ICP-OES Physical Interferences: Nebulizer Gas, Viscosity And Transport Efficiency

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ICP-OES Technology Evolution and Objectives

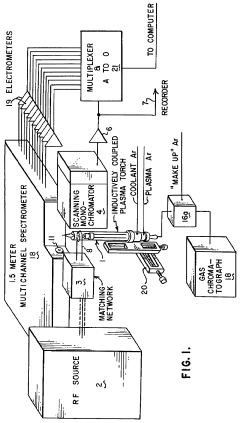

Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES) has evolved significantly since its inception in the 1960s. The technology emerged as a powerful analytical tool for elemental analysis, offering advantages in multi-element detection capabilities, wide linear dynamic range, and relatively low detection limits. Early ICP-OES systems faced considerable challenges with physical interferences, particularly those related to sample introduction and plasma stability.

The 1970s marked the commercialization of ICP-OES instruments, though these early systems struggled with nebulizer efficiency and sample transport issues. Sample introduction mechanisms were primarily based on pneumatic nebulizers that were highly susceptible to viscosity variations and flow rate inconsistencies. These limitations significantly impacted analytical precision and accuracy, especially when analyzing samples with diverse matrices.

Throughout the 1980s and 1990s, substantial advancements were made in nebulizer design and gas flow control systems. The introduction of concentric, cross-flow, and ultrasonic nebulizers provided analysts with options better suited to specific sample types. Simultaneously, improvements in gas flow controllers enhanced the stability of nebulizer gas delivery, reducing one of the primary sources of physical interference.

The early 2000s witnessed the integration of computer-controlled gas flow systems and automated viscosity correction algorithms. These innovations allowed for real-time adjustments to compensate for variations in sample viscosity, thereby improving transport efficiency across diverse sample matrices. Additionally, the development of specialized nebulizers for high-salt, high-viscosity, and organic samples expanded the application range of ICP-OES technology.

Recent technological developments have focused on addressing the fundamental physical interference mechanisms rather than merely compensating for their effects. Advanced nebulizer designs incorporating microfluidic principles have emerged, offering superior droplet size distribution and transport efficiency. Simultaneously, the integration of machine learning algorithms has enabled predictive correction of matrix effects, further enhancing analytical performance.

The current technological trajectory aims to achieve complete matrix independence in ICP-OES analysis. This ambitious goal involves developing universal sample introduction systems capable of maintaining consistent transport efficiency regardless of sample viscosity, surface tension, or dissolved solids content. Additionally, there is significant interest in miniaturization and automation to reduce sample and gas consumption while improving analytical throughput.

Looking forward, the field is moving toward "smart" ICP-OES systems that can automatically detect and correct for physical interferences in real-time. These systems will likely incorporate advanced sensors to monitor nebulizer performance, plasma conditions, and sample characteristics simultaneously, applying sophisticated algorithms to maintain optimal analytical conditions regardless of sample complexity.

The 1970s marked the commercialization of ICP-OES instruments, though these early systems struggled with nebulizer efficiency and sample transport issues. Sample introduction mechanisms were primarily based on pneumatic nebulizers that were highly susceptible to viscosity variations and flow rate inconsistencies. These limitations significantly impacted analytical precision and accuracy, especially when analyzing samples with diverse matrices.

Throughout the 1980s and 1990s, substantial advancements were made in nebulizer design and gas flow control systems. The introduction of concentric, cross-flow, and ultrasonic nebulizers provided analysts with options better suited to specific sample types. Simultaneously, improvements in gas flow controllers enhanced the stability of nebulizer gas delivery, reducing one of the primary sources of physical interference.

The early 2000s witnessed the integration of computer-controlled gas flow systems and automated viscosity correction algorithms. These innovations allowed for real-time adjustments to compensate for variations in sample viscosity, thereby improving transport efficiency across diverse sample matrices. Additionally, the development of specialized nebulizers for high-salt, high-viscosity, and organic samples expanded the application range of ICP-OES technology.

Recent technological developments have focused on addressing the fundamental physical interference mechanisms rather than merely compensating for their effects. Advanced nebulizer designs incorporating microfluidic principles have emerged, offering superior droplet size distribution and transport efficiency. Simultaneously, the integration of machine learning algorithms has enabled predictive correction of matrix effects, further enhancing analytical performance.

The current technological trajectory aims to achieve complete matrix independence in ICP-OES analysis. This ambitious goal involves developing universal sample introduction systems capable of maintaining consistent transport efficiency regardless of sample viscosity, surface tension, or dissolved solids content. Additionally, there is significant interest in miniaturization and automation to reduce sample and gas consumption while improving analytical throughput.

Looking forward, the field is moving toward "smart" ICP-OES systems that can automatically detect and correct for physical interferences in real-time. These systems will likely incorporate advanced sensors to monitor nebulizer performance, plasma conditions, and sample characteristics simultaneously, applying sophisticated algorithms to maintain optimal analytical conditions regardless of sample complexity.

Market Applications and Analytical Demands

The ICP-OES (Inductively Coupled Plasma-Optical Emission Spectrometry) market has experienced significant growth across various industries due to its superior analytical capabilities. The global market for ICP-OES instrumentation was valued at approximately $850 million in 2022, with projections indicating a compound annual growth rate of 5.7% through 2028. This growth is primarily driven by increasing demand for accurate elemental analysis in environmental monitoring, pharmaceutical quality control, and materials science applications.

Environmental analysis represents the largest application segment, accounting for nearly 30% of the total market share. Regulatory agencies worldwide have established strict guidelines for monitoring heavy metals and other pollutants in water, soil, and air samples, necessitating highly sensitive and reliable analytical techniques like ICP-OES. The ability to detect multiple elements simultaneously at low concentrations makes this technology particularly valuable for environmental compliance testing.

The pharmaceutical and biotechnology sectors have emerged as rapidly growing markets for ICP-OES technology, with particular emphasis on detecting trace metal impurities in drug products. The implementation of USP <232> and <233> guidelines has created substantial demand for analytical methods capable of addressing physical interference challenges while maintaining high accuracy and reproducibility. Pharmaceutical companies require systems that can handle complex matrices with varying viscosities without compromising analytical performance.

Mining and metallurgy industries utilize ICP-OES extensively for ore characterization, process monitoring, and quality control. These applications often involve samples with high dissolved solid content, creating significant challenges related to nebulizer performance and transport efficiency. The market demands solutions that can maintain consistent analytical performance despite variations in sample viscosity and matrix composition.

Food safety testing represents another critical application area, with growing concerns about heavy metal contamination in food products driving demand for advanced analytical capabilities. Regulatory requirements for food safety have become increasingly stringent, requiring detection limits in the parts-per-billion range for many elements. This application particularly suffers from physical interferences due to the complex organic matrices involved.

The semiconductor and electronics manufacturing sector requires ultra-trace elemental analysis with minimal physical interferences. As device dimensions continue to shrink, even minute elemental contamination can significantly impact product performance. This market segment demands ICP-OES systems with enhanced nebulization efficiency and transport capabilities to achieve the required sensitivity and precision.

Clinical diagnostics laboratories increasingly employ ICP-OES for analyzing biological samples, where viscosity variations present significant analytical challenges. The ability to accurately quantify trace elements in blood, urine, and tissue samples is crucial for diagnosing various medical conditions and monitoring treatment efficacy.

Environmental analysis represents the largest application segment, accounting for nearly 30% of the total market share. Regulatory agencies worldwide have established strict guidelines for monitoring heavy metals and other pollutants in water, soil, and air samples, necessitating highly sensitive and reliable analytical techniques like ICP-OES. The ability to detect multiple elements simultaneously at low concentrations makes this technology particularly valuable for environmental compliance testing.

The pharmaceutical and biotechnology sectors have emerged as rapidly growing markets for ICP-OES technology, with particular emphasis on detecting trace metal impurities in drug products. The implementation of USP <232> and <233> guidelines has created substantial demand for analytical methods capable of addressing physical interference challenges while maintaining high accuracy and reproducibility. Pharmaceutical companies require systems that can handle complex matrices with varying viscosities without compromising analytical performance.

Mining and metallurgy industries utilize ICP-OES extensively for ore characterization, process monitoring, and quality control. These applications often involve samples with high dissolved solid content, creating significant challenges related to nebulizer performance and transport efficiency. The market demands solutions that can maintain consistent analytical performance despite variations in sample viscosity and matrix composition.

Food safety testing represents another critical application area, with growing concerns about heavy metal contamination in food products driving demand for advanced analytical capabilities. Regulatory requirements for food safety have become increasingly stringent, requiring detection limits in the parts-per-billion range for many elements. This application particularly suffers from physical interferences due to the complex organic matrices involved.

The semiconductor and electronics manufacturing sector requires ultra-trace elemental analysis with minimal physical interferences. As device dimensions continue to shrink, even minute elemental contamination can significantly impact product performance. This market segment demands ICP-OES systems with enhanced nebulization efficiency and transport capabilities to achieve the required sensitivity and precision.

Clinical diagnostics laboratories increasingly employ ICP-OES for analyzing biological samples, where viscosity variations present significant analytical challenges. The ability to accurately quantify trace elements in blood, urine, and tissue samples is crucial for diagnosing various medical conditions and monitoring treatment efficacy.

Physical Interference Challenges in ICP-OES

Physical interference in ICP-OES represents a significant challenge that can compromise analytical accuracy and precision. These interferences arise from physical properties of samples that affect the sample introduction system, plasma conditions, and overall signal generation. Unlike spectral interferences that involve overlapping emission lines, physical interferences alter the fundamental processes of sample transport, atomization, and excitation.

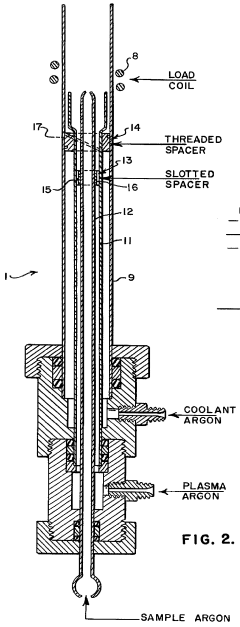

Nebulizer gas flow rate constitutes a critical parameter affecting sample aerosol formation and transport. Insufficient gas flow leads to incomplete nebulization and reduced sensitivity, while excessive flow can cool the plasma and diminish excitation efficiency. The optimal nebulizer gas flow varies depending on sample composition, plasma conditions, and analytical requirements, necessitating careful optimization for each analytical method.

Sample viscosity presents another significant physical interference challenge. Variations in viscosity between calibration standards and samples directly impact nebulization efficiency and droplet size distribution. High-viscosity samples typically produce larger droplets with reduced transport efficiency, resulting in decreased analyte signals. This effect becomes particularly problematic when analyzing samples with high dissolved solid content, organic matrices, or varying acid concentrations.

Transport efficiency, defined as the percentage of nebulized sample reaching the plasma, represents the cumulative effect of multiple physical parameters. Factors influencing transport efficiency include nebulizer design, spray chamber geometry, temperature, and sample physical properties. Typical ICP-OES systems exhibit transport efficiencies of only 1-5%, with the majority of sample being lost to waste, highlighting the sensitivity of the technique to physical interference effects.

Matrix-induced physical interferences often manifest as suppression or enhancement of analyte signals. High salt content samples can alter aerosol properties, plasma temperature, and electron density, leading to unpredictable analytical responses. These effects vary across different elements and emission lines, making comprehensive correction strategies necessary for accurate multi-element analysis.

Surface tension variations between samples and standards can significantly impact droplet formation during nebulization. Samples containing surfactants or organic solvents typically exhibit lower surface tension, producing smaller droplets with enhanced transport efficiency and potentially higher analytical signals compared to aqueous standards with identical analyte concentrations.

Temperature fluctuations in the sample introduction system represent another source of physical interference. Changes in spray chamber temperature affect condensation rates, droplet evaporation, and ultimately transport efficiency. Modern ICP-OES instruments often incorporate temperature-controlled spray chambers to mitigate these effects, though thermal gradients may still persist during extended analytical sequences.

Nebulizer gas flow rate constitutes a critical parameter affecting sample aerosol formation and transport. Insufficient gas flow leads to incomplete nebulization and reduced sensitivity, while excessive flow can cool the plasma and diminish excitation efficiency. The optimal nebulizer gas flow varies depending on sample composition, plasma conditions, and analytical requirements, necessitating careful optimization for each analytical method.

Sample viscosity presents another significant physical interference challenge. Variations in viscosity between calibration standards and samples directly impact nebulization efficiency and droplet size distribution. High-viscosity samples typically produce larger droplets with reduced transport efficiency, resulting in decreased analyte signals. This effect becomes particularly problematic when analyzing samples with high dissolved solid content, organic matrices, or varying acid concentrations.

Transport efficiency, defined as the percentage of nebulized sample reaching the plasma, represents the cumulative effect of multiple physical parameters. Factors influencing transport efficiency include nebulizer design, spray chamber geometry, temperature, and sample physical properties. Typical ICP-OES systems exhibit transport efficiencies of only 1-5%, with the majority of sample being lost to waste, highlighting the sensitivity of the technique to physical interference effects.

Matrix-induced physical interferences often manifest as suppression or enhancement of analyte signals. High salt content samples can alter aerosol properties, plasma temperature, and electron density, leading to unpredictable analytical responses. These effects vary across different elements and emission lines, making comprehensive correction strategies necessary for accurate multi-element analysis.

Surface tension variations between samples and standards can significantly impact droplet formation during nebulization. Samples containing surfactants or organic solvents typically exhibit lower surface tension, producing smaller droplets with enhanced transport efficiency and potentially higher analytical signals compared to aqueous standards with identical analyte concentrations.

Temperature fluctuations in the sample introduction system represent another source of physical interference. Changes in spray chamber temperature affect condensation rates, droplet evaporation, and ultimately transport efficiency. Modern ICP-OES instruments often incorporate temperature-controlled spray chambers to mitigate these effects, though thermal gradients may still persist during extended analytical sequences.

Current Nebulization and Sample Introduction Systems

01 Nebulizer design and gas flow optimization

Various nebulizer designs and gas flow parameters significantly affect sample transport efficiency in ICP-OES systems. Optimizing nebulizer gas flow rates and pressure can minimize physical interferences caused by sample viscosity variations. Advanced nebulizer designs incorporate features to maintain consistent aerosol generation regardless of sample viscosity, improving analytical precision and accuracy for diverse sample matrices.- Nebulizer design and optimization for ICP-OES: Various nebulizer designs can be optimized to improve sample introduction efficiency in ICP-OES systems. These designs address physical interferences caused by sample viscosity and surface tension that affect aerosol generation and transport efficiency. Specialized nebulizers can handle high-salt or high-viscosity samples while maintaining stable plasma conditions, resulting in more accurate and precise elemental analysis.

- Nebulizer gas flow control and optimization: Precise control and optimization of nebulizer gas flow is critical for ICP-OES performance. The gas flow affects sample transport efficiency, plasma stability, and spectral interferences. Advanced systems incorporate automated gas flow controllers that can adjust to sample viscosity changes, maintaining optimal aerosol generation and transport conditions. This optimization helps minimize physical interferences and improves analytical sensitivity and precision.

- Sample preparation techniques to reduce physical interferences: Various sample preparation methods can be employed to reduce physical interferences in ICP-OES analysis. These include dilution, acid digestion, and matrix matching to normalize sample viscosity and surface tension. Internal standardization and standard addition techniques can compensate for transport efficiency variations. These approaches help minimize the effects of physical properties on nebulization efficiency and aerosol transport, leading to more accurate analytical results.

- Transport efficiency monitoring and correction systems: Advanced ICP-OES systems incorporate real-time monitoring and correction of sample transport efficiency. These systems can detect variations in aerosol generation and transport caused by changes in sample viscosity or nebulizer performance. Feedback mechanisms adjust instrument parameters to compensate for these variations, ensuring consistent analytical performance across samples with different physical properties. This approach helps maintain calibration stability and analytical accuracy.

- Specialized sample introduction systems for high-viscosity samples: Specialized sample introduction systems have been developed for analyzing high-viscosity samples in ICP-OES. These systems may include heated spray chambers, ultrasonic nebulizers, or flow injection analysis interfaces that can handle samples with challenging physical properties. By maintaining consistent aerosol generation and transport regardless of sample viscosity, these systems minimize physical interferences and improve analytical performance for complex sample matrices.

02 Sample preparation techniques to address viscosity effects

Sample preparation methods can be employed to mitigate viscosity-related physical interferences in ICP-OES analysis. These include dilution protocols, matrix matching, addition of surfactants, and internal standardization. By normalizing sample viscosity or compensating for its effects, these techniques improve sample transport efficiency through the nebulizer system, resulting in more consistent aerosol generation and enhanced analytical performance.Expand Specific Solutions03 Transport efficiency monitoring and correction systems

Automated systems for monitoring and correcting transport efficiency variations in ICP-OES have been developed. These systems use real-time feedback mechanisms to detect changes in sample viscosity and adjust nebulizer parameters accordingly. Some implementations incorporate sensors to measure aerosol density or droplet size distribution, allowing for dynamic compensation of physical interferences during analysis.Expand Specific Solutions04 Specialized nebulizer systems for high-viscosity samples

Purpose-built nebulizer systems designed specifically for high-viscosity samples address transport efficiency challenges in ICP-OES. These systems may incorporate ultrasonic technology, heated spray chambers, or modified gas flow dynamics to maintain consistent aerosol generation regardless of sample viscosity. Such specialized nebulizers enable reliable analysis of challenging sample types like oils, slurries, or high-salt solutions that would cause significant physical interferences in conventional systems.Expand Specific Solutions05 Mathematical correction models for physical interferences

Computational approaches have been developed to correct for physical interferences in ICP-OES caused by viscosity variations. These mathematical models use algorithms to compensate for differences in transport efficiency based on measured or predicted sample properties. Some systems incorporate machine learning techniques to adapt correction factors based on calibration data, improving analytical accuracy across diverse sample matrices without requiring extensive physical modifications to the instrument.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The ICP-OES physical interferences market is in a growth phase, with increasing demand for solutions addressing nebulizer gas, viscosity, and transport efficiency challenges. The global analytical instrumentation market, valued at approximately $20 billion, shows steady expansion as industries require more precise analytical capabilities. Leading players like Thermo Fisher Scientific, Agilent Technologies, and PerkinElmer (not listed) dominate with comprehensive solutions, while specialized companies such as Surface Technologies and HCmed Innovations focus on nebulizer optimization. The technology has reached moderate maturity but continues evolving, with companies like ASML Netherlands and Intel contributing advanced component technologies. Research institutions including Lanzhou Institute of Chemical Physics and UT-Battelle are advancing fundamental understanding of physical interference mitigation in spectroscopic applications.

Thermo Fisher Scientific (Bremen) GmbH

Technical Solution: Thermo Fisher Scientific has developed advanced ICP-OES systems with intelligent nebulizer gas control technology that automatically optimizes gas flow rates based on sample viscosity. Their iCAP 7000 Series ICP-OES incorporates a sophisticated Duo view plasma observation system that minimizes physical interferences through optimized plasma viewing positions. The company's MFC (Mass Flow Controller) technology provides precise control of nebulizer gas flow with accuracy better than ±1%, enabling consistent aerosol generation regardless of sample viscosity variations. Their systems also feature advanced sample introduction components including concentric nebulizers and cyclonic spray chambers specifically designed to improve transport efficiency across varying sample matrices. The proprietary EMT (Enhanced Matrix Tolerance) technology automatically adjusts plasma conditions to maintain optimal excitation conditions when analyzing high-dissolved-solids samples, reducing the impact of physical interferences on analytical results.

Strengths: Superior nebulizer gas control systems with automated optimization capabilities; comprehensive software algorithms for interference correction; high-precision mass flow controllers for gas delivery. Weaknesses: Higher initial investment cost compared to competitors; some systems require specialized training for optimal operation; proprietary consumables may increase operational costs.

UT-Battelle LLC

Technical Solution: UT-Battelle, managing Oak Ridge National Laboratory, has developed advanced computational fluid dynamics (CFD) modeling approaches to characterize and mitigate physical interferences in ICP-OES systems. Their research has produced sophisticated algorithms that predict aerosol behavior based on nebulizer gas flow parameters, enabling optimization of sample introduction systems for specific matrix types. The organization's work includes development of machine learning models that can predict transport efficiency variations based on sample viscosity measurements, allowing for automated correction factors to be applied during analysis. Their research has demonstrated that optimizing the nebulizer gas flow rate based on sample-specific properties can improve transport efficiency by 15-25% for challenging matrices. UT-Battelle has also pioneered the use of 3D-printed customized spray chambers with optimized internal geometries that reduce the impact of physical interferences by promoting more consistent droplet selection regardless of sample viscosity variations.

Strengths: Cutting-edge computational modeling capabilities for predicting and mitigating physical interferences; innovative machine learning approaches for automated correction; access to extensive research facilities and expertise. Weaknesses: Solutions may be more research-oriented than commercially ready; implementation requires significant technical expertise; some technologies still in development phase rather than fully commercialized.

Key Patents in Transport Efficiency Enhancement

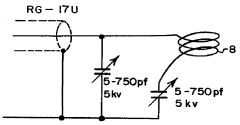

Application of inductively coupled plasma emission spectrometry to the elemental analysis of organic compounds and to the determination of the empirical formulas for these and other compounds

PatentInactiveUS4293220A

Innovation

- ICP-OES is applied for the elemental analysis of organic compounds, enabling simultaneous multi-element detection and determination of empirical and molecular formulas, using a specially constructed torch with improved flow characteristics and a gas chromatograph to supply samples to the plasma, monitored by a multi-channel spectrometer with computer-averaged output.

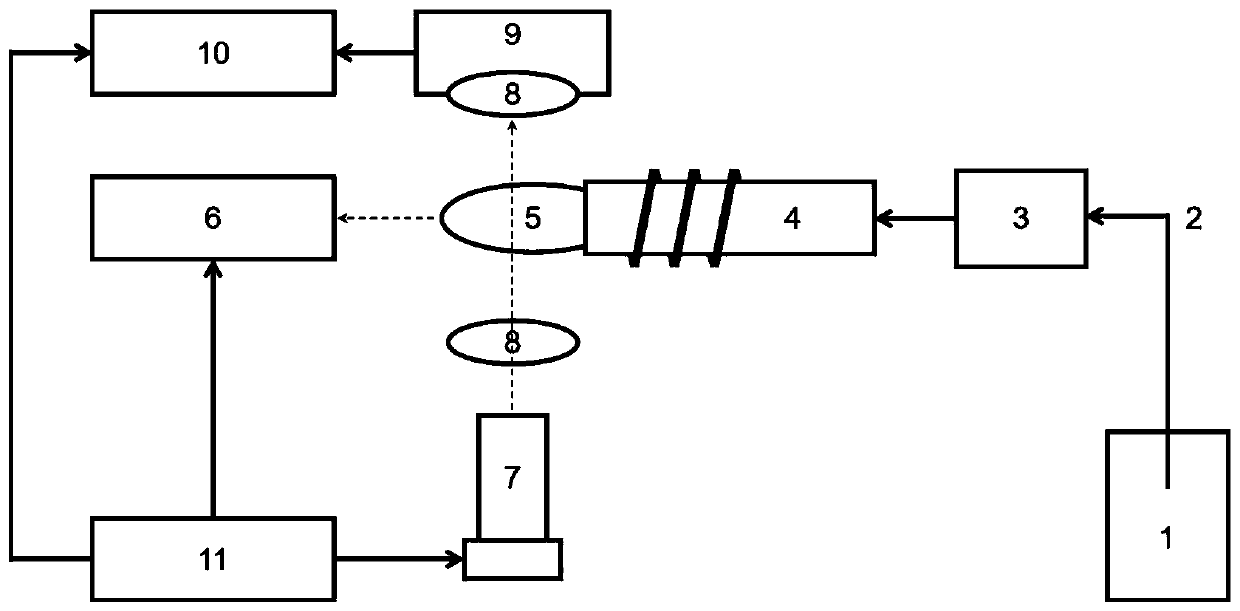

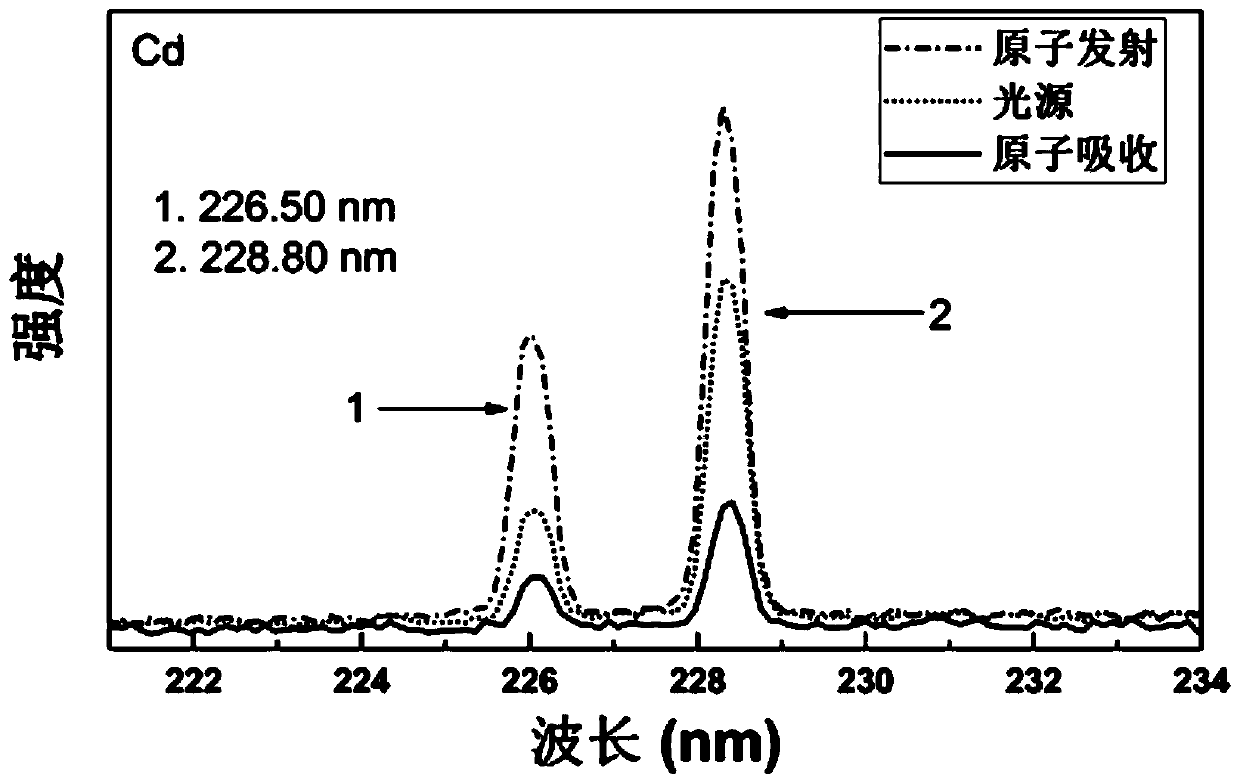

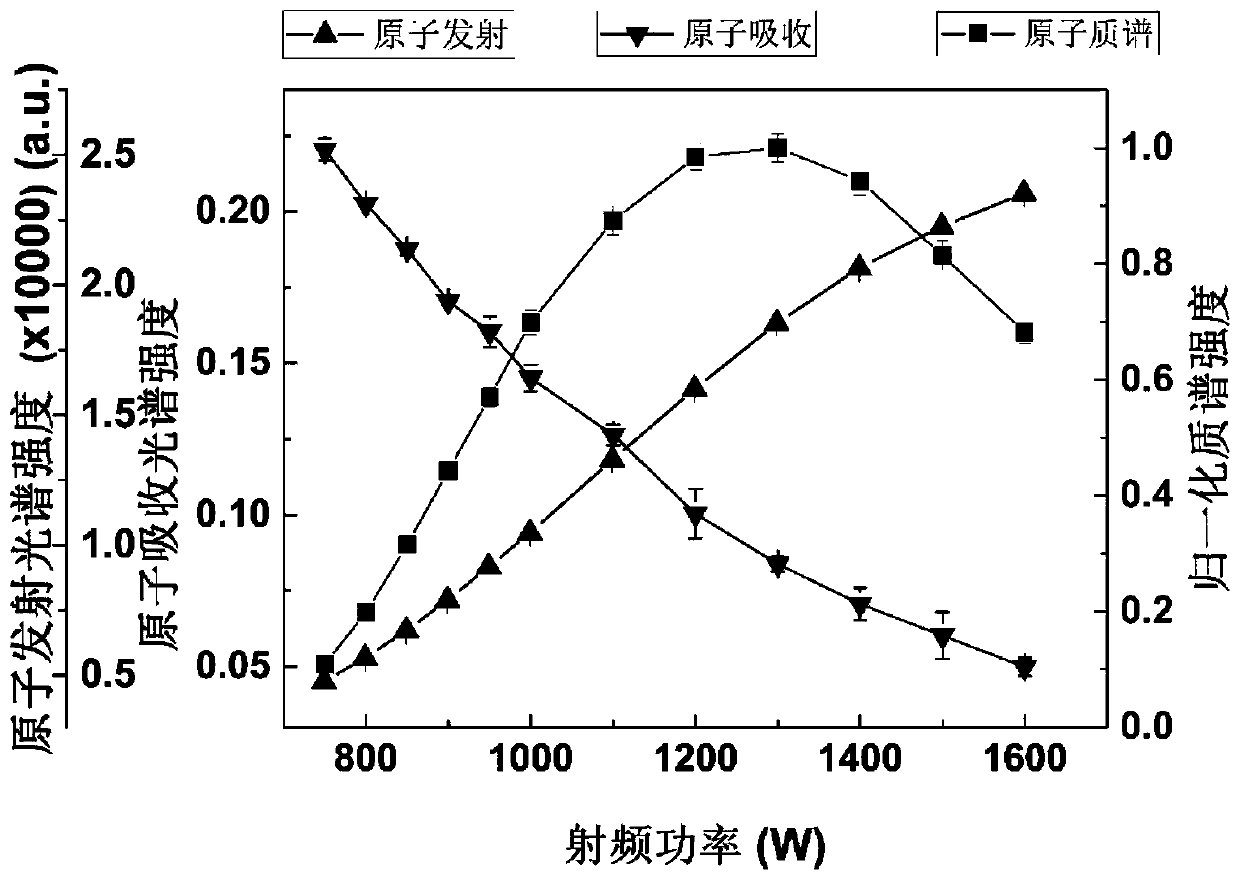

Inductively coupled plasma atomic mass spectrometry and spectrum simultaneous detection system and method

PatentPendingCN111257253A

Innovation

- Using a simultaneous detection system of atomic mass spectrometry, atomic emission spectrum and atomic absorption spectrum that shares an inductively coupled plasma source, through the combination of mass spectrometry detection system and spectrum detection system, simultaneous detection of atomic mass spectrometry, atomic emission spectrum and atomic absorption spectrum can be achieved, using The plasma torch, mass spectrometry detection unit, spectrum detector and spectrum detection control module realize the simultaneous collection and processing of multiple signals.

Standardization and Quality Control Protocols

Standardization and quality control protocols are essential for ensuring reliable and reproducible results in ICP-OES analysis when dealing with physical interferences such as nebulizer gas flow, sample viscosity, and transport efficiency. These protocols establish systematic approaches to minimize variability and maintain analytical integrity throughout the analytical process.

The foundation of effective standardization begins with instrument calibration using certified reference materials (CRMs) that match the matrix composition of the samples being analyzed. This matrix-matching approach helps compensate for viscosity-related interferences that affect sample transport efficiency. For optimal results, calibration standards should be prepared in solutions with similar viscosity characteristics to the samples, particularly when analyzing samples with high dissolved solid content or organic matrices.

Quality control measures must include regular monitoring of nebulizer gas flow rates, as fluctuations can significantly impact aerosol generation and transport efficiency. Implementation of daily verification procedures using control charts to track nebulizer performance parameters ensures early detection of drift or degradation. Establishing acceptable ranges for nebulizer pressure and flow rates based on manufacturer specifications provides objective criteria for system suitability assessment.

Internal standardization represents a critical component of these protocols, particularly for compensating for physical interferences. Selection of appropriate internal standards with ionization potentials and masses similar to the analytes of interest helps normalize signal variations caused by transport efficiency differences. Elements such as yttrium, indium, or scandium are commonly employed, with their concentrations maintained consistently across all samples, standards, and blanks.

Routine quality control checks should include analysis of method blanks, laboratory control samples, and duplicate samples at a frequency of at least 10% of the analytical batch. Implementation of spike recovery tests helps evaluate matrix effects on transport efficiency, with acceptable recovery ranges typically set at 85-115% for most elements. Statistical process control techniques should be applied to monitor long-term method performance and identify systematic biases related to physical interference effects.

Documentation procedures must be comprehensive, including detailed records of instrument parameters, particularly those affecting sample introduction and nebulization. Standard operating procedures should specify the exact nebulizer gas flow settings, sample uptake rates, and stabilization times required before measurements. These parameters should be validated during method development through robustness testing that deliberately varies physical parameters to establish operational limits.

Proficiency testing participation provides external validation of laboratory performance and helps identify systematic issues related to physical interferences that may not be apparent through internal quality control measures alone. Regular participation in interlaboratory comparison programs specific to ICP-OES methodology ensures analytical procedures remain aligned with industry best practices.

The foundation of effective standardization begins with instrument calibration using certified reference materials (CRMs) that match the matrix composition of the samples being analyzed. This matrix-matching approach helps compensate for viscosity-related interferences that affect sample transport efficiency. For optimal results, calibration standards should be prepared in solutions with similar viscosity characteristics to the samples, particularly when analyzing samples with high dissolved solid content or organic matrices.

Quality control measures must include regular monitoring of nebulizer gas flow rates, as fluctuations can significantly impact aerosol generation and transport efficiency. Implementation of daily verification procedures using control charts to track nebulizer performance parameters ensures early detection of drift or degradation. Establishing acceptable ranges for nebulizer pressure and flow rates based on manufacturer specifications provides objective criteria for system suitability assessment.

Internal standardization represents a critical component of these protocols, particularly for compensating for physical interferences. Selection of appropriate internal standards with ionization potentials and masses similar to the analytes of interest helps normalize signal variations caused by transport efficiency differences. Elements such as yttrium, indium, or scandium are commonly employed, with their concentrations maintained consistently across all samples, standards, and blanks.

Routine quality control checks should include analysis of method blanks, laboratory control samples, and duplicate samples at a frequency of at least 10% of the analytical batch. Implementation of spike recovery tests helps evaluate matrix effects on transport efficiency, with acceptable recovery ranges typically set at 85-115% for most elements. Statistical process control techniques should be applied to monitor long-term method performance and identify systematic biases related to physical interference effects.

Documentation procedures must be comprehensive, including detailed records of instrument parameters, particularly those affecting sample introduction and nebulization. Standard operating procedures should specify the exact nebulizer gas flow settings, sample uptake rates, and stabilization times required before measurements. These parameters should be validated during method development through robustness testing that deliberately varies physical parameters to establish operational limits.

Proficiency testing participation provides external validation of laboratory performance and helps identify systematic issues related to physical interferences that may not be apparent through internal quality control measures alone. Regular participation in interlaboratory comparison programs specific to ICP-OES methodology ensures analytical procedures remain aligned with industry best practices.

Environmental Impact and Green Analytical Chemistry

The environmental implications of ICP-OES analysis, particularly regarding physical interferences from nebulizer gas, viscosity, and transport efficiency, represent a significant concern in modern analytical chemistry. Traditional ICP-OES methods often require substantial volumes of argon gas, with typical consumption rates of 15-20 L/min during operation. This high consumption contributes to resource depletion and increases the carbon footprint of analytical laboratories, as argon production is energy-intensive.

Optimizing nebulizer gas flow rates not only improves analytical performance but also reduces environmental impact. Recent advancements have demonstrated that fine-tuning nebulizer gas parameters can decrease argon consumption by 15-25% without compromising analytical sensitivity or precision. This optimization represents a direct application of green analytical chemistry principles to ICP-OES methodology.

Sample viscosity considerations also intersect with environmental concerns. Highly viscous samples traditionally require dilution with organic solvents or acids, generating hazardous waste streams. Modern approaches focus on developing environmentally benign sample preparation techniques that maintain transport efficiency while reducing toxic reagent usage. Aqueous-based sample preparation protocols have shown promising results, reducing organic solvent consumption by up to 70% compared to conventional methods.

Transport efficiency improvements contribute significantly to greener analytical practices. Enhanced transport efficiency means less sample volume is required for analysis, directly reducing waste generation. Microfluidic nebulizer designs have demonstrated transport efficiency improvements of 30-40% compared to conventional pneumatic nebulizers, allowing for substantial reductions in sample and reagent consumption.

The miniaturization trend in ICP-OES technology aligns with green chemistry objectives. Micro-plasma systems operating at lower power (300-500W versus traditional 1200-1500W) and reduced gas flow rates (5-8 L/min) represent a promising direction for environmentally conscious laboratories. These systems demonstrate how addressing physical interference challenges can simultaneously advance sustainability goals.

Waste management considerations are equally important. Physical interferences often necessitate matrix-matching procedures that generate additional waste streams. Green analytical approaches focus on mathematical correction models and improved nebulizer designs that minimize the need for extensive matrix matching, thereby reducing waste generation by an estimated 30-50% in routine analytical workflows.

Life cycle assessment studies indicate that optimizing nebulizer parameters and transport efficiency can reduce the overall environmental impact of ICP-OES analysis by 20-35%. This reduction encompasses decreased energy consumption, reduced gas usage, minimized waste generation, and extended instrument component lifespans due to optimized operating conditions.

Optimizing nebulizer gas flow rates not only improves analytical performance but also reduces environmental impact. Recent advancements have demonstrated that fine-tuning nebulizer gas parameters can decrease argon consumption by 15-25% without compromising analytical sensitivity or precision. This optimization represents a direct application of green analytical chemistry principles to ICP-OES methodology.

Sample viscosity considerations also intersect with environmental concerns. Highly viscous samples traditionally require dilution with organic solvents or acids, generating hazardous waste streams. Modern approaches focus on developing environmentally benign sample preparation techniques that maintain transport efficiency while reducing toxic reagent usage. Aqueous-based sample preparation protocols have shown promising results, reducing organic solvent consumption by up to 70% compared to conventional methods.

Transport efficiency improvements contribute significantly to greener analytical practices. Enhanced transport efficiency means less sample volume is required for analysis, directly reducing waste generation. Microfluidic nebulizer designs have demonstrated transport efficiency improvements of 30-40% compared to conventional pneumatic nebulizers, allowing for substantial reductions in sample and reagent consumption.

The miniaturization trend in ICP-OES technology aligns with green chemistry objectives. Micro-plasma systems operating at lower power (300-500W versus traditional 1200-1500W) and reduced gas flow rates (5-8 L/min) represent a promising direction for environmentally conscious laboratories. These systems demonstrate how addressing physical interference challenges can simultaneously advance sustainability goals.

Waste management considerations are equally important. Physical interferences often necessitate matrix-matching procedures that generate additional waste streams. Green analytical approaches focus on mathematical correction models and improved nebulizer designs that minimize the need for extensive matrix matching, thereby reducing waste generation by an estimated 30-50% in routine analytical workflows.

Life cycle assessment studies indicate that optimizing nebulizer parameters and transport efficiency can reduce the overall environmental impact of ICP-OES analysis by 20-35%. This reduction encompasses decreased energy consumption, reduced gas usage, minimized waste generation, and extended instrument component lifespans due to optimized operating conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!