Nichrome: Key to Advanced Temperature Control Systems

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Evolution

Nichrome, an alloy primarily composed of nickel and chromium, has played a pivotal role in the evolution of advanced temperature control systems. Its journey from a simple heating element to a key component in sophisticated thermal management solutions spans over a century of technological progress.

The evolution of nichrome began in the early 1900s when Albert Marsh discovered the alloy's exceptional properties. Initially used in electrical heating elements, nichrome quickly gained popularity due to its high resistance to oxidation and ability to withstand high temperatures. This marked the first significant milestone in its development, laying the foundation for its widespread use in temperature control applications.

As industrial processes became more complex in the mid-20th century, the demand for precise temperature control grew exponentially. Nichrome's unique characteristics made it an ideal material for developing more accurate and responsive heating systems. During this period, researchers and engineers focused on optimizing the alloy's composition, experimenting with different ratios of nickel and chromium to enhance its performance characteristics.

The 1960s and 1970s saw a surge in the use of nichrome in aerospace and defense applications. Its ability to maintain stability under extreme conditions made it invaluable in the development of heat shields for spacecraft and high-performance aircraft. This period also witnessed the integration of nichrome into more sophisticated temperature control systems, incorporating feedback mechanisms and computerized controls.

The advent of microelectronics in the 1980s and 1990s brought about a new era for nichrome in temperature control. Miniaturization of heating elements allowed for the creation of highly precise and localized heating solutions. This development was particularly significant in the semiconductor industry, where precise temperature control is crucial for manufacturing processes.

In recent decades, the evolution of nichrome has been characterized by its integration with smart technologies. The rise of Internet of Things (IoT) and advanced sensors has led to the development of intelligent temperature control systems that can adapt in real-time to changing conditions. Nichrome-based heating elements are now often part of complex systems that include wireless connectivity, predictive maintenance capabilities, and energy optimization algorithms.

The ongoing evolution of nichrome continues to focus on enhancing its efficiency and expanding its applications. Research efforts are directed towards developing new alloy compositions that offer even greater temperature resistance and longevity. Additionally, there is a growing emphasis on making nichrome-based systems more environmentally friendly, aligning with global sustainability goals.

As we look to the future, the evolution of nichrome in temperature control systems is likely to be shaped by emerging technologies such as artificial intelligence and advanced materials science. These developments promise to further refine the precision and efficiency of temperature control, opening up new possibilities in fields ranging from industrial manufacturing to space exploration.

The evolution of nichrome began in the early 1900s when Albert Marsh discovered the alloy's exceptional properties. Initially used in electrical heating elements, nichrome quickly gained popularity due to its high resistance to oxidation and ability to withstand high temperatures. This marked the first significant milestone in its development, laying the foundation for its widespread use in temperature control applications.

As industrial processes became more complex in the mid-20th century, the demand for precise temperature control grew exponentially. Nichrome's unique characteristics made it an ideal material for developing more accurate and responsive heating systems. During this period, researchers and engineers focused on optimizing the alloy's composition, experimenting with different ratios of nickel and chromium to enhance its performance characteristics.

The 1960s and 1970s saw a surge in the use of nichrome in aerospace and defense applications. Its ability to maintain stability under extreme conditions made it invaluable in the development of heat shields for spacecraft and high-performance aircraft. This period also witnessed the integration of nichrome into more sophisticated temperature control systems, incorporating feedback mechanisms and computerized controls.

The advent of microelectronics in the 1980s and 1990s brought about a new era for nichrome in temperature control. Miniaturization of heating elements allowed for the creation of highly precise and localized heating solutions. This development was particularly significant in the semiconductor industry, where precise temperature control is crucial for manufacturing processes.

In recent decades, the evolution of nichrome has been characterized by its integration with smart technologies. The rise of Internet of Things (IoT) and advanced sensors has led to the development of intelligent temperature control systems that can adapt in real-time to changing conditions. Nichrome-based heating elements are now often part of complex systems that include wireless connectivity, predictive maintenance capabilities, and energy optimization algorithms.

The ongoing evolution of nichrome continues to focus on enhancing its efficiency and expanding its applications. Research efforts are directed towards developing new alloy compositions that offer even greater temperature resistance and longevity. Additionally, there is a growing emphasis on making nichrome-based systems more environmentally friendly, aligning with global sustainability goals.

As we look to the future, the evolution of nichrome in temperature control systems is likely to be shaped by emerging technologies such as artificial intelligence and advanced materials science. These developments promise to further refine the precision and efficiency of temperature control, opening up new possibilities in fields ranging from industrial manufacturing to space exploration.

Market Demand Analysis

The market demand for advanced temperature control systems utilizing Nichrome has been experiencing significant growth across various industries. This surge is primarily driven by the increasing need for precise temperature management in manufacturing processes, research laboratories, and high-tech applications.

In the industrial sector, there is a growing demand for temperature control systems that can maintain consistent and accurate temperatures in furnaces, ovens, and other heating equipment. Nichrome-based systems are particularly sought after due to their ability to provide rapid heating and cooling, as well as their durability in high-temperature environments. The automotive industry, for instance, requires advanced temperature control systems for engine testing, emissions control, and battery thermal management in electric vehicles.

The semiconductor industry is another major driver of market demand for Nichrome-based temperature control systems. As chip manufacturing processes become more complex and require tighter temperature tolerances, the need for precise temperature control has become paramount. Nichrome heating elements are essential in maintaining the exact temperatures needed for various stages of semiconductor fabrication, including wafer processing and packaging.

In the healthcare and life sciences sectors, there is an increasing demand for temperature control systems in medical devices, laboratory equipment, and pharmaceutical manufacturing. Nichrome-based systems are crucial in applications such as incubators, sterilizers, and analytical instruments where maintaining specific temperatures is critical for research outcomes and product quality.

The aerospace industry also contributes significantly to the market demand for advanced temperature control systems. Nichrome is used in aircraft de-icing systems, environmental control systems, and testing equipment for aerospace components. The ability of Nichrome-based systems to operate reliably in extreme conditions makes them indispensable in this sector.

Furthermore, the growing focus on energy efficiency and sustainability has led to increased demand for smart temperature control systems in building automation and HVAC applications. Nichrome-based systems are being integrated into smart thermostats and climate control units to provide more precise and energy-efficient heating solutions.

The global market for temperature control systems is expected to continue its upward trajectory, with a particular emphasis on systems that offer higher precision, faster response times, and improved energy efficiency. As industries continue to advance and require more sophisticated temperature management solutions, the demand for Nichrome-based systems is likely to remain strong in the foreseeable future.

In the industrial sector, there is a growing demand for temperature control systems that can maintain consistent and accurate temperatures in furnaces, ovens, and other heating equipment. Nichrome-based systems are particularly sought after due to their ability to provide rapid heating and cooling, as well as their durability in high-temperature environments. The automotive industry, for instance, requires advanced temperature control systems for engine testing, emissions control, and battery thermal management in electric vehicles.

The semiconductor industry is another major driver of market demand for Nichrome-based temperature control systems. As chip manufacturing processes become more complex and require tighter temperature tolerances, the need for precise temperature control has become paramount. Nichrome heating elements are essential in maintaining the exact temperatures needed for various stages of semiconductor fabrication, including wafer processing and packaging.

In the healthcare and life sciences sectors, there is an increasing demand for temperature control systems in medical devices, laboratory equipment, and pharmaceutical manufacturing. Nichrome-based systems are crucial in applications such as incubators, sterilizers, and analytical instruments where maintaining specific temperatures is critical for research outcomes and product quality.

The aerospace industry also contributes significantly to the market demand for advanced temperature control systems. Nichrome is used in aircraft de-icing systems, environmental control systems, and testing equipment for aerospace components. The ability of Nichrome-based systems to operate reliably in extreme conditions makes them indispensable in this sector.

Furthermore, the growing focus on energy efficiency and sustainability has led to increased demand for smart temperature control systems in building automation and HVAC applications. Nichrome-based systems are being integrated into smart thermostats and climate control units to provide more precise and energy-efficient heating solutions.

The global market for temperature control systems is expected to continue its upward trajectory, with a particular emphasis on systems that offer higher precision, faster response times, and improved energy efficiency. As industries continue to advance and require more sophisticated temperature management solutions, the demand for Nichrome-based systems is likely to remain strong in the foreseeable future.

Technical Challenges

Nichrome, a key component in advanced temperature control systems, faces several technical challenges that hinder its full potential in various applications. One of the primary issues is the material's limited temperature range. While nichrome can withstand high temperatures, it begins to degrade and lose its effectiveness at extremely elevated temperatures, typically above 1200°C. This limitation restricts its use in ultra-high temperature applications, such as aerospace and certain industrial processes.

Another significant challenge is the stability of nichrome's electrical resistance over time. As the material undergoes repeated heating and cooling cycles, its resistance can gradually change, affecting the precision of temperature control. This drift in resistance can lead to inaccuracies in temperature measurements and control, particularly in applications requiring high precision over extended periods.

The oxidation of nichrome at high temperatures presents another technical hurdle. When exposed to oxygen at elevated temperatures, nichrome forms a protective oxide layer. While this layer initially protects the material from further oxidation, it can grow thicker over time, altering the electrical and thermal properties of the nichrome element. This change can impact the overall performance and longevity of temperature control systems.

Thermal fatigue is an additional concern for nichrome-based systems. Repeated thermal cycling can lead to microscopic cracks and structural changes in the material, potentially causing failure in critical components. This issue is particularly problematic in applications with frequent temperature fluctuations or rapid heating and cooling cycles.

The manufacturing and processing of nichrome also present challenges. Achieving consistent composition and properties across different batches of nichrome can be difficult, leading to variations in performance between different heating elements or sensors. This inconsistency can complicate the design and calibration of precise temperature control systems.

Furthermore, the integration of nichrome into complex temperature control systems poses its own set of challenges. Ensuring uniform heating across large surfaces or intricate shapes requires careful design considerations. The electrical connections to nichrome elements must also be robust and resistant to high temperatures, adding complexity to system design and maintenance.

Lastly, the cost and availability of high-purity nichrome can be a limiting factor in some applications. As demand for advanced temperature control systems grows, ensuring a stable and cost-effective supply of high-quality nichrome becomes increasingly important. Balancing performance requirements with material costs remains an ongoing challenge for manufacturers and engineers in this field.

Another significant challenge is the stability of nichrome's electrical resistance over time. As the material undergoes repeated heating and cooling cycles, its resistance can gradually change, affecting the precision of temperature control. This drift in resistance can lead to inaccuracies in temperature measurements and control, particularly in applications requiring high precision over extended periods.

The oxidation of nichrome at high temperatures presents another technical hurdle. When exposed to oxygen at elevated temperatures, nichrome forms a protective oxide layer. While this layer initially protects the material from further oxidation, it can grow thicker over time, altering the electrical and thermal properties of the nichrome element. This change can impact the overall performance and longevity of temperature control systems.

Thermal fatigue is an additional concern for nichrome-based systems. Repeated thermal cycling can lead to microscopic cracks and structural changes in the material, potentially causing failure in critical components. This issue is particularly problematic in applications with frequent temperature fluctuations or rapid heating and cooling cycles.

The manufacturing and processing of nichrome also present challenges. Achieving consistent composition and properties across different batches of nichrome can be difficult, leading to variations in performance between different heating elements or sensors. This inconsistency can complicate the design and calibration of precise temperature control systems.

Furthermore, the integration of nichrome into complex temperature control systems poses its own set of challenges. Ensuring uniform heating across large surfaces or intricate shapes requires careful design considerations. The electrical connections to nichrome elements must also be robust and resistant to high temperatures, adding complexity to system design and maintenance.

Lastly, the cost and availability of high-purity nichrome can be a limiting factor in some applications. As demand for advanced temperature control systems grows, ensuring a stable and cost-effective supply of high-quality nichrome becomes increasingly important. Balancing performance requirements with material costs remains an ongoing challenge for manufacturers and engineers in this field.

Current Applications

01 Nichrome heating element design

Nichrome wire is commonly used as a heating element in temperature control systems. The design of the nichrome heating element, including its shape, thickness, and length, affects its resistance and heat distribution. Proper design ensures efficient and uniform heating, which is crucial for accurate temperature control in various applications.- Nichrome heating element design: Nichrome wire is commonly used as a heating element in temperature control systems. The design of the nichrome heating element, including its shape, thickness, and arrangement, plays a crucial role in achieving precise temperature control. Optimizing these factors can improve heat distribution and temperature stability.

- Temperature sensing and feedback mechanisms: Effective temperature control with nichrome elements often involves integrating temperature sensors and feedback mechanisms. These systems continuously monitor the temperature and adjust the power supplied to the nichrome element, ensuring accurate and responsive temperature regulation.

- Power supply and control circuits: Specialized power supply and control circuits are essential for managing the electrical current through nichrome heating elements. These circuits can include features such as pulse-width modulation (PWM) or proportional-integral-derivative (PID) control to achieve precise temperature regulation.

- Thermal insulation and heat distribution: Proper thermal insulation and heat distribution techniques are crucial when using nichrome for temperature control. This includes the selection of appropriate insulating materials and the design of heat-spreading components to ensure uniform temperature across the target area.

- Application-specific nichrome temperature control: Nichrome temperature control systems are adapted for various applications, such as laboratory equipment, industrial processes, and consumer electronics. Each application may require specific design considerations, such as miniaturization for portable devices or high-temperature capabilities for industrial use.

02 Temperature sensing and feedback mechanisms

Effective temperature control with nichrome elements often involves temperature sensing and feedback mechanisms. These systems use sensors to monitor the temperature and adjust the power supplied to the nichrome element accordingly. This closed-loop control allows for precise and stable temperature regulation in devices and processes.Expand Specific Solutions03 Power supply and current regulation

Controlling the temperature of nichrome elements requires careful management of power supply and current regulation. This involves using power controllers, voltage regulators, or pulse-width modulation (PWM) techniques to adjust the electrical input to the nichrome wire. Proper current regulation ensures accurate temperature control and prevents overheating.Expand Specific Solutions04 Insulation and heat dissipation

Effective insulation and heat dissipation are crucial in nichrome temperature control systems. Proper insulation helps maintain the desired temperature and prevents heat loss, while efficient heat dissipation mechanisms protect surrounding components from excessive heat. This balance is essential for the safety and efficiency of devices using nichrome heating elements.Expand Specific Solutions05 Application-specific temperature control

Nichrome temperature control systems are adapted for various specific applications, such as in laboratory equipment, industrial processes, and consumer devices. These adaptations may include specialized control algorithms, unique heating element configurations, or integration with other components to meet the specific temperature requirements of different applications.Expand Specific Solutions

Industry Leaders

The competitive landscape for Nichrome in advanced temperature control systems is characterized by a mature market with established players and ongoing technological advancements. The global market size for temperature control systems is substantial, driven by increasing demand across various industries. Companies like Gaona Aero Material Co., Ltd. and SAGE Electrochromics, Inc. are at the forefront of developing high-performance materials and smart glass technologies, respectively. Research institutions such as Xi'an Thermal Power Research Institute Co., Ltd. and The Israel Institute for Biological Research contribute to the field's technological progress. Major semiconductor equipment manufacturers like Lam Research Corp. and ASML Holding NV also play a significant role in advancing temperature control technologies for their specialized applications.

Lam Research Corp.

Technical Solution: Lam Research has developed a cutting-edge temperature control system leveraging nichrome technology for their semiconductor fabrication equipment. Their solution incorporates a network of ultra-thin nichrome filaments embedded within the wafer support platform, allowing for precise and responsive heating across the entire wafer surface. The company's system employs advanced machine learning algorithms to predict and compensate for temperature fluctuations, achieving temperature uniformity of ±0.5°C across 300mm wafers [5]. Lam's nichrome-based system also features a unique pulsed power delivery method that enhances energy efficiency and reduces thermal stress on components. Furthermore, they have integrated real-time temperature mapping capabilities using infrared sensors, enabling dynamic adjustments during processing [6].

Strengths: High-precision temperature control, energy-efficient operation, and advanced predictive capabilities for process optimization. Weaknesses: Complexity of the ML-driven control system may require specialized expertise for maintenance and troubleshooting.

ASML Holding NV

Technical Solution: ASML has incorporated nichrome-based temperature control systems into their advanced lithography equipment for semiconductor manufacturing. Their approach utilizes a network of nichrome heating elements strategically placed within the wafer stage and surrounding components. ASML's system achieves temperature stability of ±0.01°C, crucial for maintaining nanometer-scale accuracy in lithography processes [7]. The company has developed a proprietary control algorithm that compensates for thermal expansion effects in real-time, ensuring consistent imaging performance. Additionally, ASML's nichrome heating system is integrated with their immersion lithography technology, allowing for precise temperature management of the water medium used in the imaging process [8].

Strengths: Extremely high temperature stability, integrated thermal expansion compensation, and compatibility with advanced immersion lithography. Weaknesses: High system complexity may lead to increased costs and potential downtime for maintenance.

Key Innovations

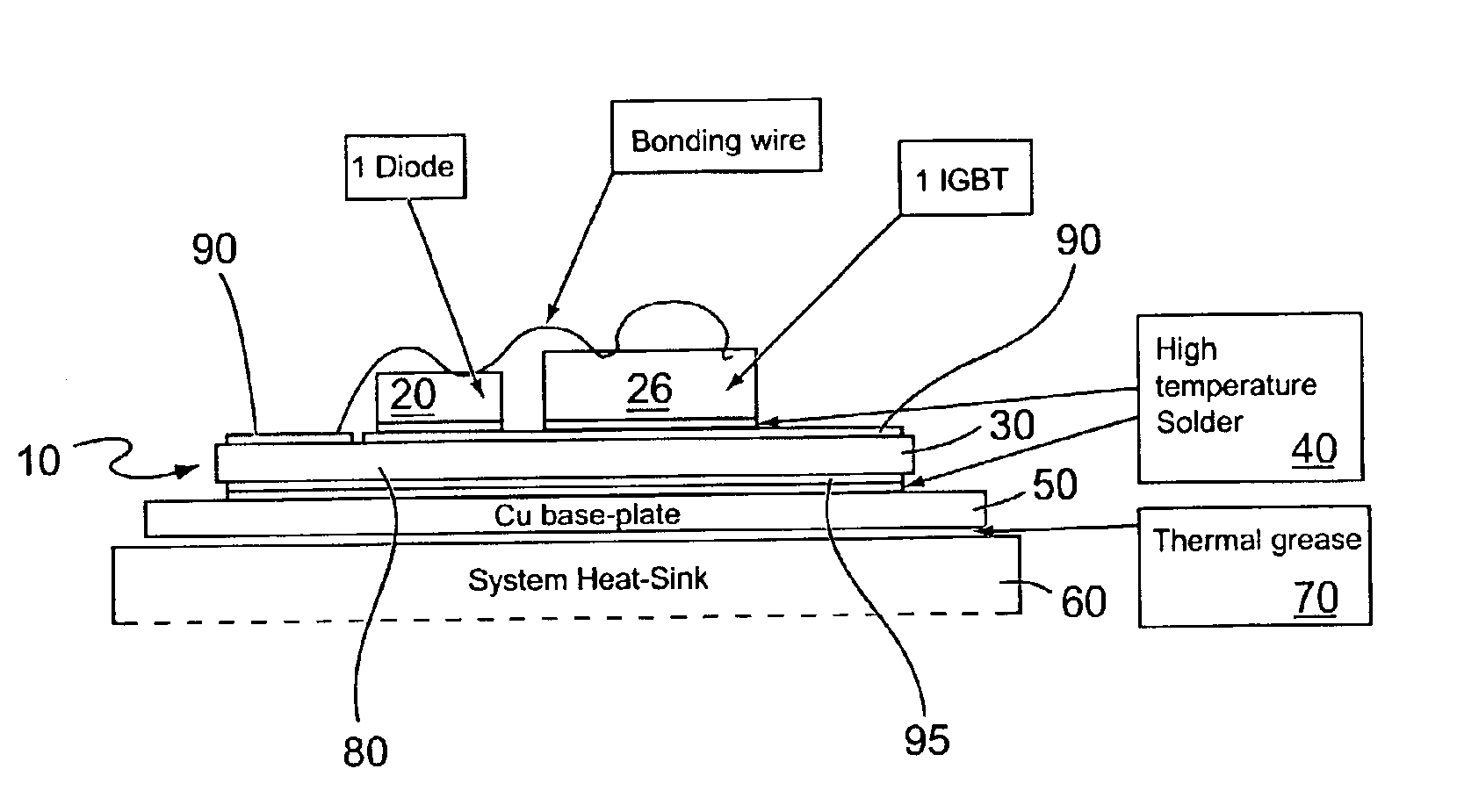

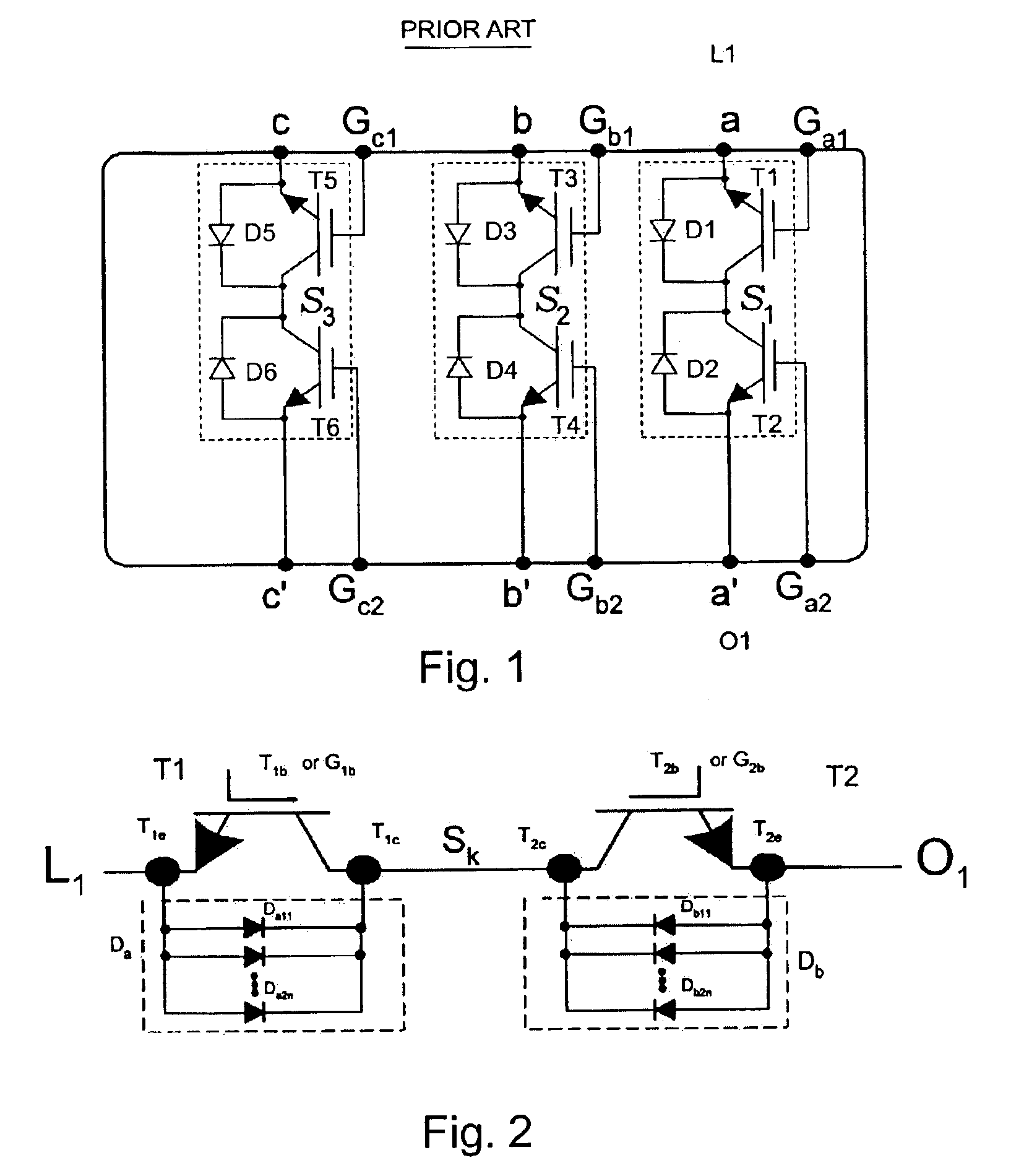

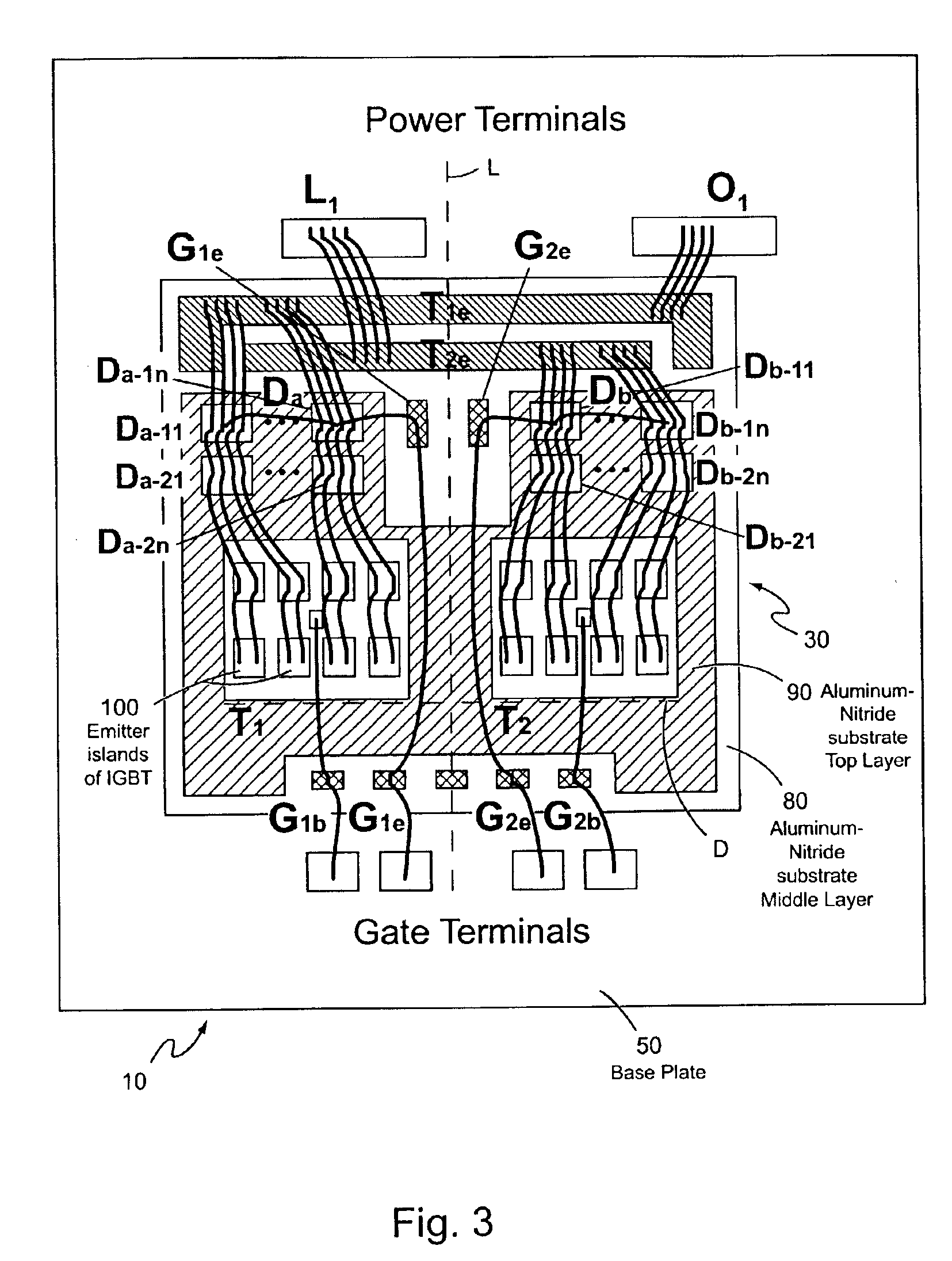

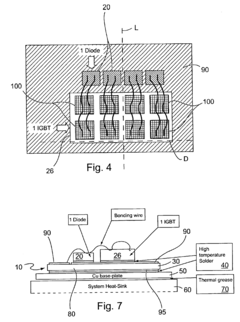

High-power, integrated AC switch module with distributed array of hybrid devices

PatentInactiveUS7034345B2

Innovation

- A high-power hybrid integrated four-quadrant AC switch module combining high-current trench gate non-punch through IGBTs with arrays of wide band-gap diodes, optimized for symmetrical circuit layout and heat dissipation, using advanced materials like aluminum nitride and copper tungsten alloy to manage high heat flux and thermal impedance.

Material Properties

Nichrome, an alloy primarily composed of nickel and chromium, exhibits exceptional material properties that make it indispensable in advanced temperature control systems. Its unique combination of high electrical resistivity and excellent oxidation resistance at elevated temperatures sets it apart from other materials. The electrical resistivity of nichrome remains relatively stable across a wide temperature range, typically varying by less than 10% between room temperature and 1000°C. This stability ensures consistent heat generation in temperature control applications.

The thermal conductivity of nichrome is relatively low compared to pure metals, which contributes to its efficiency in heating elements. This property allows for localized heating and precise temperature control. The specific heat capacity of nichrome is approximately 0.11 cal/g°C, enabling it to respond quickly to temperature changes and maintain thermal stability in control systems.

Nichrome's high melting point, around 1400°C, allows it to operate reliably at temperatures up to 1200°C without significant degradation. This characteristic is crucial for applications requiring sustained high-temperature performance. The alloy's coefficient of thermal expansion is approximately 17 × 10^-6 /°C, which is relatively low and helps minimize thermal stress in temperature control systems.

The mechanical properties of nichrome further enhance its suitability for temperature control applications. It maintains good strength and ductility at elevated temperatures, with a tensile strength ranging from 650 to 1000 MPa, depending on the specific composition and processing. This strength ensures the structural integrity of heating elements and sensors in demanding environments.

Nichrome's excellent oxidation resistance is attributed to the formation of a protective chromium oxide layer on its surface. This layer prevents further oxidation and extends the lifespan of components in high-temperature applications. The alloy's corrosion resistance in various chemical environments also contributes to its durability and reliability in diverse industrial settings.

The material's workability allows for the fabrication of thin wires, ribbons, and sheets, enabling the design of compact and efficient heating elements. This versatility in form factor is crucial for integrating nichrome into a wide range of temperature control systems, from precision laboratory equipment to large-scale industrial processes.

The thermal conductivity of nichrome is relatively low compared to pure metals, which contributes to its efficiency in heating elements. This property allows for localized heating and precise temperature control. The specific heat capacity of nichrome is approximately 0.11 cal/g°C, enabling it to respond quickly to temperature changes and maintain thermal stability in control systems.

Nichrome's high melting point, around 1400°C, allows it to operate reliably at temperatures up to 1200°C without significant degradation. This characteristic is crucial for applications requiring sustained high-temperature performance. The alloy's coefficient of thermal expansion is approximately 17 × 10^-6 /°C, which is relatively low and helps minimize thermal stress in temperature control systems.

The mechanical properties of nichrome further enhance its suitability for temperature control applications. It maintains good strength and ductility at elevated temperatures, with a tensile strength ranging from 650 to 1000 MPa, depending on the specific composition and processing. This strength ensures the structural integrity of heating elements and sensors in demanding environments.

Nichrome's excellent oxidation resistance is attributed to the formation of a protective chromium oxide layer on its surface. This layer prevents further oxidation and extends the lifespan of components in high-temperature applications. The alloy's corrosion resistance in various chemical environments also contributes to its durability and reliability in diverse industrial settings.

The material's workability allows for the fabrication of thin wires, ribbons, and sheets, enabling the design of compact and efficient heating elements. This versatility in form factor is crucial for integrating nichrome into a wide range of temperature control systems, from precision laboratory equipment to large-scale industrial processes.

Energy Efficiency

Nichrome's role in advanced temperature control systems significantly contributes to energy efficiency. The alloy's unique properties allow for precise and rapid heating, enabling systems to reach and maintain desired temperatures with minimal energy waste. This efficiency is particularly evident in industrial processes, where accurate temperature control is crucial for product quality and operational costs.

In heating elements, nichrome's high electrical resistance and thermal stability ensure consistent heat output over extended periods. This reliability reduces the need for frequent adjustments or replacements, thereby conserving energy that would otherwise be expended in system maintenance or compensating for performance degradation. The material's quick response to electrical current changes allows for dynamic temperature adjustments, optimizing energy use in variable-demand scenarios.

Nichrome-based systems often incorporate advanced control algorithms and sensors, further enhancing their energy efficiency. These intelligent systems can predict heating requirements, adjust power input in real-time, and minimize temperature overshoots. By preventing unnecessary heating cycles, they significantly reduce overall energy consumption.

In applications such as HVAC systems, nichrome elements enable zonal heating control. This targeted approach allows for heating specific areas as needed, rather than entire spaces, resulting in substantial energy savings in large buildings or industrial facilities. The precise control also helps maintain optimal comfort levels with minimal energy expenditure.

The durability of nichrome contributes to long-term energy efficiency. Its resistance to oxidation and corrosion at high temperatures ensures that heating systems maintain their performance characteristics over time. This longevity reduces the frequency of replacements and the associated energy costs of manufacturing and installing new components.

In the context of renewable energy integration, nichrome-based systems can efficiently convert excess electrical energy from intermittent sources like solar or wind into heat for storage or immediate use. This capability supports the broader goal of energy conservation by enabling more effective utilization of renewable resources.

As industries and households increasingly focus on reducing their carbon footprint, the energy efficiency provided by nichrome in temperature control systems becomes increasingly valuable. It not only contributes to cost savings but also aligns with global efforts to minimize energy consumption and mitigate climate change impacts.

In heating elements, nichrome's high electrical resistance and thermal stability ensure consistent heat output over extended periods. This reliability reduces the need for frequent adjustments or replacements, thereby conserving energy that would otherwise be expended in system maintenance or compensating for performance degradation. The material's quick response to electrical current changes allows for dynamic temperature adjustments, optimizing energy use in variable-demand scenarios.

Nichrome-based systems often incorporate advanced control algorithms and sensors, further enhancing their energy efficiency. These intelligent systems can predict heating requirements, adjust power input in real-time, and minimize temperature overshoots. By preventing unnecessary heating cycles, they significantly reduce overall energy consumption.

In applications such as HVAC systems, nichrome elements enable zonal heating control. This targeted approach allows for heating specific areas as needed, rather than entire spaces, resulting in substantial energy savings in large buildings or industrial facilities. The precise control also helps maintain optimal comfort levels with minimal energy expenditure.

The durability of nichrome contributes to long-term energy efficiency. Its resistance to oxidation and corrosion at high temperatures ensures that heating systems maintain their performance characteristics over time. This longevity reduces the frequency of replacements and the associated energy costs of manufacturing and installing new components.

In the context of renewable energy integration, nichrome-based systems can efficiently convert excess electrical energy from intermittent sources like solar or wind into heat for storage or immediate use. This capability supports the broader goal of energy conservation by enabling more effective utilization of renewable resources.

As industries and households increasingly focus on reducing their carbon footprint, the energy efficiency provided by nichrome in temperature control systems becomes increasingly valuable. It not only contributes to cost savings but also aligns with global efforts to minimize energy consumption and mitigate climate change impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!