Impact of battery recycling on PHEV sustainability

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHEV Battery Recycling Background and Objectives

Plug-in Hybrid Electric Vehicles (PHEVs) have emerged as a significant technological advancement in the automotive industry, offering a bridge between conventional internal combustion engines and fully electric vehicles. As the adoption of PHEVs continues to grow, the sustainability of these vehicles has become a critical concern, particularly regarding the lifecycle of their batteries. Battery recycling plays a crucial role in addressing this sustainability challenge.

The evolution of PHEV technology has been marked by continuous improvements in battery performance, energy density, and longevity. However, as these vehicles reach the end of their lifecycle, the proper disposal and recycling of their batteries have become increasingly important. The objectives of PHEV battery recycling are multifaceted, aiming to reduce environmental impact, conserve valuable resources, and enhance the overall sustainability of the PHEV industry.

One of the primary goals of battery recycling is to recover critical materials used in battery production, such as lithium, cobalt, and nickel. These materials are often sourced from limited reserves and their extraction can have significant environmental and social impacts. By recycling PHEV batteries, we can reduce the demand for raw materials, minimize mining activities, and decrease the carbon footprint associated with battery production.

Another key objective is to address the growing concern of battery waste. As the number of PHEVs on the road increases, so does the potential volume of discarded batteries. Effective recycling processes can prevent these batteries from ending up in landfills, where they pose environmental risks due to the toxic materials they contain. By establishing efficient recycling systems, we can mitigate these risks and promote a circular economy within the automotive industry.

The development of advanced recycling technologies is also a crucial aspect of PHEV battery recycling. Current recycling methods often focus on recovering only the most valuable materials, leaving a significant portion of the battery components as waste. Research and innovation in this field aim to improve the efficiency and comprehensiveness of recycling processes, enabling the recovery of a wider range of materials and components.

Furthermore, battery recycling has the potential to create new economic opportunities within the green technology sector. As the demand for recycling services grows, it can lead to the establishment of new industries, job creation, and technological advancements in material recovery and processing.

In the context of global sustainability goals and increasing environmental regulations, PHEV battery recycling aligns with broader initiatives to reduce carbon emissions and promote sustainable transportation solutions. It supports the transition towards a more circular and resource-efficient automotive industry, contributing to the overall sustainability of PHEVs as a long-term mobility solution.

The evolution of PHEV technology has been marked by continuous improvements in battery performance, energy density, and longevity. However, as these vehicles reach the end of their lifecycle, the proper disposal and recycling of their batteries have become increasingly important. The objectives of PHEV battery recycling are multifaceted, aiming to reduce environmental impact, conserve valuable resources, and enhance the overall sustainability of the PHEV industry.

One of the primary goals of battery recycling is to recover critical materials used in battery production, such as lithium, cobalt, and nickel. These materials are often sourced from limited reserves and their extraction can have significant environmental and social impacts. By recycling PHEV batteries, we can reduce the demand for raw materials, minimize mining activities, and decrease the carbon footprint associated with battery production.

Another key objective is to address the growing concern of battery waste. As the number of PHEVs on the road increases, so does the potential volume of discarded batteries. Effective recycling processes can prevent these batteries from ending up in landfills, where they pose environmental risks due to the toxic materials they contain. By establishing efficient recycling systems, we can mitigate these risks and promote a circular economy within the automotive industry.

The development of advanced recycling technologies is also a crucial aspect of PHEV battery recycling. Current recycling methods often focus on recovering only the most valuable materials, leaving a significant portion of the battery components as waste. Research and innovation in this field aim to improve the efficiency and comprehensiveness of recycling processes, enabling the recovery of a wider range of materials and components.

Furthermore, battery recycling has the potential to create new economic opportunities within the green technology sector. As the demand for recycling services grows, it can lead to the establishment of new industries, job creation, and technological advancements in material recovery and processing.

In the context of global sustainability goals and increasing environmental regulations, PHEV battery recycling aligns with broader initiatives to reduce carbon emissions and promote sustainable transportation solutions. It supports the transition towards a more circular and resource-efficient automotive industry, contributing to the overall sustainability of PHEVs as a long-term mobility solution.

Market Analysis for Sustainable PHEV Solutions

The market for sustainable PHEV (Plug-in Hybrid Electric Vehicle) solutions is experiencing significant growth, driven by increasing environmental concerns and stringent regulations on vehicle emissions. As battery recycling plays a crucial role in enhancing the sustainability of PHEVs, it has become a key focus area for market players and policymakers alike.

The global PHEV market is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding 30% between 2021 and 2026. This growth is primarily fueled by government incentives, advancements in battery technology, and rising consumer awareness about environmental issues. The market for sustainable PHEV solutions, including battery recycling, is expected to follow a similar growth trajectory.

Battery recycling is becoming increasingly important in the PHEV ecosystem due to its potential to reduce the environmental impact of battery production and disposal. The market for EV battery recycling is forecasted to grow at a CAGR of over 25% from 2021 to 2026, reaching a market value of several billion dollars by the end of the forecast period.

Consumer demand for more sustainable transportation options is a significant driver for the PHEV market. A recent survey indicated that over 60% of potential car buyers consider environmental impact as a crucial factor in their purchasing decisions. This trend is expected to continue, further boosting the demand for PHEVs with sustainable battery solutions.

The regulatory landscape is also shaping the market for sustainable PHEV solutions. Many countries have implemented or are planning to implement regulations that mandate the recycling of EV batteries. For instance, the European Union's proposed Battery Regulation aims to ensure that all EV batteries are collected and recycled at the end of their life cycle.

Major automotive manufacturers are increasingly investing in sustainable PHEV solutions, including battery recycling initiatives. These investments are driven by both regulatory pressures and the potential for cost savings through the recovery of valuable materials from used batteries. Several leading automakers have announced partnerships with battery recycling companies to develop closed-loop recycling systems for their PHEV batteries.

The market for sustainable PHEV solutions is also seeing the emergence of new business models. Battery-as-a-service (BaaS) and battery swapping services are gaining traction, offering potential solutions to extend battery life and improve recycling efficiency. These innovative approaches are expected to further drive the growth of the sustainable PHEV market.

The global PHEV market is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding 30% between 2021 and 2026. This growth is primarily fueled by government incentives, advancements in battery technology, and rising consumer awareness about environmental issues. The market for sustainable PHEV solutions, including battery recycling, is expected to follow a similar growth trajectory.

Battery recycling is becoming increasingly important in the PHEV ecosystem due to its potential to reduce the environmental impact of battery production and disposal. The market for EV battery recycling is forecasted to grow at a CAGR of over 25% from 2021 to 2026, reaching a market value of several billion dollars by the end of the forecast period.

Consumer demand for more sustainable transportation options is a significant driver for the PHEV market. A recent survey indicated that over 60% of potential car buyers consider environmental impact as a crucial factor in their purchasing decisions. This trend is expected to continue, further boosting the demand for PHEVs with sustainable battery solutions.

The regulatory landscape is also shaping the market for sustainable PHEV solutions. Many countries have implemented or are planning to implement regulations that mandate the recycling of EV batteries. For instance, the European Union's proposed Battery Regulation aims to ensure that all EV batteries are collected and recycled at the end of their life cycle.

Major automotive manufacturers are increasingly investing in sustainable PHEV solutions, including battery recycling initiatives. These investments are driven by both regulatory pressures and the potential for cost savings through the recovery of valuable materials from used batteries. Several leading automakers have announced partnerships with battery recycling companies to develop closed-loop recycling systems for their PHEV batteries.

The market for sustainable PHEV solutions is also seeing the emergence of new business models. Battery-as-a-service (BaaS) and battery swapping services are gaining traction, offering potential solutions to extend battery life and improve recycling efficiency. These innovative approaches are expected to further drive the growth of the sustainable PHEV market.

Current Challenges in PHEV Battery Recycling

The recycling of Plug-in Hybrid Electric Vehicle (PHEV) batteries presents several significant challenges that impact the overall sustainability of these vehicles. One of the primary obstacles is the complex composition of PHEV batteries, which typically contain a mixture of materials including lithium, cobalt, nickel, and manganese. This heterogeneous composition makes it difficult to develop efficient and cost-effective recycling processes that can recover all valuable materials.

Another major challenge is the lack of standardization in battery design and chemistry across different manufacturers. This variability complicates the development of universal recycling methods and necessitates the creation of multiple specialized processes, potentially increasing the cost and reducing the efficiency of recycling operations.

The current recycling infrastructure is also inadequate to handle the projected volume of end-of-life PHEV batteries. As the adoption of PHEVs continues to grow, there is a pressing need to scale up recycling facilities and technologies to match the increasing demand. This scaling challenge is further compounded by the long lifespan of PHEV batteries, which can delay the availability of recyclable materials and create uncertainties in supply chain planning.

Safety concerns pose another significant challenge in PHEV battery recycling. The high voltage and potential for thermal runaway in lithium-ion batteries require specialized handling and processing techniques to ensure worker safety and prevent environmental hazards. This necessity for advanced safety measures adds complexity and cost to the recycling process.

Economic viability remains a critical challenge for PHEV battery recycling. The current costs associated with collecting, transporting, and processing end-of-life batteries often exceed the value of recovered materials, making recycling financially unattractive without regulatory incentives or technological breakthroughs. This economic barrier hinders the widespread adoption of recycling practices and limits the potential environmental benefits.

Furthermore, the environmental impact of the recycling process itself is a concern. Energy-intensive recycling methods can potentially offset some of the sustainability gains achieved through battery reuse and material recovery. Developing more energy-efficient and environmentally friendly recycling technologies is crucial to maximizing the net positive impact on sustainability.

Lastly, there is a challenge in establishing effective reverse logistics systems for collecting end-of-life PHEV batteries. The geographically dispersed nature of battery disposal, combined with the need for specialized handling, creates logistical complexities that must be addressed to ensure a steady supply of recyclable materials to processing facilities.

Another major challenge is the lack of standardization in battery design and chemistry across different manufacturers. This variability complicates the development of universal recycling methods and necessitates the creation of multiple specialized processes, potentially increasing the cost and reducing the efficiency of recycling operations.

The current recycling infrastructure is also inadequate to handle the projected volume of end-of-life PHEV batteries. As the adoption of PHEVs continues to grow, there is a pressing need to scale up recycling facilities and technologies to match the increasing demand. This scaling challenge is further compounded by the long lifespan of PHEV batteries, which can delay the availability of recyclable materials and create uncertainties in supply chain planning.

Safety concerns pose another significant challenge in PHEV battery recycling. The high voltage and potential for thermal runaway in lithium-ion batteries require specialized handling and processing techniques to ensure worker safety and prevent environmental hazards. This necessity for advanced safety measures adds complexity and cost to the recycling process.

Economic viability remains a critical challenge for PHEV battery recycling. The current costs associated with collecting, transporting, and processing end-of-life batteries often exceed the value of recovered materials, making recycling financially unattractive without regulatory incentives or technological breakthroughs. This economic barrier hinders the widespread adoption of recycling practices and limits the potential environmental benefits.

Furthermore, the environmental impact of the recycling process itself is a concern. Energy-intensive recycling methods can potentially offset some of the sustainability gains achieved through battery reuse and material recovery. Developing more energy-efficient and environmentally friendly recycling technologies is crucial to maximizing the net positive impact on sustainability.

Lastly, there is a challenge in establishing effective reverse logistics systems for collecting end-of-life PHEV batteries. The geographically dispersed nature of battery disposal, combined with the need for specialized handling, creates logistical complexities that must be addressed to ensure a steady supply of recyclable materials to processing facilities.

Existing PHEV Battery Recycling Methods

01 Sustainable battery recycling processes

Development of environmentally friendly and efficient methods for recycling batteries, focusing on reducing waste and recovering valuable materials. These processes aim to minimize environmental impact while maximizing the recovery of reusable components from spent batteries.- Sustainable battery recycling processes: Development of environmentally friendly and efficient methods for recycling batteries, focusing on reducing waste and recovering valuable materials. These processes aim to minimize environmental impact while maximizing the recovery of reusable components from spent batteries.

- Battery lifecycle management systems: Implementation of comprehensive systems to track and manage batteries throughout their lifecycle, from production to disposal. These systems help optimize battery use, predict end-of-life, and facilitate efficient recycling processes, contributing to overall sustainability in battery management.

- Innovative battery design for recyclability: Development of battery designs that facilitate easier disassembly and recycling at the end of their life. These designs incorporate features that allow for more efficient separation of components and recovery of materials, enhancing the sustainability of battery production and recycling.

- Energy-efficient battery recycling technologies: Advancements in recycling technologies that reduce energy consumption during the battery recycling process. These technologies focus on minimizing the carbon footprint of recycling operations while maintaining high recovery rates of valuable materials.

- Circular economy approaches in battery industry: Implementation of circular economy principles in the battery industry, focusing on reducing waste, reusing materials, and recycling components. This approach aims to create a closed-loop system that maximizes resource efficiency and minimizes environmental impact throughout the battery lifecycle.

02 Battery lifecycle management systems

Implementation of comprehensive systems for managing the entire lifecycle of batteries, from production to disposal. These systems incorporate tracking, monitoring, and optimization techniques to enhance sustainability and extend battery life, reducing overall environmental impact.Expand Specific Solutions03 Innovative battery design for recyclability

Creation of battery designs that facilitate easier disassembly and recycling at the end of their life cycle. These designs incorporate materials and construction methods that enhance the recyclability of batteries, reducing waste and improving sustainability in the battery industry.Expand Specific Solutions04 Energy-efficient battery recycling technologies

Development of energy-efficient technologies for battery recycling, focusing on reducing the energy consumption and carbon footprint of the recycling process. These technologies aim to make battery recycling more sustainable by minimizing resource use and emissions during the recycling operations.Expand Specific Solutions05 Circular economy approaches in battery manufacturing

Implementation of circular economy principles in battery manufacturing, emphasizing the use of recycled materials and designing for recyclability. This approach aims to create a closed-loop system that minimizes waste, conserves resources, and enhances the overall sustainability of battery production and use.Expand Specific Solutions

Key Players in PHEV Battery Recycling Industry

The battery recycling market for PHEVs is in a growth phase, driven by increasing adoption of electric vehicles and sustainability concerns. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, battery recycling for PHEVs is advancing, but still maturing. Companies like Northvolt, Smartville, and Ascend Elements are developing innovative recycling processes to improve efficiency and reduce environmental impact. Established automotive players such as Toyota, Audi, and Cummins are also investing in recycling technologies to support their sustainability goals. Academic institutions like Zhejiang University and IIT Bombay are contributing to research and development in this field, indicating a collaborative effort to enhance the technology's maturity and effectiveness.

Toyota Motor Corp.

Technical Solution: Toyota has developed an innovative battery recycling system for PHEVs that focuses on maximizing the recovery of rare earth elements and other valuable materials. Their process involves a combination of mechanical and hydrometallurgical techniques to achieve high purity recovery rates. Toyota's system can recover up to 95% of critical materials from used PHEV batteries[1]. The company has also implemented a closed-loop recycling program, where recovered materials are directly used in the production of new PHEV batteries, significantly reducing the need for virgin materials[2]. Additionally, Toyota has invested in developing more easily recyclable battery designs, incorporating features that facilitate disassembly and material separation[3].

Strengths: High recovery rates of critical materials, closed-loop recycling system, and improved battery designs for recyclability. Weaknesses: The process may be energy-intensive and require significant initial investment.

Northvolt Systems AB

Technical Solution: Northvolt has developed a hydrometallurgical recycling process for PHEV batteries that focuses on minimizing environmental impact while maximizing material recovery. Their technology can recover up to 95% of metals from used batteries, including nickel, manganese, cobalt, and lithium[4]. The company's recycling process is powered by 100% renewable energy, significantly reducing the carbon footprint of battery recycling[5]. Northvolt has also implemented a traceability system using blockchain technology to track materials throughout the recycling process, ensuring transparency and accountability[6]. Furthermore, they have developed a modular recycling facility design that can be easily scaled and adapted to different locations and battery chemistries.

Strengths: High material recovery rates, use of renewable energy, advanced traceability system, and scalable facility design. Weaknesses: May require high initial investment and specific infrastructure for renewable energy sources.

Innovative Approaches in Battery Recycling

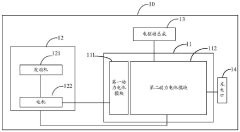

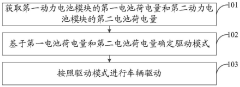

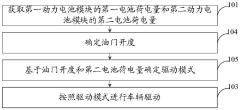

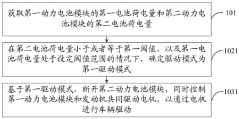

Vehicle driving method, device and equipment, vehicle equipment and storage medium

PatentPendingCN117103974A

Innovation

- Using a hybrid power battery module, by obtaining the battery charge of the first power battery module and the second power battery module, the driving mode is determined based on the charge, and the vehicle is driven adaptively to ensure long battery life and pure electric range.

Environmental Regulations on Battery Disposal

Environmental regulations on battery disposal have become increasingly stringent in recent years, reflecting growing concerns about the environmental impact of improperly discarded batteries from plug-in hybrid electric vehicles (PHEVs). These regulations aim to minimize the release of toxic materials into the environment and promote sustainable practices in the automotive industry.

At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides a framework for managing hazardous waste, including spent batteries. This convention has been ratified by numerous countries and serves as a foundation for national and regional regulations.

In the European Union, the Directive 2006/66/EC on batteries and accumulators and waste batteries and accumulators sets specific targets for the collection and recycling of batteries. It mandates that at least 45% of batteries must be collected for recycling, with higher targets set for future years. The directive also prohibits the disposal of automotive batteries in landfills or through incineration.

The United States has implemented regulations through the Resource Conservation and Recovery Act (RCRA), which classifies certain types of batteries as hazardous waste. The Mercury-Containing and Rechargeable Battery Management Act of 1996 further regulates the disposal of rechargeable batteries, including those used in PHEVs.

China, a major player in the electric vehicle market, has introduced regulations such as the Interim Measures for the Management of Recovery and Utilization of New Energy Vehicle Power Batteries. These measures establish a framework for the recycling and reuse of EV batteries, placing responsibility on manufacturers to ensure proper disposal.

Many countries have adopted extended producer responsibility (EPR) policies, which require manufacturers to take responsibility for the entire lifecycle of their products, including end-of-life disposal. This approach incentivizes companies to design batteries with recyclability in mind and establish efficient recycling systems.

Compliance with these regulations often requires manufacturers to implement battery tracking systems, establish collection networks, and partner with certified recycling facilities. Failure to adhere to these regulations can result in significant fines and reputational damage.

As PHEV technology continues to evolve, regulations are likely to become more comprehensive, addressing emerging concerns such as the recycling of new battery chemistries and the recovery of critical materials. The development of standardized labeling systems and the harmonization of international regulations are ongoing efforts to improve the effectiveness of battery disposal regulations globally.

At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides a framework for managing hazardous waste, including spent batteries. This convention has been ratified by numerous countries and serves as a foundation for national and regional regulations.

In the European Union, the Directive 2006/66/EC on batteries and accumulators and waste batteries and accumulators sets specific targets for the collection and recycling of batteries. It mandates that at least 45% of batteries must be collected for recycling, with higher targets set for future years. The directive also prohibits the disposal of automotive batteries in landfills or through incineration.

The United States has implemented regulations through the Resource Conservation and Recovery Act (RCRA), which classifies certain types of batteries as hazardous waste. The Mercury-Containing and Rechargeable Battery Management Act of 1996 further regulates the disposal of rechargeable batteries, including those used in PHEVs.

China, a major player in the electric vehicle market, has introduced regulations such as the Interim Measures for the Management of Recovery and Utilization of New Energy Vehicle Power Batteries. These measures establish a framework for the recycling and reuse of EV batteries, placing responsibility on manufacturers to ensure proper disposal.

Many countries have adopted extended producer responsibility (EPR) policies, which require manufacturers to take responsibility for the entire lifecycle of their products, including end-of-life disposal. This approach incentivizes companies to design batteries with recyclability in mind and establish efficient recycling systems.

Compliance with these regulations often requires manufacturers to implement battery tracking systems, establish collection networks, and partner with certified recycling facilities. Failure to adhere to these regulations can result in significant fines and reputational damage.

As PHEV technology continues to evolve, regulations are likely to become more comprehensive, addressing emerging concerns such as the recycling of new battery chemistries and the recovery of critical materials. The development of standardized labeling systems and the harmonization of international regulations are ongoing efforts to improve the effectiveness of battery disposal regulations globally.

Economic Viability of Battery Recycling

The economic viability of battery recycling for plug-in hybrid electric vehicles (PHEVs) is a critical factor in determining the overall sustainability of these vehicles. As the adoption of PHEVs continues to grow, the demand for lithium-ion batteries is expected to increase significantly, raising concerns about the availability of raw materials and the environmental impact of battery production and disposal.

Battery recycling offers a potential solution to these challenges by recovering valuable materials and reducing the need for new raw material extraction. However, the economic feasibility of recycling processes plays a crucial role in determining whether large-scale battery recycling can be implemented effectively.

One of the primary factors affecting the economic viability of battery recycling is the cost of the recycling process itself. Current recycling methods, such as pyrometallurgy and hydrometallurgy, require significant energy inputs and specialized equipment, which can make the process expensive. As technology advances and economies of scale are achieved, these costs are expected to decrease, improving the economic viability of recycling.

The value of recovered materials is another key consideration. Lithium-ion batteries contain valuable metals such as lithium, cobalt, and nickel, which can be extracted and reused in new battery production. As the demand for these materials increases and their supply becomes more constrained, the value of recovered materials is likely to rise, making recycling more economically attractive.

Market dynamics also play a crucial role in the economic viability of battery recycling. The fluctuating prices of raw materials can impact the profitability of recycling operations. When raw material prices are high, recycling becomes more economically viable as it offers a cost-effective alternative to new material extraction. Conversely, low raw material prices may reduce the economic incentives for recycling.

Government policies and regulations can significantly influence the economic landscape of battery recycling. Incentives, such as tax breaks or subsidies for recycling operations, can improve the financial viability of these processes. Additionally, regulations mandating the recycling of end-of-life batteries can create a stable market for recycling services, further enhancing their economic viability.

The development of more efficient and cost-effective recycling technologies is crucial for improving the economic viability of battery recycling. Innovations in automated disassembly, material separation, and purification processes can reduce operational costs and increase the recovery rates of valuable materials, making recycling more profitable.

As the PHEV market matures and the volume of end-of-life batteries increases, economies of scale are expected to improve the economic viability of recycling operations. Larger recycling facilities can process batteries more efficiently, reducing per-unit costs and improving overall profitability.

In conclusion, while challenges remain, the economic viability of battery recycling for PHEVs is likely to improve in the coming years. Technological advancements, increasing material values, supportive policies, and growing economies of scale are expected to contribute to making battery recycling a financially sustainable and environmentally beneficial practice in the PHEV industry.

Battery recycling offers a potential solution to these challenges by recovering valuable materials and reducing the need for new raw material extraction. However, the economic feasibility of recycling processes plays a crucial role in determining whether large-scale battery recycling can be implemented effectively.

One of the primary factors affecting the economic viability of battery recycling is the cost of the recycling process itself. Current recycling methods, such as pyrometallurgy and hydrometallurgy, require significant energy inputs and specialized equipment, which can make the process expensive. As technology advances and economies of scale are achieved, these costs are expected to decrease, improving the economic viability of recycling.

The value of recovered materials is another key consideration. Lithium-ion batteries contain valuable metals such as lithium, cobalt, and nickel, which can be extracted and reused in new battery production. As the demand for these materials increases and their supply becomes more constrained, the value of recovered materials is likely to rise, making recycling more economically attractive.

Market dynamics also play a crucial role in the economic viability of battery recycling. The fluctuating prices of raw materials can impact the profitability of recycling operations. When raw material prices are high, recycling becomes more economically viable as it offers a cost-effective alternative to new material extraction. Conversely, low raw material prices may reduce the economic incentives for recycling.

Government policies and regulations can significantly influence the economic landscape of battery recycling. Incentives, such as tax breaks or subsidies for recycling operations, can improve the financial viability of these processes. Additionally, regulations mandating the recycling of end-of-life batteries can create a stable market for recycling services, further enhancing their economic viability.

The development of more efficient and cost-effective recycling technologies is crucial for improving the economic viability of battery recycling. Innovations in automated disassembly, material separation, and purification processes can reduce operational costs and increase the recovery rates of valuable materials, making recycling more profitable.

As the PHEV market matures and the volume of end-of-life batteries increases, economies of scale are expected to improve the economic viability of recycling operations. Larger recycling facilities can process batteries more efficiently, reducing per-unit costs and improving overall profitability.

In conclusion, while challenges remain, the economic viability of battery recycling for PHEVs is likely to improve in the coming years. Technological advancements, increasing material values, supportive policies, and growing economies of scale are expected to contribute to making battery recycling a financially sustainable and environmentally beneficial practice in the PHEV industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!