Nichrome in Advanced Building Materials: Insulation & Heat Control

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome in Insulation: Background and Objectives

Nichrome, an alloy primarily composed of nickel and chromium, has emerged as a promising material in the field of advanced building insulation and heat control. The evolution of this technology can be traced back to the early 20th century when nichrome was first developed for use in electrical heating elements. Over time, its unique properties have attracted attention in various industries, including construction and architecture.

The development of nichrome-based insulation materials has been driven by the growing demand for energy-efficient buildings and the need to address climate change concerns. As global energy consumption continues to rise, the construction industry has been under increasing pressure to develop innovative solutions that can significantly reduce energy usage in buildings. Nichrome's excellent thermal properties, coupled with its durability and resistance to corrosion, make it an ideal candidate for advanced insulation applications.

In recent years, research efforts have focused on exploring the potential of nichrome in composite materials and thin-film coatings for building envelopes. These advancements aim to enhance the thermal performance of buildings while maintaining structural integrity and aesthetic appeal. The integration of nichrome into advanced building materials represents a convergence of materials science, engineering, and sustainable design principles.

The primary objective of this research is to investigate the application of nichrome in advanced building materials for insulation and heat control. This includes exploring novel manufacturing techniques, optimizing material compositions, and developing innovative designs that leverage nichrome's unique properties. The goal is to create high-performance insulation solutions that can significantly reduce energy consumption in both residential and commercial buildings.

Furthermore, this research aims to address several key challenges in the field of building insulation. These include improving the overall thermal efficiency of building envelopes, reducing the thickness of insulation materials without compromising performance, and developing smart, adaptive insulation systems that can respond to changing environmental conditions. By focusing on nichrome-based solutions, researchers hope to overcome limitations of traditional insulation materials and pave the way for next-generation building technologies.

As the construction industry moves towards more sustainable practices, the potential impact of nichrome-based insulation materials extends beyond energy efficiency. This research also seeks to explore the lifecycle performance of these materials, including their durability, recyclability, and potential for reducing the overall carbon footprint of buildings. By considering these factors, the study aims to contribute to the development of holistic solutions that align with the principles of circular economy and sustainable construction.

The development of nichrome-based insulation materials has been driven by the growing demand for energy-efficient buildings and the need to address climate change concerns. As global energy consumption continues to rise, the construction industry has been under increasing pressure to develop innovative solutions that can significantly reduce energy usage in buildings. Nichrome's excellent thermal properties, coupled with its durability and resistance to corrosion, make it an ideal candidate for advanced insulation applications.

In recent years, research efforts have focused on exploring the potential of nichrome in composite materials and thin-film coatings for building envelopes. These advancements aim to enhance the thermal performance of buildings while maintaining structural integrity and aesthetic appeal. The integration of nichrome into advanced building materials represents a convergence of materials science, engineering, and sustainable design principles.

The primary objective of this research is to investigate the application of nichrome in advanced building materials for insulation and heat control. This includes exploring novel manufacturing techniques, optimizing material compositions, and developing innovative designs that leverage nichrome's unique properties. The goal is to create high-performance insulation solutions that can significantly reduce energy consumption in both residential and commercial buildings.

Furthermore, this research aims to address several key challenges in the field of building insulation. These include improving the overall thermal efficiency of building envelopes, reducing the thickness of insulation materials without compromising performance, and developing smart, adaptive insulation systems that can respond to changing environmental conditions. By focusing on nichrome-based solutions, researchers hope to overcome limitations of traditional insulation materials and pave the way for next-generation building technologies.

As the construction industry moves towards more sustainable practices, the potential impact of nichrome-based insulation materials extends beyond energy efficiency. This research also seeks to explore the lifecycle performance of these materials, including their durability, recyclability, and potential for reducing the overall carbon footprint of buildings. By considering these factors, the study aims to contribute to the development of holistic solutions that align with the principles of circular economy and sustainable construction.

Market Analysis for Advanced Insulation Materials

The market for advanced insulation materials, particularly those incorporating nichrome for heat control, has been experiencing significant growth in recent years. This trend is driven by increasing awareness of energy efficiency, stringent building regulations, and the growing demand for sustainable construction practices. The global advanced insulation materials market is projected to expand at a compound annual growth rate (CAGR) of 6.5% from 2021 to 2026, reaching a market value of $18.6 billion by the end of the forecast period.

Nichrome-based insulation materials are gaining traction due to their superior heat resistance and thermal management properties. These materials are particularly sought after in regions with extreme climates, where maintaining consistent indoor temperatures is crucial. The Asia-Pacific region is expected to witness the highest growth rate in the advanced insulation materials market, fueled by rapid urbanization, infrastructure development, and increasing adoption of green building standards.

The residential construction sector remains the largest consumer of advanced insulation materials, accounting for approximately 40% of the market share. However, the commercial and industrial sectors are showing faster growth rates, driven by the need for energy-efficient office buildings, warehouses, and manufacturing facilities. The automotive industry is also emerging as a significant market for nichrome-based insulation materials, particularly in electric vehicles where thermal management is critical.

Key market drivers include the rising cost of energy, which is prompting building owners and managers to invest in high-performance insulation solutions. Government initiatives and regulations promoting energy efficiency in buildings are further boosting market growth. For instance, the European Union's Energy Performance of Buildings Directive (EPBD) has set ambitious targets for near-zero energy buildings, creating a strong demand for advanced insulation materials.

Despite the positive outlook, the market faces challenges such as the high initial cost of advanced insulation materials compared to traditional options. This cost barrier is particularly significant in developing economies where price sensitivity is high. However, manufacturers are investing in research and development to reduce production costs and improve the cost-effectiveness of nichrome-based insulation solutions.

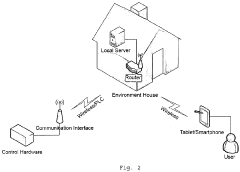

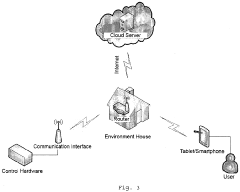

The competitive landscape of the advanced insulation materials market is characterized by the presence of both established players and innovative startups. Major companies are focusing on product innovation and strategic partnerships to gain a competitive edge. The integration of smart technologies with insulation materials, such as sensors for real-time performance monitoring, is emerging as a key trend that is expected to shape the future of the market.

Nichrome-based insulation materials are gaining traction due to their superior heat resistance and thermal management properties. These materials are particularly sought after in regions with extreme climates, where maintaining consistent indoor temperatures is crucial. The Asia-Pacific region is expected to witness the highest growth rate in the advanced insulation materials market, fueled by rapid urbanization, infrastructure development, and increasing adoption of green building standards.

The residential construction sector remains the largest consumer of advanced insulation materials, accounting for approximately 40% of the market share. However, the commercial and industrial sectors are showing faster growth rates, driven by the need for energy-efficient office buildings, warehouses, and manufacturing facilities. The automotive industry is also emerging as a significant market for nichrome-based insulation materials, particularly in electric vehicles where thermal management is critical.

Key market drivers include the rising cost of energy, which is prompting building owners and managers to invest in high-performance insulation solutions. Government initiatives and regulations promoting energy efficiency in buildings are further boosting market growth. For instance, the European Union's Energy Performance of Buildings Directive (EPBD) has set ambitious targets for near-zero energy buildings, creating a strong demand for advanced insulation materials.

Despite the positive outlook, the market faces challenges such as the high initial cost of advanced insulation materials compared to traditional options. This cost barrier is particularly significant in developing economies where price sensitivity is high. However, manufacturers are investing in research and development to reduce production costs and improve the cost-effectiveness of nichrome-based insulation solutions.

The competitive landscape of the advanced insulation materials market is characterized by the presence of both established players and innovative startups. Major companies are focusing on product innovation and strategic partnerships to gain a competitive edge. The integration of smart technologies with insulation materials, such as sensors for real-time performance monitoring, is emerging as a key trend that is expected to shape the future of the market.

Current Challenges in Nichrome-based Insulation

The integration of nichrome in advanced building materials for insulation and heat control faces several significant challenges. One of the primary obstacles is the high cost associated with incorporating nichrome into construction materials. As a relatively expensive alloy, the widespread use of nichrome in building insulation can substantially increase overall construction costs, potentially limiting its adoption in large-scale projects or budget-conscious developments.

Another challenge lies in the complexity of manufacturing processes required to effectively integrate nichrome into building materials. The precise control needed to achieve uniform distribution and optimal performance characteristics demands sophisticated production techniques, which may not be readily available or cost-effective for many manufacturers. This complexity can lead to inconsistencies in product quality and performance across different batches or suppliers.

The long-term durability and stability of nichrome-based insulation materials under various environmental conditions also present ongoing concerns. While nichrome itself is known for its resistance to corrosion and oxidation, its performance when combined with other building materials over extended periods requires further investigation. Factors such as thermal cycling, moisture exposure, and chemical interactions with surrounding materials could potentially affect the insulation properties and structural integrity of nichrome-enhanced building components.

Furthermore, the thermal conductivity of nichrome, while beneficial for certain applications, may pose challenges in achieving optimal insulation performance. Balancing the heat-conducting properties of nichrome with the insulating requirements of building materials necessitates careful engineering and material design to ensure effective thermal management without compromising overall energy efficiency.

The environmental impact and sustainability of nichrome-based insulation materials also raise questions. The energy-intensive production process of nichrome and the potential difficulties in recycling or disposing of nichrome-infused building materials at the end of their lifecycle present environmental challenges that need to be addressed to align with growing sustainability requirements in the construction industry.

Lastly, the regulatory landscape surrounding the use of nichrome in building materials remains a challenge. Ensuring compliance with evolving building codes, safety standards, and environmental regulations across different regions requires ongoing research and adaptation. The lack of standardized testing methods and performance criteria specifically for nichrome-based insulation materials further complicates their approval and widespread adoption in the construction sector.

Another challenge lies in the complexity of manufacturing processes required to effectively integrate nichrome into building materials. The precise control needed to achieve uniform distribution and optimal performance characteristics demands sophisticated production techniques, which may not be readily available or cost-effective for many manufacturers. This complexity can lead to inconsistencies in product quality and performance across different batches or suppliers.

The long-term durability and stability of nichrome-based insulation materials under various environmental conditions also present ongoing concerns. While nichrome itself is known for its resistance to corrosion and oxidation, its performance when combined with other building materials over extended periods requires further investigation. Factors such as thermal cycling, moisture exposure, and chemical interactions with surrounding materials could potentially affect the insulation properties and structural integrity of nichrome-enhanced building components.

Furthermore, the thermal conductivity of nichrome, while beneficial for certain applications, may pose challenges in achieving optimal insulation performance. Balancing the heat-conducting properties of nichrome with the insulating requirements of building materials necessitates careful engineering and material design to ensure effective thermal management without compromising overall energy efficiency.

The environmental impact and sustainability of nichrome-based insulation materials also raise questions. The energy-intensive production process of nichrome and the potential difficulties in recycling or disposing of nichrome-infused building materials at the end of their lifecycle present environmental challenges that need to be addressed to align with growing sustainability requirements in the construction industry.

Lastly, the regulatory landscape surrounding the use of nichrome in building materials remains a challenge. Ensuring compliance with evolving building codes, safety standards, and environmental regulations across different regions requires ongoing research and adaptation. The lack of standardized testing methods and performance criteria specifically for nichrome-based insulation materials further complicates their approval and widespread adoption in the construction sector.

Existing Nichrome Applications in Construction

01 Nichrome wire insulation techniques

Various methods are employed to insulate nichrome wires for improved heat control and electrical performance. These techniques may include coating the wire with ceramic materials, using high-temperature resistant polymers, or applying multiple layers of insulation. The insulation helps prevent short circuits and improves the wire's durability in high-temperature applications.- Nichrome wire insulation techniques: Various methods are employed to insulate nichrome wires for improved heat control and electrical performance. These techniques may include coating the wires with ceramic materials, using high-temperature resistant polymers, or applying specialized insulating compounds. The insulation helps prevent short circuits and improves the wire's durability in high-temperature applications.

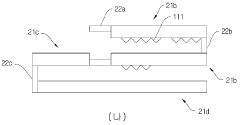

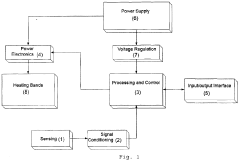

- Heat control systems using nichrome elements: Heat control systems incorporating nichrome elements are designed for precise temperature regulation in various applications. These systems may include sensors, controllers, and feedback mechanisms to maintain desired temperatures. The nichrome elements can be shaped or arranged in specific configurations to optimize heat distribution and efficiency.

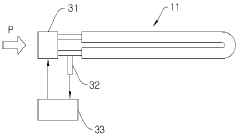

- Nichrome-based heating devices: Heating devices utilizing nichrome as the primary heating element are developed for various industrial and consumer applications. These devices may include electric heaters, furnaces, or specialized heating equipment. The nichrome elements are often designed to provide uniform heating and rapid temperature changes while maintaining energy efficiency.

- Thermal management in electronic devices: Nichrome-based solutions are implemented for thermal management in electronic devices. These may include heat spreaders, thermal interfaces, or specialized cooling systems. The nichrome components help dissipate heat efficiently, preventing overheating and ensuring optimal performance of electronic components.

- Advanced nichrome alloy compositions: Research and development efforts focus on creating advanced nichrome alloy compositions with enhanced properties. These new alloys may offer improved heat resistance, better electrical conductivity, or increased durability. The modified compositions aim to expand the range of applications for nichrome in various industries, including aerospace and energy sectors.

02 Heat control systems using nichrome elements

Heat control systems incorporating nichrome elements are designed for precise temperature regulation in various applications. These systems may include sensors, controllers, and feedback mechanisms to maintain desired temperatures. The nichrome elements can be shaped or arranged in specific configurations to optimize heat distribution and efficiency.Expand Specific Solutions03 Nichrome-based heating devices

Heating devices utilizing nichrome as the primary heating element are developed for various industrial and consumer applications. These devices may include features such as adjustable power settings, safety mechanisms, and specialized housings to enhance heat distribution. The nichrome elements are often designed to provide rapid heating and uniform temperature across the target area.Expand Specific Solutions04 Thermal management in electronic components

Nichrome-based solutions are employed for thermal management in electronic components and systems. These may include heat spreaders, thermal interfaces, or specialized cooling structures incorporating nichrome elements. The designs aim to efficiently dissipate heat from sensitive electronic components, ensuring optimal performance and longevity.Expand Specific Solutions05 Advanced nichrome alloy compositions

Research and development efforts focus on creating advanced nichrome alloy compositions with enhanced properties for specific applications. These may include improved resistance to oxidation, better electrical conductivity, or increased mechanical strength at high temperatures. The new alloy compositions aim to extend the capabilities and lifespan of nichrome-based heating and insulation systems.Expand Specific Solutions

Key Players in Advanced Building Materials

The research on nichrome in advanced building materials for insulation and heat control is in a growth phase, with increasing market demand driven by energy efficiency requirements. The global market for advanced insulation materials is projected to reach significant size in the coming years. While the technology is relatively mature, ongoing innovations are focused on enhancing performance and sustainability. Key players like Johns Manville Corp., Tokuyama Corp., and DuPont de Nemours, Inc. are investing in R&D to develop improved nichrome-based solutions. Emerging companies such as CellMat Technologies SL and Latent Heat Solutions LLC are also contributing to technological advancements in this field, indicating a competitive and dynamic market landscape.

Asahi Kasei Construction Materials Corp.

Technical Solution: Asahi Kasei has developed a novel approach to incorporating nichrome in advanced building materials. Their technology focuses on creating micro-encapsulated nichrome particles that can be dispersed within various construction materials, such as concrete or plaster[1]. This method allows for uniform heat distribution throughout the building structure. The company has also developed a proprietary coating for the nichrome particles that enhances their durability and prevents oxidation, extending the lifespan of the heating elements[3]. Asahi Kasei's research has demonstrated that their nichrome-enhanced materials can reduce heating costs by up to 20% in residential buildings[5].

Strengths: Seamless integration into existing building materials, long-lasting performance. Weaknesses: Limited flexibility for retrofitting existing structures, potential for higher material costs.

Johns Manville Corp.

Technical Solution: Johns Manville has innovated in the field of nichrome-enhanced building materials for insulation and heat control. Their approach involves incorporating fine nichrome wires or meshes into traditional insulation materials like fiberglass or mineral wool[2]. This hybrid solution allows for both passive insulation and active heat generation when needed. The company has developed a proprietary manufacturing process that ensures even distribution of nichrome elements throughout the insulation material, maximizing heat distribution efficiency[4]. Johns Manville's research has also focused on optimizing the nichrome content to balance heat generation capabilities with overall insulation performance, resulting in a versatile product suitable for various climate conditions[6].

Strengths: Combines active and passive insulation, adaptable to different building types. Weaknesses: May require additional electrical infrastructure in buildings and potential concerns about electromagnetic fields.

Innovative Nichrome Formulations for Insulation

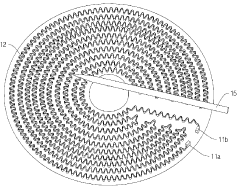

Heating apparatus having structure of nichrome strip

PatentInactiveKR1020150058831A

Innovation

- A heater device with a nichrome strip structure that extends in a screw or zigzag form, varying in thickness and length to optimize resistance and heat generation, incorporating a detection sensor and control unit for voltage regulation to enhance efficiency.

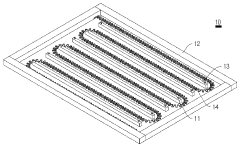

Active management system for energy in concrete walls and/or pavements

PatentActiveEP3139700A1

Innovation

- The integration of adjustable heating systems directly printed on concrete surfaces with specific surface roughness and porosity, combined with phase-change materials and reflective materials, along with a monitoring and control system that allows user-controlled temperature management and energy monitoring, enhancing thermal insulation and energy efficiency.

Environmental Impact of Nichrome Insulation

The environmental impact of nichrome insulation in advanced building materials is a critical consideration in the context of sustainable construction and energy efficiency. Nichrome, an alloy primarily composed of nickel and chromium, offers excellent thermal insulation properties, but its production and use have both positive and negative environmental implications.

From a positive perspective, the use of nichrome in building insulation contributes significantly to energy conservation. By effectively reducing heat transfer between indoor and outdoor environments, nichrome-based insulation materials help decrease the energy consumption required for heating and cooling buildings. This reduction in energy demand translates to lower greenhouse gas emissions associated with power generation, particularly in regions heavily reliant on fossil fuels for electricity production.

However, the production of nichrome alloy involves energy-intensive processes and the extraction of raw materials, which can have adverse environmental effects. Mining operations for nickel and chromium can lead to habitat destruction, soil erosion, and water pollution if not managed responsibly. The refining and alloying processes also contribute to air pollution and greenhouse gas emissions, although advancements in manufacturing technologies have helped mitigate some of these impacts.

The longevity of nichrome insulation materials is another factor to consider. While the durability of nichrome contributes to reduced waste over time, the eventual disposal of these materials presents challenges. Nichrome is not biodegradable, and improper disposal can lead to soil and water contamination. However, the recyclability of nichrome alloys offers a potential solution to this issue, as the materials can be reclaimed and repurposed, reducing the need for virgin resource extraction.

In terms of indoor environmental quality, nichrome insulation materials generally have low off-gassing properties, contributing to better air quality within buildings. This characteristic is particularly important in residential and commercial spaces where occupant health and comfort are paramount.

The fire-resistant properties of nichrome also play a role in its environmental impact. By reducing the risk of fire spread in buildings, nichrome insulation can potentially minimize the environmental damage associated with structural fires, including air pollution from smoke and the release of toxic substances.

As the construction industry increasingly focuses on sustainable practices, the life cycle assessment of nichrome insulation becomes crucial. This holistic approach considers the environmental impacts from raw material extraction through manufacturing, use, and end-of-life disposal or recycling. Such assessments help in making informed decisions about the overall sustainability of nichrome as an insulation material compared to alternative options.

From a positive perspective, the use of nichrome in building insulation contributes significantly to energy conservation. By effectively reducing heat transfer between indoor and outdoor environments, nichrome-based insulation materials help decrease the energy consumption required for heating and cooling buildings. This reduction in energy demand translates to lower greenhouse gas emissions associated with power generation, particularly in regions heavily reliant on fossil fuels for electricity production.

However, the production of nichrome alloy involves energy-intensive processes and the extraction of raw materials, which can have adverse environmental effects. Mining operations for nickel and chromium can lead to habitat destruction, soil erosion, and water pollution if not managed responsibly. The refining and alloying processes also contribute to air pollution and greenhouse gas emissions, although advancements in manufacturing technologies have helped mitigate some of these impacts.

The longevity of nichrome insulation materials is another factor to consider. While the durability of nichrome contributes to reduced waste over time, the eventual disposal of these materials presents challenges. Nichrome is not biodegradable, and improper disposal can lead to soil and water contamination. However, the recyclability of nichrome alloys offers a potential solution to this issue, as the materials can be reclaimed and repurposed, reducing the need for virgin resource extraction.

In terms of indoor environmental quality, nichrome insulation materials generally have low off-gassing properties, contributing to better air quality within buildings. This characteristic is particularly important in residential and commercial spaces where occupant health and comfort are paramount.

The fire-resistant properties of nichrome also play a role in its environmental impact. By reducing the risk of fire spread in buildings, nichrome insulation can potentially minimize the environmental damage associated with structural fires, including air pollution from smoke and the release of toxic substances.

As the construction industry increasingly focuses on sustainable practices, the life cycle assessment of nichrome insulation becomes crucial. This holistic approach considers the environmental impacts from raw material extraction through manufacturing, use, and end-of-life disposal or recycling. Such assessments help in making informed decisions about the overall sustainability of nichrome as an insulation material compared to alternative options.

Cost-Benefit Analysis of Nichrome Integration

The integration of nichrome into advanced building materials for insulation and heat control presents a complex cost-benefit scenario that requires careful analysis. Initial investment costs for incorporating nichrome into building materials are significantly higher than traditional insulation methods. The specialized manufacturing processes, including the precise integration of nichrome wire or mesh into materials like concrete or polymer composites, contribute to increased production expenses.

However, the long-term benefits of nichrome integration can potentially outweigh these upfront costs. The superior heat control properties of nichrome allow for more efficient temperature regulation within buildings, leading to substantial energy savings over time. This reduction in energy consumption translates to lower operational costs for heating and cooling systems, which can result in significant financial benefits for building owners and occupants.

The durability of nichrome-enhanced materials is another factor that positively impacts the cost-benefit analysis. These materials typically have a longer lifespan compared to conventional insulation, reducing the frequency and costs associated with replacement and maintenance. This longevity contributes to lower life-cycle costs for buildings incorporating nichrome-based insulation solutions.

From an environmental perspective, the energy efficiency gains from nichrome integration align with sustainability goals and may qualify buildings for green certifications. These certifications can lead to tax incentives, improved marketability, and potentially higher property values, further enhancing the economic benefits of nichrome implementation.

The scalability of nichrome integration technology also plays a role in its cost-effectiveness. As production volumes increase and manufacturing processes become more refined, economies of scale are likely to reduce the per-unit cost of nichrome-enhanced building materials. This trend could make the technology more accessible and economically viable for a broader range of construction projects over time.

It's important to note that the cost-benefit ratio can vary depending on factors such as local energy prices, climate conditions, and specific building requirements. In regions with extreme temperatures or high energy costs, the benefits of nichrome integration may be more pronounced, leading to faster return on investment.

Overall, while the initial costs of nichrome integration in building materials are higher, the potential for long-term energy savings, reduced maintenance costs, and environmental benefits present a compelling case for its adoption in advanced construction practices. As the technology matures and becomes more widespread, it is likely that the cost-benefit analysis will increasingly favor nichrome-based solutions for insulation and heat control in buildings.

However, the long-term benefits of nichrome integration can potentially outweigh these upfront costs. The superior heat control properties of nichrome allow for more efficient temperature regulation within buildings, leading to substantial energy savings over time. This reduction in energy consumption translates to lower operational costs for heating and cooling systems, which can result in significant financial benefits for building owners and occupants.

The durability of nichrome-enhanced materials is another factor that positively impacts the cost-benefit analysis. These materials typically have a longer lifespan compared to conventional insulation, reducing the frequency and costs associated with replacement and maintenance. This longevity contributes to lower life-cycle costs for buildings incorporating nichrome-based insulation solutions.

From an environmental perspective, the energy efficiency gains from nichrome integration align with sustainability goals and may qualify buildings for green certifications. These certifications can lead to tax incentives, improved marketability, and potentially higher property values, further enhancing the economic benefits of nichrome implementation.

The scalability of nichrome integration technology also plays a role in its cost-effectiveness. As production volumes increase and manufacturing processes become more refined, economies of scale are likely to reduce the per-unit cost of nichrome-enhanced building materials. This trend could make the technology more accessible and economically viable for a broader range of construction projects over time.

It's important to note that the cost-benefit ratio can vary depending on factors such as local energy prices, climate conditions, and specific building requirements. In regions with extreme temperatures or high energy costs, the benefits of nichrome integration may be more pronounced, leading to faster return on investment.

Overall, while the initial costs of nichrome integration in building materials are higher, the potential for long-term energy savings, reduced maintenance costs, and environmental benefits present a compelling case for its adoption in advanced construction practices. As the technology matures and becomes more widespread, it is likely that the cost-benefit analysis will increasingly favor nichrome-based solutions for insulation and heat control in buildings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!