]. They have also developed a proprietary ceramic coating technology that enhances the thermal efficiency and longevity of nichrome heating elements[6]. In recent years, Kyocera has been working on integrating their nichrome heating solutions with renewable energy sources, such as solar power, to create more sustainable heating systems for residential and commercial use[8].

Strengths: Efficient heating element design, ceramic coating technology, integration with renewable energy. Weaknesses: Limited to specific application areas, potential scalability challenges for large-scale industrial use.

Nichrome Innovations

Electric heater and heat exchanger employing the same

PatentWO1985000084A1

Innovation

- A bare nichrome wire is immersed in silicone oil, which provides rapid temperature rise, excellent insulation, oxidation resistance, and durability, preventing oxidation and ensuring safety by using silicone oil with good thermal and electrical properties.

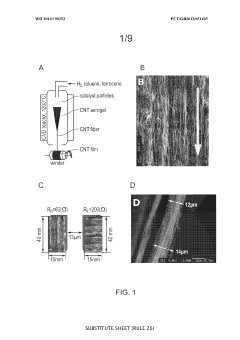

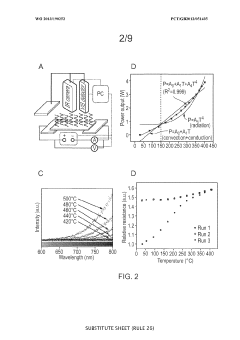

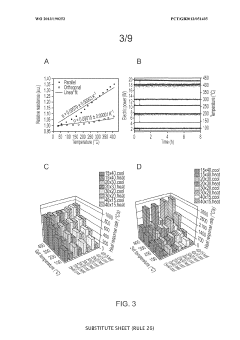

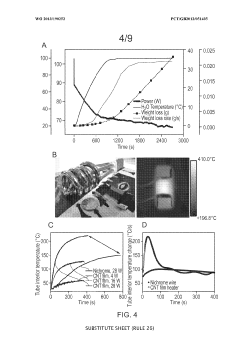

Heating using carbon nanotube-based heater elements

PatentWO2013190252A1

Innovation

- The use of aligned carbon nanotube layers for Joule heating, where the electrical current is passed perpendicular to the nanotube alignment, offering high resistivity and flexibility, enabling efficient heat generation and various applications.

Energy Efficiency Policies

Energy efficiency policies play a crucial role in shaping the development and adoption of sustainable heating solutions, including those utilizing Nichrome technology. These policies are designed to reduce energy consumption, minimize environmental impact, and promote the use of more efficient heating systems across various sectors.

At the national level, many countries have implemented stringent energy efficiency standards for heating appliances and systems. These standards often set minimum performance requirements for energy consumption, heat output, and overall efficiency. For Nichrome-based heating solutions, this has led to the development of more advanced control systems and improved heating element designs to meet or exceed these standards.

Incentive programs and tax credits have been introduced by governments to encourage the adoption of energy-efficient heating technologies. These financial incentives have stimulated research and development in Nichrome-based heating solutions, driving innovations in materials science and manufacturing processes to enhance the performance and longevity of heating elements.

Building codes and regulations have also been updated to incorporate energy efficiency requirements for heating systems. This has created a demand for more efficient Nichrome heating solutions in both residential and commercial applications. Manufacturers have responded by developing integrated heating systems that combine Nichrome elements with smart controls and insulation technologies to maximize energy efficiency.

The European Union's Ecodesign Directive has been particularly influential in shaping the market for energy-efficient heating products. This directive sets mandatory ecological requirements for energy-using and energy-related products sold in the EU. For Nichrome-based heating solutions, this has led to the development of more precise temperature control mechanisms and improved thermal management systems.

In the industrial sector, energy efficiency policies have driven the adoption of waste heat recovery systems and process optimization techniques. Nichrome heating elements have been integrated into these systems to improve overall energy efficiency in manufacturing processes. This has resulted in the development of specialized Nichrome alloys and configurations designed for high-temperature industrial applications.

Energy labeling schemes have also been implemented in many countries, providing consumers with clear information about the energy efficiency of heating appliances. This transparency has increased consumer awareness and demand for more efficient products, further driving innovation in Nichrome-based heating technologies.

As energy efficiency policies continue to evolve, they are likely to push for even greater advancements in Nichrome heating solutions. Future policies may focus on promoting the integration of renewable energy sources with electric heating systems, potentially leading to the development of hybrid systems that combine Nichrome heating elements with solar or geothermal technologies.

At the national level, many countries have implemented stringent energy efficiency standards for heating appliances and systems. These standards often set minimum performance requirements for energy consumption, heat output, and overall efficiency. For Nichrome-based heating solutions, this has led to the development of more advanced control systems and improved heating element designs to meet or exceed these standards.

Incentive programs and tax credits have been introduced by governments to encourage the adoption of energy-efficient heating technologies. These financial incentives have stimulated research and development in Nichrome-based heating solutions, driving innovations in materials science and manufacturing processes to enhance the performance and longevity of heating elements.

Building codes and regulations have also been updated to incorporate energy efficiency requirements for heating systems. This has created a demand for more efficient Nichrome heating solutions in both residential and commercial applications. Manufacturers have responded by developing integrated heating systems that combine Nichrome elements with smart controls and insulation technologies to maximize energy efficiency.

The European Union's Ecodesign Directive has been particularly influential in shaping the market for energy-efficient heating products. This directive sets mandatory ecological requirements for energy-using and energy-related products sold in the EU. For Nichrome-based heating solutions, this has led to the development of more precise temperature control mechanisms and improved thermal management systems.

In the industrial sector, energy efficiency policies have driven the adoption of waste heat recovery systems and process optimization techniques. Nichrome heating elements have been integrated into these systems to improve overall energy efficiency in manufacturing processes. This has resulted in the development of specialized Nichrome alloys and configurations designed for high-temperature industrial applications.

Energy labeling schemes have also been implemented in many countries, providing consumers with clear information about the energy efficiency of heating appliances. This transparency has increased consumer awareness and demand for more efficient products, further driving innovation in Nichrome-based heating technologies.

As energy efficiency policies continue to evolve, they are likely to push for even greater advancements in Nichrome heating solutions. Future policies may focus on promoting the integration of renewable energy sources with electric heating systems, potentially leading to the development of hybrid systems that combine Nichrome heating elements with solar or geothermal technologies.

Nichrome Recycling

Nichrome recycling plays a crucial role in developing sustainable heating solutions, addressing both environmental concerns and resource conservation. As the demand for efficient heating systems continues to grow, the importance of recycling nichrome, a key component in many heating elements, becomes increasingly apparent.

The recycling process for nichrome involves several steps, beginning with the collection of used or discarded heating elements containing the alloy. These elements are typically sourced from various appliances, industrial equipment, and electrical devices that have reached the end of their lifecycle. Once collected, the nichrome-containing components are separated from other materials through mechanical and chemical processes.

One of the primary methods for recycling nichrome involves melting the alloy in high-temperature furnaces. This process allows for the separation of nichrome from other metals and impurities. The molten nichrome can then be cast into ingots or formed into new wire or ribbon shapes, ready for use in manufacturing new heating elements. This recycling method not only conserves valuable resources but also reduces the energy consumption associated with producing new nichrome from raw materials.

Another innovative approach to nichrome recycling involves the use of advanced chemical extraction techniques. These methods allow for the selective recovery of nickel and chromium, the primary components of nichrome, from complex mixtures of materials. By using specific solvents and controlled reaction conditions, it is possible to achieve high purity levels in the recovered metals, making them suitable for reuse in high-performance heating applications.

The benefits of nichrome recycling extend beyond resource conservation. By reducing the need for primary nickel and chromium mining, recycling helps minimize the environmental impact associated with these activities. Additionally, the recycling process typically requires less energy compared to the production of new nichrome, contributing to overall energy savings and reduced carbon emissions in the heating industry.

Implementing effective nichrome recycling programs also presents economic advantages. As the prices of raw nickel and chromium fluctuate in global markets, recycling provides a more stable and potentially cost-effective source of these materials for manufacturers. This stability can help companies maintain competitive pricing for their heating products while adhering to sustainable practices.

However, challenges remain in optimizing nichrome recycling processes. The varying compositions of nichrome alloys used in different applications can complicate the recycling process, requiring sophisticated sorting and processing techniques. Additionally, ensuring the quality and consistency of recycled nichrome to meet the high standards required for heating elements presents ongoing technical challenges that researchers and industry professionals continue to address.

The recycling process for nichrome involves several steps, beginning with the collection of used or discarded heating elements containing the alloy. These elements are typically sourced from various appliances, industrial equipment, and electrical devices that have reached the end of their lifecycle. Once collected, the nichrome-containing components are separated from other materials through mechanical and chemical processes.

One of the primary methods for recycling nichrome involves melting the alloy in high-temperature furnaces. This process allows for the separation of nichrome from other metals and impurities. The molten nichrome can then be cast into ingots or formed into new wire or ribbon shapes, ready for use in manufacturing new heating elements. This recycling method not only conserves valuable resources but also reduces the energy consumption associated with producing new nichrome from raw materials.

Another innovative approach to nichrome recycling involves the use of advanced chemical extraction techniques. These methods allow for the selective recovery of nickel and chromium, the primary components of nichrome, from complex mixtures of materials. By using specific solvents and controlled reaction conditions, it is possible to achieve high purity levels in the recovered metals, making them suitable for reuse in high-performance heating applications.

The benefits of nichrome recycling extend beyond resource conservation. By reducing the need for primary nickel and chromium mining, recycling helps minimize the environmental impact associated with these activities. Additionally, the recycling process typically requires less energy compared to the production of new nichrome, contributing to overall energy savings and reduced carbon emissions in the heating industry.

Implementing effective nichrome recycling programs also presents economic advantages. As the prices of raw nickel and chromium fluctuate in global markets, recycling provides a more stable and potentially cost-effective source of these materials for manufacturers. This stability can help companies maintain competitive pricing for their heating products while adhering to sustainable practices.

However, challenges remain in optimizing nichrome recycling processes. The varying compositions of nichrome alloys used in different applications can complicate the recycling process, requiring sophisticated sorting and processing techniques. Additionally, ensuring the quality and consistency of recycled nichrome to meet the high standards required for heating elements presents ongoing technical challenges that researchers and industry professionals continue to address.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!