Nichrome in Renewable Technologies: Driving Energy Efficiency

JUL 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome in Renewables: Evolution and Objectives

Nichrome, an alloy primarily composed of nickel and chromium, has played a significant role in the evolution of renewable energy technologies. Its journey in this sector began in the mid-20th century when researchers recognized its potential for high-temperature applications. The alloy's exceptional resistance to oxidation and corrosion, coupled with its ability to maintain structural integrity at elevated temperatures, made it an ideal candidate for various renewable energy systems.

The evolution of nichrome in renewable technologies can be traced through several key phases. Initially, it found applications in solar thermal systems, where it was used in heat exchangers and absorber tubes. As solar energy technologies advanced, nichrome's role expanded to include concentrated solar power (CSP) systems, where it became a crucial component in receiver tubes and heat transfer fluid pipes.

In the wind energy sector, nichrome's evolution took a different path. Its high electrical resistivity and temperature stability made it valuable in the manufacturing of heating elements for de-icing systems in wind turbine blades. This application became increasingly important as wind farms expanded into colder regions, where ice accumulation on turbine blades posed significant operational challenges.

The geothermal energy industry also benefited from nichrome's unique properties. As geothermal power plants evolved to harness higher temperature resources, nichrome alloys found applications in heat exchangers and piping systems, where they could withstand the corrosive and high-temperature environments typical of geothermal fluids.

More recently, nichrome has been at the forefront of advancements in fuel cell technology, particularly in solid oxide fuel cells (SOFCs). Its ability to withstand high temperatures and resist oxidation makes it an excellent material for interconnects and electrode supports in these advanced energy conversion devices.

The primary objective of nichrome in renewable technologies has consistently been to enhance energy efficiency and system reliability. By enabling components to operate at higher temperatures and in more challenging environments, nichrome has contributed to improving the overall performance and durability of renewable energy systems.

Looking forward, the objectives for nichrome in renewable technologies are multifaceted. There is a growing focus on developing new nichrome-based alloys with even higher temperature capabilities and improved resistance to extreme environments. Additionally, researchers are exploring ways to optimize nichrome's properties for specific renewable energy applications, such as tailoring its composition for enhanced performance in next-generation solar receivers or advanced geothermal systems.

Another key objective is to improve the cost-effectiveness of nichrome-based components, making renewable energy technologies more economically viable. This includes efforts to develop more efficient manufacturing processes and to explore alternative alloying elements that could provide similar properties at a lower cost.

The evolution of nichrome in renewable technologies can be traced through several key phases. Initially, it found applications in solar thermal systems, where it was used in heat exchangers and absorber tubes. As solar energy technologies advanced, nichrome's role expanded to include concentrated solar power (CSP) systems, where it became a crucial component in receiver tubes and heat transfer fluid pipes.

In the wind energy sector, nichrome's evolution took a different path. Its high electrical resistivity and temperature stability made it valuable in the manufacturing of heating elements for de-icing systems in wind turbine blades. This application became increasingly important as wind farms expanded into colder regions, where ice accumulation on turbine blades posed significant operational challenges.

The geothermal energy industry also benefited from nichrome's unique properties. As geothermal power plants evolved to harness higher temperature resources, nichrome alloys found applications in heat exchangers and piping systems, where they could withstand the corrosive and high-temperature environments typical of geothermal fluids.

More recently, nichrome has been at the forefront of advancements in fuel cell technology, particularly in solid oxide fuel cells (SOFCs). Its ability to withstand high temperatures and resist oxidation makes it an excellent material for interconnects and electrode supports in these advanced energy conversion devices.

The primary objective of nichrome in renewable technologies has consistently been to enhance energy efficiency and system reliability. By enabling components to operate at higher temperatures and in more challenging environments, nichrome has contributed to improving the overall performance and durability of renewable energy systems.

Looking forward, the objectives for nichrome in renewable technologies are multifaceted. There is a growing focus on developing new nichrome-based alloys with even higher temperature capabilities and improved resistance to extreme environments. Additionally, researchers are exploring ways to optimize nichrome's properties for specific renewable energy applications, such as tailoring its composition for enhanced performance in next-generation solar receivers or advanced geothermal systems.

Another key objective is to improve the cost-effectiveness of nichrome-based components, making renewable energy technologies more economically viable. This includes efforts to develop more efficient manufacturing processes and to explore alternative alloying elements that could provide similar properties at a lower cost.

Market Demand for Energy-Efficient Solutions

The global market for energy-efficient solutions has experienced significant growth in recent years, driven by increasing awareness of climate change, rising energy costs, and stringent government regulations. This trend has created a substantial demand for technologies that can improve energy efficiency across various sectors, including renewable energy generation, industrial processes, and consumer applications.

In the renewable energy sector, there is a growing need for materials and components that can enhance the performance and efficiency of energy generation systems. Nichrome, an alloy of nickel and chromium, has emerged as a promising material in this context due to its unique properties. The demand for nichrome in renewable technologies is primarily fueled by its high electrical resistivity, excellent heat resistance, and corrosion resistance.

Solar energy, one of the fastest-growing renewable energy sources, has seen a surge in demand for nichrome-based components. Nichrome is used in the manufacturing of thin-film solar cells, where it serves as a crucial element in the electrode structure. The material's ability to withstand high temperatures and maintain stability under harsh environmental conditions makes it ideal for improving the longevity and efficiency of solar panels.

In wind energy applications, nichrome finds use in the production of heating elements for de-icing systems in wind turbine blades. As wind farms expand into colder regions, the need for effective de-icing solutions becomes critical to maintain optimal energy production. Nichrome's superior heat generation properties make it an excellent choice for these systems, driving its demand in the wind energy sector.

The geothermal energy industry also presents a significant market opportunity for nichrome-based solutions. The material's corrosion resistance and ability to perform under high-temperature conditions make it suitable for use in geothermal power plant components, such as heat exchangers and piping systems.

Beyond renewable energy generation, there is a growing demand for nichrome in energy storage technologies. As the integration of renewable energy sources into the grid increases, the need for efficient and reliable energy storage solutions becomes paramount. Nichrome is being explored for use in advanced battery technologies and thermal energy storage systems, where its unique properties can contribute to improved performance and longevity.

The industrial sector represents another significant market for nichrome-based energy-efficient solutions. In manufacturing processes that require precise temperature control, nichrome heating elements are in high demand due to their ability to provide uniform and efficient heating. This application extends to industries such as automotive, aerospace, and electronics manufacturing, where energy efficiency is a key factor in reducing operational costs and meeting sustainability goals.

As governments worldwide implement stricter energy efficiency standards and offer incentives for adopting energy-saving technologies, the market for nichrome-based solutions is expected to expand further. This regulatory environment, coupled with the increasing focus on sustainable practices in the corporate world, is likely to drive continued innovation and adoption of nichrome technologies in the pursuit of greater energy efficiency across various sectors.

In the renewable energy sector, there is a growing need for materials and components that can enhance the performance and efficiency of energy generation systems. Nichrome, an alloy of nickel and chromium, has emerged as a promising material in this context due to its unique properties. The demand for nichrome in renewable technologies is primarily fueled by its high electrical resistivity, excellent heat resistance, and corrosion resistance.

Solar energy, one of the fastest-growing renewable energy sources, has seen a surge in demand for nichrome-based components. Nichrome is used in the manufacturing of thin-film solar cells, where it serves as a crucial element in the electrode structure. The material's ability to withstand high temperatures and maintain stability under harsh environmental conditions makes it ideal for improving the longevity and efficiency of solar panels.

In wind energy applications, nichrome finds use in the production of heating elements for de-icing systems in wind turbine blades. As wind farms expand into colder regions, the need for effective de-icing solutions becomes critical to maintain optimal energy production. Nichrome's superior heat generation properties make it an excellent choice for these systems, driving its demand in the wind energy sector.

The geothermal energy industry also presents a significant market opportunity for nichrome-based solutions. The material's corrosion resistance and ability to perform under high-temperature conditions make it suitable for use in geothermal power plant components, such as heat exchangers and piping systems.

Beyond renewable energy generation, there is a growing demand for nichrome in energy storage technologies. As the integration of renewable energy sources into the grid increases, the need for efficient and reliable energy storage solutions becomes paramount. Nichrome is being explored for use in advanced battery technologies and thermal energy storage systems, where its unique properties can contribute to improved performance and longevity.

The industrial sector represents another significant market for nichrome-based energy-efficient solutions. In manufacturing processes that require precise temperature control, nichrome heating elements are in high demand due to their ability to provide uniform and efficient heating. This application extends to industries such as automotive, aerospace, and electronics manufacturing, where energy efficiency is a key factor in reducing operational costs and meeting sustainability goals.

As governments worldwide implement stricter energy efficiency standards and offer incentives for adopting energy-saving technologies, the market for nichrome-based solutions is expected to expand further. This regulatory environment, coupled with the increasing focus on sustainable practices in the corporate world, is likely to drive continued innovation and adoption of nichrome technologies in the pursuit of greater energy efficiency across various sectors.

Current State and Challenges of Nichrome Applications

Nichrome, an alloy primarily composed of nickel and chromium, has gained significant traction in renewable energy technologies due to its unique properties. The current state of nichrome applications in this field is characterized by both promising advancements and notable challenges.

In solar energy systems, nichrome is widely used in the production of thin-film photovoltaic cells. Its high electrical resistance and thermal stability make it an ideal material for the conductive layers in these cells. However, the efficiency of nichrome-based thin-film solar cells still lags behind traditional silicon-based cells, presenting a significant challenge for widespread adoption.

Wind energy applications have also embraced nichrome, particularly in the manufacturing of heating elements for de-icing systems in wind turbine blades. These systems are crucial for maintaining optimal performance in cold climates. The main challenge here lies in optimizing the power consumption of these heating elements without compromising their effectiveness.

In the realm of energy storage, nichrome plays a role in the development of advanced battery technologies. Its corrosion resistance and high-temperature stability make it suitable for use in certain types of flow batteries and high-temperature sodium-sulfur batteries. However, the high cost of nichrome compared to alternative materials poses a challenge to large-scale implementation.

Fuel cell technology is another area where nichrome finds application, particularly in solid oxide fuel cells (SOFCs). The alloy's resistance to oxidation at high temperatures makes it valuable for interconnects and other components. Yet, researchers are still grappling with issues related to long-term stability and performance degradation in these systems.

The geothermal energy sector utilizes nichrome in heating elements for geothermal heat pumps. While effective, the challenge lies in improving the longevity of these elements in the corrosive environments often associated with geothermal applications.

One of the overarching challenges across all these applications is the need for more sustainable and cost-effective production methods for nichrome. Current manufacturing processes are energy-intensive and contribute to significant carbon emissions, which somewhat contradicts the green objectives of renewable energy technologies.

Additionally, the global supply chain for nickel and chromium, the primary components of nichrome, faces potential disruptions due to geopolitical factors and increasing demand. This situation necessitates the development of alternative alloys or more efficient use of existing nichrome resources.

In conclusion, while nichrome has proven its worth in various renewable energy applications, significant challenges remain in terms of efficiency improvements, cost reduction, and sustainability of production. Overcoming these hurdles will be crucial for the continued integration of nichrome in the drive towards more efficient and sustainable energy technologies.

In solar energy systems, nichrome is widely used in the production of thin-film photovoltaic cells. Its high electrical resistance and thermal stability make it an ideal material for the conductive layers in these cells. However, the efficiency of nichrome-based thin-film solar cells still lags behind traditional silicon-based cells, presenting a significant challenge for widespread adoption.

Wind energy applications have also embraced nichrome, particularly in the manufacturing of heating elements for de-icing systems in wind turbine blades. These systems are crucial for maintaining optimal performance in cold climates. The main challenge here lies in optimizing the power consumption of these heating elements without compromising their effectiveness.

In the realm of energy storage, nichrome plays a role in the development of advanced battery technologies. Its corrosion resistance and high-temperature stability make it suitable for use in certain types of flow batteries and high-temperature sodium-sulfur batteries. However, the high cost of nichrome compared to alternative materials poses a challenge to large-scale implementation.

Fuel cell technology is another area where nichrome finds application, particularly in solid oxide fuel cells (SOFCs). The alloy's resistance to oxidation at high temperatures makes it valuable for interconnects and other components. Yet, researchers are still grappling with issues related to long-term stability and performance degradation in these systems.

The geothermal energy sector utilizes nichrome in heating elements for geothermal heat pumps. While effective, the challenge lies in improving the longevity of these elements in the corrosive environments often associated with geothermal applications.

One of the overarching challenges across all these applications is the need for more sustainable and cost-effective production methods for nichrome. Current manufacturing processes are energy-intensive and contribute to significant carbon emissions, which somewhat contradicts the green objectives of renewable energy technologies.

Additionally, the global supply chain for nickel and chromium, the primary components of nichrome, faces potential disruptions due to geopolitical factors and increasing demand. This situation necessitates the development of alternative alloys or more efficient use of existing nichrome resources.

In conclusion, while nichrome has proven its worth in various renewable energy applications, significant challenges remain in terms of efficiency improvements, cost reduction, and sustainability of production. Overcoming these hurdles will be crucial for the continued integration of nichrome in the drive towards more efficient and sustainable energy technologies.

Existing Nichrome-based Energy Efficiency Solutions

01 Nichrome heating element design

Optimizing the design of nichrome heating elements can improve energy efficiency. This includes considerations such as wire thickness, coil spacing, and overall geometry to maximize heat transfer while minimizing energy consumption. Advanced designs may incorporate multiple layers or specialized shapes to enhance performance.- Nichrome heating element design: Optimizing the design of nichrome heating elements can improve energy efficiency. This includes considerations such as wire thickness, coil spacing, and overall geometry to maximize heat transfer while minimizing energy consumption. Advanced designs may incorporate multiple layers or specialized shapes to enhance performance.

- Control systems for nichrome heating: Implementing sophisticated control systems can significantly improve the energy efficiency of nichrome-based heating applications. These systems may include precise temperature regulation, adaptive power management, and intelligent scheduling to optimize energy usage based on demand and environmental conditions.

- Insulation and heat retention techniques: Enhancing insulation and heat retention around nichrome heating elements can boost overall energy efficiency. This may involve using advanced insulating materials, designing efficient heat distribution systems, or implementing reflective surfaces to minimize heat loss and maximize the utilization of generated heat.

- Integration with renewable energy sources: Combining nichrome heating systems with renewable energy sources can improve overall energy efficiency. This may include integrating solar power, wind energy, or other sustainable power sources to supplement or replace traditional electricity supply for nichrome heating elements, reducing reliance on non-renewable energy.

- Material improvements and alloy modifications: Developing new nichrome alloys or modifying existing compositions can enhance energy efficiency. This may involve adjusting the ratio of nickel to chromium, incorporating additional elements, or applying surface treatments to improve electrical resistance properties and heat generation capabilities while reducing energy consumption.

02 Energy-efficient control systems

Implementing sophisticated control systems can significantly improve the energy efficiency of nichrome-based heating applications. These systems may include precise temperature regulation, adaptive power management, and intelligent scheduling to minimize energy waste while maintaining optimal performance.Expand Specific Solutions03 Nichrome alloy composition optimization

Modifying the composition of nichrome alloys can enhance their energy efficiency. By adjusting the ratio of nickel to chromium and incorporating other elements, researchers can develop alloys with improved electrical resistance properties and better heat distribution characteristics, leading to more efficient energy use.Expand Specific Solutions04 Integration with renewable energy sources

Combining nichrome heating systems with renewable energy sources can improve overall energy efficiency. This may involve integrating solar panels, wind turbines, or other clean energy technologies to power nichrome heating elements, reducing reliance on traditional energy sources and improving sustainability.Expand Specific Solutions05 Thermal insulation and heat recovery

Enhancing thermal insulation around nichrome heating elements and implementing heat recovery systems can significantly improve energy efficiency. This approach minimizes heat loss to the environment and allows for the capture and reuse of waste heat, maximizing the overall energy utilization of the system.Expand Specific Solutions

Key Players in Nichrome and Renewable Energy Sectors

The renewable energy sector, particularly in the context of nichrome applications, is in a growth phase characterized by increasing market size and evolving technological maturity. The global push for energy efficiency is driving innovation and competition among key players. Companies like LG Chem, TDK Corp, and Sumitomo Chemical are leveraging their expertise in materials science to develop advanced nichrome-based solutions. Research institutions such as Central South University and Northeastern University are contributing to technological advancements. The market is seeing a blend of established industrial giants and specialized firms like Shaanxi Lighte Optoelectronics and Yancheng Xinyang Electric Heating Material, indicating a diverse competitive landscape with opportunities for both innovation and scale.

Ceres

Technical Solution: Ceres has developed innovative Solid Oxide Fuel Cell (SOFC) technology utilizing nichrome as a key component in their fuel cell stacks. Their SOFCs operate at high temperatures (500-1000°C) where nichrome's excellent heat resistance and electrical conductivity are crucial. Ceres' fuel cells achieve electrical efficiencies of up to 60% [1], significantly higher than traditional power generation methods. The company's unique Steel Cell technology incorporates a steel substrate with a nichrome coating, providing structural support and electrical connectivity while reducing overall system cost [2]. This approach allows for scalable manufacturing and integration into various applications, from small-scale residential units to large industrial systems.

Strengths: High electrical efficiency, scalable manufacturing, cost-effective design. Weaknesses: High operating temperatures may limit some applications, potential long-term durability challenges in extreme conditions.

LG Chem Ltd.

Technical Solution: LG Chem has leveraged nichrome technology in the development of advanced battery systems for renewable energy storage. The company has incorporated nichrome-based heating elements in their battery thermal management systems, enabling precise temperature control and improved battery performance in extreme conditions. LG Chem's nichrome-enhanced thermal management has extended battery life by up to 20% in cold climates [9]. Furthermore, LG Chem has developed innovative nichrome-coated current collectors for lithium-ion batteries, improving conductivity and reducing internal resistance. This technology has contributed to their latest energy storage systems achieving round-trip efficiencies of over 95% [10], significantly enhancing the viability of large-scale renewable energy integration.

Strengths: Improved battery performance and longevity, high energy storage efficiency. Weaknesses: Increased production costs, potential safety concerns with high-energy density batteries.

Core Innovations in Nichrome for Renewable Technologies

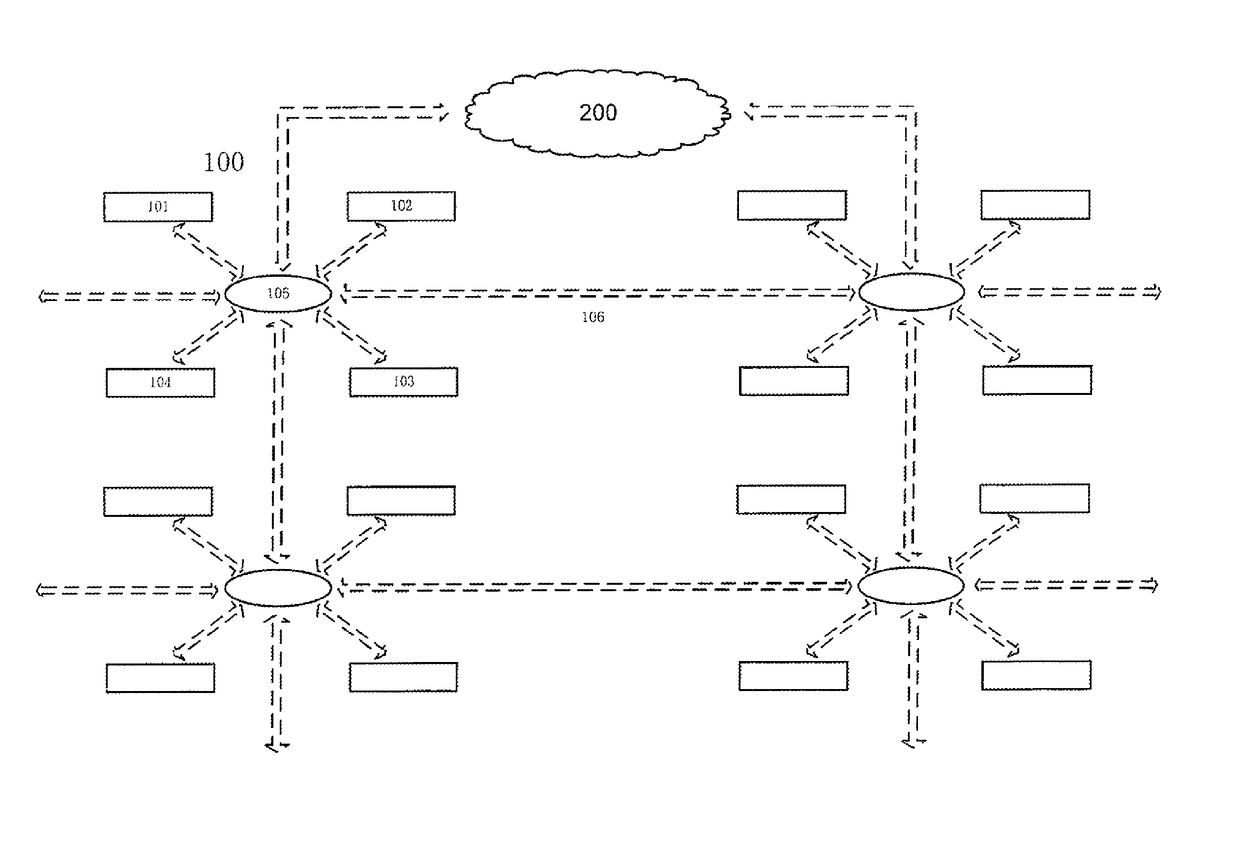

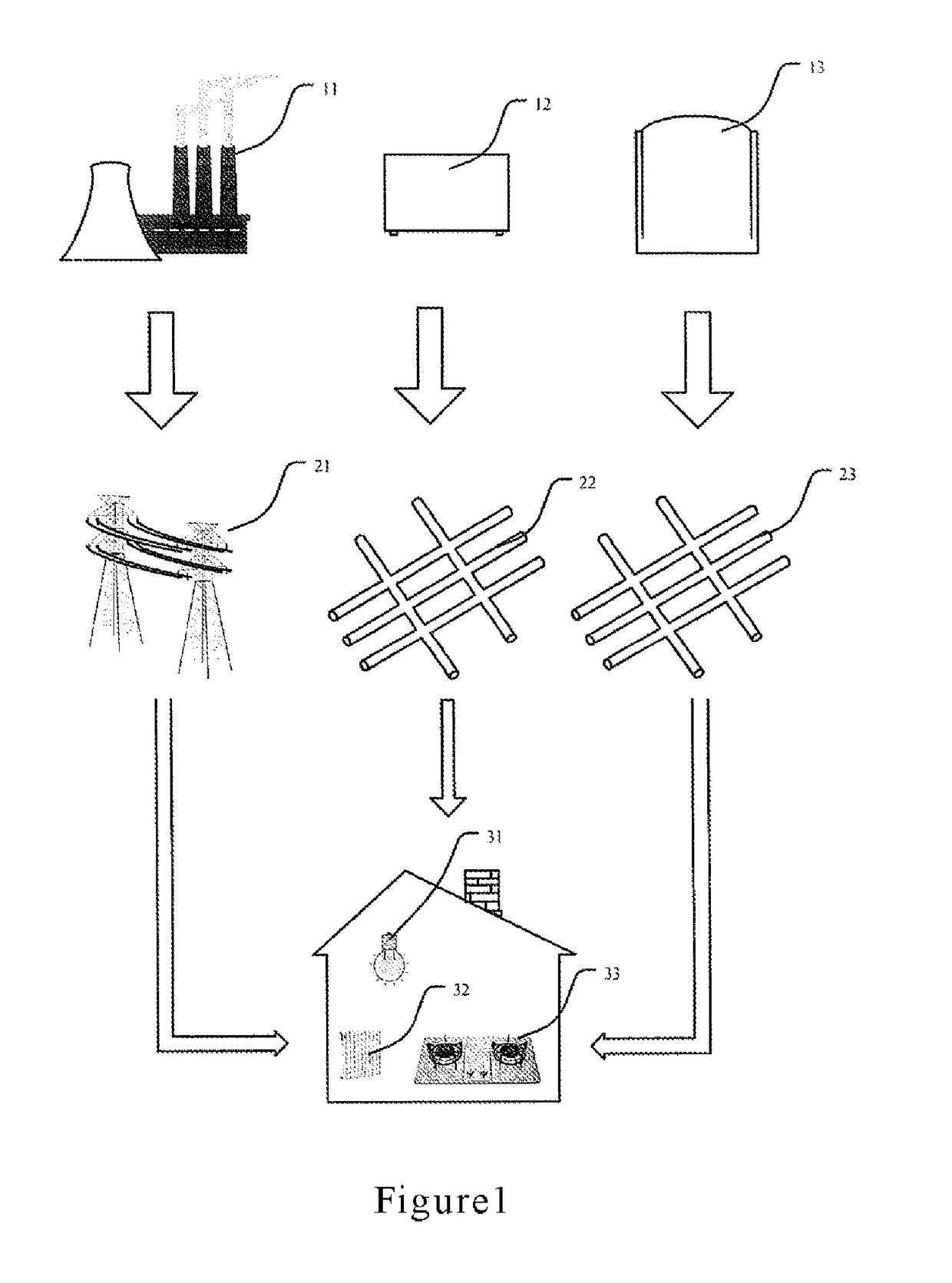

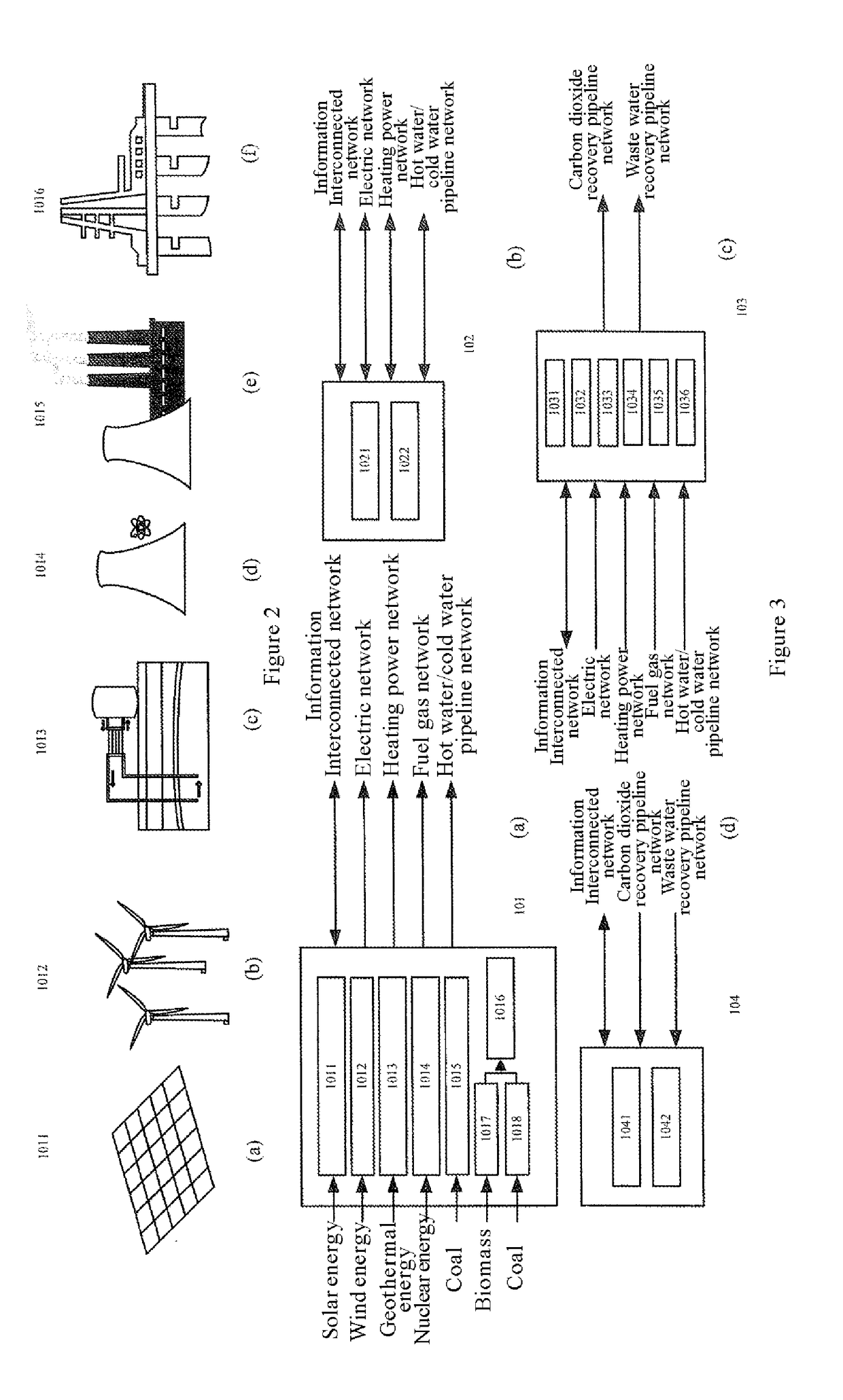

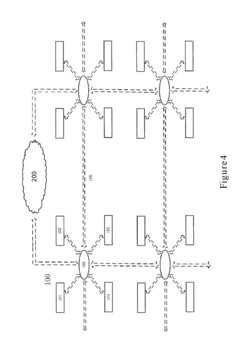

System energy efficiency controller, energy efficiency gain device and smart energy service system used for energy utilization

PatentActiveUS9690275B2

Innovation

- A ubiquitous energy network system that integrates energy, material, and information flows across four stages of energy generation, storage, utilization, and regeneration, using a system energy efficiency controller to optimize input and output, enabling cooperative control and maximizing energy efficiency through bidirectional energy transmission and dynamic matching.

Efficient use of regenerative energy in high-speed electric vehicles

PatentPendingIN202441016639A

Innovation

- The integration of advanced energy management algorithms for real-time data analysis and predictive control strategies, coupled with innovative energy storage solutions and emerging technologies like vehicle-to-grid communication, to optimize regenerative energy capture, storage, and utilization, ensuring maximum energy recovery and efficient power delivery.

Environmental Impact and Sustainability Considerations

The integration of nichrome in renewable technologies presents significant environmental and sustainability considerations that warrant careful examination. As a material widely used in heating elements and electrical resistors, nichrome's application in renewable energy systems can contribute to improved energy efficiency and reduced carbon emissions.

One of the primary environmental benefits of utilizing nichrome in renewable technologies is its potential to enhance the overall efficiency of energy conversion processes. By leveraging nichrome's excellent electrical resistance properties, renewable energy systems can achieve higher performance levels, ultimately leading to increased clean energy production and reduced reliance on fossil fuels. This shift towards more efficient renewable energy solutions directly contributes to global efforts in mitigating climate change and reducing greenhouse gas emissions.

However, the environmental impact of nichrome production and disposal must also be considered. The mining and processing of nickel and chromium, the primary components of nichrome, can have significant ecological consequences, including habitat disruption and potential water and soil contamination. To address these concerns, sustainable sourcing practices and responsible mining techniques should be prioritized to minimize the environmental footprint of nichrome production.

From a lifecycle perspective, the durability and longevity of nichrome components in renewable energy systems contribute positively to sustainability efforts. The material's resistance to corrosion and high-temperature stability ensures extended operational lifespans for renewable energy equipment, reducing the need for frequent replacements and minimizing waste generation. This aspect aligns well with circular economy principles, promoting resource efficiency and reducing the overall environmental impact of renewable energy infrastructure.

Recycling and proper disposal of nichrome-containing components at the end of their useful life present both challenges and opportunities. Developing efficient recycling processes for nichrome can help recover valuable materials and reduce the demand for virgin resources. However, the complexity of separating nichrome from other materials in renewable energy systems requires innovative recycling technologies and infrastructure development.

As the renewable energy sector continues to grow, the demand for nichrome and similar materials is expected to increase. This trend underscores the importance of sustainable material management strategies, including the exploration of alternative materials with similar properties but lower environmental impacts. Research into bio-based or recycled alternatives that can match nichrome's performance characteristics could pave the way for even more sustainable renewable energy technologies in the future.

In conclusion, while nichrome plays a crucial role in driving energy efficiency in renewable technologies, its environmental impact and sustainability considerations must be carefully balanced. By adopting responsible production practices, optimizing material use, and investing in recycling technologies, the renewable energy sector can harness the benefits of nichrome while minimizing its ecological footprint, contributing to a more sustainable and environmentally friendly energy landscape.

One of the primary environmental benefits of utilizing nichrome in renewable technologies is its potential to enhance the overall efficiency of energy conversion processes. By leveraging nichrome's excellent electrical resistance properties, renewable energy systems can achieve higher performance levels, ultimately leading to increased clean energy production and reduced reliance on fossil fuels. This shift towards more efficient renewable energy solutions directly contributes to global efforts in mitigating climate change and reducing greenhouse gas emissions.

However, the environmental impact of nichrome production and disposal must also be considered. The mining and processing of nickel and chromium, the primary components of nichrome, can have significant ecological consequences, including habitat disruption and potential water and soil contamination. To address these concerns, sustainable sourcing practices and responsible mining techniques should be prioritized to minimize the environmental footprint of nichrome production.

From a lifecycle perspective, the durability and longevity of nichrome components in renewable energy systems contribute positively to sustainability efforts. The material's resistance to corrosion and high-temperature stability ensures extended operational lifespans for renewable energy equipment, reducing the need for frequent replacements and minimizing waste generation. This aspect aligns well with circular economy principles, promoting resource efficiency and reducing the overall environmental impact of renewable energy infrastructure.

Recycling and proper disposal of nichrome-containing components at the end of their useful life present both challenges and opportunities. Developing efficient recycling processes for nichrome can help recover valuable materials and reduce the demand for virgin resources. However, the complexity of separating nichrome from other materials in renewable energy systems requires innovative recycling technologies and infrastructure development.

As the renewable energy sector continues to grow, the demand for nichrome and similar materials is expected to increase. This trend underscores the importance of sustainable material management strategies, including the exploration of alternative materials with similar properties but lower environmental impacts. Research into bio-based or recycled alternatives that can match nichrome's performance characteristics could pave the way for even more sustainable renewable energy technologies in the future.

In conclusion, while nichrome plays a crucial role in driving energy efficiency in renewable technologies, its environmental impact and sustainability considerations must be carefully balanced. By adopting responsible production practices, optimizing material use, and investing in recycling technologies, the renewable energy sector can harness the benefits of nichrome while minimizing its ecological footprint, contributing to a more sustainable and environmentally friendly energy landscape.

Cost-Benefit Analysis of Nichrome in Renewables

The cost-benefit analysis of nichrome in renewable technologies reveals a compelling case for its adoption, particularly in enhancing energy efficiency. Nichrome, an alloy primarily composed of nickel and chromium, offers several advantages that contribute to its favorable economic profile in renewable energy applications.

One of the primary benefits of nichrome is its exceptional heat resistance and durability. This characteristic translates to longer operational lifespans for components in renewable energy systems, such as solar thermal collectors and wind turbine heating elements. The extended lifespan reduces replacement frequency, thereby lowering long-term maintenance costs and improving the overall return on investment for renewable energy projects.

Moreover, nichrome's high electrical resistivity makes it an ideal material for heating elements in various renewable energy applications. This property allows for efficient conversion of electrical energy into heat, which is crucial in applications like biomass processing and geothermal energy extraction. The improved energy conversion efficiency directly contributes to reduced operational costs and increased energy output.

The corrosion resistance of nichrome is another significant factor in its cost-effectiveness. In renewable energy systems exposed to harsh environmental conditions, such as offshore wind turbines or solar installations in coastal areas, nichrome's ability to withstand corrosive elements minimizes degradation and extends the operational life of critical components. This resilience translates to reduced maintenance requirements and associated costs over the lifetime of the installation.

However, the initial cost of nichrome can be higher compared to some alternative materials. This upfront investment may present a barrier to adoption, particularly for smaller-scale projects or in regions with limited financial resources. Nevertheless, the long-term benefits often outweigh the initial costs, especially when considering the total cost of ownership over the lifespan of renewable energy systems.

From an environmental perspective, the use of nichrome aligns well with the sustainability goals of renewable energy. Its durability and efficiency contribute to reduced material waste and energy consumption over time. This aspect not only supports cost savings but also enhances the overall environmental benefits of renewable energy technologies.

In conclusion, while the initial investment in nichrome may be higher, its superior properties in terms of heat resistance, electrical efficiency, and corrosion resistance offer significant long-term cost benefits in renewable energy applications. These advantages, coupled with its contribution to improved energy efficiency and reduced maintenance needs, make nichrome a valuable material in driving the economic viability and sustainability of renewable energy technologies.

One of the primary benefits of nichrome is its exceptional heat resistance and durability. This characteristic translates to longer operational lifespans for components in renewable energy systems, such as solar thermal collectors and wind turbine heating elements. The extended lifespan reduces replacement frequency, thereby lowering long-term maintenance costs and improving the overall return on investment for renewable energy projects.

Moreover, nichrome's high electrical resistivity makes it an ideal material for heating elements in various renewable energy applications. This property allows for efficient conversion of electrical energy into heat, which is crucial in applications like biomass processing and geothermal energy extraction. The improved energy conversion efficiency directly contributes to reduced operational costs and increased energy output.

The corrosion resistance of nichrome is another significant factor in its cost-effectiveness. In renewable energy systems exposed to harsh environmental conditions, such as offshore wind turbines or solar installations in coastal areas, nichrome's ability to withstand corrosive elements minimizes degradation and extends the operational life of critical components. This resilience translates to reduced maintenance requirements and associated costs over the lifetime of the installation.

However, the initial cost of nichrome can be higher compared to some alternative materials. This upfront investment may present a barrier to adoption, particularly for smaller-scale projects or in regions with limited financial resources. Nevertheless, the long-term benefits often outweigh the initial costs, especially when considering the total cost of ownership over the lifespan of renewable energy systems.

From an environmental perspective, the use of nichrome aligns well with the sustainability goals of renewable energy. Its durability and efficiency contribute to reduced material waste and energy consumption over time. This aspect not only supports cost savings but also enhances the overall environmental benefits of renewable energy technologies.

In conclusion, while the initial investment in nichrome may be higher, its superior properties in terms of heat resistance, electrical efficiency, and corrosion resistance offer significant long-term cost benefits in renewable energy applications. These advantages, coupled with its contribution to improved energy efficiency and reduced maintenance needs, make nichrome a valuable material in driving the economic viability and sustainability of renewable energy technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!