ICP-OES Plasma Stability: RF Power, Cool/aux Flows And Matrix Load

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ICP-OES Technology Evolution and Stability Objectives

Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES) has evolved significantly since its commercial introduction in the 1970s. Initially developed as an alternative to flame atomic absorption spectroscopy, ICP-OES offered superior detection limits and multi-element analysis capabilities. The technology's evolution has been marked by continuous improvements in plasma generation, sample introduction systems, and detection methodologies.

Early ICP-OES systems struggled with plasma stability issues, particularly when analyzing complex matrices. The 1980s saw the introduction of robust plasma configurations and improved RF generators, which enhanced stability but still faced challenges with high-salt matrices and organic solvents. The 1990s brought significant advancements in RF power control systems, allowing for more precise regulation of power delivery to the plasma.

The technological trajectory has consistently aimed at achieving greater plasma robustness while maintaining analytical sensitivity. Modern systems incorporate sophisticated feedback mechanisms that continuously monitor and adjust RF power in response to changing sample matrices, representing a significant advancement from the manual adjustments required in earlier generations.

Cool and auxiliary gas flows have undergone parallel evolution. Initial systems utilized fixed flow rates, which limited adaptability to varying sample types. Contemporary instruments feature programmable gas controllers that can dynamically adjust flow rates based on sample characteristics, significantly enhancing plasma stability during analysis of challenging samples.

The fundamental objective of plasma stability research centers on maintaining consistent excitation conditions regardless of matrix composition or concentration. This stability is critical for ensuring accurate and reproducible analytical results across diverse sample types, from environmental waters to complex industrial materials.

Current technological goals focus on developing "matrix-independent" plasma conditions, where RF power and gas flow parameters automatically optimize in response to changing sample loads. This adaptive approach aims to eliminate the need for extensive method development when transitioning between different sample matrices.

Another key objective is reducing the energy consumption of ICP systems while maintaining analytical performance. Modern research explores lower-power plasma configurations that can maintain stability with reduced RF input, addressing both operational costs and environmental considerations.

The integration of artificial intelligence and machine learning algorithms represents the newest frontier in plasma stability management. These systems aim to predict and preemptively adjust for potential instabilities based on sample composition data, potentially eliminating matrix-induced fluctuations before they occur.

The ultimate technological goal remains consistent: to develop ICP-OES systems capable of maintaining optimal plasma conditions across all sample types without operator intervention, thereby maximizing analytical reliability while minimizing method development time and expertise requirements.

Early ICP-OES systems struggled with plasma stability issues, particularly when analyzing complex matrices. The 1980s saw the introduction of robust plasma configurations and improved RF generators, which enhanced stability but still faced challenges with high-salt matrices and organic solvents. The 1990s brought significant advancements in RF power control systems, allowing for more precise regulation of power delivery to the plasma.

The technological trajectory has consistently aimed at achieving greater plasma robustness while maintaining analytical sensitivity. Modern systems incorporate sophisticated feedback mechanisms that continuously monitor and adjust RF power in response to changing sample matrices, representing a significant advancement from the manual adjustments required in earlier generations.

Cool and auxiliary gas flows have undergone parallel evolution. Initial systems utilized fixed flow rates, which limited adaptability to varying sample types. Contemporary instruments feature programmable gas controllers that can dynamically adjust flow rates based on sample characteristics, significantly enhancing plasma stability during analysis of challenging samples.

The fundamental objective of plasma stability research centers on maintaining consistent excitation conditions regardless of matrix composition or concentration. This stability is critical for ensuring accurate and reproducible analytical results across diverse sample types, from environmental waters to complex industrial materials.

Current technological goals focus on developing "matrix-independent" plasma conditions, where RF power and gas flow parameters automatically optimize in response to changing sample loads. This adaptive approach aims to eliminate the need for extensive method development when transitioning between different sample matrices.

Another key objective is reducing the energy consumption of ICP systems while maintaining analytical performance. Modern research explores lower-power plasma configurations that can maintain stability with reduced RF input, addressing both operational costs and environmental considerations.

The integration of artificial intelligence and machine learning algorithms represents the newest frontier in plasma stability management. These systems aim to predict and preemptively adjust for potential instabilities based on sample composition data, potentially eliminating matrix-induced fluctuations before they occur.

The ultimate technological goal remains consistent: to develop ICP-OES systems capable of maintaining optimal plasma conditions across all sample types without operator intervention, thereby maximizing analytical reliability while minimizing method development time and expertise requirements.

Market Analysis for High-Precision Analytical Instruments

The global market for high-precision analytical instruments continues to experience robust growth, driven by increasing demand across multiple sectors including environmental monitoring, pharmaceutical research, food safety, and materials science. The ICP-OES (Inductively Coupled Plasma - Optical Emission Spectrometry) segment represents a significant portion of this market, valued at approximately $1.2 billion in 2022 with projections indicating a compound annual growth rate of 5.7% through 2028.

Key market drivers for ICP-OES technology include stringent regulatory requirements for elemental analysis, growing environmental concerns necessitating precise monitoring of heavy metals and contaminants, and expanding applications in pharmaceutical quality control. The technology's ability to perform multi-element analysis with high sensitivity makes it particularly valuable in research environments where sample throughput and accuracy are critical factors.

Regional analysis reveals North America and Europe as dominant markets, collectively accounting for over 60% of global revenue. However, the Asia-Pacific region, particularly China and India, is experiencing the fastest growth rate at nearly 8% annually, fueled by increasing industrialization, environmental regulations, and research investments.

End-user segmentation shows laboratories in environmental testing representing the largest market share at 32%, followed by pharmaceutical quality control at 27%, academic research at 21%, and mining/metallurgy at 15%. The remaining 5% encompasses various specialized applications including forensics and clinical diagnostics.

Market challenges include the high initial investment cost for ICP-OES systems, which typically range from $50,000 to $150,000 depending on specifications and capabilities. This creates a significant barrier to entry for smaller laboratories and research facilities, particularly in developing economies. Additionally, operational expertise requirements and maintenance costs further impact total ownership expenses.

Competitive analysis reveals a concentrated market with five major manufacturers controlling approximately 75% of global sales. These key players are increasingly focusing on innovations addressing plasma stability issues through advanced RF power management systems and automated flow control technologies that optimize cool/auxiliary gas flows regardless of matrix complexity.

Customer demand trends indicate growing preference for instruments offering enhanced plasma stability across varying sample matrices, with 68% of procurement specialists citing this feature as "very important" or "critical" in purchasing decisions. This directly correlates with the technical challenges of maintaining consistent plasma conditions when analyzing complex or high-salt matrices, highlighting the commercial relevance of advances in RF power management and gas flow optimization technologies.

Key market drivers for ICP-OES technology include stringent regulatory requirements for elemental analysis, growing environmental concerns necessitating precise monitoring of heavy metals and contaminants, and expanding applications in pharmaceutical quality control. The technology's ability to perform multi-element analysis with high sensitivity makes it particularly valuable in research environments where sample throughput and accuracy are critical factors.

Regional analysis reveals North America and Europe as dominant markets, collectively accounting for over 60% of global revenue. However, the Asia-Pacific region, particularly China and India, is experiencing the fastest growth rate at nearly 8% annually, fueled by increasing industrialization, environmental regulations, and research investments.

End-user segmentation shows laboratories in environmental testing representing the largest market share at 32%, followed by pharmaceutical quality control at 27%, academic research at 21%, and mining/metallurgy at 15%. The remaining 5% encompasses various specialized applications including forensics and clinical diagnostics.

Market challenges include the high initial investment cost for ICP-OES systems, which typically range from $50,000 to $150,000 depending on specifications and capabilities. This creates a significant barrier to entry for smaller laboratories and research facilities, particularly in developing economies. Additionally, operational expertise requirements and maintenance costs further impact total ownership expenses.

Competitive analysis reveals a concentrated market with five major manufacturers controlling approximately 75% of global sales. These key players are increasingly focusing on innovations addressing plasma stability issues through advanced RF power management systems and automated flow control technologies that optimize cool/auxiliary gas flows regardless of matrix complexity.

Customer demand trends indicate growing preference for instruments offering enhanced plasma stability across varying sample matrices, with 68% of procurement specialists citing this feature as "very important" or "critical" in purchasing decisions. This directly correlates with the technical challenges of maintaining consistent plasma conditions when analyzing complex or high-salt matrices, highlighting the commercial relevance of advances in RF power management and gas flow optimization technologies.

Current Challenges in Plasma Stability Control

Despite significant advancements in ICP-OES technology, maintaining plasma stability remains a fundamental challenge that affects analytical performance across various applications. The interaction between RF power settings, gas flow rates, and sample matrix composition creates a complex system where instability can manifest in multiple ways, compromising measurement accuracy and precision.

RF power fluctuations represent a primary concern in plasma stability control. Even minor variations in power delivery can lead to significant changes in plasma characteristics, affecting excitation efficiency and emission intensity. Modern instruments typically operate between 1000-1500W, but maintaining consistent power transfer to the plasma becomes increasingly difficult when analyzing complex matrices or during extended analytical runs.

Gas flow management presents another critical challenge. The cool (plasma) gas flow, typically argon at 12-18 L/min, must maintain precise laminar flow patterns to ensure proper plasma formation. Meanwhile, auxiliary gas flow (0.5-2.0 L/min) stabilizes the base of the plasma, but optimal settings vary significantly depending on sample composition. Even small deviations in these parameters can lead to plasma flickering, positional shifts, or complete extinguishment.

Matrix-induced plasma instability represents perhaps the most persistent challenge in routine analysis. High dissolved solid content (>1% TDS) introduces significant thermal loading that can constrict plasma channels and alter energy distribution. Elements with low ionization potentials (e.g., Na, K) dramatically affect plasma characteristics when present at high concentrations, creating localized "cold zones" that compromise analyte excitation.

Transient plasma instabilities during sample introduction transitions pose particular difficulties in sequential multi-element analysis. The momentary introduction of volatile organic solvents or high-salt matrices can trigger plasma fluctuations that persist beyond the immediate sample, creating carryover effects that compromise subsequent measurements.

Instrument manufacturers have implemented various compensation mechanisms, including digital power control systems and automated gas flow adjustments. However, these solutions often address symptoms rather than fundamental stability challenges, particularly when analyzing unpredictable or highly variable sample types.

The development of robust plasma stability control systems is further complicated by the need to maintain compatibility with existing sample introduction systems and detection technologies. Innovations must balance stability improvements against practical considerations such as gas consumption, power efficiency, and operational simplicity.

RF power fluctuations represent a primary concern in plasma stability control. Even minor variations in power delivery can lead to significant changes in plasma characteristics, affecting excitation efficiency and emission intensity. Modern instruments typically operate between 1000-1500W, but maintaining consistent power transfer to the plasma becomes increasingly difficult when analyzing complex matrices or during extended analytical runs.

Gas flow management presents another critical challenge. The cool (plasma) gas flow, typically argon at 12-18 L/min, must maintain precise laminar flow patterns to ensure proper plasma formation. Meanwhile, auxiliary gas flow (0.5-2.0 L/min) stabilizes the base of the plasma, but optimal settings vary significantly depending on sample composition. Even small deviations in these parameters can lead to plasma flickering, positional shifts, or complete extinguishment.

Matrix-induced plasma instability represents perhaps the most persistent challenge in routine analysis. High dissolved solid content (>1% TDS) introduces significant thermal loading that can constrict plasma channels and alter energy distribution. Elements with low ionization potentials (e.g., Na, K) dramatically affect plasma characteristics when present at high concentrations, creating localized "cold zones" that compromise analyte excitation.

Transient plasma instabilities during sample introduction transitions pose particular difficulties in sequential multi-element analysis. The momentary introduction of volatile organic solvents or high-salt matrices can trigger plasma fluctuations that persist beyond the immediate sample, creating carryover effects that compromise subsequent measurements.

Instrument manufacturers have implemented various compensation mechanisms, including digital power control systems and automated gas flow adjustments. However, these solutions often address symptoms rather than fundamental stability challenges, particularly when analyzing unpredictable or highly variable sample types.

The development of robust plasma stability control systems is further complicated by the need to maintain compatibility with existing sample introduction systems and detection technologies. Innovations must balance stability improvements against practical considerations such as gas consumption, power efficiency, and operational simplicity.

RF Power and Gas Flow Management Solutions

01 Plasma stabilization techniques for ICP-OES

Various techniques are employed to stabilize plasma in ICP-OES systems, including optimized gas flow control, radio frequency power regulation, and specialized torch designs. These methods help maintain consistent plasma conditions during analysis, reducing signal drift and improving measurement precision. Stabilization techniques often involve monitoring and adjusting key parameters in real-time to compensate for fluctuations that could affect analytical results.- Plasma stabilization techniques in ICP-OES: Various techniques are employed to stabilize plasma in ICP-OES systems, including optimized gas flow control, RF power regulation, and specialized torch designs. These methods help maintain consistent plasma conditions during analysis, reducing signal drift and improving measurement precision. Stabilization techniques often involve monitoring and adjusting critical parameters in real-time to compensate for fluctuations that might affect analytical performance.

- Sample introduction systems for plasma stability: Advanced sample introduction systems are crucial for maintaining plasma stability in ICP-OES. These include specialized nebulizers, spray chambers, and sample transport mechanisms designed to deliver consistent aerosol to the plasma. Proper sample preparation and introduction help prevent plasma fluctuations caused by varying sample matrices, high dissolved solids, or volatile organic components, thereby ensuring more reliable analytical results.

- Monitoring and feedback control systems: Automated monitoring and feedback control systems are implemented in modern ICP-OES instruments to maintain plasma stability. These systems continuously measure critical parameters such as plasma temperature, emission intensity, and spectral background, making real-time adjustments to maintain optimal conditions. Advanced algorithms and sensors detect deviations from ideal plasma conditions and initiate corrective actions, ensuring consistent analytical performance even during extended operation periods.

- Matrix effect mitigation for plasma stability: Techniques to mitigate matrix effects are essential for maintaining plasma stability in ICP-OES analysis. These include the use of internal standards, matrix matching, standard addition methods, and specialized sample preparation protocols. By minimizing the impact of complex sample matrices on plasma conditions, these approaches help prevent plasma fluctuations, reduce signal suppression or enhancement, and improve the accuracy and precision of elemental analysis across diverse sample types.

- Hardware innovations for enhanced plasma stability: Hardware innovations in ICP-OES systems focus on enhancing plasma stability through improved torch designs, more efficient RF generators, and optimized interface configurations. These advancements include vertical torch arrangements, dual-view plasma configurations, and shielded plasma technology. Such hardware improvements help maintain consistent plasma conditions even when analyzing challenging samples, reducing maintenance requirements and extending the operational lifetime of system components while improving analytical performance.

02 Sample introduction systems for plasma stability

Advanced sample introduction systems are critical for maintaining plasma stability in ICP-OES. These include specialized nebulizers, spray chambers, and sample transport mechanisms designed to deliver consistent sample aerosol to the plasma. Proper sample preparation and introduction help prevent plasma fluctuations caused by varying sample matrices, high dissolved solids, or volatile organic components, thereby ensuring more reliable analytical results.Expand Specific Solutions03 Monitoring and feedback control systems

Automated monitoring and feedback control systems are implemented in modern ICP-OES instruments to maintain plasma stability. These systems continuously measure critical parameters such as plasma temperature, emission intensity, and spectral background, making real-time adjustments to maintain optimal conditions. Advanced algorithms and sensors detect deviations from ideal plasma conditions and initiate corrective actions, ensuring consistent analytical performance even during extended operation periods.Expand Specific Solutions04 Interference reduction methods for stable plasma

Various methods are employed to reduce interferences that can destabilize plasma in ICP-OES analysis. These include matrix matching, internal standardization, and specialized spectral correction algorithms. Physical modifications to the plasma interface, such as collision/reaction cells or specialized cones, can also be implemented to minimize matrix effects and spectral interferences. These approaches help maintain plasma stability when analyzing complex or variable sample types.Expand Specific Solutions05 Hardware innovations for enhanced plasma stability

Hardware innovations in ICP-OES systems focus on enhancing plasma stability through improved torch designs, more efficient radio frequency generators, and optimized gas delivery systems. These advancements include vertical torch configurations, dual-view plasma observation capabilities, and temperature-controlled spray chambers. Such hardware improvements help maintain consistent plasma conditions across a wide range of sample types and analytical conditions, leading to better precision and accuracy in elemental analysis.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The ICP-OES plasma stability market is currently in a growth phase, with increasing demand driven by semiconductor manufacturing and analytical applications. The market size is expanding steadily as industries require more precise elemental analysis capabilities. Technologically, the field shows moderate maturity with ongoing innovations focused on improving stability parameters. Leading players include Applied Materials, Lam Research, and Tokyo Electron dominating the established market, while emerging competitors like AMEC China and NAURA are gaining ground through focused R&D. MKS and Advanced Energy Industries provide specialized power solutions critical for plasma stability. The competitive landscape is characterized by increasing collaboration between equipment manufacturers and research institutions like Stevens Institute of Technology to address challenges in RF power management and matrix load handling.

MKS, Inc.

Technical Solution: MKS, Inc. has developed advanced RF power delivery systems specifically designed for ICP-OES plasma stability. Their technology utilizes sophisticated impedance matching networks that automatically adjust to maintain optimal power transfer during varying sample matrices and plasma conditions. The company's SmartPower™ technology incorporates real-time monitoring and feedback control systems that continuously measure plasma parameters and make microsecond adjustments to RF power delivery, ensuring consistent plasma performance even under challenging analytical conditions. MKS has also pioneered adaptive gas flow control systems that automatically optimize cool and auxiliary gas flows based on detected matrix load variations, preventing plasma instabilities before they occur. Their integrated solution combines hardware innovations with proprietary algorithms that predict and compensate for matrix-induced fluctuations, maintaining excitation efficiency across diverse sample types.

Strengths: Superior RF power stability under varying matrix loads; integrated approach combining power, gas flow, and matrix compensation; microsecond response times to plasma fluctuations. Weaknesses: Higher implementation costs compared to standard systems; requires specialized training for operators; some proprietary components limit third-party integration options.

Advanced Energy Industries, Inc.

Technical Solution: Advanced Energy Industries has developed a comprehensive plasma stability management system for ICP-OES applications that focuses on precise RF power control and dynamic gas flow optimization. Their technology employs a multi-parameter feedback control system that continuously monitors plasma impedance, emission intensity, and spectral background to make real-time adjustments to RF power delivery. The system features their patented PowerSync™ technology that maintains exceptionally stable power transfer efficiency (>98%) even during significant matrix load variations. Advanced Energy's solution incorporates intelligent gas flow controllers that automatically adjust cool and auxiliary flows based on detected sample viscosity and aerosol characteristics, preventing plasma extinction events during high-salt or organic matrix analysis. Their system also includes predictive matrix compensation algorithms that pre-emptively adjust operating parameters based on sample queue characteristics, ensuring consistent analytical performance across diverse sample types.

Strengths: Exceptional power transfer efficiency; sophisticated multi-parameter feedback control; predictive matrix compensation capabilities. Weaknesses: Complex implementation requiring significant system integration; higher initial investment compared to conventional systems; optimization algorithms require periodic recalibration for maximum effectiveness.

Critical Patents in Matrix Interference Reduction

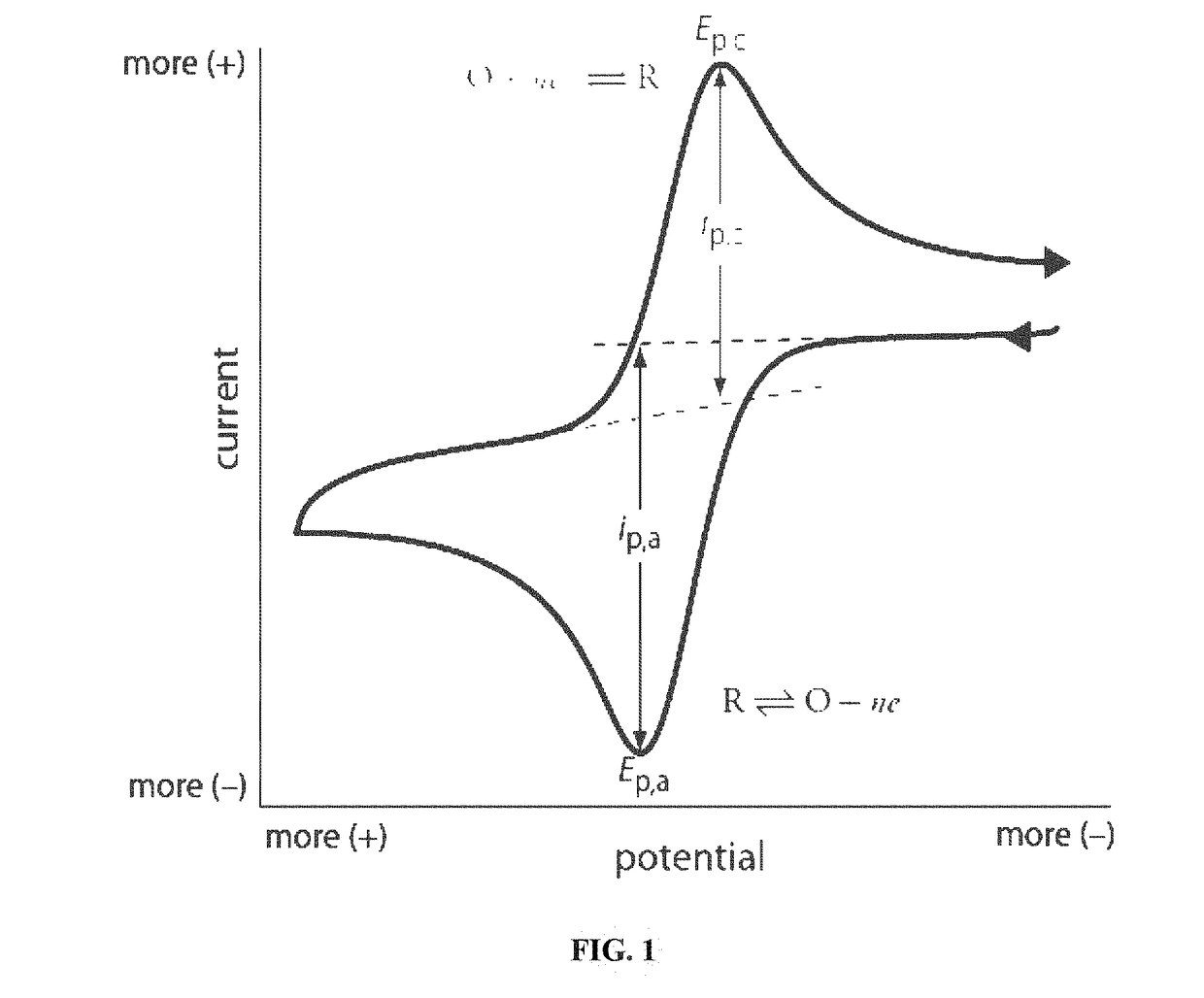

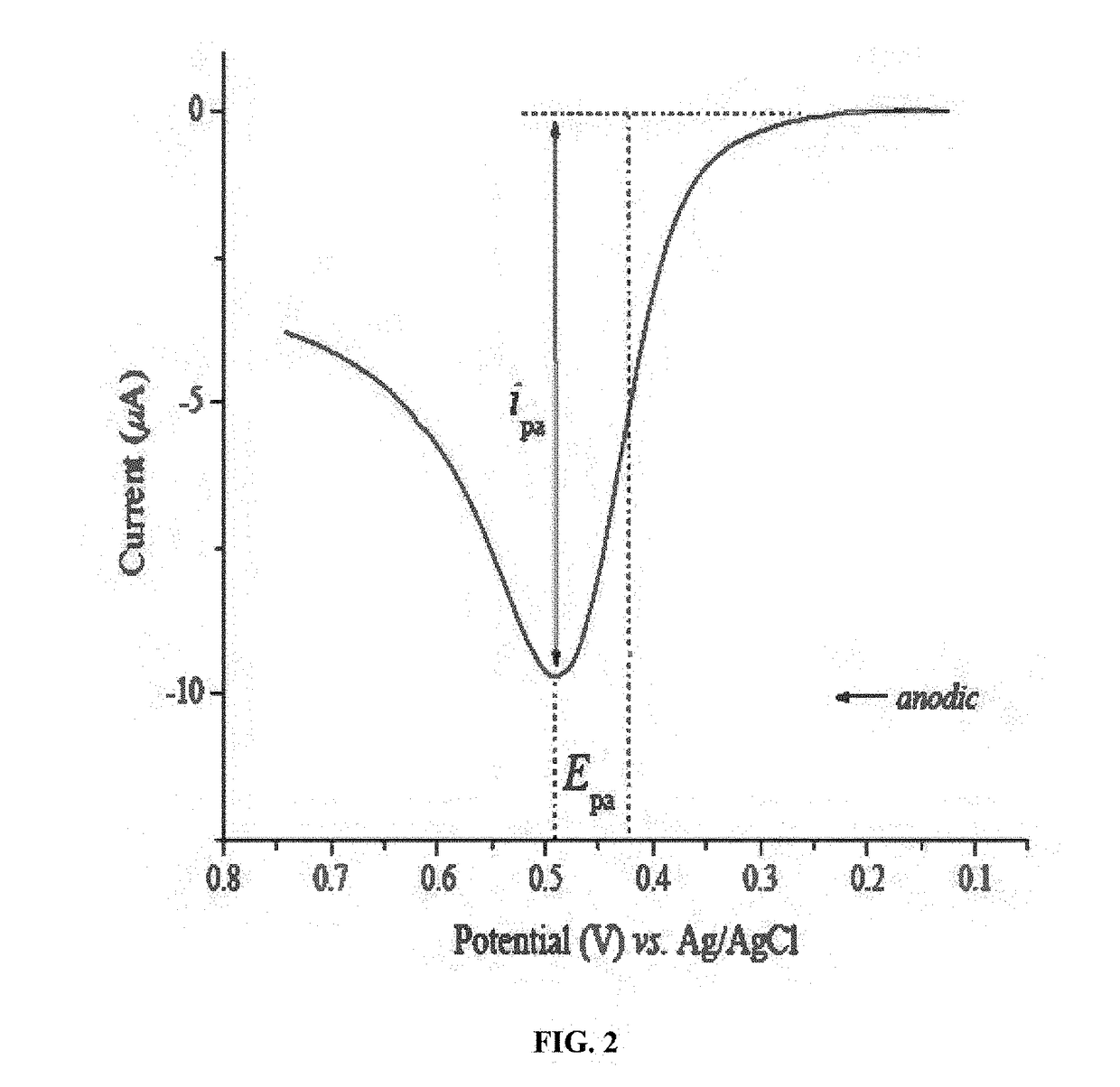

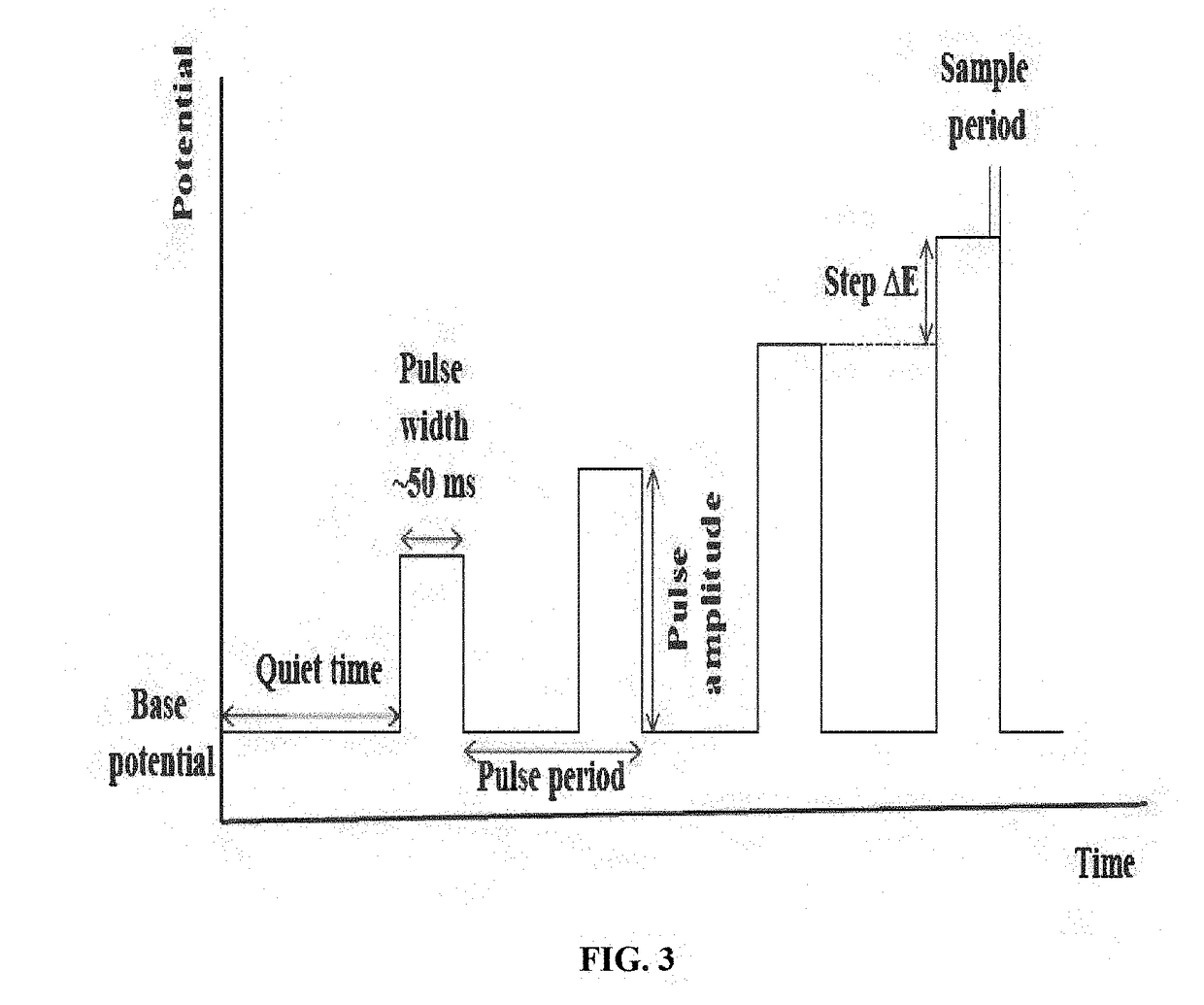

Rare earth metal incorporated zeolite modified electrodes for detection and quantification of heavy metal ions in aqueous solution

PatentInactiveUS20170315079A1

Innovation

- Development of rare earth metal impregnated zeolite modified carbon paste electrodes, specifically lanthanum or cerium impregnated mordenite electrodes, for use in square wave anodic stripping voltammetry, enhancing electroactive surface area and detection limits.

Environmental Impact and Sustainability Considerations

The environmental impact of ICP-OES technology extends beyond its analytical capabilities, encompassing resource consumption, waste generation, and sustainability considerations. Modern ICP-OES systems consume significant electrical power, primarily through the radio frequency (RF) generator that maintains plasma stability. Typical instruments operate between 1000-1500 watts continuously during analysis, contributing to substantial energy consumption in laboratories conducting routine analyses. This power requirement has direct implications for carbon footprint and operational costs, particularly in regions dependent on fossil fuel energy sources.

Argon gas consumption represents another significant environmental concern, with conventional systems requiring 10-20 L/min for plasma maintenance. The cool and auxiliary gas flows, critical for plasma stability, account for the majority of this consumption. Given that argon production is energy-intensive, involving cryogenic air separation, the environmental impact extends beyond the laboratory to industrial gas production facilities.

Sample preparation processes for ICP-OES frequently involve hazardous chemicals, including strong acids for digestion and organic solvents for extraction. These chemicals eventually become waste streams requiring specialized disposal procedures. Additionally, the analysis of high matrix-load samples often necessitates dilution, increasing both reagent usage and waste generation.

Recent technological innovations have begun addressing these sustainability challenges. Energy-efficient RF generators with improved power transfer efficiency have reduced power consumption by 15-20% compared to older systems. Advanced plasma torch designs with optimized gas flow dynamics have demonstrated argon consumption reductions of up to 30% while maintaining analytical performance. These developments represent significant progress toward more sustainable analytical practices.

The implementation of microwave-assisted sample preparation techniques has further reduced chemical consumption and waste generation. These methods typically require smaller volumes of reagents and shorter digestion times, decreasing both environmental impact and operational costs. Additionally, the development of direct solid sampling techniques eliminates many wet chemistry preparation steps entirely for certain applications.

Future sustainability improvements will likely focus on further reducing argon consumption through alternative plasma gas compositions, developing more energy-efficient RF coupling mechanisms, and implementing intelligent power management systems that adjust plasma parameters based on analytical requirements. These advancements will be essential as environmental regulations become increasingly stringent and laboratories face growing pressure to minimize their ecological footprint.

Argon gas consumption represents another significant environmental concern, with conventional systems requiring 10-20 L/min for plasma maintenance. The cool and auxiliary gas flows, critical for plasma stability, account for the majority of this consumption. Given that argon production is energy-intensive, involving cryogenic air separation, the environmental impact extends beyond the laboratory to industrial gas production facilities.

Sample preparation processes for ICP-OES frequently involve hazardous chemicals, including strong acids for digestion and organic solvents for extraction. These chemicals eventually become waste streams requiring specialized disposal procedures. Additionally, the analysis of high matrix-load samples often necessitates dilution, increasing both reagent usage and waste generation.

Recent technological innovations have begun addressing these sustainability challenges. Energy-efficient RF generators with improved power transfer efficiency have reduced power consumption by 15-20% compared to older systems. Advanced plasma torch designs with optimized gas flow dynamics have demonstrated argon consumption reductions of up to 30% while maintaining analytical performance. These developments represent significant progress toward more sustainable analytical practices.

The implementation of microwave-assisted sample preparation techniques has further reduced chemical consumption and waste generation. These methods typically require smaller volumes of reagents and shorter digestion times, decreasing both environmental impact and operational costs. Additionally, the development of direct solid sampling techniques eliminates many wet chemistry preparation steps entirely for certain applications.

Future sustainability improvements will likely focus on further reducing argon consumption through alternative plasma gas compositions, developing more energy-efficient RF coupling mechanisms, and implementing intelligent power management systems that adjust plasma parameters based on analytical requirements. These advancements will be essential as environmental regulations become increasingly stringent and laboratories face growing pressure to minimize their ecological footprint.

Validation Protocols and Quality Assurance Standards

Validation protocols for ICP-OES plasma stability must adhere to rigorous standards to ensure reliable analytical results. These protocols typically begin with instrument qualification procedures, including Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ). For plasma stability specifically, validation should include systematic assessment of RF power stability across the operational range (typically 750-1500W), with acceptance criteria of ±1% variation during extended operation periods.

Quality assurance standards require continuous monitoring of cool and auxiliary gas flows, with recommended validation of flow rate accuracy within ±2% of set values. Matrix load tolerance testing must be incorporated into validation protocols, typically involving progressive increases in total dissolved solids (TDS) from 0.1% to 5% to determine the upper operational limits before plasma instability occurs.

Statistical process control methods should be implemented for ongoing quality assurance, including the use of control charts to monitor key stability indicators such as background emission intensities and internal standard response ratios. Acceptance criteria typically specify that these parameters must remain within ±3 standard deviations of established means during routine operation.

Method validation protocols should include robustness testing specifically focused on plasma stability under varying matrix conditions. This involves deliberate perturbation of RF power (±5% of optimal setting), gas flow rates (±10% of optimal setting), and introduction of interfering elements to assess system resilience. Recovery rates of 95-105% for certified reference materials under these stressed conditions generally indicate acceptable plasma stability.

Documentation requirements for validation include detailed records of all stability tests, with particular emphasis on the correlation between RF power settings, gas flow parameters, and analytical performance metrics such as detection limits and precision. Standard operating procedures should specify regular verification of plasma stability using certified reference materials that match the matrix complexity of routine samples.

Interlaboratory comparison programs provide an external quality assurance mechanism for validating plasma stability protocols. Participation in such programs allows laboratories to benchmark their stability performance against peer institutions and identify potential systematic issues in their validation approaches. ISO/IEC 17025 accreditation standards specifically address requirements for validation of instrumental parameters, including those affecting plasma stability in spectroscopic techniques.

Quality assurance standards require continuous monitoring of cool and auxiliary gas flows, with recommended validation of flow rate accuracy within ±2% of set values. Matrix load tolerance testing must be incorporated into validation protocols, typically involving progressive increases in total dissolved solids (TDS) from 0.1% to 5% to determine the upper operational limits before plasma instability occurs.

Statistical process control methods should be implemented for ongoing quality assurance, including the use of control charts to monitor key stability indicators such as background emission intensities and internal standard response ratios. Acceptance criteria typically specify that these parameters must remain within ±3 standard deviations of established means during routine operation.

Method validation protocols should include robustness testing specifically focused on plasma stability under varying matrix conditions. This involves deliberate perturbation of RF power (±5% of optimal setting), gas flow rates (±10% of optimal setting), and introduction of interfering elements to assess system resilience. Recovery rates of 95-105% for certified reference materials under these stressed conditions generally indicate acceptable plasma stability.

Documentation requirements for validation include detailed records of all stability tests, with particular emphasis on the correlation between RF power settings, gas flow parameters, and analytical performance metrics such as detection limits and precision. Standard operating procedures should specify regular verification of plasma stability using certified reference materials that match the matrix complexity of routine samples.

Interlaboratory comparison programs provide an external quality assurance mechanism for validating plasma stability protocols. Participation in such programs allows laboratories to benchmark their stability performance against peer institutions and identify potential systematic issues in their validation approaches. ISO/IEC 17025 accreditation standards specifically address requirements for validation of instrumental parameters, including those affecting plasma stability in spectroscopic techniques.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!