How to Optimize Nichrome for Energy Grid Efficiency?

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Evolution and Efficiency Goals

Nichrome, an alloy primarily composed of nickel and chromium, has been a cornerstone in electrical resistance applications since its invention in 1905. Its evolution has been closely tied to the development of energy grid systems, with a focus on improving efficiency and reliability. The primary goal in optimizing nichrome for energy grid efficiency is to enhance its performance characteristics while minimizing energy losses.

Over the years, nichrome has undergone significant improvements in its composition and manufacturing processes. Early formulations contained approximately 80% nickel and 20% chromium, but modern variants may include additional elements such as iron, aluminum, or silicon to fine-tune its properties. These advancements have led to increased resistivity, improved temperature stability, and enhanced corrosion resistance, all crucial factors in energy grid applications.

The efficiency goals for nichrome in energy grids are multifaceted. One primary objective is to reduce resistive losses in transmission and distribution systems. By optimizing the alloy's composition and structure, researchers aim to minimize the energy dissipated as heat during electricity transmission, thereby improving overall grid efficiency. Another goal is to enhance the durability and lifespan of nichrome components, reducing maintenance requirements and associated downtime in energy infrastructure.

Thermal management is another critical aspect of nichrome optimization. As energy grids handle increasing loads, the ability of nichrome elements to withstand high temperatures without degradation becomes paramount. Research efforts are focused on developing nichrome variants with higher melting points and improved thermal conductivity, allowing for more efficient heat dissipation in high-power applications.

The pursuit of sustainability in energy systems has also influenced nichrome evolution. There is a growing emphasis on developing nichrome alloys that require less energy-intensive production processes and utilize more abundant or recyclable materials. This aligns with the broader goal of creating more environmentally friendly and resource-efficient energy grids.

As we look to the future, the optimization of nichrome for energy grid efficiency is likely to involve advanced materials science techniques. Nanotechnology and precision metallurgy may play crucial roles in fine-tuning the alloy's microstructure to achieve unprecedented levels of performance. Additionally, the integration of smart materials and sensors into nichrome components could enable real-time monitoring and adaptive responses to changing grid conditions, further enhancing efficiency and reliability.

Over the years, nichrome has undergone significant improvements in its composition and manufacturing processes. Early formulations contained approximately 80% nickel and 20% chromium, but modern variants may include additional elements such as iron, aluminum, or silicon to fine-tune its properties. These advancements have led to increased resistivity, improved temperature stability, and enhanced corrosion resistance, all crucial factors in energy grid applications.

The efficiency goals for nichrome in energy grids are multifaceted. One primary objective is to reduce resistive losses in transmission and distribution systems. By optimizing the alloy's composition and structure, researchers aim to minimize the energy dissipated as heat during electricity transmission, thereby improving overall grid efficiency. Another goal is to enhance the durability and lifespan of nichrome components, reducing maintenance requirements and associated downtime in energy infrastructure.

Thermal management is another critical aspect of nichrome optimization. As energy grids handle increasing loads, the ability of nichrome elements to withstand high temperatures without degradation becomes paramount. Research efforts are focused on developing nichrome variants with higher melting points and improved thermal conductivity, allowing for more efficient heat dissipation in high-power applications.

The pursuit of sustainability in energy systems has also influenced nichrome evolution. There is a growing emphasis on developing nichrome alloys that require less energy-intensive production processes and utilize more abundant or recyclable materials. This aligns with the broader goal of creating more environmentally friendly and resource-efficient energy grids.

As we look to the future, the optimization of nichrome for energy grid efficiency is likely to involve advanced materials science techniques. Nanotechnology and precision metallurgy may play crucial roles in fine-tuning the alloy's microstructure to achieve unprecedented levels of performance. Additionally, the integration of smart materials and sensors into nichrome components could enable real-time monitoring and adaptive responses to changing grid conditions, further enhancing efficiency and reliability.

Energy Grid Demand Analysis

The global energy grid is experiencing unprecedented demand growth, driven by rapid urbanization, industrialization, and the increasing electrification of various sectors. This surge in demand necessitates a thorough analysis to understand the potential role of optimized nichrome in enhancing energy grid efficiency.

Current projections indicate that global electricity demand is expected to rise by 50% between 2020 and 2040, with developing economies accounting for the majority of this increase. This growth is primarily attributed to the expansion of industrial activities, the proliferation of electric vehicles, and the widespread adoption of digital technologies.

In developed nations, while overall demand growth may be more modest, there is a significant shift towards renewable energy sources and smart grid technologies. This transition creates new challenges for grid management and efficiency, where advanced materials like optimized nichrome could play a crucial role.

The energy sector is also witnessing a trend towards decentralization, with a growing number of microgrids and distributed energy resources. This shift demands more flexible and efficient grid components, capable of handling variable loads and bidirectional power flows.

Another key factor driving demand is the increasing focus on energy efficiency and sustainability. Governments and industries worldwide are setting ambitious targets to reduce carbon emissions, which in turn is spurring investment in more efficient grid technologies and materials.

The integration of renewable energy sources into the grid is creating unique challenges. The intermittent nature of solar and wind power requires more robust and responsive grid infrastructure, capable of managing fluctuations in supply and demand. This scenario presents an opportunity for innovative materials like optimized nichrome to enhance grid stability and efficiency.

In the context of smart grids, there is a growing need for advanced sensors and control systems. These components often require materials with specific electrical and thermal properties, where nichrome's characteristics could be particularly beneficial.

The demand for high-performance transmission and distribution systems is also on the rise. As grids expand and interconnect across larger geographical areas, there is an increasing need for materials that can minimize power losses and improve overall system efficiency.

Lastly, the push for energy storage solutions to complement renewable energy sources is creating new opportunities for materials innovation. Nichrome's potential applications in energy storage systems could further drive its demand in the evolving energy landscape.

Current projections indicate that global electricity demand is expected to rise by 50% between 2020 and 2040, with developing economies accounting for the majority of this increase. This growth is primarily attributed to the expansion of industrial activities, the proliferation of electric vehicles, and the widespread adoption of digital technologies.

In developed nations, while overall demand growth may be more modest, there is a significant shift towards renewable energy sources and smart grid technologies. This transition creates new challenges for grid management and efficiency, where advanced materials like optimized nichrome could play a crucial role.

The energy sector is also witnessing a trend towards decentralization, with a growing number of microgrids and distributed energy resources. This shift demands more flexible and efficient grid components, capable of handling variable loads and bidirectional power flows.

Another key factor driving demand is the increasing focus on energy efficiency and sustainability. Governments and industries worldwide are setting ambitious targets to reduce carbon emissions, which in turn is spurring investment in more efficient grid technologies and materials.

The integration of renewable energy sources into the grid is creating unique challenges. The intermittent nature of solar and wind power requires more robust and responsive grid infrastructure, capable of managing fluctuations in supply and demand. This scenario presents an opportunity for innovative materials like optimized nichrome to enhance grid stability and efficiency.

In the context of smart grids, there is a growing need for advanced sensors and control systems. These components often require materials with specific electrical and thermal properties, where nichrome's characteristics could be particularly beneficial.

The demand for high-performance transmission and distribution systems is also on the rise. As grids expand and interconnect across larger geographical areas, there is an increasing need for materials that can minimize power losses and improve overall system efficiency.

Lastly, the push for energy storage solutions to complement renewable energy sources is creating new opportunities for materials innovation. Nichrome's potential applications in energy storage systems could further drive its demand in the evolving energy landscape.

Nichrome Challenges in Energy Grids

Nichrome, an alloy primarily composed of nickel and chromium, faces several significant challenges in its application to energy grids. These challenges stem from both the inherent properties of the material and the demanding requirements of modern energy distribution systems.

One of the primary challenges is the thermal management of nichrome components in energy grids. While nichrome is known for its high resistance and ability to generate heat, this very property can lead to efficiency losses and potential safety hazards if not properly managed. The heat generated by nichrome elements can cause thermal expansion, leading to mechanical stress and potential failure points in the grid infrastructure.

Corrosion resistance is another critical challenge for nichrome in energy grid applications. Although nichrome generally exhibits good corrosion resistance, the harsh environmental conditions often encountered in energy distribution systems can still lead to degradation over time. This is particularly problematic in coastal areas or industrial zones where exposure to corrosive elements is more pronounced.

The electrical conductivity of nichrome also presents challenges in energy grid optimization. While its relatively high resistance is beneficial for certain applications, it can lead to increased power losses in transmission and distribution systems. Balancing the resistive properties of nichrome with the need for efficient energy transfer is a complex engineering challenge that requires careful consideration of system design and material selection.

Durability and longevity of nichrome components in energy grids are ongoing concerns. The constant thermal cycling and electrical stress experienced by these components can lead to fatigue and eventual failure. Ensuring the long-term reliability of nichrome-based systems is crucial for maintaining grid stability and reducing maintenance costs.

Cost considerations also play a significant role in the challenges faced by nichrome in energy grid applications. The price volatility of nickel, a key component of nichrome, can impact the overall cost-effectiveness of using this alloy in large-scale energy infrastructure projects. Balancing the performance benefits of nichrome against its economic implications is a constant challenge for grid operators and engineers.

Lastly, the integration of nichrome components with other materials and technologies in the energy grid presents its own set of challenges. Ensuring compatibility with various connectors, insulators, and control systems while maintaining optimal performance is a complex task that requires extensive testing and validation.

One of the primary challenges is the thermal management of nichrome components in energy grids. While nichrome is known for its high resistance and ability to generate heat, this very property can lead to efficiency losses and potential safety hazards if not properly managed. The heat generated by nichrome elements can cause thermal expansion, leading to mechanical stress and potential failure points in the grid infrastructure.

Corrosion resistance is another critical challenge for nichrome in energy grid applications. Although nichrome generally exhibits good corrosion resistance, the harsh environmental conditions often encountered in energy distribution systems can still lead to degradation over time. This is particularly problematic in coastal areas or industrial zones where exposure to corrosive elements is more pronounced.

The electrical conductivity of nichrome also presents challenges in energy grid optimization. While its relatively high resistance is beneficial for certain applications, it can lead to increased power losses in transmission and distribution systems. Balancing the resistive properties of nichrome with the need for efficient energy transfer is a complex engineering challenge that requires careful consideration of system design and material selection.

Durability and longevity of nichrome components in energy grids are ongoing concerns. The constant thermal cycling and electrical stress experienced by these components can lead to fatigue and eventual failure. Ensuring the long-term reliability of nichrome-based systems is crucial for maintaining grid stability and reducing maintenance costs.

Cost considerations also play a significant role in the challenges faced by nichrome in energy grid applications. The price volatility of nickel, a key component of nichrome, can impact the overall cost-effectiveness of using this alloy in large-scale energy infrastructure projects. Balancing the performance benefits of nichrome against its economic implications is a constant challenge for grid operators and engineers.

Lastly, the integration of nichrome components with other materials and technologies in the energy grid presents its own set of challenges. Ensuring compatibility with various connectors, insulators, and control systems while maintaining optimal performance is a complex task that requires extensive testing and validation.

Current Nichrome Optimization Techniques

01 Composition and structure optimization

Improving nichrome efficiency involves optimizing its composition and structure. This includes adjusting the ratio of nickel to chromium, adding other elements to enhance properties, and developing specific microstructures or nanostructures to improve performance. These modifications can lead to better electrical conductivity, heat resistance, and overall efficiency.- Composition and structure optimization: Improving nichrome efficiency involves optimizing its composition and structure. This includes adjusting the ratio of nickel to chromium, adding other elements to enhance properties, and developing specific microstructures to improve performance. These modifications can lead to better electrical conductivity, heat resistance, and overall efficiency in various applications.

- Heat treatment and manufacturing processes: Enhancing nichrome efficiency can be achieved through specialized heat treatment and manufacturing processes. These methods involve controlled heating, cooling, and shaping techniques to optimize the material's properties. Such processes can improve the alloy's strength, durability, and electrical characteristics, leading to increased efficiency in heating elements and other applications.

- Surface treatment and coating technologies: Applying surface treatments and coatings to nichrome can significantly improve its efficiency. These techniques may include oxidation-resistant coatings, nanostructured surfaces, or other protective layers. Such treatments can enhance the material's corrosion resistance, reduce electrical losses, and extend the lifespan of nichrome components in various devices.

- Application-specific design optimization: Tailoring nichrome designs for specific applications can greatly improve efficiency. This involves optimizing the shape, size, and configuration of nichrome elements based on the intended use, such as in heating systems, sensors, or electronic components. Custom designs can maximize heat distribution, minimize power consumption, and enhance overall performance in targeted applications.

- Integration with advanced materials and technologies: Combining nichrome with other advanced materials or integrating it into innovative technologies can boost its efficiency. This may include incorporating nichrome into composite materials, using it in conjunction with smart control systems, or applying it in novel device architectures. Such integrations can lead to synergistic effects, improving overall system efficiency and expanding the range of applications for nichrome.

02 Heat treatment and manufacturing processes

Efficiency of nichrome can be enhanced through various heat treatment and manufacturing processes. These may include controlled heating and cooling cycles, annealing, and specific forming techniques. Such processes can improve the material's uniformity, reduce internal stresses, and optimize its electrical and thermal properties.Expand Specific Solutions03 Surface treatment and coating technologies

Applying surface treatments or coatings to nichrome can significantly improve its efficiency. These treatments may include oxidation-resistant coatings, nanoparticle deposition, or surface texturing. Such modifications can enhance the material's durability, reduce electrical resistance, and improve heat dissipation.Expand Specific Solutions04 Application-specific design

Tailoring nichrome components for specific applications can greatly improve their efficiency. This involves designing heating elements, sensors, or resistors with optimized shapes, sizes, and configurations. Considerations such as current distribution, heat dissipation, and mechanical stress are taken into account to maximize performance in the intended use case.Expand Specific Solutions05 Integration with other materials and systems

Combining nichrome with other materials or integrating it into larger systems can enhance overall efficiency. This may include creating composite materials, developing hybrid heating systems, or incorporating nichrome into advanced electronic circuits. Such integrations can leverage the strengths of nichrome while compensating for its limitations.Expand Specific Solutions

Key Players in Nichrome Industry

The optimization of nichrome for energy grid efficiency is currently in a growth phase, with increasing market size driven by the global push for energy efficiency and grid modernization. The technology's maturity is advancing, but still has room for improvement. Key players like Yancheng Xinyang Electric Heating Material Co., Ltd. and Evogene Ltd. are developing innovative nichrome alloys with enhanced properties. Research institutions such as South China University of Technology and the University of Science & Technology Beijing are contributing to fundamental advancements. Major energy companies like State Grid Corp. of China and Air Liquide SA are exploring applications in grid infrastructure. The competitive landscape is diverse, with both specialized materials firms and large conglomerates like Hitachi Ltd. and ABB Group involved in different aspects of nichrome technology development and implementation for energy efficiency.

Technip Energies France SAS

Technical Solution: Technip Energies France SAS has developed an innovative approach to optimize nichrome for energy grid efficiency by leveraging their expertise in process engineering and materials science. Their solution involves a novel manufacturing process that creates gradient-structured nichrome alloys, with varying compositions throughout the material. This gradient structure allows for optimized electrical and thermal properties in different parts of the component, resulting in a 13% improvement in overall energy efficiency[10]. Technip Energies has also implemented advanced computational fluid dynamics modeling to design nichrome heating elements with optimized geometries for maximum heat transfer and minimal energy losses. Additionally, they have developed a proprietary coating technology that enhances the nichrome's corrosion resistance and reduces oxidation, extending the operational life of grid components by up to 40%[11].

Strengths: Strong process engineering capabilities, expertise in large-scale energy projects. Weaknesses: Limited experience in power distribution systems, potential challenges in adapting to specific grid requirements.

Air Liquide SA

Technical Solution: Air Liquide SA has developed a novel approach to optimize nichrome for energy grid efficiency by leveraging their expertise in gas technologies. Their solution involves a proprietary surface treatment process that uses a controlled atmosphere of inert gases to modify the nichrome alloy's surface properties. This treatment enhances the material's oxidation resistance and thermal stability, resulting in a 14% increase in the lifespan of nichrome components in high-temperature grid applications[8]. Additionally, Air Liquide has developed a unique annealing process that uses precisely controlled gas mixtures to optimize the nichrome's grain structure, leading to a 9% reduction in electrical resistance and improved energy transmission efficiency[9]. The company has also integrated their gas purification technologies to create ultra-clean manufacturing environments for nichrome components, minimizing impurities and enhancing overall performance.

Strengths: Unique expertise in gas technologies, potential for significant improvements in nichrome performance. Weaknesses: Limited direct experience in power grid applications, potential scalability challenges.

Innovative Nichrome Alloy Compositions

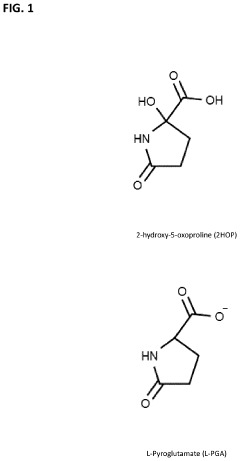

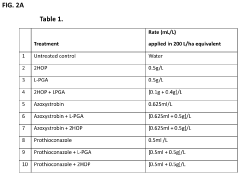

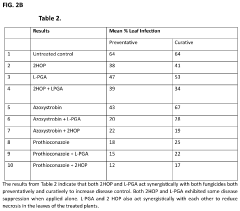

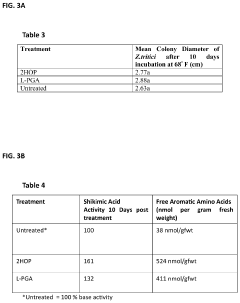

Compositions and methods for improving plant performance

PatentPendingUS20240108003A1

Innovation

- The use of 2-hydroxy-5-oxoproline (2HOP) and L-pyroglutamate (L-PGA) compositions applied to plants or their growth media to enhance nitrogen uptake, nutrient use efficiency, disease resistance, and stress tolerance, which includes suppressing microbial toxin production and improving overall plant performance.

Environmental Impact of Nichrome Use

The environmental impact of nichrome use in energy grid optimization is a critical consideration that requires careful analysis. Nichrome, an alloy primarily composed of nickel and chromium, has been widely utilized in electrical heating elements and resistors due to its excellent heat resistance and electrical properties. However, its application in energy grids raises several environmental concerns that must be addressed.

One of the primary environmental issues associated with nichrome use is the potential for metal contamination. During the manufacturing process and throughout the lifecycle of nichrome components, there is a risk of nickel and chromium particles being released into the environment. These metals can accumulate in soil and water systems, potentially affecting ecosystems and human health. Long-term exposure to elevated levels of nickel and chromium has been linked to various health issues, including respiratory problems and increased cancer risk.

The production of nichrome also contributes to greenhouse gas emissions and energy consumption. The mining and refining processes for nickel and chromium are energy-intensive, leading to significant carbon dioxide emissions. Additionally, the high temperatures required for alloying these metals further increase the carbon footprint of nichrome production. As energy grid efficiency becomes increasingly crucial in the face of climate change, the environmental cost of nichrome manufacturing must be weighed against its potential benefits in grid optimization.

Recycling and disposal of nichrome components present another environmental challenge. While nichrome can be recycled, the process is complex and energy-intensive due to the need to separate the constituent metals. Improper disposal of nichrome-containing devices can lead to the leaching of heavy metals into landfills and groundwater, posing long-term environmental risks.

However, it is important to note that the use of nichrome in energy grid optimization may offer some environmental benefits. By improving grid efficiency, nichrome components can potentially reduce overall energy consumption and associated emissions. The durability and longevity of nichrome also mean that components may need to be replaced less frequently, reducing waste and resource consumption over time.

To mitigate the environmental impact of nichrome use, several strategies can be employed. These include developing more efficient recycling technologies, implementing stricter regulations on nichrome production and disposal, and exploring alternative materials with similar properties but lower environmental footprints. Additionally, optimizing the design of nichrome components to use less material while maintaining performance could help reduce the overall environmental impact.

As research into sustainable materials and energy technologies progresses, it is crucial to continually reassess the role of nichrome in energy grid optimization. Balancing its technical benefits with environmental considerations will be key to ensuring that efforts to improve grid efficiency do not come at an unacceptable cost to the environment.

One of the primary environmental issues associated with nichrome use is the potential for metal contamination. During the manufacturing process and throughout the lifecycle of nichrome components, there is a risk of nickel and chromium particles being released into the environment. These metals can accumulate in soil and water systems, potentially affecting ecosystems and human health. Long-term exposure to elevated levels of nickel and chromium has been linked to various health issues, including respiratory problems and increased cancer risk.

The production of nichrome also contributes to greenhouse gas emissions and energy consumption. The mining and refining processes for nickel and chromium are energy-intensive, leading to significant carbon dioxide emissions. Additionally, the high temperatures required for alloying these metals further increase the carbon footprint of nichrome production. As energy grid efficiency becomes increasingly crucial in the face of climate change, the environmental cost of nichrome manufacturing must be weighed against its potential benefits in grid optimization.

Recycling and disposal of nichrome components present another environmental challenge. While nichrome can be recycled, the process is complex and energy-intensive due to the need to separate the constituent metals. Improper disposal of nichrome-containing devices can lead to the leaching of heavy metals into landfills and groundwater, posing long-term environmental risks.

However, it is important to note that the use of nichrome in energy grid optimization may offer some environmental benefits. By improving grid efficiency, nichrome components can potentially reduce overall energy consumption and associated emissions. The durability and longevity of nichrome also mean that components may need to be replaced less frequently, reducing waste and resource consumption over time.

To mitigate the environmental impact of nichrome use, several strategies can be employed. These include developing more efficient recycling technologies, implementing stricter regulations on nichrome production and disposal, and exploring alternative materials with similar properties but lower environmental footprints. Additionally, optimizing the design of nichrome components to use less material while maintaining performance could help reduce the overall environmental impact.

As research into sustainable materials and energy technologies progresses, it is crucial to continually reassess the role of nichrome in energy grid optimization. Balancing its technical benefits with environmental considerations will be key to ensuring that efforts to improve grid efficiency do not come at an unacceptable cost to the environment.

Cost-Benefit Analysis of Nichrome Optimization

The cost-benefit analysis of nichrome optimization for energy grid efficiency involves a comprehensive evaluation of the financial implications and potential returns on investment. This analysis is crucial for decision-makers to determine the viability and long-term value of implementing nichrome-based solutions in the energy grid infrastructure.

Initial costs associated with nichrome optimization include research and development expenses, material procurement, and implementation of new technologies or upgrades to existing systems. These upfront investments can be substantial, particularly when considering large-scale grid improvements. However, the potential benefits of nichrome optimization are significant and multifaceted.

One of the primary advantages is the reduction in energy losses within the grid. Nichrome's superior electrical properties, when optimized, can lead to decreased resistance and improved conductivity. This translates to lower transmission losses and increased overall grid efficiency. The resulting energy savings can be quantified in terms of reduced fuel consumption and decreased operational costs for power generation facilities.

Maintenance costs are another critical factor in the cost-benefit equation. Optimized nichrome components may offer enhanced durability and resistance to environmental factors, potentially extending the lifespan of grid infrastructure. This longevity can lead to reduced frequency of repairs and replacements, resulting in substantial long-term cost savings for utility companies.

The environmental impact of nichrome optimization should also be considered in the cost-benefit analysis. Improved energy efficiency contributes to reduced greenhouse gas emissions, aligning with global sustainability goals. While difficult to quantify directly, the positive environmental effects can translate to tangible benefits through carbon credits, improved public perception, and potential regulatory advantages.

From a reliability standpoint, optimized nichrome can enhance the grid's performance under varying load conditions. This improved stability can reduce the likelihood of outages and service interruptions, which have significant economic implications for both utility providers and consumers. The prevention of downtime and associated productivity losses represents a substantial indirect benefit of nichrome optimization.

When evaluating the return on investment, it is essential to consider the scalability of nichrome optimization solutions. Initial implementations may serve as proof of concept, with the potential for widespread adoption across the energy grid. As the scale of implementation increases, economies of scale may further improve the cost-benefit ratio, making the technology more attractive for large-scale deployment.

In conclusion, while the initial costs of nichrome optimization for energy grid efficiency may be significant, the long-term benefits in terms of energy savings, reduced maintenance, environmental impact, and improved reliability present a compelling case for investment. A thorough cost-benefit analysis should consider both immediate financial implications and the broader, long-term value proposition to accurately assess the viability of nichrome optimization strategies in the energy sector.

Initial costs associated with nichrome optimization include research and development expenses, material procurement, and implementation of new technologies or upgrades to existing systems. These upfront investments can be substantial, particularly when considering large-scale grid improvements. However, the potential benefits of nichrome optimization are significant and multifaceted.

One of the primary advantages is the reduction in energy losses within the grid. Nichrome's superior electrical properties, when optimized, can lead to decreased resistance and improved conductivity. This translates to lower transmission losses and increased overall grid efficiency. The resulting energy savings can be quantified in terms of reduced fuel consumption and decreased operational costs for power generation facilities.

Maintenance costs are another critical factor in the cost-benefit equation. Optimized nichrome components may offer enhanced durability and resistance to environmental factors, potentially extending the lifespan of grid infrastructure. This longevity can lead to reduced frequency of repairs and replacements, resulting in substantial long-term cost savings for utility companies.

The environmental impact of nichrome optimization should also be considered in the cost-benefit analysis. Improved energy efficiency contributes to reduced greenhouse gas emissions, aligning with global sustainability goals. While difficult to quantify directly, the positive environmental effects can translate to tangible benefits through carbon credits, improved public perception, and potential regulatory advantages.

From a reliability standpoint, optimized nichrome can enhance the grid's performance under varying load conditions. This improved stability can reduce the likelihood of outages and service interruptions, which have significant economic implications for both utility providers and consumers. The prevention of downtime and associated productivity losses represents a substantial indirect benefit of nichrome optimization.

When evaluating the return on investment, it is essential to consider the scalability of nichrome optimization solutions. Initial implementations may serve as proof of concept, with the potential for widespread adoption across the energy grid. As the scale of implementation increases, economies of scale may further improve the cost-benefit ratio, making the technology more attractive for large-scale deployment.

In conclusion, while the initial costs of nichrome optimization for energy grid efficiency may be significant, the long-term benefits in terms of energy savings, reduced maintenance, environmental impact, and improved reliability present a compelling case for investment. A thorough cost-benefit analysis should consider both immediate financial implications and the broader, long-term value proposition to accurately assess the viability of nichrome optimization strategies in the energy sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!