Investigating Propionic Acid's Eco-Friendly Manufacturing Options

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propionic Acid Overview

Propionic acid, a three-carbon carboxylic acid with the chemical formula C3H6O2, is a versatile compound widely used in various industries. It is a colorless liquid with a pungent odor, naturally occurring in small quantities in dairy products and produced by certain bacteria in the human gut. The compound's name is derived from the Greek words "protos" (first) and "pion" (fat), reflecting its position as the smallest fatty acid that exhibits typical fatty acid properties.

In the chemical industry, propionic acid serves as an important intermediate in the production of cellulose plastics, herbicides, and pharmaceuticals. Its antimicrobial properties make it a valuable food preservative, particularly in baked goods and animal feed. The compound also finds applications in the production of artificial fruit flavors and perfumes due to its characteristic odor.

The global market for propionic acid has been steadily growing, driven by increasing demand in the food and feed industries. As consumers become more health-conscious, the use of propionic acid as a natural preservative has gained traction. Additionally, its role in the production of vitamin E and various pharmaceuticals has further bolstered its market position.

Traditionally, propionic acid has been manufactured through petrochemical routes, primarily via the oxidation of propanol or the carbonylation of ethylene. However, these methods rely heavily on fossil fuel-based feedstocks and often involve energy-intensive processes with significant environmental impacts. As sustainability concerns grow, there is an increasing push towards developing more eco-friendly manufacturing options for propionic acid.

Recent research has focused on bio-based production methods, leveraging renewable resources and microbial fermentation processes. These approaches aim to reduce the carbon footprint of propionic acid production while maintaining economic viability. Potential feedstocks for bio-based production include agricultural waste, glycerol (a byproduct of biodiesel production), and other renewable carbon sources.

The investigation into eco-friendly manufacturing options for propionic acid is driven by several factors, including the need to reduce greenhouse gas emissions, minimize dependence on fossil fuels, and meet growing consumer demand for sustainable products. This shift towards greener production methods aligns with global efforts to transition to a circular economy and mitigate climate change impacts.

As the industry explores these alternative production routes, challenges such as process efficiency, scalability, and cost-competitiveness must be addressed. The successful development of eco-friendly manufacturing options for propionic acid could not only revolutionize its production but also serve as a model for sustainable chemical manufacturing practices across the industry.

In the chemical industry, propionic acid serves as an important intermediate in the production of cellulose plastics, herbicides, and pharmaceuticals. Its antimicrobial properties make it a valuable food preservative, particularly in baked goods and animal feed. The compound also finds applications in the production of artificial fruit flavors and perfumes due to its characteristic odor.

The global market for propionic acid has been steadily growing, driven by increasing demand in the food and feed industries. As consumers become more health-conscious, the use of propionic acid as a natural preservative has gained traction. Additionally, its role in the production of vitamin E and various pharmaceuticals has further bolstered its market position.

Traditionally, propionic acid has been manufactured through petrochemical routes, primarily via the oxidation of propanol or the carbonylation of ethylene. However, these methods rely heavily on fossil fuel-based feedstocks and often involve energy-intensive processes with significant environmental impacts. As sustainability concerns grow, there is an increasing push towards developing more eco-friendly manufacturing options for propionic acid.

Recent research has focused on bio-based production methods, leveraging renewable resources and microbial fermentation processes. These approaches aim to reduce the carbon footprint of propionic acid production while maintaining economic viability. Potential feedstocks for bio-based production include agricultural waste, glycerol (a byproduct of biodiesel production), and other renewable carbon sources.

The investigation into eco-friendly manufacturing options for propionic acid is driven by several factors, including the need to reduce greenhouse gas emissions, minimize dependence on fossil fuels, and meet growing consumer demand for sustainable products. This shift towards greener production methods aligns with global efforts to transition to a circular economy and mitigate climate change impacts.

As the industry explores these alternative production routes, challenges such as process efficiency, scalability, and cost-competitiveness must be addressed. The successful development of eco-friendly manufacturing options for propionic acid could not only revolutionize its production but also serve as a model for sustainable chemical manufacturing practices across the industry.

Market Demand Analysis

The market demand for propionic acid has been steadily growing, driven by its diverse applications across various industries. The global propionic acid market size was valued at approximately 1.5 billion USD in 2020 and is projected to reach 2.1 billion USD by 2027, exhibiting a compound annual growth rate (CAGR) of around 5% during the forecast period.

The food and beverage industry remains the largest consumer of propionic acid, accounting for over 40% of the total market share. Its use as a preservative in bakery products, cheese, and other processed foods continues to drive demand. The increasing consumer preference for packaged and convenience foods, particularly in developing economies, further fuels this growth.

In the animal feed sector, propionic acid's role as an effective mold inhibitor and feed preservative has led to increased adoption. The growing livestock industry, coupled with stricter regulations on feed quality and safety, has contributed to the rising demand in this segment.

The pharmaceutical industry represents another significant market for propionic acid, where it is used in the production of various medications and as a precursor for vitamin E synthesis. The expanding pharmaceutical sector, especially in emerging markets, is expected to create new opportunities for propionic acid manufacturers.

Environmental concerns and sustainability initiatives have sparked interest in eco-friendly manufacturing options for propionic acid. This trend aligns with the growing demand for bio-based chemicals and green alternatives across industries. As a result, there is a notable shift towards developing and adopting more sustainable production methods.

The Asia-Pacific region is anticipated to witness the highest growth rate in the propionic acid market, driven by rapid industrialization, increasing population, and rising disposable incomes. China and India are expected to be the key contributors to this regional growth, with their expanding food processing and animal feed industries.

North America and Europe continue to be significant markets for propionic acid, with a focus on high-quality, sustainable products. The stringent regulations on food safety and increasing awareness of eco-friendly solutions in these regions are likely to drive the demand for bio-based propionic acid.

In conclusion, the market demand for propionic acid remains robust, with a clear trend towards more sustainable and environmentally friendly production methods. This shift presents both challenges and opportunities for manufacturers to innovate and adapt to changing consumer preferences and regulatory landscapes.

The food and beverage industry remains the largest consumer of propionic acid, accounting for over 40% of the total market share. Its use as a preservative in bakery products, cheese, and other processed foods continues to drive demand. The increasing consumer preference for packaged and convenience foods, particularly in developing economies, further fuels this growth.

In the animal feed sector, propionic acid's role as an effective mold inhibitor and feed preservative has led to increased adoption. The growing livestock industry, coupled with stricter regulations on feed quality and safety, has contributed to the rising demand in this segment.

The pharmaceutical industry represents another significant market for propionic acid, where it is used in the production of various medications and as a precursor for vitamin E synthesis. The expanding pharmaceutical sector, especially in emerging markets, is expected to create new opportunities for propionic acid manufacturers.

Environmental concerns and sustainability initiatives have sparked interest in eco-friendly manufacturing options for propionic acid. This trend aligns with the growing demand for bio-based chemicals and green alternatives across industries. As a result, there is a notable shift towards developing and adopting more sustainable production methods.

The Asia-Pacific region is anticipated to witness the highest growth rate in the propionic acid market, driven by rapid industrialization, increasing population, and rising disposable incomes. China and India are expected to be the key contributors to this regional growth, with their expanding food processing and animal feed industries.

North America and Europe continue to be significant markets for propionic acid, with a focus on high-quality, sustainable products. The stringent regulations on food safety and increasing awareness of eco-friendly solutions in these regions are likely to drive the demand for bio-based propionic acid.

In conclusion, the market demand for propionic acid remains robust, with a clear trend towards more sustainable and environmentally friendly production methods. This shift presents both challenges and opportunities for manufacturers to innovate and adapt to changing consumer preferences and regulatory landscapes.

Current Manufacturing Challenges

The current manufacturing process of propionic acid faces several significant challenges that hinder its eco-friendly production. One of the primary issues is the reliance on petrochemical feedstocks, particularly propanol or propanal, which are derived from non-renewable fossil fuels. This dependency not only contributes to environmental concerns but also exposes the production process to price volatility in the oil market.

Energy intensity is another major challenge in propionic acid manufacturing. The traditional oxidation process requires high temperatures and pressures, resulting in substantial energy consumption and associated greenhouse gas emissions. This energy-intensive nature of production contradicts the principles of sustainable manufacturing and increases the carbon footprint of the final product.

The use of metal catalysts, often containing precious or rare earth metals, presents both economic and environmental challenges. These catalysts can be expensive, difficult to recover, and may lead to metal contamination in the final product. Additionally, the disposal or recycling of spent catalysts poses environmental risks if not managed properly.

Waste management is a significant concern in current manufacturing processes. The production of propionic acid often generates byproducts and waste streams that require treatment or disposal. These waste products can include unreacted raw materials, side-reaction products, and spent catalysts, all of which contribute to environmental pollution if not handled correctly.

Water usage and wastewater treatment represent another set of challenges. Many current processes require substantial amounts of water for reactions, cooling, and cleaning. The resulting wastewater often contains organic compounds and traces of catalysts, necessitating extensive treatment before release, which adds to the overall environmental impact and production costs.

The use of corrosive materials in the manufacturing process, such as strong acids or bases, presents safety concerns and requires specialized equipment. This not only increases production costs but also poses potential risks to workers and the environment in case of accidents or leaks.

Yield and selectivity issues in current manufacturing methods lead to inefficient use of raw materials. Side reactions and incomplete conversions result in lower yields of propionic acid, necessitating additional purification steps and increasing overall resource consumption.

Lastly, the scalability of eco-friendly alternatives to traditional manufacturing processes remains a significant challenge. While several green chemistry approaches have shown promise in laboratory settings, scaling these methods to industrial production levels while maintaining efficiency and cost-effectiveness has proven difficult. This scalability issue is a major hurdle in transitioning to more sustainable production methods for propionic acid.

Energy intensity is another major challenge in propionic acid manufacturing. The traditional oxidation process requires high temperatures and pressures, resulting in substantial energy consumption and associated greenhouse gas emissions. This energy-intensive nature of production contradicts the principles of sustainable manufacturing and increases the carbon footprint of the final product.

The use of metal catalysts, often containing precious or rare earth metals, presents both economic and environmental challenges. These catalysts can be expensive, difficult to recover, and may lead to metal contamination in the final product. Additionally, the disposal or recycling of spent catalysts poses environmental risks if not managed properly.

Waste management is a significant concern in current manufacturing processes. The production of propionic acid often generates byproducts and waste streams that require treatment or disposal. These waste products can include unreacted raw materials, side-reaction products, and spent catalysts, all of which contribute to environmental pollution if not handled correctly.

Water usage and wastewater treatment represent another set of challenges. Many current processes require substantial amounts of water for reactions, cooling, and cleaning. The resulting wastewater often contains organic compounds and traces of catalysts, necessitating extensive treatment before release, which adds to the overall environmental impact and production costs.

The use of corrosive materials in the manufacturing process, such as strong acids or bases, presents safety concerns and requires specialized equipment. This not only increases production costs but also poses potential risks to workers and the environment in case of accidents or leaks.

Yield and selectivity issues in current manufacturing methods lead to inefficient use of raw materials. Side reactions and incomplete conversions result in lower yields of propionic acid, necessitating additional purification steps and increasing overall resource consumption.

Lastly, the scalability of eco-friendly alternatives to traditional manufacturing processes remains a significant challenge. While several green chemistry approaches have shown promise in laboratory settings, scaling these methods to industrial production levels while maintaining efficiency and cost-effectiveness has proven difficult. This scalability issue is a major hurdle in transitioning to more sustainable production methods for propionic acid.

Eco-Friendly Production Methods

01 Production methods of propionic acid

Various methods for producing propionic acid are described, including fermentation processes, chemical synthesis, and catalytic reactions. These methods aim to improve yield, efficiency, and purity of propionic acid production for industrial applications.- Production methods of propionic acid: Various methods for producing propionic acid are described, including fermentation processes, chemical synthesis routes, and catalytic reactions. These methods aim to improve yield, efficiency, and purity of propionic acid production for industrial applications.

- Applications of propionic acid in food preservation: Propionic acid and its salts are widely used as food preservatives due to their antimicrobial properties. They are effective in preventing mold growth and extending the shelf life of various food products, particularly in bakery items and dairy products.

- Use of propionic acid in pharmaceutical formulations: Propionic acid and its derivatives find applications in pharmaceutical formulations. They are used as excipients, pH adjusters, and in some cases as active pharmaceutical ingredients for various therapeutic purposes.

- Industrial applications of propionic acid: Propionic acid has diverse industrial applications beyond food and pharmaceuticals. It is used in the production of plastics, herbicides, and as a chemical intermediate in various manufacturing processes. The acid's properties make it valuable in multiple industries.

- Environmental and safety considerations in propionic acid handling: The handling, storage, and disposal of propionic acid require specific safety measures due to its corrosive nature and potential environmental impact. Proper containment, neutralization techniques, and waste management practices are essential for safe industrial use of propionic acid.

02 Applications of propionic acid in food preservation

Propionic acid and its salts are widely used as food preservatives due to their antimicrobial properties. They are effective in preventing mold growth and extending the shelf life of various food products, particularly in bakery items and animal feed.Expand Specific Solutions03 Use of propionic acid in pharmaceutical formulations

Propionic acid and its derivatives are utilized in pharmaceutical compositions for various therapeutic applications. These include topical treatments, oral medications, and drug delivery systems, leveraging the acid's properties for improved efficacy and stability of formulations.Expand Specific Solutions04 Industrial applications of propionic acid

Propionic acid finds diverse industrial applications beyond food and pharmaceuticals. It is used in the production of plastics, herbicides, and as a chemical intermediate in various manufacturing processes. The acid's versatility makes it valuable in multiple industries.Expand Specific Solutions05 Purification and analysis techniques for propionic acid

Various methods for purifying and analyzing propionic acid are described. These include distillation techniques, chromatographic methods, and spectroscopic analyses to ensure high purity and quality control in propionic acid production and use.Expand Specific Solutions

Key Industry Players

The eco-friendly manufacturing of propionic acid is in a transitional phase, with growing market demand driven by sustainability concerns. The global market size is expanding, expected to reach $1.5 billion by 2025. Technologically, the field is advancing rapidly, with both established players and innovative startups contributing. Companies like LG Chem, Dow Global Technologies, and DuPont are leading in traditional petrochemical-based production, while firms such as Novomer and Braskem are pioneering bio-based and CO2-utilization methods. Universities, including Ohio State and Xiamen University, are actively researching novel catalysts and processes, indicating a strong focus on innovation and sustainability in this sector.

Evonik Operations GmbH

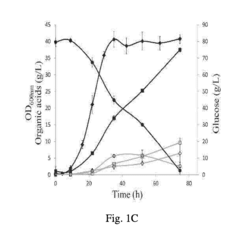

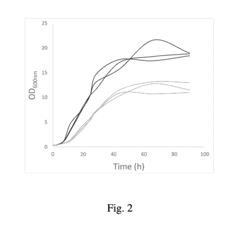

Technical Solution: Evonik has developed a bio-based production method for propionic acid using renewable resources. Their process involves fermenting biomass-derived sugars using proprietary microorganisms. The company has optimized the fermentation conditions and downstream processing to achieve high yields and purity. Evonik's method incorporates advanced bioreactor designs and continuous fermentation techniques to enhance productivity[1]. They have also implemented energy-efficient separation and purification steps, including membrane filtration and distillation, to minimize environmental impact[2]. The process is scalable and has been successfully demonstrated at pilot plant scale.

Strengths: Renewable feedstock, reduced carbon footprint, scalable process. Weaknesses: Potentially higher production costs compared to petrochemical routes, reliance on biomass availability.

LG Chem Ltd.

Technical Solution: LG Chem has invested in developing a novel catalytic process for propionic acid production from renewable ethanol. Their approach utilizes a heterogeneous catalyst system based on modified zeolites to convert bio-ethanol to propionic acid in a single-step reaction[3]. The process operates under moderate temperature and pressure conditions, reducing energy requirements. LG Chem has engineered the catalyst to achieve high selectivity towards propionic acid, minimizing byproduct formation. The company has also implemented an innovative reactive distillation setup, combining reaction and separation in a single unit to improve process efficiency[4]. This integrated approach results in reduced equipment footprint and lower operating costs.

Strengths: High selectivity, energy-efficient process, potential for integration with existing bio-ethanol production. Weaknesses: Catalyst stability and longevity may be challenging, dependence on bio-ethanol availability.

Innovative Catalytic Processes

Improved propionibacterium strains for the production of propionic acid

PatentWO2017055932A2

Innovation

- Genome shuffling between selected Propionibacterium strains, such as P. acidipropionici ATCC 4875 and P. acidipropionici ATCC 55737, to generate novel strains with enhanced growth rates and propionic acid production, utilizing genetic material exchange to create strains with improved metabolic pathways and regulatory mechanisms.

Improved propionibacterium strains for the production of propionic acid

PatentInactiveUS20190071697A1

Innovation

- Selecting and combining Propionibacterium strains with high potential for propionic acid production, such as P. acidipropionici ATCC 4875 and P. acidipropionici ATCC 55737, through genome shuffling to create novel strains with improved growth rates and reduced byproduct production, such as P. acidipropionici F3E8, which achieves enhanced propionic acid yields and growth rates.

Environmental Impact Assessment

The environmental impact assessment of propionic acid manufacturing is crucial for evaluating eco-friendly production options. Traditional methods of propionic acid production, primarily through petrochemical processes, have significant environmental drawbacks. These include high energy consumption, greenhouse gas emissions, and the use of non-renewable fossil fuel resources.

In contrast, bio-based production methods offer promising alternatives with potentially lower environmental footprints. Fermentation processes using renewable feedstocks such as glucose or glycerol can reduce dependency on fossil fuels and decrease carbon dioxide emissions. However, these methods also present challenges, including water consumption and the generation of organic waste streams that require proper management.

Life cycle assessment (LCA) studies have shown that bio-based propionic acid production can result in lower global warming potential compared to petrochemical routes. For instance, some studies indicate a reduction of up to 50% in greenhouse gas emissions when using renewable feedstocks. However, the environmental benefits can vary depending on the specific production process, feedstock source, and energy mix used in manufacturing.

Water usage is another critical factor in the environmental impact assessment. While bio-based processes may require more water than petrochemical routes, advancements in water recycling and treatment technologies can mitigate this concern. Additionally, the use of agricultural by-products or waste streams as feedstocks can improve the overall water footprint of the production process.

Land use change is an important consideration, especially when agricultural feedstocks are used. The expansion of crops for industrial use can potentially lead to deforestation or competition with food production. However, utilizing waste streams or non-food crops can help address these concerns and improve the sustainability profile of propionic acid production.

The disposal and potential environmental fate of propionic acid and its by-products must also be assessed. While propionic acid is biodegradable and poses low environmental persistence, proper handling and waste management practices are essential to prevent soil and water contamination.

Eco-toxicity studies have shown that propionic acid has relatively low toxicity to aquatic organisms compared to many other industrial chemicals. However, concentrated releases could still have localized impacts on ecosystems, emphasizing the importance of responsible manufacturing practices and effective effluent treatment.

In conclusion, the environmental impact assessment of propionic acid production reveals that eco-friendly manufacturing options, particularly bio-based methods, have the potential to significantly reduce the overall environmental footprint. However, a holistic approach considering all aspects of the production lifecycle is necessary to ensure true sustainability and minimize negative environmental impacts.

In contrast, bio-based production methods offer promising alternatives with potentially lower environmental footprints. Fermentation processes using renewable feedstocks such as glucose or glycerol can reduce dependency on fossil fuels and decrease carbon dioxide emissions. However, these methods also present challenges, including water consumption and the generation of organic waste streams that require proper management.

Life cycle assessment (LCA) studies have shown that bio-based propionic acid production can result in lower global warming potential compared to petrochemical routes. For instance, some studies indicate a reduction of up to 50% in greenhouse gas emissions when using renewable feedstocks. However, the environmental benefits can vary depending on the specific production process, feedstock source, and energy mix used in manufacturing.

Water usage is another critical factor in the environmental impact assessment. While bio-based processes may require more water than petrochemical routes, advancements in water recycling and treatment technologies can mitigate this concern. Additionally, the use of agricultural by-products or waste streams as feedstocks can improve the overall water footprint of the production process.

Land use change is an important consideration, especially when agricultural feedstocks are used. The expansion of crops for industrial use can potentially lead to deforestation or competition with food production. However, utilizing waste streams or non-food crops can help address these concerns and improve the sustainability profile of propionic acid production.

The disposal and potential environmental fate of propionic acid and its by-products must also be assessed. While propionic acid is biodegradable and poses low environmental persistence, proper handling and waste management practices are essential to prevent soil and water contamination.

Eco-toxicity studies have shown that propionic acid has relatively low toxicity to aquatic organisms compared to many other industrial chemicals. However, concentrated releases could still have localized impacts on ecosystems, emphasizing the importance of responsible manufacturing practices and effective effluent treatment.

In conclusion, the environmental impact assessment of propionic acid production reveals that eco-friendly manufacturing options, particularly bio-based methods, have the potential to significantly reduce the overall environmental footprint. However, a holistic approach considering all aspects of the production lifecycle is necessary to ensure true sustainability and minimize negative environmental impacts.

Regulatory Compliance Landscape

The regulatory landscape for eco-friendly manufacturing of propionic acid is complex and evolving, with various international, national, and regional regulations impacting production processes, emissions, and waste management. At the global level, the Paris Agreement and United Nations Sustainable Development Goals provide overarching frameworks for reducing environmental impact across industries, including chemical manufacturing.

In the European Union, the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation sets stringent requirements for chemical production and use. Manufacturers of propionic acid must register their substances with the European Chemicals Agency (ECHA) and provide detailed safety and environmental impact data. The EU's Industrial Emissions Directive (IED) also applies, setting emission limits and mandating the use of Best Available Techniques (BAT) in production processes.

In the United States, the Environmental Protection Agency (EPA) regulates chemical manufacturing under various acts, including the Clean Air Act, Clean Water Act, and Toxic Substances Control Act (TSCA). The EPA's Safer Choice program encourages the development of environmentally preferable chemicals and processes, which could influence future regulations on propionic acid production.

China, a major player in chemical manufacturing, has implemented increasingly stringent environmental regulations. The country's Environmental Protection Law and Circular Economy Promotion Law set standards for emissions, waste management, and resource efficiency in industrial processes, including those used in propionic acid production.

Many countries have implemented carbon pricing mechanisms, such as carbon taxes or cap-and-trade systems, which can impact the economic viability of different production methods for propionic acid. These policies incentivize the adoption of more environmentally friendly manufacturing processes.

Waste management regulations also play a crucial role in the regulatory landscape. The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal sets global standards for the management of hazardous waste, which may apply to certain byproducts of propionic acid manufacturing.

As sustainability becomes increasingly important to consumers and investors, voluntary standards and certifications are gaining prominence. Programs like ISO 14001 for environmental management systems and various green chemistry certifications can provide a competitive advantage for manufacturers adopting eco-friendly production methods.

Looking ahead, regulatory trends indicate a continued push towards stricter environmental standards and increased emphasis on circular economy principles. This may lead to new regulations promoting bio-based feedstocks, mandating energy efficiency improvements, or requiring life cycle assessments for chemical products. Manufacturers exploring eco-friendly options for propionic acid production should anticipate and prepare for these evolving regulatory requirements to ensure long-term compliance and competitiveness.

In the European Union, the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation sets stringent requirements for chemical production and use. Manufacturers of propionic acid must register their substances with the European Chemicals Agency (ECHA) and provide detailed safety and environmental impact data. The EU's Industrial Emissions Directive (IED) also applies, setting emission limits and mandating the use of Best Available Techniques (BAT) in production processes.

In the United States, the Environmental Protection Agency (EPA) regulates chemical manufacturing under various acts, including the Clean Air Act, Clean Water Act, and Toxic Substances Control Act (TSCA). The EPA's Safer Choice program encourages the development of environmentally preferable chemicals and processes, which could influence future regulations on propionic acid production.

China, a major player in chemical manufacturing, has implemented increasingly stringent environmental regulations. The country's Environmental Protection Law and Circular Economy Promotion Law set standards for emissions, waste management, and resource efficiency in industrial processes, including those used in propionic acid production.

Many countries have implemented carbon pricing mechanisms, such as carbon taxes or cap-and-trade systems, which can impact the economic viability of different production methods for propionic acid. These policies incentivize the adoption of more environmentally friendly manufacturing processes.

Waste management regulations also play a crucial role in the regulatory landscape. The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal sets global standards for the management of hazardous waste, which may apply to certain byproducts of propionic acid manufacturing.

As sustainability becomes increasingly important to consumers and investors, voluntary standards and certifications are gaining prominence. Programs like ISO 14001 for environmental management systems and various green chemistry certifications can provide a competitive advantage for manufacturers adopting eco-friendly production methods.

Looking ahead, regulatory trends indicate a continued push towards stricter environmental standards and increased emphasis on circular economy principles. This may lead to new regulations promoting bio-based feedstocks, mandating energy efficiency improvements, or requiring life cycle assessments for chemical products. Manufacturers exploring eco-friendly options for propionic acid production should anticipate and prepare for these evolving regulatory requirements to ensure long-term compliance and competitiveness.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!