Longitudinal wave interaction with liquid-metal jet technologies

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid-Metal Jet Tech Background and Objectives

Liquid-metal jet technology has emerged as a promising field in advanced manufacturing and materials science, with roots tracing back to the mid-20th century. Initially developed for nuclear reactor cooling systems, this technology has since found applications in various industries, including additive manufacturing, heat transfer systems, and advanced propulsion.

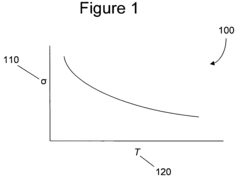

The evolution of liquid-metal jet technology has been driven by the unique properties of liquid metals, such as high thermal conductivity, low vapor pressure, and the ability to remain in liquid form at high temperatures. These characteristics make liquid metals ideal for applications requiring efficient heat transfer and precise control of material properties.

In recent years, the interaction between longitudinal waves and liquid-metal jets has gained significant attention from researchers and engineers. This phenomenon offers potential breakthroughs in areas such as material processing, energy harvesting, and advanced sensing technologies. The study of wave-material interactions in liquid metals provides insights into fundamental physics and opens up new possibilities for manipulating matter at the microscale.

The primary objective of research in this field is to understand and harness the effects of longitudinal wave propagation through liquid-metal jets. This includes investigating how different wave frequencies and amplitudes influence the behavior of the liquid metal, as well as exploring methods to control and optimize these interactions for specific applications.

Key technical goals in this area include developing precise control mechanisms for liquid-metal jet formation and manipulation, enhancing the stability of liquid-metal streams under various wave conditions, and improving the efficiency of energy transfer between longitudinal waves and liquid metals. Additionally, researchers aim to expand the range of materials compatible with this technology and scale up processes for industrial applications.

As the field progresses, there is a growing focus on integrating liquid-metal jet technologies with other advanced manufacturing techniques, such as 3D printing and rapid prototyping. This convergence of technologies is expected to enable the creation of novel materials and structures with unprecedented properties and functionalities.

The future trajectory of liquid-metal jet technology, particularly in the context of longitudinal wave interactions, points towards miniaturization, increased precision, and broader application in fields such as microfluidics, advanced cooling systems for electronics, and next-generation energy conversion devices. As research continues, the potential for groundbreaking discoveries and innovative applications in this dynamic field remains substantial.

The evolution of liquid-metal jet technology has been driven by the unique properties of liquid metals, such as high thermal conductivity, low vapor pressure, and the ability to remain in liquid form at high temperatures. These characteristics make liquid metals ideal for applications requiring efficient heat transfer and precise control of material properties.

In recent years, the interaction between longitudinal waves and liquid-metal jets has gained significant attention from researchers and engineers. This phenomenon offers potential breakthroughs in areas such as material processing, energy harvesting, and advanced sensing technologies. The study of wave-material interactions in liquid metals provides insights into fundamental physics and opens up new possibilities for manipulating matter at the microscale.

The primary objective of research in this field is to understand and harness the effects of longitudinal wave propagation through liquid-metal jets. This includes investigating how different wave frequencies and amplitudes influence the behavior of the liquid metal, as well as exploring methods to control and optimize these interactions for specific applications.

Key technical goals in this area include developing precise control mechanisms for liquid-metal jet formation and manipulation, enhancing the stability of liquid-metal streams under various wave conditions, and improving the efficiency of energy transfer between longitudinal waves and liquid metals. Additionally, researchers aim to expand the range of materials compatible with this technology and scale up processes for industrial applications.

As the field progresses, there is a growing focus on integrating liquid-metal jet technologies with other advanced manufacturing techniques, such as 3D printing and rapid prototyping. This convergence of technologies is expected to enable the creation of novel materials and structures with unprecedented properties and functionalities.

The future trajectory of liquid-metal jet technology, particularly in the context of longitudinal wave interactions, points towards miniaturization, increased precision, and broader application in fields such as microfluidics, advanced cooling systems for electronics, and next-generation energy conversion devices. As research continues, the potential for groundbreaking discoveries and innovative applications in this dynamic field remains substantial.

Market Analysis for Liquid-Metal Jet Applications

The market for liquid-metal jet applications is experiencing significant growth, driven by advancements in longitudinal wave interaction technologies. This emerging field combines the unique properties of liquid metals with the precision control offered by longitudinal wave manipulation, opening up new possibilities across various industries.

In the manufacturing sector, liquid-metal jet technologies are revolutionizing additive manufacturing processes. The ability to precisely control liquid metal streams using longitudinal waves allows for the creation of complex, high-resolution 3D printed components with superior mechanical properties. This has attracted considerable interest from aerospace and automotive industries, where lightweight yet strong materials are in high demand.

The electronics industry is another key market for liquid-metal jet applications. The technology enables the production of flexible and stretchable electronic circuits, which are crucial for wearable devices and next-generation displays. As consumer demand for more versatile and durable electronic products continues to rise, the market potential for liquid-metal jet technologies in this sector is expected to expand rapidly.

In the energy sector, liquid-metal jet applications are gaining traction in nuclear reactor designs and advanced cooling systems. The unique heat transfer properties of liquid metals, combined with the precise control offered by longitudinal wave interaction, provide innovative solutions for managing high-temperature environments efficiently. This has sparked interest from both traditional energy companies and emerging clean energy startups.

The medical field represents another promising market for liquid-metal jet technologies. Applications in targeted drug delivery systems and minimally invasive surgical tools are being explored, leveraging the controllable nature of liquid metal streams. As healthcare continues to move towards more personalized and precise treatments, the demand for such advanced technologies is likely to increase.

Market analysts project substantial growth in the global liquid-metal jet technology market over the next decade. While specific market size figures vary, the consensus indicates a compound annual growth rate (CAGR) in the double digits. This growth is attributed to increasing adoption across multiple industries and ongoing research and development efforts to expand the technology's capabilities.

However, the market faces challenges that could impact its growth trajectory. These include the high initial costs associated with implementing liquid-metal jet technologies, regulatory hurdles in sensitive industries like healthcare and aerospace, and the need for specialized expertise to operate and maintain these systems. Overcoming these barriers will be crucial for widespread market adoption and realizing the full potential of liquid-metal jet applications.

In the manufacturing sector, liquid-metal jet technologies are revolutionizing additive manufacturing processes. The ability to precisely control liquid metal streams using longitudinal waves allows for the creation of complex, high-resolution 3D printed components with superior mechanical properties. This has attracted considerable interest from aerospace and automotive industries, where lightweight yet strong materials are in high demand.

The electronics industry is another key market for liquid-metal jet applications. The technology enables the production of flexible and stretchable electronic circuits, which are crucial for wearable devices and next-generation displays. As consumer demand for more versatile and durable electronic products continues to rise, the market potential for liquid-metal jet technologies in this sector is expected to expand rapidly.

In the energy sector, liquid-metal jet applications are gaining traction in nuclear reactor designs and advanced cooling systems. The unique heat transfer properties of liquid metals, combined with the precise control offered by longitudinal wave interaction, provide innovative solutions for managing high-temperature environments efficiently. This has sparked interest from both traditional energy companies and emerging clean energy startups.

The medical field represents another promising market for liquid-metal jet technologies. Applications in targeted drug delivery systems and minimally invasive surgical tools are being explored, leveraging the controllable nature of liquid metal streams. As healthcare continues to move towards more personalized and precise treatments, the demand for such advanced technologies is likely to increase.

Market analysts project substantial growth in the global liquid-metal jet technology market over the next decade. While specific market size figures vary, the consensus indicates a compound annual growth rate (CAGR) in the double digits. This growth is attributed to increasing adoption across multiple industries and ongoing research and development efforts to expand the technology's capabilities.

However, the market faces challenges that could impact its growth trajectory. These include the high initial costs associated with implementing liquid-metal jet technologies, regulatory hurdles in sensitive industries like healthcare and aerospace, and the need for specialized expertise to operate and maintain these systems. Overcoming these barriers will be crucial for widespread market adoption and realizing the full potential of liquid-metal jet applications.

Current Challenges in Longitudinal Wave Interactions

The interaction between longitudinal waves and liquid-metal jets presents several significant challenges that researchers and engineers are currently grappling with. One of the primary difficulties lies in the complex nature of wave propagation through liquid metals, which exhibit unique properties due to their high electrical conductivity and fluid dynamics.

A major challenge is the accurate modeling and prediction of wave behavior in liquid-metal jets. The non-linear interactions between the longitudinal waves and the liquid metal's surface tension, viscosity, and electromagnetic properties make it challenging to develop precise mathematical models. This complexity is further compounded by the high-speed flow characteristics of liquid-metal jets, which can lead to instabilities and unpredictable wave patterns.

Another significant hurdle is the development of robust measurement techniques for studying these interactions. Traditional sensing methods often struggle to capture the rapid changes and fine-scale phenomena occurring at the liquid-metal interface. The extreme temperatures and reactive nature of many liquid metals also pose substantial difficulties in designing and implementing suitable experimental setups.

The control and manipulation of longitudinal waves in liquid-metal jets represent another area of ongoing challenge. Researchers are striving to develop methods for precisely directing and focusing these waves to achieve desired effects, such as material processing or energy transfer. However, the inherent instability of liquid-metal flows and the sensitivity of wave propagation to small perturbations make fine control a formidable task.

Furthermore, the integration of longitudinal wave interactions with liquid-metal jet technologies into practical applications faces several obstacles. These include scaling issues when moving from laboratory experiments to industrial-scale implementations, as well as concerns about the long-term stability and reliability of such systems under operational conditions.

Researchers are also confronting challenges related to the energy efficiency of longitudinal wave generation and propagation in liquid-metal jets. The high power requirements for producing and maintaining controlled wave patterns in these systems can limit their practical applicability in various industrial and scientific contexts.

Lastly, there are significant safety and environmental considerations that need to be addressed. The handling of liquid metals, particularly at high temperatures, poses inherent risks, and the potential for electromagnetic interference from high-power wave generators must be carefully managed. Additionally, ensuring the containment and proper disposal of liquid-metal materials used in these applications presents ongoing challenges for researchers and engineers in the field.

A major challenge is the accurate modeling and prediction of wave behavior in liquid-metal jets. The non-linear interactions between the longitudinal waves and the liquid metal's surface tension, viscosity, and electromagnetic properties make it challenging to develop precise mathematical models. This complexity is further compounded by the high-speed flow characteristics of liquid-metal jets, which can lead to instabilities and unpredictable wave patterns.

Another significant hurdle is the development of robust measurement techniques for studying these interactions. Traditional sensing methods often struggle to capture the rapid changes and fine-scale phenomena occurring at the liquid-metal interface. The extreme temperatures and reactive nature of many liquid metals also pose substantial difficulties in designing and implementing suitable experimental setups.

The control and manipulation of longitudinal waves in liquid-metal jets represent another area of ongoing challenge. Researchers are striving to develop methods for precisely directing and focusing these waves to achieve desired effects, such as material processing or energy transfer. However, the inherent instability of liquid-metal flows and the sensitivity of wave propagation to small perturbations make fine control a formidable task.

Furthermore, the integration of longitudinal wave interactions with liquid-metal jet technologies into practical applications faces several obstacles. These include scaling issues when moving from laboratory experiments to industrial-scale implementations, as well as concerns about the long-term stability and reliability of such systems under operational conditions.

Researchers are also confronting challenges related to the energy efficiency of longitudinal wave generation and propagation in liquid-metal jets. The high power requirements for producing and maintaining controlled wave patterns in these systems can limit their practical applicability in various industrial and scientific contexts.

Lastly, there are significant safety and environmental considerations that need to be addressed. The handling of liquid metals, particularly at high temperatures, poses inherent risks, and the potential for electromagnetic interference from high-power wave generators must be carefully managed. Additionally, ensuring the containment and proper disposal of liquid-metal materials used in these applications presents ongoing challenges for researchers and engineers in the field.

Existing Solutions for Wave-Jet Interactions

01 Liquid metal jet formation and control

This category focuses on techniques for generating and manipulating liquid metal jets. It includes methods for creating stable jets, controlling their shape and trajectory, and optimizing their properties for various applications. The technology involves precise control of temperature, pressure, and flow rates to achieve desired jet characteristics.- Liquid metal jet formation and control: This category focuses on techniques for generating and controlling liquid metal jets. It includes methods for creating stable jets, manipulating their properties, and controlling their trajectory. These techniques are crucial for various applications in manufacturing, materials processing, and advanced technologies.

- Wave interaction with liquid metal surfaces: This area explores the phenomena occurring when waves interact with liquid metal surfaces. It covers the study of surface tension effects, wave propagation characteristics, and the resulting patterns or disturbances on the liquid metal surface. Understanding these interactions is important for optimizing processes involving liquid metals.

- Liquid metal jet printing and additive manufacturing: This category encompasses the use of liquid metal jets in printing and additive manufacturing processes. It includes techniques for precise deposition of liquid metals, layer-by-layer construction, and the creation of complex structures. These methods enable the fabrication of unique components and materials with specific properties.

- Electromagnetic manipulation of liquid metal jets: This area focuses on the use of electromagnetic fields to control and manipulate liquid metal jets. It includes techniques for shaping, steering, and modulating the behavior of liquid metal streams using magnetic and electric fields. These methods offer precise control over liquid metal behavior in various applications.

- Liquid metal jet cooling and heat transfer: This category explores the use of liquid metal jets for cooling and heat transfer applications. It covers methods for enhancing heat dissipation, managing thermal loads, and improving energy efficiency in various systems. Liquid metal jets offer unique advantages in heat transfer due to their high thermal conductivity and other properties.

02 Wave interaction with liquid metal surfaces

This area explores the behavior of waves when they interact with liquid metal surfaces. It covers studies on wave propagation, reflection, and absorption in liquid metal environments. The research aims to understand and utilize these interactions for applications in areas such as heat transfer, fluid dynamics, and material processing.Expand Specific Solutions03 Liquid metal printing and additive manufacturing

This category encompasses technologies that use liquid metal jets for 3D printing and additive manufacturing processes. It includes methods for depositing and solidifying liquid metal to create complex structures and components. The techniques focus on achieving high precision, resolution, and material properties in the printed objects.Expand Specific Solutions04 Liquid metal cooling systems

This area covers the use of liquid metal jets in advanced cooling systems. It includes designs for heat exchangers, thermal management solutions, and cooling techniques for high-performance electronics and industrial equipment. The technology leverages the unique thermal properties of liquid metals to achieve efficient heat dissipation.Expand Specific Solutions05 Liquid metal atomization and spray forming

This category focuses on techniques for atomizing liquid metals into fine droplets or sprays. It includes methods for producing metal powders, coatings, and rapidly solidified materials. The technology involves controlling jet breakup, droplet formation, and solidification processes to achieve desired particle characteristics and material properties.Expand Specific Solutions

Key Players in Liquid-Metal Jet Industry

The longitudinal wave interaction with liquid-metal jet technologies market is in an early growth stage, characterized by ongoing research and development efforts. The market size is relatively small but expanding as applications in advanced manufacturing and materials processing emerge. Technological maturity varies among key players, with companies like Synova SA and Excillum AB leading in commercialization of liquid-metal jet systems. Established industrial firms such as Kennametal and Eastman Kodak are exploring potential applications, while research institutions like Fraunhofer-Gesellschaft and the Chinese Academy of Sciences are advancing fundamental understanding. The competitive landscape is diverse, with specialized equipment manufacturers, materials science companies, and academic institutions all contributing to technological progress in this niche field.

Chinese Academy of Sciences Institute of Acoustics

Technical Solution: The Chinese Academy of Sciences Institute of Acoustics has developed advanced techniques for longitudinal wave interaction with liquid-metal jets. Their approach involves using high-frequency ultrasonic waves to manipulate the behavior of liquid metal streams. By precisely controlling the acoustic field, they can induce specific patterns and structures in the liquid metal, enhancing its properties for various applications. The institute has also explored the use of acoustic cavitation to generate micro-bubbles within the liquid metal, which can be used to create novel materials with unique properties[1][3]. Their research extends to the development of acoustic metamaterials that can guide and focus longitudinal waves to achieve more precise control over liquid metal jets[5].

Strengths: Cutting-edge research in acoustic manipulation of liquid metals, potential for creating novel materials. Weaknesses: May face challenges in scaling up laboratory techniques for industrial applications.

University of Electronic Science & Technology of China

Technical Solution: The University of Electronic Science & Technology of China has made significant strides in the field of longitudinal wave interaction with liquid-metal jet technologies. Their research focuses on the development of advanced sensors and actuators that utilize the unique properties of liquid metals. By employing longitudinal waves, they have created highly sensitive strain sensors that can detect minute deformations in structures[2]. The university has also pioneered the use of acoustic streaming in liquid metal microfluidics, enabling precise control of liquid metal flow for applications in flexible electronics and soft robotics[4]. Their work extends to the development of liquid metal-based antennas that can be dynamically reconfigured using longitudinal wave interactions[6].

Strengths: Innovative applications in flexible electronics and sensing technologies. Weaknesses: May require further development for commercialization and mass production.

Core Innovations in Longitudinal Wave Control

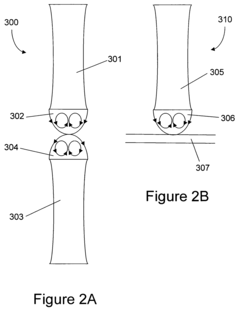

Droplet transport system and methods

PatentInactiveUS7670560B2

Innovation

- The use of thermocapillary convection to levitate and move droplets by exploiting the variation of surface tension with temperature, employing a heat source to create a lubricating gas film that prevents contact and reduces friction, and encapsulating aqueous samples in immiscible oils to minimize contamination and evaporation.

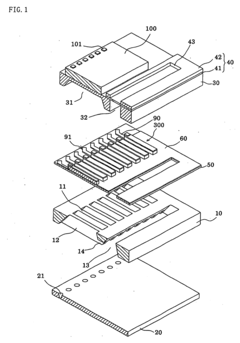

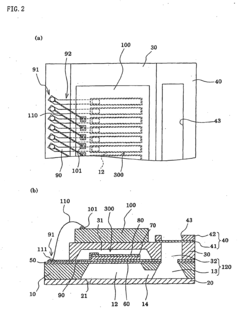

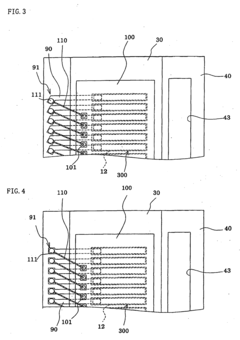

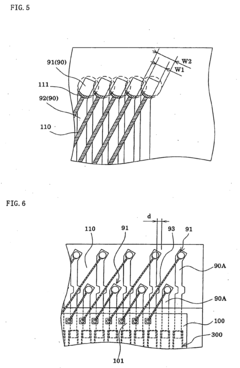

Liquid jet head and liquid jet device

PatentInactiveEP1493568B1

Innovation

- The liquid jet head design features connection wires formed by wire bonding that intersect the drawn wires' connection portions, with optimized shapes and angles to increase contact areas and prevent short-circuits, allowing for high-density alignment of piezoelectric elements while maintaining secure connections.

Safety Considerations for Liquid-Metal Technologies

Safety considerations are paramount when working with liquid-metal technologies, especially in the context of longitudinal wave interactions. The high temperatures and potentially reactive nature of liquid metals necessitate stringent safety protocols. Proper containment systems are crucial to prevent leaks or spills, which could lead to severe burns or environmental contamination. These systems must be designed to withstand thermal expansion and potential pressure changes resulting from wave interactions.

Personal protective equipment (PPE) is essential for operators working with liquid-metal systems. This includes heat-resistant clothing, face shields, and specialized gloves to protect against splashes and thermal radiation. Regular training on proper handling procedures and emergency response protocols is vital to ensure worker safety.

The potential for chemical reactions between liquid metals and surrounding materials must be carefully considered. Compatibility studies should be conducted to select appropriate containment materials that can withstand both the high temperatures and potential corrosive effects of the liquid metal. This is particularly important in systems where longitudinal waves may induce rapid temperature fluctuations or localized hot spots.

Electromagnetic safety is another critical aspect, especially when dealing with liquid metals that are often highly conductive. The interaction between longitudinal waves and liquid-metal jets can generate electromagnetic fields, which may pose risks to both equipment and personnel. Proper shielding and grounding techniques must be implemented to mitigate these risks.

Environmental safety considerations are equally important. Proper disposal methods for used liquid metals and contaminated materials must be established to prevent environmental pollution. Recycling processes should be developed where possible to minimize waste and reduce the environmental impact of these technologies.

Emergency response plans must be in place to address potential accidents or equipment failures. This includes procedures for rapid shutdown of systems, containment of spills, and evacuation protocols. Regular drills and simulations should be conducted to ensure all personnel are familiar with these procedures.

Monitoring systems play a crucial role in maintaining safety. Real-time temperature, pressure, and flow sensors should be integrated into liquid-metal systems to detect anomalies quickly. Advanced control systems can use this data to implement automatic safety measures, such as emergency shutdowns or pressure relief, in response to dangerous conditions.

Personal protective equipment (PPE) is essential for operators working with liquid-metal systems. This includes heat-resistant clothing, face shields, and specialized gloves to protect against splashes and thermal radiation. Regular training on proper handling procedures and emergency response protocols is vital to ensure worker safety.

The potential for chemical reactions between liquid metals and surrounding materials must be carefully considered. Compatibility studies should be conducted to select appropriate containment materials that can withstand both the high temperatures and potential corrosive effects of the liquid metal. This is particularly important in systems where longitudinal waves may induce rapid temperature fluctuations or localized hot spots.

Electromagnetic safety is another critical aspect, especially when dealing with liquid metals that are often highly conductive. The interaction between longitudinal waves and liquid-metal jets can generate electromagnetic fields, which may pose risks to both equipment and personnel. Proper shielding and grounding techniques must be implemented to mitigate these risks.

Environmental safety considerations are equally important. Proper disposal methods for used liquid metals and contaminated materials must be established to prevent environmental pollution. Recycling processes should be developed where possible to minimize waste and reduce the environmental impact of these technologies.

Emergency response plans must be in place to address potential accidents or equipment failures. This includes procedures for rapid shutdown of systems, containment of spills, and evacuation protocols. Regular drills and simulations should be conducted to ensure all personnel are familiar with these procedures.

Monitoring systems play a crucial role in maintaining safety. Real-time temperature, pressure, and flow sensors should be integrated into liquid-metal systems to detect anomalies quickly. Advanced control systems can use this data to implement automatic safety measures, such as emergency shutdowns or pressure relief, in response to dangerous conditions.

Environmental Impact of Liquid-Metal Jet Systems

The environmental impact of liquid-metal jet systems is a critical consideration in the development and implementation of this technology. These systems, which utilize the interaction between longitudinal waves and liquid metal jets, have both potential benefits and drawbacks in terms of their environmental footprint.

One of the primary environmental advantages of liquid-metal jet systems is their potential for improved energy efficiency. By harnessing the unique properties of liquid metals and their interaction with longitudinal waves, these systems can potentially achieve higher energy conversion rates compared to traditional technologies. This increased efficiency could lead to reduced overall energy consumption and, consequently, lower greenhouse gas emissions associated with power generation.

However, the use of liquid metals in these systems raises concerns about potential environmental contamination. Many liquid metals, such as mercury or gallium, can be toxic to ecosystems if released into the environment. Proper containment and handling procedures are essential to prevent accidental spills or leaks that could harm soil, water resources, or wildlife.

The manufacturing process for liquid-metal jet systems may also have environmental implications. The extraction and processing of the required metals can be energy-intensive and may involve environmentally disruptive mining practices. Additionally, the production of specialized components for these systems could generate industrial waste that requires careful management and disposal.

On the positive side, liquid-metal jet technologies may offer opportunities for more compact and efficient cooling systems in various applications. This could lead to reduced water consumption in industrial processes and power generation, addressing water scarcity concerns in many regions.

The end-of-life disposal and recycling of liquid-metal jet systems present both challenges and opportunities. While the metals used can often be recycled, the process may require specialized facilities and techniques to handle potentially hazardous materials safely. Developing effective recycling protocols could mitigate the long-term environmental impact of these systems and promote a more circular economy approach.

As research and development in this field progress, there is a growing focus on identifying and utilizing more environmentally friendly liquid metals. This includes exploring alternatives with lower toxicity profiles and investigating bio-inspired liquid metal formulations that could offer enhanced compatibility with natural ecosystems.

In conclusion, the environmental impact of liquid-metal jet systems is multifaceted, with potential benefits in energy efficiency and resource conservation balanced against concerns about material toxicity and manufacturing processes. Ongoing research and careful implementation will be crucial in maximizing the positive environmental aspects of this technology while mitigating its potential negative impacts.

One of the primary environmental advantages of liquid-metal jet systems is their potential for improved energy efficiency. By harnessing the unique properties of liquid metals and their interaction with longitudinal waves, these systems can potentially achieve higher energy conversion rates compared to traditional technologies. This increased efficiency could lead to reduced overall energy consumption and, consequently, lower greenhouse gas emissions associated with power generation.

However, the use of liquid metals in these systems raises concerns about potential environmental contamination. Many liquid metals, such as mercury or gallium, can be toxic to ecosystems if released into the environment. Proper containment and handling procedures are essential to prevent accidental spills or leaks that could harm soil, water resources, or wildlife.

The manufacturing process for liquid-metal jet systems may also have environmental implications. The extraction and processing of the required metals can be energy-intensive and may involve environmentally disruptive mining practices. Additionally, the production of specialized components for these systems could generate industrial waste that requires careful management and disposal.

On the positive side, liquid-metal jet technologies may offer opportunities for more compact and efficient cooling systems in various applications. This could lead to reduced water consumption in industrial processes and power generation, addressing water scarcity concerns in many regions.

The end-of-life disposal and recycling of liquid-metal jet systems present both challenges and opportunities. While the metals used can often be recycled, the process may require specialized facilities and techniques to handle potentially hazardous materials safely. Developing effective recycling protocols could mitigate the long-term environmental impact of these systems and promote a more circular economy approach.

As research and development in this field progress, there is a growing focus on identifying and utilizing more environmentally friendly liquid metals. This includes exploring alternatives with lower toxicity profiles and investigating bio-inspired liquid metal formulations that could offer enhanced compatibility with natural ecosystems.

In conclusion, the environmental impact of liquid-metal jet systems is multifaceted, with potential benefits in energy efficiency and resource conservation balanced against concerns about material toxicity and manufacturing processes. Ongoing research and careful implementation will be crucial in maximizing the positive environmental aspects of this technology while mitigating its potential negative impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!